In modern apartments, hot water is not a luxury, but a necessity. Agree, heating water for domestic needs on a stove in the 21st century is crazy. Since in our country it is more profitable to use gas than electricity, gas water heaters (instantaneous gas water heaters) are simply irreplaceable.

Thanks to this equipment, hot water is available in the house all year round. However, all gas appliances are potentially dangerous. We will tell you whether a geyser can explode and for what reasons.

You will also learn the basic rules for the safe operation of a gas water heater, what protective devices are installed in modern water heating equipment, and what to look for when buying a gas water heater.

The most common causes of explosions:

- Self-installation. It is recommended that the water heater be installed by a professional. If you supplied the equipment yourself, you must follow all safety regulations.

- Old Soviet column. Unlike modern heaters, Soviet models are not equipped with protective equipment. They will not turn off if overheated or gas leaks.

- Independent changes in the design of a household geyser. For safety reasons, it is prohibited to change the water heater device yourself.

Technically, an explosion can occur if there is a gas leak and its concentration in the room is 5-15%. That is why modern devices have a gas leak detector. When it is triggered, the column automatically turns off.

This is interesting: How to hide a gas meter in the kitchen: safety requirements and the best disguise ideas

Key reasons

Why do propane gas tanks explode at home? In this situation, the most common reason is associated with improper, unsafe maintenance and use of such containers.

When the valve is not closed tightly, fuel comes out and fills the room. And any manifestation of flame, even a modest spark, can cause a serious explosion or fire.

Air is lighter than gas. And when the fuel leaves the cylinder, it concentrates near the floor. Therefore, a person cannot always smell a leak. And due to a small spark or static electricity, the gas can ignite.

The second most popular reason is that the cylinder was left in the cold for a long time and was brought indoors. With a sharp temperature jump, the gas expands and the risk of leakage increases significantly.

When the container was in the cold, the fuel in it remained in liquefied conditions. When the container is placed in heat, the gas rapidly transforms into a gas-like state and seriously expands.

Therefore, it is prohibited to place such a container near a heat source. Pressure builds up inside it. This is a consequence of the expansion of the fuel. And the balloon can explode at any moment.

It is impossible to bring such a vessel directly from the cold into a room where there is a high positive temperature due to condensation. At this moment it forms on the balloon. There is a high risk of corrosion and accidents. BUT if the container is not metal, there is no such threat.

In general, temperature metamorphoses do not pose any particular danger. The containers can cope with a wide temperature range: from -40 to +50 C. Such metamorphosis is only a trigger for an accident.

The third reason is related to corrosion and microscopic cracks in the container. They may appear gradually and not be visually noticeable. But they pose a significant internal threat.

In general, it is very difficult to monitor the gas level in metal vessels. And an explosion can also occur due to an abnormal ratio of fuel in the cylinder.

List of other popular reasons:

- Gas tanks were not subjected to the necessary tests - re-examination.

- When filling the cylinder, the fuel level in it was analyzed not by pressure, but by the mass of the vessel.

- The cylinder was placed in general premises.

To protect yourself, you should follow a number of rules:

- The water heater should only be purchased in specialized stores. Only then will you have a guarantee of proper operation of the device. If there are any problems, you can contact the store for repairs.

- Once a year you need to call specialists to check the equipment. This is a paid service, but it is important to understand that you are responsible for your safety. If necessary, they can additionally carry out preventive cleaning of the equipment - clean the heat exchanger pipes from scale, remove soot from the radiator and clean the chimney.

- If you smell gas in the room, close the gas valve, turn off the fire and all electrical appliances, ventilate and call the emergency service. Household gas is odorless, but impurities are specially added to it to make the leak audible.

- In case of any malfunctions: popping noises when turned on, or too low heating of the water, call specialists for repairs.

It is also strictly forbidden to make any changes to the water heater or leave the house and leave the heater on.

Why the gas water heater lights up with a bang: reasons. ways to fix breakdowns

There may be several reasons for the gas water heater to ignite with cotton:

- the battery charge has decreased; the smoke channel is clogged and the draft has weakened;

- the gas supply nozzle is clogged;

- the main burner hole is clogged;

- delayed gas ignition;

- there is no flow of fresh air into the room;

- with a constantly burning wick;

- with automatic ignition.

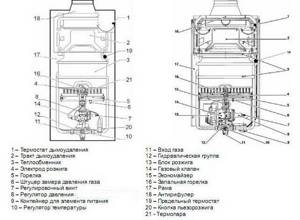

Interior of gas burner

The bang occurs from the explosion of the air-gas mixture accumulated in the ignition zone. If you don’t do anything, there may come a moment of such a loud bang that the windows in the apartment will break out. Gas is no joke. Therefore, when the first small pops appear, take measures to eliminate this phenomenon. There are two options for solving this issue: 1. Call a locksmith. 2. Solve the problem yourself. Why does a bang occur when you turn on the geyser and what should you do first? For those who decide to eliminate the problem of “claps” on their own, our step-by-step instructions

Cases of explosions

In September 2008, a Prague water pump exploded in Kharkov. The device was purchased not in a specialized store, but on the market and only worked for a year. The device exploded into pieces, but no one was in the kitchen at the time, so no one was injured.

In 2008, domestic gas exploded in a private house in Krasnodar. Due to a malfunction, gas began to leak from the column. When a critical mass of gas accumulated in the house, someone lit a cigarette and an explosion occurred. Residents of the house received numerous burns.

In February 2013, there was an explosion in Volgograd. The water heater in the bathroom exploded. The explosion destroyed the wall between the kitchen and the bathroom.

In January 2021, an explosion occurred in the city of Borisov, Belarus. This is an old five-story house, built in the 60s, in which Soviet gas water heaters were installed. The reason was that the residents did not immediately react to the smell of gas and did not call the gas workers.

If you have modern, working equipment and you comply with all safety requirements, then the likelihood of an explosion is minimal.

Video excerpt from the news:

Can a modern gas boiler/heater explode?

Theoretically, for a vehicle to explode, the following reasons are necessary:

- The empty pipe is heated without coolant.

- The water in the radiator does not circulate, but stands and boils to critical temperatures.

Both are impossible, because even the cheapest Economy Class speakers have a security system installed. Empty pipes will not heat up because until you open the faucet to supply water, the burner will not start. And as soon as you close it, the heating will stop.

The heating temperature and liquid flow rate are controlled by special sensors. All models are equipped with these sensors:

- Thermal sensor. Monitors temperature rise. As soon as the water heats up to the set value, it sends a signal to the main module and it turns off the heating.

- Flow sensor. Fixes the pressure speed in pipes.

- Flexible diaphragm. Serves to open the gas valve. If the pressure in the line is sufficient, then the membrane bends and fuel enters the burner. As soon as the pressure decreases, the membrane returns to its original position and the gas supply stops.

- Ionization sensor. If the flame in the burner goes out, the sensor sends a signal to turn off the equipment.

- Exhaust product sensor. Reacts to the lack of draft in the chimney. Ideally, smoke should exit normally through the smoke shaft. If this does not happen, protection is triggered. Did you hear that it smells like burning? Then check the chimney. If there is a blockage, the shaft is cleaned.

Smell of gas from the boiler in the house? Close the shut-off valves and call the gas service to check.

Danger arises when the operation of equipment gets out of control. What experts recommend doing to avoid emergency situations:

- Buy heating equipment only in specialized stores. Get a guarantee so that in case of a breakdown you can contact a service center.

- Trust the connection to specialists.

- Carry out breakdown prevention and maintenance once a year. Clean components and parts from scale, soot and blockages.

- If problems are observed during ignition (the column bangs or slams), be sure to contact a specialist.

Any technique can be dangerous if used incorrectly. Monitor the operation of your devices, then you won’t have to deal with the consequences.

This is interesting: How to light an oven in a Hephaestus gas stove: how the oven works and how to turn it on correctly

Features of ignition of gas heating boilers

Each heating device is equipped with automation. The ignition procedure depends on its design and features. Modern boilers are equipped with piezo ignition or automatic start. Rarely in villages, there are still old KST boilers that can operate on solid fuel and gas. During the conversion, the heating devices were equipped with primitive automation, where the igniter was ignited with matches.

Ignition features depend on the gas boiler automation

Regardless of the boiler model and its automation, preparatory measures are carried out before ignition:

- Before the first start after the summer season, all components of the gas supply line and automation are checked for the absence of gas leaks. This can be done easily with soapy water. If a thread or connection is gassed, soap bubbles will appear.

- It’s a good idea to check the heating system itself for leaks. Make sure there is enough coolant. To do this, in a closed system, the pressure is checked on a pressure gauge. If the heating is gravity-fed, make sure the expansion tank is filled with water.

- After renovations, a lot of dust is generated in the house. With the help of draft, it partially enters the boiler furnace and settles on the burners. A similar situation occurs if the heating device at the dacha has been idle for a long time. Before ignition, try to clean all burner units with a vacuum cleaner or other devices.

- Immediately before starting ignition, check the presence of draft. This can be easily done with a strip of paper. If it is pulled inside the firebox, then there is a draft.

After the preparatory activities, they move on to the process of igniting the boiler.

To properly ignite a gas appliance, you need to know the features of the automation. Important! When using a new gas boiler for the first time, you should carefully read the instructions from the manufacturer.

The ignition process begins by opening the gas supply valve to the boiler from the main line. If the heating is equipped with a circulation pump, be sure to put it into operation. Further actions depend on the features of the automation:

- Old KST with ancient automatic equipment are lit manually. First, a burning match or splinter is inserted into the window and gas is supplied with the regulator. After igniting the igniter, allow it to warm up for a couple of minutes. The regulator lever is moved to the next position. The main burners are ignited.

- Modern budget boilers are also started manually, but with the help of a piezoelectric element. Press the flame regulator with one hand. Continuing to hold it, press the piezoelectric element button with the other hand. With each action, a click occurs and a spark is formed near the igniter on the electrodes. The action continues until the flame appears. After the pilot light ignites, the regulator is held for about 30 seconds to allow the thermocouple to heat up. Now you can release it and turn it to light the main burner.

- Expensive gas boilers are equipped with electronic start. There are even models that are controlled from a remote control. Ignition of such devices is carried out with one click of the “Start” button. Then the automation will do everything itself. It is only important not to forget to connect the unit to the electrical network.

Setting up the automation is trusted only to a specialist. Each gas automation has its own characteristics. The regulators are marked with numbers, stars, and circles. They indicate different positions at which a spark is supplied, the burner is ignited, and the temperature is set. All the nuances of a particular model are described in the manufacturer’s instructions. It must be studied before starting ignition.

How to determine power

First of all, you need to decide on the power or performance of the gas water heater. These are two interrelated characteristics that simply reflect different characteristics of the unit. Performance is how many liters of water a column can heat per minute, and power is how much heat it can release. Some manufacturers indicate power, others indicate performance, so you need to understand exactly what you need.

Let's first figure out what kind of performance you need from your geyser. This depends on the number of consumers who need to be provided with warm water. There are consumption standards for different types of equipment:

- kitchen sink, washbasin - 4 l/min;

- shower - 7-10 l/min.

If you have a kitchen sink, shower and washbasin connected to hot water, so that all three points work simultaneously and the water temperature does not drop, you need a capacity of 4 + 4 + 10 = 18 l/min. This is a lot, the price tag will be substantial. If you think about it, you will realize that all three devices are almost never turned on at the same time. There are situations when the shower and one of the taps work together. To provide them with hot water, the capacity must be 14 l/min. This is a little more modest, but quite enough for a comfortable stay. Look for the found value in the technical specifications; it should not be less.

Now let's look at power. Gas water heaters can allocate from 6 kW to 40 kW of heat for heating water. Here the division is:

- a gas water heater with a capacity of up to 19 kW is suitable for heating water for one water collection point;

- for two points the power should be from 20 kW to 28 kW;

- three require more than 29 kW.

Now, you can definitely say which geyser is better in terms of power in relation to your needs.

Water flow problem

Often the column does not light up when the water is turned on due to a decrease in water flow. With such a malfunction in the tap, the stream of water when turned on is observed to be very thin and weak. There is a feeling that the gas water heater is faulty in appearance. This happens with absolutely any brand: Neva, Oasis, Bosch.

A decrease in water flow can occur:

- Abruptly, the loss of performance disappears instantly.

- Gradually, with a noticeable decrease in the performance of the gas water heater;

A sharp loss of performance of a geyser can occur in connection with street work. During this time, the street water supply may be repaired. Accordingly, the overall pressure of cold water everywhere will be sharply reduced. The owner can easily skip this moment and look for the cause in the gas water heater, disassembling it. The reason lies on the surface, but a person gets confused and looks for it in something completely different.

Also, the water pressure in a gas water heater may gradually decrease due to simple contamination of the aerator intended for the mixer. To eliminate the cause of the malfunction related to the aerator in the faucet itself, it is necessary to remove it and clean it.

This is a standard aerator that is installed on the faucet. Try cleaning it

Owners who have a mesh filter at the inlet should also not forget about it and periodically clean it.

Coarse filter. It is installed to supply cold water to the column. Clean it too

The filter flask can also cause a gradual decrease in water pressure in the gas water heater

You should not forget about this and, first of all, if the wick of the gas water heater does not ignite, pay attention to it. If you miss the reason that lies on the surface, there is a risk of investing money in unnecessary diagnostics or repair of the gas water heater.

Repair and diagnostics of the gas water heater are not appropriate in this case.

Two filters for water purification in flasks. They can also get clogged

There is another case associated with a lack of water pressure when the gas water heater is turned on. This happens due to mechanical clogging of the hose. Scale was found in the hose, and it blocked the path of water. The scale could have come from the heat exchanger.

Internal breakdowns

If the reason is in the column, then you need to figure out what it could be? There are two reasons: either the filters are clogged or the membrane is deformed

. If the water is too hard, then the water supply pipes may become clogged, as well as the filters that are additionally installed in various models of geysers. Due to lime or other deposits, the metal filter grid, which is installed on the pipe in front of the water supply unit, may become clogged. To restore normal operation of the column, you need to clean or completely replace the filter in the mixer.

To do this, you just need to unscrew the nuts and see how serious the contamination is. If there are a lot of lime deposits, then it will be easier to buy a new filter. If there is a small amount of lime deposits, then you can clean the filter using special detergents or traditional methods. As practice shows, cleaning is quite simple, you just need to work a little. Also, you need to clean the column from soot and other combustion processes.

If this does not help, then you need to examine the membrane of the column water block

. It is located inside the column itself, to get there you will need to unscrew the bolts holding the column cover. Inspect the rubber membrane; it should be free of visible cracks and breaks, and of the correct shape. If it is deformed or damaged, it must be replaced. It is better to purchase a new silicone-based membrane. Silicone gives the membrane a more resistant surface; such a membrane will be more resistant to temperature changes, more elastic and will last much longer.

The membrane must be installed carefully so as not to damage it during installation. The fastening screws must be tightened not all in order, but in opposite directions, gradually squeezing the lid with it. All these procedures can be done independently, but it will be safer to call a specialist who will comprehensively clean the column of all contaminants and assess the condition of the entire unit, and perhaps identify other faults.

There are times when a gas water heater goes out. The main reason for this event is that the pressure of cold water is stronger than hot water. It is better to adjust the hot water supply temperature to a comfortable temperature so that you do not have to dilute it with cold water. Turning on cold water while the column is on not only leads to the column going out, but is also considered improper operation of this unit, which can lead to its rapid breakdown.

Also, the water heater may go out when turned on, this may be due to the fact that you did not hold the ignition button long enough. On average, you need to hold this button for at least twenty seconds; if you hold it for less, the speaker immediately goes out. Also, it may go out due to a malfunction of the exhaust gas sensor. To check whether the sensor is working, you need to ring it by connecting both of its terminals; its resistance must be equal to infinity. If not, replace the sensor.

Step-by-step instructions for troubleshooting gas water heaters

Apartment owners can identify and eliminate some faults themselves, except those that affect the safe operation of gas water heaters and warranty repairs. If the geyser starts making popping noises, doesn’t want to turn on, and the warranty period has not yet expired, then the issue is easily resolved. Call a specialist to your home. Gas water heaters begin to “pop” after 5–10 years of operation without periodic maintenance.

Checking the draft in the chimney of a gas water heater

It should be borne in mind that the apartment must have not only a chimney, but also a ventilation duct. Both must have sufficient draft to remove combustion products and foreign odors both in the bathroom, toilet and kitchen. If gas leaks, some of it will be removed through the ventilation duct.

Checking traction with a match

If gas is not completely burned, carbon monoxide can form. There is a misconception that carbon monoxide can rise up and be removed through ventilation. It is heavier than air, has no odor and will slowly fill the room. Carbon monoxide, chemical formula CO, is a free radical seeking oxygen to join. Once in a person's lungs, it takes oxygen from the blood, and the person suffocates. Therefore, there can be no jokes with a gas water heater that started making popping noises. Checking the traction:

Use an anemometer. We can assume that no one has it, so we move on to the second method. Use thin tissue paper. Attach it to the ventilation duct

It should stick to the ventilation grill and not fall. Do the same to check the chimney duct. To check the chimney, use a match or lighter with care to avoid igniting the soot. The flame should be strongly drawn into the channel

If there is no draft, you will have to clean the chimney.

Checking the draft in the ventilation duct with an anemometer.

The draft is significantly affected by a heat exchanger clogged with soot deposits. To clean it, disassemble the gas water heater. If you don’t have the skills, then entrust this work to a mechanic from a company that is licensed to service gas equipment.

Prevention of causes and consequences

Rules for handling gas appliances.

It is easier to prevent any situation than to eliminate the consequences. For prevention purposes, it is necessary to follow general safety rules:

- Regularly talk with children about what gas is and how dangerous it can be.

- Purchase only serviceable gas appliances that have a warranty period and relevant certificates. At the same time, do not do the installation yourself, but invite professionals in this field who have special permits for such types of work.

- Store gas cylinders only in an upright position away from heating appliances. The cylinder should not be placed in a room with high humidity or in direct sunlight. After replacing the cylinder, it is necessary to check the tightness of the connections.

- Constantly monitor the position of gas valves.

- Avoid clogging the burners and clean them regularly.

- When leaving the apartment, it is recommended to turn off the gas valve and disconnect all electrical appliances from the network.

- Do not move far from the stove while cooking.

A specialized gas service must systematically inspect the operation of the equipment. So in apartments with gas stoves, where there is a centralized gas supply, inspection is carried out once every 5 years, and in houses with gas heating - once every 3 years.

There is special equipment on sale that signals the presence of a gas leak. It is inexpensive, and its installation will help save lives.

Why might an explosion happen?

Experts list the main reasons for such consequences:

- Self-connection . Please note that it is possible to install and install the speaker yourself. You can hang the device and connect a water pipeline to it. But you must entrust the connection to the gas main to a professional. Initially, you need to collect documents and permits for installation. Then you contact the gas service, which will come to the call and connect the device. Only after this can the column be put into operation.

- Soviet gas water heater . Why is this dangerous? Outdated equipment does not have a protection system. This includes control sensors and thermostats that monitor the operation of each unit. In case of overheating or fuel leakage, the old device will not respond.

It has been proven that an explosion occurs when the gas concentration in the air reaches 5–15%.

- Unauthorized changes to the design of equipment . It is prohibited to change anything in the speaker structure yourself. If work is disrupted, not only a breakdown, but also an explosion is quite possible.

Domestic gas explosion prevention

Knowing why gas most often explodes in apartments, you can draw up a list of actions to prevent accidents.

It will include:

- operation of authorized equipment that is within its expiration date;

- connection and installation performed by licensed professionals;

- proper storage and installation of cylinders;

- coordination of all project changes with the gas service;

- regular inspection of the gas pipeline, connections and equipment by gas workers;

- maintaining the ventilation system in working order;

- cooking on a gas stove in the constant presence of capable adults;

- use the equipment strictly for its intended purpose.

In addition, it is important to listen to odors and monitor the tightness of valves, taps, and flange connections. At the slightest suspicion, contact the gas service that supplies fuel.

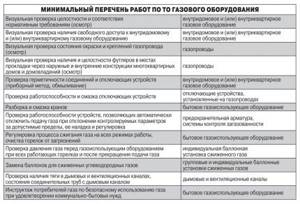

Unfortunately, reviews from people living in gasified houses contain many messages about a formal approach to servicing gas equipment. To avoid this, you should look at the list of mandatory works and make sure that all declared activities have been carried out in full

Since apartment buildings make residents dependent on each other, sometimes you have to look after more than just your own gas equipment. If neighbors violate safety regulations, you must write a statement to the gas service.

It must indicate the exact address, the reason for the appeal, the names of the residents who signed the application, information about the violators, and the date of recording. The reason may be the presence of prohibited equipment, violation of operating rules, or the smell of gas.

What else to look for when choosing

There are a few more lines in the technical characteristics of geysers that are worth paying attention to. First, look at the minimum water and gas pressure that this model can work with

Imported gas water heaters from European manufacturers are more capricious in this regard - they are designed for stable pressure and do not tolerate changes well. But under normal conditions they work stably and without breakdowns.

Some manufacturers, in order to adapt their equipment to our conditions, install gearboxes that compensate for surges. If the model you like does not have such a device, and your water and/or gas pressure fluctuates, you can install the reducer in front of the entrance to the dispenser. This device is simply placed into a pipe break; installation is standard. At the same time, your other consumers will be protected.

Operating parameters must be monitored

It is also useful to review the list of utility programs and protection levels. The safety and comfort of equipment operation depends on them. It is highly desirable to have the following functionality:

- Gas control. Monitors the presence of a flame on the burner; if it goes out, it shuts off the gas supply.

- Traction control. The presence of draft in the chimney is controlled. If combustion products are not removed, the gas supply is shut off.

- Flow control or hydraulic valve. Turns off the column if the water pressure is too weak or there is none at all.

- Overheat protection. The temperature sensor monitors the temperature of the water in the heat exchanger; when it approaches a critical point (boiling), it turns off the column. This extends the service life of the equipment (if it boils, the heat exchanger can rupture, as can the pipes).

These functions are necessary for the safe operation of the geyser. This is almost a standard set that is found in all good gas water heaters. All others are optional. They, as a rule, are no longer so critical (for example, the remote control).

Battery check

In dispensers that ignite automatically when water is supplied, the delayed appearance of a spark may be affected by discharged batteries. If there is a delay of several seconds, too much air-gas mixture is formed in the combustion zone. Use a multimeter to check the condition of the batteries.

Solution: If the discharge is severe, replace the batteries.

Checking the nozzle supplying gas to the combustion zone

In columns with piezo ignition, if the nozzle (nozzle) is clogged, gas may occasionally be supplied to the combustion zone and the wick will light up irregularly. The nozzle hole can only be cleaned with thin copper wire. Take it from stranded copper wire for electrical wiring.

jet (nozzle)

The second reason is the incorrect location of the nozzle (gas injector). It may be too far from the burner.

Cleaning the main burner from blockages

One of the reasons for poor performance of a gas water heater may be a clogged main burner. To get to it, remove the protective cover. The nozzle can be cleaned without unscrewing it.

Heat exchanger clogged with soot

For what reason does the gas water heater ignite late?

One of the reasons for the appearance of popping noises when igniting a gas water heater may be the delayed or irregular appearance of a spark in gas water heaters with automatic ignition.

If an electronic traction control system is installed in the automatic column, but it is not there or it is weak, then in this case the automatic system may work and cut off the gas supply.

In the absence of supply and exhaust ventilation, interruptions in the operation of the gas water heater may also occur.

Common breakdowns

Popping noises when turned on are typical for Soviet models. Due to flaws in the design, undesirable effects arose, causing concern to the owners. When using modern instantaneous water heaters, this problem is rarely encountered.

If this problem is not corrected, the consequences will be very serious. The gas will concentrate in the gas pipe and gradually move into the chimney, which is why it explodes. Therefore, at the first sign of a problem, you should carry out diagnostics and find out why the device is breathing.

The process of gas accumulation is usually associated with:

- Clogging of the chimney, which makes normal draft impossible;

- Damage to the valve, which causes a fire after switching on;

- Deflection of the ignition wick light.

If popping noises when turned on are heard from a modern water heater model that ignites automatically, this may be due to:

- Low battery;

- A faulty microswitch;

- Defective spark plug.

Strange sounds require close attention. Therefore, it is advisable to contact specialists who will determine the causes of the problems and correct them.

Preventative measures and prevention of overheating

- Install an additional circuit to cool a boiler that runs on solid fuel. In a double-circuit boiler, when the coolant increases, the liquid can be cooled due to the water supply system.

- Installing a buffer tank, it will prevent the boiler from boiling, take on excess temperature, and can also store heat for the heating circuit.

- You need to install an uninterruptible power supply. If there is a power outage, the uninterruptible power supply will automatically turn on, energy will come from the battery, and the system will continue to operate.

- Periodically clean the ventilation system.

The best models of pellet-wood boilers

Combined heaters are produced by many Russian and foreign companies. A number of models with the best price-quality ratio are especially popular.

Heiztechnik HT Daspell Duo

The Polish unit operates on all types of fuel, incl. on coal. The line includes models with power from 12 to 65 kW.

Description:

- 1 circuit;

- Heiztechnik Pellhard Plus torch burner with self-cleaning and ignition function;

- water-cooled grate;

- electronic weather-compensating automation;

- possibility of installing a display, ash removal system and Internet connection.

Heiztechnik HT Daspell Duo is a Polish boiler.

The device is made of steel 5 mm thick.

Zota Pellet 15S

Russian 2-burner unit with a power of 15 kW.

Main characteristics:

- automatic switch to pellets after firewood burns out;

- maximum pressure of the working medium – 3 atm.;

- only forced circulation;

- 2-screw feed (protection against flame penetration into the hopper);

- flow meter – calculates daily and total fuel costs;

- control panel with the ability to connect up to 3 pumps and indicate their priority.

Zota Pellet 15S is a two-furnace unit.

Additionally you can install:

- 12 kW heating elements - turn on automatically if the user forgot to add solid fuel in time;

- GPS module for controlling SMS commands from a smartphone;

- Matrix uninterruptible power supply.

The fire is maintained at the top of the burner, which prevents the auger from burning out.

Automation – weather-sensitive, with programming function.

The device is resistant to high temperatures and voltage surges.

Stropuva Mini S8 P

Lithuanian top combustion boiler with a power of 8 kW. There is no automatic fuel supply. But due to the fact that the load is ignited from above and the air is supplied strictly to the combustion zone, the duration of operation is (in hours):

- wood-burning – 18;

- on briquettes – 30;

- on pellets – 42.

The firebox volume is 163 liters. It holds 106 kg of pellets.

Stropuva Mini S8 P is a top combustion boiler.

The advantage of the heater is energy independence. The coolant temperature and performance are controlled by a bimetallic mechanical sensor connected to the air damper.

Installation efficiency is 85%.

Svetlobor VD 16

Russian equipment with a power of 16 kW. Together with the boiler, a pneumatic fuel supply system from a remote storage facility is offered. It frees the user from even having to load pellets into the hopper. The boiler is approached once a month for maintenance.

Description:

- volumetric type burner;

- automatic cleaning of grates and heat exchanger, removal of ash;

- Efficiency – 94%;

- pellet consumption in nominal performance mode – 3.5 kg/hour;

- weight – 450 kg;

- option – GSM module.

Svetlobor VD 16 - Russian equipment.

The boiler tank is located vertically, which reduces the rate of formation of deposits on its walls.

The entry of flame into the feed auger and hopper is prevented due to the special shape of the burner. It is designed for pellets of any quality.

Metal Fach SD Duo 14

Single-circuit boiler with a capacity of 14 kW, made in Poland. Description:

- water-cooled grate;

- volumetric type burner;

- cast iron screw;

- Efficiency – 90%;

- control – electronic, information is displayed;

- weight – 485 kg;

- ability to connect 4 pumps, weather and room thermostat to the controller.

Metal Fach SD Duo 14 is a 14 kW boiler.

The unit operates on all types of fuel, incl. on coal. Fire protection for the feeder must be purchased separately.

Faci Base 15

Italian 1-circuit unit with a power of 15 kW. Equipped with an automatic feeder for the following types of fuel:

- pellet;

- coal up to 15 mm in size.

The volume of the standard bunker (263 l) is enough for 3 days of work.

The device is made of heat-resistant steel and equipped with a volumetric pellet burner.

Fire precautions:

- 2-screw feed;

- screw temperature sensor;

- extinguishing system (emergencyly dumps all ignited pellets into the boiler).

Faci Base 15 is an Italian unit.

Options:

- auto ignition;

- GSM module;

- more spacious bunker.

Efficiency – 92%.

Conversion to gas is possible.

How does a gas water heater work?

The term “gas water heater” is a legacy of the Soviet period. In those days, when hot water supply was just being established, during the construction of houses, simplified wall-mounted gas boilers were installed in apartments, not equipped with automation and security systems.

Morally, technically and technologically outdated units were inconvenient and dangerous. Modern equipment is radically different from its ancestor. The devices are convenient, beautiful and do not pose any threat to the health and property of the owners.

Instantaneous gas water heaters are a metal structure with a heating system. Pipes are connected to it for cold water inlet and hot water outlet, for coolant circulating through the heat exchanger, as well as for gas. The igniter is located at the bottom of the equipment. It functions like a lighter.

The gas valve opens automatically immediately after turning on the water or activating the heating process of the coolant. Gas enters the main burner, which is ignited by the igniter and produces heat. The water enters the heat exchanger, which is a spiral tube, where it is prepared for supply to the heating circuit or to the hot water supply.

Hot water is already flowing into the water tap. It heats up within 2-3 seconds after turning on the burner. Its temperature depends on individual settings. To remove combustion products, a chimney is required.

How to prevent explosion of gas equipment?

To protect your home and prevent emergencies, it is recommended to purchase gas equipment in specialized stores.

All technical devices, including geysers, are certified by Gosstandart of Russia. Without this permit, gas appliances are not allowed for domestic use.

In a specialized store, when purchasing, you are required to provide a “certificate of conformity”. If the equipment is not of domestic production, it is worth asking whether the dispenser has been tested and certified in Russia. Take a look at the technical data sheet of the wall-mounted gas boiler and see what security systems it is equipped with.

Purchasing a instantaneous gas water heater at specialized outlets is a guarantee of quality. In addition, you can subsequently contact the center in case of a malfunction of the device and the need to replace it if a manufacturing defect is detected.

To prevent breakdowns, it is recommended that gas workers inspect the device annually. You should also study the instructions for the purchased device, which indicate under what conditions the device can operate and how to operate it correctly. The connection should be trusted only to specialists from the gas service with which the contract has been concluded.

Components and parts must be regularly cleaned of soot and debris. If problems are observed during ignition or malfunctions are detected (the column slams), call a specialist. Any technique, even potentially dangerous, if used correctly and constantly monitored for functionality, will not cause trouble or lead to dire consequences.

Operating principle of the heating system

To describe it very briefly, then the principle of the heating system in a private home is that a certain liquid, be it water or frequently used antifreeze, is heated in the boiler to a temperature specified by the user.

Heating system diagram

Then it flows through the heating main (pipe) to the radiators, where it gives off its heat, then circulates back using a return circuit to the heating device. There it warms up again, it is essentially a closed circuit.

- Single-pipe.

It is the most economical and easiest to implement. It looks like a ring into which heating radiators are mounted in series. The coolant circulates in a circle, while the warmest liquid flows to the first radiator, which shares heat with it and at the same time loses several degrees, while the coolant, which has already cooled down considerably, reaches the fifth or sixth radiator. The way out of this situation, so that the batteries do not become cold, is to increase the number of sections with each subsequent radiator, so that heat losses are not so noticeable. Or increase the temperature of the coolant in the boiler, and this will entail significant costs. However, you can install a circulation pump, which will artificially increase the speed of movement of the coolant and, accordingly, reduce heat loss, and this will also slightly shorten the heating interval. However, there is a drawback here, namely, energy costs. - Double-pipe, many times superior in energy performance. It involves branching the coolant into two outlets, as a result of which heat losses are halved. They have a common return circuit. However, to build such a system you will need twice as many pipes, shut-off valves, and sensors. Most often used in gasified rooms.

Overheat

Most often, overheating occurs for the following reasons:

- The user dilutes hot water with cold. Due to the addition of cold water, the consumption of hot water is reduced, therefore, the heat extraction is reduced and the water in the heat exchanger overheats. Remember: you can regulate the temperature of hot water only by changing its pressure or using the regulator on the column.

- The heat exchanger is clogged with scale somewhere. This also leads to a decrease in water consumption with subsequent overheating. You can guess what happened by the clearly weakened pressure of hot water, despite the fact that cold water flows properly. To prevent such troubles, the heat exchanger must be periodically washed with special anti-scale compounds.

If the mesh filter (dirt filter) installed on the water supply in front of the column is clogged, the flow rate in this case will drop with all the ensuing consequences.

The pressure in the boiler exceeds the permissible

The most common cause of explosion of solid fuel boilers is excess pressure, which occurs due to boiling of the coolant. This is especially true for heating systems with a closed type expansion tank. When the expansion tanks are open, excess pressure is released into the tank and in most cases it is possible to avoid a boiler explosion or damage to the coolant tubes. In turn, there are several reasons for increasing coolant pressure:

- Stopping the circulation pump.

- The boiler automation is not adjusted correctly.

- Heat exchanger leakage, which occurs when microcracks form in the heat exchanger. In this case, it is difficult to detect the leak as it evaporates quickly.

- Water seeping through the make-up tap. Occurs when it is faulty or open.

- Three way valve problems. The functionality of the valve is impaired due to its blockage.

- Lack of coolant in the heating system

If eliminating the above reasons does not give the desired result, call a gas technician.

Steam boiler explosions

Details Category:

STEAM BOILER EXPLOSIONS

, destruction of the walls of the boiler, which results in instant equalization of the pressure inside the boiler and atmospheric pressure, and the water heated in the boiler also instantly turns into a vapor state, and its enormous potential energy is converted into kinetic energy. Statistics on steam boiler explosions in different countries show that about 60% of such explosions occur due to poor maintenance and cleaning. Thus, for 1925 and 1926, in Germany, explosions of steam boilers for reasons are distributed as follows: from design, material and installation flaws - 24%, from water loss in the boiler - 39%, from corrosion and overheating of the walls - 23% and from various other reasons - 14%. Data on steam boiler explosions in France from 1880 to 1900, published in the Annales des Mines, also confirm that the largest number of explosions are due to poor boiler maintenance. So, for example, for the period 1895-1900. Explosions of steam boilers were distributed according to the following causes: from design and installation defects - 14%, from unsatisfactory maintenance and cleaning - 55%, from low water levels - 6%, from excess pressure - 5% and from various other reasons - 20%.

The force of the explosion and the destruction it causes depend on the size of the water space of the boiler and the temperature of the heated water. Therefore, explosions of steam boilers with a large water space (for example, cylindrical boilers) are the most severe in their consequences.

Nowadays, despite the use of higher pressures, explosions of steam boilers occur less frequently and are less dangerous in their consequences than before, which can be explained by: the publication in almost all countries of rules and regulations that regulate the construction of new boilers and supervision during operation; improvement of boiler designs, quality of boiler material (Fig. 1) and methods of its processing; the ever-increasing use of water-tube boilers (i.e. boilers that are more productive, but with a relatively small water space); improved methods of studying the causes of the explosions themselves and, finally, raising the level of qualification of stokers.

Causes of steam boiler explosions

. These reasons can be summed up under two categories: 1) reasons beyond the control of the fireman - design and installation flaws, unsatisfactory boiler repairs (bad riveting, welding, etc.) and low strength of the material; 2) reasons depending on the fireman - poor condition of the boiler and its fittings, an increase in pressure above the permitted level, a decrease in the water level, which can lead to heating of the boiler walls.

1. Disadvantages of design and materials. A number of recent explosions have occurred due to dangerous stresses in the boiler material during heating due to poor connections, unnecessary thickening of the material, heating of parts of the steam space in contact with high-temperature gases, poor water circulation and other design defects boiler Due to uneven heating of the boiler walls, the latter are deformed and sag, and the edges of the bottoms are especially severely deformed. The same threat in terms of explosions is posed by bottoms that have an irrational convexity, as well as flat bottoms in which the edge is bent at a right angle. The design flaws should also include: inaccurate fit of sheets, inept riveting of sheets and a number of other defects. Typically, most of these defects make themselves felt in the form of bulges and cracks (Fig. 2, 3 and 4).

In this case d.b. began a thorough renovation to eliminate these causes. Bottoms of incorrect design must be replaced by others in accordance with the latest standards.

One of the best measures to prevent explosions of steam boilers is to use high-quality material when constructing or repairing them and to properly process this material. If processed incorrectly, harmful remaining stresses are created in the sheets, which can, if other defects accidentally occur (for example, overheating or corrosion of the material), lead to a boiler explosion. The transformation of the structure of boiler iron into a coarse-grained one due to overvoltage and subsequent heating to 600-700° is shown in Fig. 5.

2. Excess pressure, if not the result of an oversight on the part of the fireman, may occur due to improper loading of the safety valve or insufficient dimensions of the latter.

3. Lack of water in the boiler can occur. arr. due to poor condition or improper functioning of water indicating and feeding devices. A lack of water in boilers with fire tubes is especially dangerous, since overheating of the fire tubes leads to their collapse and possible destruction (Fig. 6).

If a lack of water is detected in the boiler, it is necessary to immediately rake the fire out of the firebox and isolate the boiler by closing the steam and feed valves. Only after identifying deficiencies and eliminating them can you begin to fill the boiler with water.

4. Corrosion of boiler walls can be internal or external. a) Internal corrosion is the result of oxidation under the influence of acids or air. Magnesium, calcium and sodium chloride salts are often dissolved in feed water, which, decomposing at a relatively low temperature, form hydrochloric acid, which quickly corrodes the walls of the boiler. Sulfate salts of iron, aluminum and magnesium are also very dangerous; the destructive effect of the first two salts is especially noticeable in the case of scale formation in certain places of the boiler, since in such places, due to the accumulation of heat, the decomposition of these salts occurs and the formation of free sulfuric acid, which corrodes the walls of the boiler (Fig. 7).

The harmful effect of such feed water is usually detected by leaks at the edges of sheets and near rivets. Air dissolved in water can corrode the boiler wall to the point of cracking if the metal stress is above the elastic limit (Fig. 8).

Recently, Professor Parr (USA), based on a number of studies, put forward the so-called alkaline hypothesis, specifically relating to the destruction of rivet joints under the influence of alkalis. According to this hypothesis, the alkalis present in the feed water, especially caustic soda, penetrate into the rivet seams, under the rivet heads, etc. and concentrate there; at the same time, if there are stresses in the material that exceed its yield strength, alkalis make the metal brittle and thereby cause destruction in it; The cracks that form in this case usually go from one rivet hole to another, but never go further than the rivet seam.

The prerequisites for this hypothesis are therefore two conditions: a strong concentration of alkali in the rivet seams and overstressing of the material. The first premise, which assumes that all rivet joints are loose (otherwise the feed water could not penetrate into them), is still disputed by the German school headed by Professor Baumann; the second premise does not meet with objections, since Professor Bauman also establishes that stresses in boiler seams sometimes exceed the yield strength of the material. To prevent all these types of corrosion, feed water, before it enters the boiler, is neutralized by appropriate cleaning or sediments and scale are promptly removed. Internal corrosion can also be caused by the use of condensation water containing lubricating oil. Fat deposits on the walls of the boiler, preventing the passage of heat into the water space, cause overheating of the material and the formation of acids. A locomotive boiler that exploded due to internal corrosion is shown in Fig. 9.

b) External corrosion occurs under the influence of oxygen acting in the presence of moisture on the outer surface of the boiler. One of the more common causes of external corrosion is unsatisfactory riveting or poor chasing. The resulting leak is detected during a hydraulic test of the boiler. The most reliable measure may be. riveting several rivets. Another form of external corrosion is observed in locomotive and vertical boilers with an internal firebox, namely in the lower part of them, in contact with the grate, where the presence of ash, greedily absorbing moisture, causes oxidation of the walls (Fig. 10).

Countermeasures: systematic cleaning of the lower surface of the boiler walls and timely removal of ash. Further, corrosion can occur if the boiler rests directly on brickwork, as water seeping through it can cause the boiler walls to rust. Therefore, boilers are supported on cast iron beams or iron rails, or the masonry is built on cement. Riveted seams covered with lining can pose a particular danger, as they impede inspection. External corrosion is also caused by improper design and poor adjustment of fittings, especially valves, which can lead to dangerous leaks. Finally, the cause of corrosion can be sulfur dioxide gases (sulfur dioxide, sulfates, etc.) released by fuel and causing rapid destruction of rivet joints (Fig. 11). Countermeasures: switching to another fuel and caulking or re-riveting defective seams.

5. Scale prevents the passage of heat into the water space and leads to the complete destruction of individual parts of the boiler, causing a danger of explosions (Fig. 12).

One of the more rational measures to prevent scale formation is to clean the feed water before it enters the boiler. This cleaning can be done mechanically or chemically. Mechanical method

consists of trapping impurities in a special vessel, and those that are heavier than water are directly deposited;

those that are lighter than water are retained in a filter filled with a layer of gravel or coke (Reisert-type filter). Chemical purification

is carried out in special devices (for example, Dervo systems), where feed water, depending on its composition, is treated with various reagents: lime - to precipitate calcium, then soda, and more recently, permutite (alumina silicate) - to convert insoluble lime sulfate into sodium sulfate, which has high solubility in water.

The need for feedwater purification depends on the boiler system, the nature of its operation and the degree of its boost. For boilers with a large water space, purification of the feed water can be considered necessary if its hardness exceeds 12 German degrees (1 German degree of hardness corresponds to the content of 1 g

of CaO in 100 liters of water). For those types of boilers in which descaling is difficult, water purification is strongly recommended already at 6-7 German degrees. Another very rational, but expensive way to purify water is to evaporate it and deposit the resulting steam in evaporators. This method has recently found application, in addition to ship boilers, also for stationary steam installations, especially in the presence of steam turbines. Since in the latter case the condensate can be used to feed the boiler, it is necessary to purify only approximately 5-15% of the total amount of feed water. Other measures to prevent scale formation include systematic boiler purging and, finally, a circulation device that ensures sedimentation in designated areas.

6. Weakening of the material after a long boiler service. After prolonged operation, the boiler material degenerates. Although the issue of aging (fatigue) of boiler material has not yet been finally resolved, there is no doubt that over time it loses its original properties and, above all, the necessary viscosity. In addition, over time, the thickness of the sheets, as a result of rusting, decreases, and defects occur in the rivet joints, for example, their weakening, etc.

Measures to combat explosions of steam boilers

. These measures can be divided into two categories: 1) measures taken during the service of the boiler - timely elimination of detected defects, which are often precursors of an explosion (these measures were indicated when considering individual causes of explosions of steam boilers); 2) legislative measures: a) norms regulating the construction of steam boilers in relation to: quality of material, research of material and methods of its processing; b) mandatory regulations and rules governing the supervision of steam boilers.

a) Standards governing the construction of steam boilers. The use of high pressures for boilers, reaching up to 50-100 atm, and high superheating temperatures of steam, reaching 400°, necessitated the need to revise the standards already existing in some countries for the construction of steam boilers and issue new ones in their place. That. The Würzburg and Hamburg standards that existed in Germany, published in the last years of the last and the first years of this century, were replaced by new standards that came into force on October 12, 1926. According to the new standards, materials used for the construction of steam boilers must be inspected by experts who issue the appropriate certificates. In addition to tensile strength and permissible elongation for various materials used in boiler construction, new standards establish, which is especially important, minimum limits for the radii of the sides of the bottoms, since the irregular shape of the bottoms has often been the cause of explosions. The same standards were published in 1924 in the USA. New American standards distinguish between fire and side plates. In addition, they prescribe for boiler sheets, depending on the grade, maximum contents of carbon, manganese, phosphorus and sulfur, which is not provided for by German standards. These standards establish minimum limits for tensile strength and elongation for sidewalls, fire sheets and other materials. In general, these norms are largely based on empirical formulas, in contrast to the German norms based on Ch. arr. based on calculated data and being the product of many years of research.

b) Mandatory regulations and rules governing the supervision of steam boilers. Almost all countries have issued regulations governing the supervision of steam boilers. This supervision is carried out in different countries directly by government bodies, or by private societies representing associations of boiler owners, who are obliged in their actions to obey the rules existing for this purpose. These rules provide for the technical examination of steam boilers within the established time limits. Thus, regular inspections of the boiler should, according to the USSR tubing regulations, be carried out normally within the following periods: external inspection - once a year, internal inspection - once every three years, hydraulic testing combined with internal inspection - once every six years. In relation to boilers that are more than 25 years old, the tubing rules provide for the examination of the material during the next boiler repair.

Source: Martens. Technical encyclopedia. Volume 3 - 1928

- < Back

- Forward >