Gasification of populated areas covers the most remote corners of the Russian Federation.

Gasification of suburban summer cottages in rural areas

The current situation has pushed the domestic market to expand the range of heating equipment operating on compressed natural gas or liquefied petroleum gas.

Spreading

Currently, residential premises and industrial buildings are heated not only with traditional water heating radiators, but also with gas convectors and infrared emitters. The high rating and demand for gas heating equipment is explained by several factors:

- availability of gas fuel;

- ease of maintenance of gas appliances;

- the ability to automate the operation of the heating system (hereinafter referred to as CO) or individual heaters using thermoregulatory equipment;

- the presence of non-volatile gas models, allowing you to choose a high-power heat generator sufficient for heating a private home.

In autonomous heating systems, apartments and private buildings, gas heating boilers of various capacities, wall-mounted or floor-mounted, continue to be the leaders. They are capable of heating a house and its extensions, a garage, a greenhouse or a bathhouse.

The homeowner can only clarify his needs, choose the appropriate gas boiler, the layout of the autonomous heating system and decide on the cost of equipment and installation work.

Gas floor-standing boiler for heating a private house

There are two types of gas boilers installed in private homes:

- Floor-standing units with high power. Most often, single-circuit products are used, intended only for heating.

- Wall-mounted boilers that operate simultaneously for heating and for the domestic hot water supply system.

Criterias of choice

Let's first look at the parameters by which such equipment is selected, and then we will take a closer look at the features of each type.

So, first you need to analyze the initial data: the type and area of the living space, the presence of a main pipeline in close proximity to it. And also choose a method for heating water for domestic needs.

- You can install any boiler in a country house, especially if a separate room is provided for it and there is the possibility of installing a chimney. But in the apartment, the instructions allow the installation of only one type of gas equipment - with forced draft. They have a closed combustion chamber and a special chimney, through which exhaust gases are simultaneously removed and fresh air necessary for combustion is supplied.

Boiler room in a private house

- The boiler power is selected according to many parameters, the main ones being the heated area and ceiling height. Using a simplified formula, it is calculated by multiplying the area by 0.2 kW - provided that the ceiling height is 2.5 meters.

To keep your home warm, it is important to correctly determine the required power of the equipment.

Note! It is also necessary to take into account the region of residence, the quality of insulation of the house, the number of windows and doors, and other individual data. In addition, if you use gas boilers for hot water supply, you need to add another 40-50% to the calculated power.

- If the house cannot be connected to a centralized gas supply, the boiler can be powered from bottled liquefied gas. But the cost of heating and water heating in this case will be much higher, and ease of use will be lower. In such cases, it is better to consider alternative heat sources.

Heating with propane is allowed only in a private house with a separate room for installing cylinders

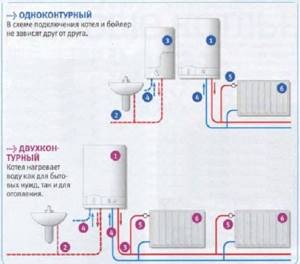

- Equipment functionality. You can choose whether it will work only for heating, or whether it will also provide you with hot water on an ongoing basis. In the first case, you need a single-circuit boiler, in the second - a double-circuit boiler.

Differences in the heating and hot water supply scheme between a single- and double-circuit boiler

Advantages of a water heating system

Electric boilers for heating a private house

Autonomous CO with water coolant and gas energy carrier is the most effective way to heat a private home. The cost of fuel consumption for heating a small cottage (100-200 sq. meters) is much lower than similar indicators for liquid fuel and electric heat generators. However, it exceeds the prices for solid fuel boilers on coal or pallets.

At the same time, there are several factors that ensure higher profitability of gas boilers over several years of operation compared to the same solid fuel boilers. Among them:

- The operation of system heating from a gas fuel boiler can be carried out in a programmed mode, maintaining the set temperature in the rooms using automation. This achieves optimal gas consumption, often amounting to only 50% of the consumption when operating without thermal control.

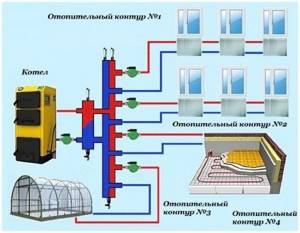

- The possibility of arranging a collector system along several circuits for different functional purposes (radiator heating, heated floors, boiler, heating a greenhouse or garage) with automatic control of the volume of coolant in one or another thread of each circuit.

The principle of arranging water heating from a solid fuel or gas boiler

The figure shows the principle of arranging a water collector heating system. Where hot water from solid fuel or gas heating boilers is distributed through a manifold over several heating circuits:

- heating circuits No. 1 and 2 – heating the first and second floors of the building;

- heating circuit No. 3 – greenhouse heating;

- heating circuit No. 4 - warm floors.

Condensing boilers for low temperature heating systems

Having appeared relatively recently, “warm floor” systems are now becoming increasingly common as the main ones, especially in new houses and apartments with individual heating. They manage to implement them even on wooden joists, not to mention slab foundations, ground floors and concrete floors. The main difference between a heated floor and a radiator piping is not even the laying of the line in the screed, but the low temperature of the coolant and efficiency due to lower fuel consumption and high thermal inertia. Traditional gas boilers are used in such systems, but a condensing boiler will work more efficiently in it. It is characterized by increased efficiency due to the removal of thermal energy from flue gases, but in order for the equipment to function at full efficiency, the temperature in the “return” must be less than 55˚C. And these are just the parameters of warm floors or warm walls, but the latter are practically not found in our country.

In tandem with a heated floor, a condensing gas boiler will allow you to consume less gas, which is vitally important given the enviable stability of tariff growth. Condensing boilers also have one more undoubted advantage - the ability to operate at a power several times lower than the nominal one. Do not clock, switching on and off, but work in optimal mode.

SirazhudinForumHouse Member

I laid 70 square meters in my apartment. pipes for TP made of cross-linked polyethylene, 20-diameter, 5 circuits, about 400 m. In general, the next stage is choosing a boiler, since I only have a heated floor without radiators, I decided to buy a condensing type boiler. The store told me that they have a 400 sq.m. condensing boiler. So the question is, is it possible for me to install a boiler with such a reserve on my 70 sq. m. and will it work correctly?

Sergey BugaevProduct Specialist

It is better for you to pay attention to boilers of lower power; 24 kW will be enough. In general, gas condensing boilers have a higher modulation range, and they can easily operate in a small area even in spring and autumn. With a minimum power of 2.4 kW it will correspond to 24 kW.

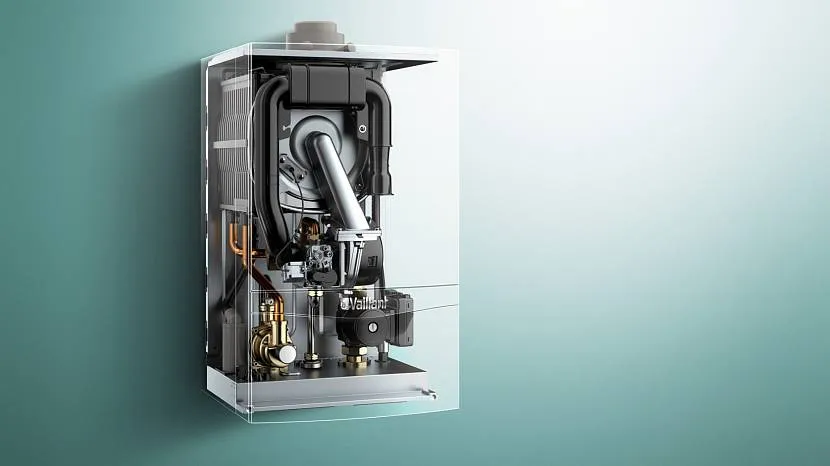

The latest generation wall-mounted condensing boilers are characterized not only by efficiency and a large modulation range, but also by expanded functionality.

- Efficiency – up to 109.8%.

- Energy efficiency – A+.

- Weather-dependent regulation - maintains a constant temperature in the rooms, reducing or increasing power, depending on the ambient temperature.

- Built-in Wi-Fi module, remote control.

- Possibility of integration into a smart home control system.

Even the most reliable European equipment needs service in order for the boiler to be guaranteed; the installation must be trusted not just to professionals, but to certified installers. The process itself does not require any special manipulations, there is only one nuance.

polshinForumHouse Member

...Is the boiler piping and installation of the heating system of a condensing boiler very different from a conventional one?

Sergey BugaevProduct Specialist

There is only one difference: condensing boilers have condensate drained into the sewer system. This is a small tube through which condensate flows in a weak stream.

If we are talking about a private house with local treatment facilities, condensate in its pure form cannot be discharged into the sewer system. It must be pre-treated in a specialized neutralizer (a container with marble granules).

Operating principle of a gas boiler (GK)

Schemes for water heating of a private house

A gas wall-mounted or floor-standing boiler is the central element of an autonomous heating system. The operating principle is determined by its functional purpose, which includes the following tasks:

- ensuring complete combustion of gas fuel;

- heating the water coolant with heat from the burnt gas.

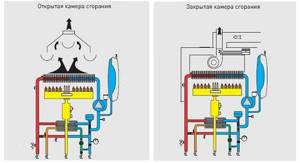

The process of gas combustion in a boiler occurs in a combustion chamber, which, depending on the draft method, can be open or closed.

The principle of operation of a gas boiler

There are several main points in the process of gas combustion in a heating boiler:

- Gas is supplied to the gas burner (yellow pipe).

- Air is supplied there too. The method of air supply is natural (open combustion chamber in the figure) or forced using a fan (closed combustion chamber).

- A piezoelectric spark, an electronic ignition, initiates combustion of the gas-air mixture.

- The gas-air mixture is burned in the combustion chamber.

- Smoke combustion products are removed from the combustion chamber (black arrows).

The coolant water is heated in a heat exchanger located in the combustion chamber. Wherein:

- the boiler includes lines with cold water from the water supply and cooled water from the return of the heating system (blue pipes);

- incoming cold water passes through the heat exchanger, is heated by the heat of the combustion gas and is discharged from the boiler to the heating system and other hot water systems (red lines).

Principle of operation

The thermal regime for a gas boiler is set using modern weather-dependent automation, which is adjusted according to the outside air temperature, and therefore the principle of its operation is simplified as much as possible. The process of starting and operating the unit is controlled by a microprocessor.

At this time, when the water in the heating circuit reaches the set temperature, the burner switches to modulation mode or, in other words, standby mode. The thermal cycle resumes when the water temperature in the circuit drops below the user-set conditions.

A fan built into the design in closed models supplies primary air to the furnace to ensure complete combustion of gas and creates an aerodynamic regime of flue gas movement sufficient to completely remove waste flue gases into the atmosphere.

When there is weak hot water pressure in the heating circuit, a centrifugal pump is installed, which directs the coolant to the final heating point in the house and returns it back to the boiler.

An electromechanical three-way valve switches the coolant between the DHW and heating circuits. When the user turns on the hot water tap on the mixer, the three-way tap directs the coolant through a small circuit, as a result the hot water is heated in high-speed heating mode.

The heating system does not work during this period. After turning off the tap on the mixer, the three-way valve switches the coolant to heating.

GK device

Gas heating scheme for a private house

The main functional modules as part of gas wall-mounted and floor-standing boilers are:

- burners necessary for the formation of a gas-air combustible mixture and its combustion in the combustion chamber (furnace) of the boiler to heat the coolant;

- heat exchangers that receive the thermal energy of burning fuel and transfer it to the water coolant;

- circulation pumps that provide operating pressure in the pipelines of heating circuits;

- expansion tanks into which excess hot coolant is discharged when the volume of water in the circuits increases due to overheating;

- devices for removing smoke-like products from combustion of a gas-air combustible mixture;

- automatic control and protection devices.

The figure below shows the structure of a double-circuit floor-standing gas boiler, which includes:

- modulation burner capable of regulating gas fuel consumption in accordance with commands from the control automation;

- two heat exchangers, one of which heats the water for the heating circuit, the other – the heat exchanger of the DHW circuit;

- expansion tank;

- exhaust fan for forced removal of combustion products;

- Control block.

The main elements of a double-circuit floor-standing gas boiler

Design features of the Rinnai double-circuit boiler

Due to many objective reasons, the greatest demand is for gas boilers that have two circuits, thanks to which they solve the issue not only of heating, but also of the simultaneous organization of hot water supply. Among other analogues in this class, the Rinnai brand of boilers differs in a number of special advantages:

- The design has a regulator, thanks to which it was possible to get rid of the complicated connection of a separate pressure relief valve. The regulator ensures optimal water flow in accordance with the set temperature parameters, despite fluctuations in water pressure.

- Also, the maximum safe operation of the unit is guaranteed by the presence of a large number of microcomputer safety modules. Among them is an emergency operation system, the use of which ensures the functionality of the boiler even if the control panel is damaged. To activate this option in the event of a remote control failure, the consumer simply needs to initiate an emergency start using the button on the unit body. The heating mode will remain unchanged.

- The primary heat exchanger is made of copper, which is highly resistant to corrosion.

- Durable metals are also used in other internal elements of the boiler, which guarantees a long service life of the model.

- All equipment has control panels stored in any place convenient for the consumer.

- The revolutionary function of automatic regulation of gas combustion in a smooth mode proportional to fuel pressure is to correct the flame size in accordance with the specified temperature parameters.

- The combustion chamber purge system eliminates noise pollution due to popping noises when the mixture suddenly ignites.

- Possible troubles with starting the boiler in a frozen room are eliminated thanks to the unit being equipped with a freeze prevention function. For this purpose, it is enough to maintain the power supply to the boiler, which will heat itself independently, including the hot water supply circuit.

- It is possible to start the DHW preheating option, eliminating the need to wait. The consumer can even set the volume of hot water he needs.

- Any losses will not bother you, because... Rinnai gas double-circuit boiler has a system for recognizing gas residues.

Reasons to buy a Rinnai double-circuit boiler

- High versatility thanks to adaptation to our conditions. Normal operation is not affected by reduced mixture pressure (up to 3 mbar). This is rare for imported equipment, the use of which is problematic in Russian conditions.

- The small body of the unit contains an entire boiler room, starting with a heat exchanger and ending with a three-way valve, automation and a number of related components.

- High efficiency (from 94 to 97%).

- Compact dimensions (600x440x266 mm).

- Implementation of the most advanced developments, which are reflected in 18 Japanese patents.

- Minimum weight (the weight of the most powerful unit does not exceed 32 kg).

- There is no need to install a bulky chimney.

- Gas consumption is reduced by 20% due to complete combustion of LPG.

- A soft start and long, trouble-free operation are the key to a long service life.

- Convenient placement in any room.

- The presence of a unique sealless circulation pump equipped with a magnetic coupling ensures the reliability of the Rinnai boiler.

- The fan burner operates silently and ensures complete combustion of the gas.

- This is accompanied by a very low content of toxic emissions in the exhaust gases.

- The power is adjustable over a wide range - from a quarter of the nominal value to the full value.

- The components of the gas-air mixture maintain optimal proportions.

- Maintaining sufficient traction even in difficult climatic conditions.

- Eliminates the risk of flame rupture.

- Absolutely simple installation and maintenance.

- Operating the boiler does not require special knowledge or complex measures.

- Rinnai wall-mounted gas boilers are characterized by an optimal ratio of quality and cost.

Boiler selection

To choose a gas-fueled heating unit for CO with a water coolant for a private home, users operate on three main factors:

- thermal power of a floor or wall heating boiler;

- design option that determines the location and method of installation of the gas boiler;

- type of draft, according to the principle of which air is supplied to the burner and smoke is removed from the combustion chamber.

Power

The power of the boiler clearly indicates its functionality for heating the house and creating a comfortable stay in it. However, choosing a heat generator with excessively high power does not at all mean the optimal solution to ensure its efficiency over a long service life. Excessive fuel consumption can be avoided if you use the empirical relationship:

- for heating 10 sq. m of insulated living space with a ceiling height of no more than 3 m, 1 kW of boiler thermal power is sufficient;

- for a double-circuit boiler, which additionally requires hot water for sanitary needs, it is necessary to increase the power by 25-50%.

The rated power of gas boilers is indicated for the nominal pressure of the supplied gas. Often in domestic gas mains the pressure is lower, and accordingly, the actual power of floor-standing and wall-mounted boilers will be less.

The table below provides indicative recommendations for the power of gas boilers, based only on the heating needs of the building.

Power of gas boilers for heating a residential building

| House area, m2 | Boiler power, kW | Maximum fuel consumption, kg/h |

| 100 | 5-12 | 3,2 |

| 130 | 6-16 | 4,7 |

| 160 | 6-20 | 6,0 |

| 200 | 7-24 | 7,6 |

| 220 | 8-25 | 7,9 |

| 270 | 10-32 | 8,9 |

| 370 | 18 and over | from 14.0 |

The power of a gas boiler can be selected more accurately if you use the table below. This table already reflects options for additional water use.

Power of gas boilers taking into account water use options

| Option | House area, sq.m. | Heating, kW | Number of devices | Number of people | GBS boiler, l/kW | TP, kW | Total power | Boiler power with DHW priority |

| 1 | 2 | 3 | 4 | 5 | 6 | 8 | 9 | 10 |

| 1 | 150 | 19 | 10 | 4 | 100/28 | 0,75 | 48 | 28 |

| 2 | 200 | 22 | 11 | 4 | 100/28 | 1 | 51 | 28 |

| 3 | 250 | 25,5 | 17 | 4 | 160/33 | 1 | 60 | 33 |

| 4 | 300 | 27 | 20 | 6 | 160/33 | 1,5 | 62 | 34 |

| 5 | 350 | 31 | 26 | 6 | 200/33 | 2 | 66 | 39 |

| 6 | 400 | 34 | 30 | 6 | 200/33 | 2,5 | 70 | 43 |

| 7 | 450 | 36 | 44 | 6 | 300/36 | 3 | 75 | 45 |

For floor-mounted gas boilers with a power not exceeding 60 kW, installation in common areas is allowed. Most often, wall and floor units are installed in the kitchen. For appliances with a power above 60 kW, it is necessary to select and arrange a separate room similar to a home boiler room.

Floor and wall models

Floor-standing and wall-mounted designs of gas boilers differ in the size of the housings and the compactness of placement of equipment in them. The list of indicators that are compared to select the required optimum includes the following factors:

- Floor products have higher power.

- Wall-mounted models discharge combustion products directly through the wall to the street in a forced manner using coaxial chimneys. For floor-mounted units it is necessary to construct brick chimneys.

- Wall-mounted models are smaller in size, the equipment is placed in a common heat-insulated housing, and there are no piping outside the housing.

- Floor-standing units are produced in energy-independent versions. Wall-mounted gas boilers do not work without power supply.

The energy dependence of wall-mounted models is caused by the requirements for the energy supply of electronic control automation of wall-mounted boilers. De-energizing the equipment leads to shutting off the gas supply and stopping the operation of the boiler.

Wall-mounted gas boiler in a home setting

Traction type

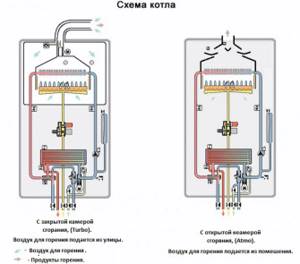

The type of draft is a factor that comprehensively affects the composition of boiler equipment. There are two types of traction:

- Natural draft, which helps remove combustion products of the gas-air mixture naturally. Natural draft boilers are often called atmospheric boilers.

- Forced draft created by fans built into the unit. Forced draft boilers are called fan or inflatable.

Atmospheric boilers have the following aspects:

- Positive:

- energy independence of work;

- silent operation;

- the possibility of arranging chimneys from scrap materials that are not structurally tied to any specific model.

- Negative:

- air consumption from the room in which the boiler is installed;

- the need to arrange a separate room;

- instability of operation up to the extinguishing of the flame when the main gas pressure decreases.

The figure shows a coaxial chimney of a wall-mounted boiler (inflatable type).

Coaxial chimney of inflatable boiler

Main aspects of using inflatable boilers:

- Positive:

- Possibility of installation in any room;

- oxygen from the room is not burned;

- ease of installation of equipment and chimney;

- stability of operation at reduced main gas pressure.

- Negative:

- energy dependence;

- fan noise;

- high price.

Choosing a gas heating boiler

Let's start with the fact that on the modern market there is a huge variety of heating boilers that run on natural gas. They differ from each other not only in technical and operational characteristics, but also in purely design features. Therefore, we will compare boilers according to different positions, and then provide a rating of gas boilers.

Floor or wall mounted boiler

From the names of the two gas units it is clear that one is installed on the floor, the second is hung on the wall. But this is not the only difference between them.

Firstly, wall-mounted models are low-power compared to floor-mounted ones. Therefore, they are installed in small private houses. Although there is an option when one floor-standing unit is replaced with two or three wall-mounted units, connecting them to different heating circuits. This type of heating system is often used in large houses with several floors. That is, the owner has the opportunity to weakly heat that part of the house where people are rarely present, which leads to significant savings in gas fees.

Gas boiler: floor or wall mounted Source gazblog.ru

Wall-mounted boilers have a small weight - no more than 80 kg. The reason is because they are wall mounted. As for power, it does not exceed 35 kW, and the tank capacity does not exceed 40 liters. That is, this is an excellent option for a house with a total heated area of 100-120 m². But wall-mounted models have two more significant advantages:

- There is no need to organize a separate boiler room for it. Any utility room will do.

- In this case, all wall-mounted units are equipped with a closed combustion chamber. That is, their design includes a coaxial chimney, which is built into the wall where the boiler itself is located. The chimney simply sticks out on the street from the wall of the house in a horizontal position.

In this regard, floor-standing appliances are heavier. Their minimum weight is 100 kg. They are more powerful in terms of generating thermal energy and are larger in size. Therefore, they can only be installed in premises that meet the requirements of specialized SNiP. That is, such premises must comply with standard dimensions: ceiling height, height of the foundation on which the boiler is installed. A very important parameter is the air exchange rate. That is, there are a lot of problems with the floor-standing unit.

Wall-mounted models powered by gas Source demo.landistore.com

Plus, these models are mainly equipped with open-type combustion chambers. Therefore, it is necessary to install a properly designed chimney for them. And the air flow must be appropriate.

But it should be noted that wall-mounted gas boilers have a thin spot - this is the heat exchanger. It is made of either steel or copper. The second option is expensive, but it will last two or three times longer than steel. Why - because condensation will constantly form on the steel heat exchanger, which leads to corrosion processes. And this is a serious minus.

As for floor-type heat exchangers, they are made of cast iron. After all, the weight of the unit as such does not matter here. There is no need to broadcast it on the wall. And cast iron will serve faithfully for decades. So in this regard, floor-standing models are better.

It is clear that in terms of price, wall-mounted ones are preferable. In addition, it should be added that they are equipped with both a circulation pump and an expansion tank. That is, all this is already included in the cost of heating equipment. For floor-mounted ones, both elements will have to be purchased separately. And this is another additional expense item.

Copper heat exchanger for gas boiler Source static.wixstatic.com

Connecting a gas boiler, both floor-mounted and wall-mounted, is not the easiest process. In this regard they are equal. The main thing is no amateur performance. This should be done by professionals.

Single or double circuit boiler

What is the difference between a double-circuit gas boiler for heating a private house and a single-circuit one? Let's start with the last one. This is a classic heating option. It contains one heat exchanger, which heats the water circulating through the heating system.

Double-circuit gas boilers are designed for heating and hot water supply. They have two circuits, two heat exchangers, hence the name. But it should be noted that heating water for a hot water supply system can be done differently in different models. Manufacturers of gas boilers use three options:

- A flow-through heating element is used.

- A separate heating tank is installed in the boiler body.

- A boiler is installed next to the boiler.

Now about the choice. It would seem that the optimal solution is to choose a double-circuit gas boiler for heating for a large house, and a single-circuit gas boiler for a small house. But it's not that simple.

Double-circuit gas boiler with two heat exchangers Source koffkindom.ru

The operating principle of a double-circuit gas boiler is as follows: two circuits cannot operate simultaneously. That is, when the hot water supply system is turned on for consumption, the circuit to the heating system is turned off. This is done in order to increase the efficiency of water heating in the DHW system. It turns out that while you are bathing in the bath or taking a shower, the heating radiators in your house are gradually cooling down.

Another situation often happens. You are taking a shower, and your wife decided to wash the dishes. The result is that you get a contrast shower, when either hot or cold water flows from the watering can. It may not be possible to solve the problem by purchasing a more powerful double-circuit gas boiler. An accurate calculation of both the heating system and hot water supply will be required regarding hot water consumption.

There is a way out - install one or more single-circuit gas boilers for heating, and use a boiler for the hot water system. The latter is selected by volume. For example, if this parameter is 200 liters, then it is enough for a family of 5-6 people. The boiler itself is a heat-insulated steel container in which a coil is installed that acts as a heat exchanger. It is connected to the heating system, so there will always be hot water in the house.

Single-circuit wall-mounted gas boiler with boiler Source oteple.com

But compared to double-circuit gas boilers for heating and hot water, this combination will be more expensive. In addition, you will have to organize a separate room for it.

And one more drawback. The practice of operating double-circuit boilers shows that often, due to increased water hardness, the DHW heat exchanger quickly fails. And its repair is almost 50% of the cost of the entire boiler.

If we think sensibly, then the optimal solution for installing double-circuit floor and wall-mounted gas boilers for heating and hot water would be a small private house.

See also: Catalog of popular house designs for year-round use

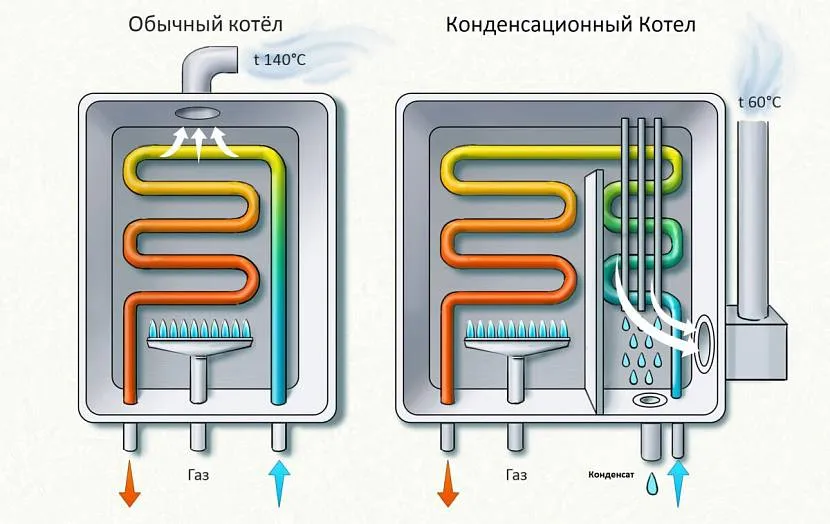

Convection or condensation boiler

Scientific and technological progress has recently presented a large number of technologies and materials. He did not bypass heating units either. Therefore, today there are two types of gas boilers on the market, which are based on different heating methods. This is the traditional option, also known as convection and condensation.

How does a regular gas boiler work? Natural gas burns in the firebox, which heats the heat exchanger, inside which water moves. In this case, the burned fuel releases a certain amount of thermal energy, which is not completely used by the boiler. She simply flies out into the street through the chimney. Hence the efficiency of such devices is no higher than 90%.

Gas condensing boiler Source www.vaillant.info

Condensation models differ in design in that they have two chambers. In one, fuel burns, in the other, carbon monoxide and excess heat condense on the surface of the heat exchanger. The condensation process is accompanied by the release of thermal energy, which increases the heating temperature of the heating water.

It should be noted that condensing units are economical. And it would seem that replacing convection heating devices with condensing ones will lead to significant savings in natural gas. But here, too, not everything is so simple.

Condensate from burnt gas is a chemically active liquid. Not any material can withstand it. This means that both the heat exchanger and the chimney must be made of appropriate materials. And this leads to higher prices for heating equipment. In addition, the condensate will need to be drained somewhere. Problems can arise here too.

For example, active liquid cannot be drained into a septic tank or sewer. This means that additional equipment will be needed to neutralize the condensate. Plus, you can’t do without consumables here either.

Operating principle of a condensing boiler Source teploknam.ru

There is one more nuance that will have to be taken into account when purchasing a condensing gas boiler. It does not work well in high temperature heating systems. Usually this is a radiator option. The thing is that the outlet water temperature is +50C. In contact with the heat exchanger, where the water is not lower than the indicated value, condensation occurs weakly. This means that thermal energy will be released weakly. That is, the efficiency of the unit will decrease. It will be good, but not maximum.

But if the system has a heated floor, then condensation models here will show themselves in the best possible way. Because this type of heating requires water with a temperature of no more than 30-35C. Therefore, the condensation process on the heat exchanger will occur more efficiently.

That is why manufacturers of condensing boilers indicate two efficiencies in their data sheets: for a system with a temperature of 30-50C and for a system with a temperature of 30-50C and for 50-80C. That is, it turns out that if the question is which type to choose from the two indicated above, then everything will depend on what type of heating is installed or planned to be installed in the house.

Advantages of Lemax boilers

Summarizing all of the above, we can highlight the following advantages of heating boilers:

- A wide product range that allows you to select a heating boiler based on a number of parameters and includes low-power models that are optimal for installation in a country house.

- High efficiency of devices, ensured by the most efficient combustion of fuel.

- Energy independence of boilers (most models can operate successfully without connecting to the mains).

- Safety ensured by automatic control systems from European manufacturers.

Well, and of course, the advantages include an acceptable cost: domestic assembly allows you to reduce the cost of producing heating devices, so the boilers are quite affordable.

The product line of Lemax boilers is quite extensive and includes more than a dozen models that differ in functionality, configuration, and a number of other parameters. In order not to make a mistake and choose the truly optimal option for heating a country house, you should seek advice from specialists. Call the contact number, and our employees will help you choose a boiler, place an order, and if necessary, deliver it to the specified address and professionally connect it to the heating system.

Factors for choosing a gas convector

- power. This is one of the most important parameters on which the choice of unit is based. Because it determines both the heating level and gas consumption. In turn, power is determined by the volume of the room. It has been experimentally established that the optimal power is 1 kW per 30 cubic meters. space subject to standard insulation.

Note that different manufacturers are developing certain market segments, offering customers convectors of different power:

| Manufacturer | Country of manufacture | Power range, kW |

| Alpine Air | Italy | 2,3-9,46 |

| Hosseven | Türkiye | 2,7-10 |

| ACOG | Ukraine | 2,3-6 |

| Emax | Hungary | 2,5-5,8 |

| FEG | Hungary | 3-7 |

| Karma | Czech | 2-4,7 |

| Cordy | Ukraine | 2,3-5,2 |

| FERRAD (Adarad) This brand has replaced | Türkiye | 2,2-4,9 |

Material prepared for the website www.moydomik.net

- method of gas supply - from the main line or from a cylinder;

- Efficiency The efficiency of the most modern convector models reaches 97%, but on average ranges from 80 to 97%;

- heating efficiency. Compared to traditional heating, the cost of using a gas convector is reduced by 500%;

- the extremely low temperature at which the unit can operate. Relevant for northern regions. The gas convector can operate at air temperatures down to -50°C;

- life time. Most manufacturers declare that the unit will operate for 20 years;

- price. In absolute terms (acquisition costs), a gas convector is more expensive than an electric one. But due to operating costs, gas is cheaper. The estimated payback period is 2 heating seasons (depending on the area).

Just purchasing a gas convector that meets all the requirements imposed by the premises and the user is not the key to its successful operation. Maximum efficiency is possible only with proper transportation and installation.

Source: moydomik.net/kommunik/otoplenie/433-gazovye-konvektory-otopleniya.html

Similarities and differences between gas convectors and gas boilers

Power calculation

In order to calculate the necessary power required to heat a dacha with gas convectors, the same principle is taken as a basis as for electric heating. The average ceiling height in the room is 2.8 meters. For 1 sq. meter of room requires about 100 watts of thermal power of the device.

Thus, it turns out that to heat a room with an area of 20 square meters. meters, you will need a gas heating converter with a power of 2 kW.

However, as practice shows, a small power reserve is always required. The thickness of the walls in the room, the number of windows, the outside air temperature, and more are taken into account.

Calculation of gas consumption for heating a house

So, we know the required power of a gas boiler. Now we can calculate how much gas will be needed to heat the entire house, as well as how profitable it will be.

First of all, you need to find out how many cubic meters of gas are consumed per hour. Let's assume that we need a boiler with a power of 26 kW. We multiply the thermal power by one tenth of the gas volume:

26 kW * 0.1 m³ = 2.6 m³/h

Now let’s calculate the consumption per day:

2.6 m³/h * 24 h = 62.4 m³

Then in a month it turns out:

62.4 m³ * 30 d = 1872 m³

Three months of winter and another three months when the boiler operates at half power are counted as a year:

(62.4 m³ * 100 in) + (31.2 m³ * 100 in) = 9360 m³

Now all that remains is to multiply this figure by the cost of gas in your region. So we not only calculated gas consumption, but also found out how much it would cost us to heat the house.

For your convenience, we have developed a calculator to calculate gas consumption for home heating .

But don’t be afraid of such numbers: usually in reality less gas is spent than in mathematical calculations. There are also ways to save gas when heating your home. In short:

- install a gas meter;

- work on insulating your home;

- automate your heating system;

- make the ventilation system work for you;

- reduce the cost of heating water;

- Be sure to maintain your gas equipment.

Using these recommendations together, you will achieve maximum gas savings.

Features of a gas heating convector: pros and cons

How convenient and profitable is heating with a gas battery? Does it have any disadvantages? First let's look at their advantages :

- The cheapest way to heat both an apartment and a house. However, if gas convectors using bottled gas are used, heating costs are almost equal to those of an electric boiler. And less profitable than a solid fuel boiler or heat pump. Gas convector with reduced gas

- The efficiency of such heating devices can reach up to 97%, i.e. they are economical.

- They can operate at any temperature, even at -50°C.

- There is no combustion of oxygen in the air of the room. Since air is used for combustion, which comes from outside the house.

- Service life - at least 20 years.

- Installation of a gas convector is simple and can be done with your own hands. See below for more details. Modern gas radiator

- Autonomy: you can easily heat several rooms of the house or just one room.

- Low cost - from 3 thousand rubles. (see article “Where to buy a gas convector”).

As with the operation of any gas equipment, batteries (convectors) must be used in compliance with strict safety measures, since the gas is explosive!

When using gas convectors using bottled gas, the saving effect from using such heating batteries is reduced to zero. Gas batteries are only useful when there is no electricity. At the same time, the process of replacing the cylinder with an interval of 1 to 4 days may seem quite tedious.

More cons:

- Gas radiator heating cannot be used to heat water.

- Quite limited thermal conductivity - 2-7 kW (for most models). Gas convectors are quite large

- Despite their rather beautiful appearance, they are quite large in size, so they are not easy to disguise.

- Since this equipment runs on gas, its installation and connection requires obtaining permission from a special gas service.

If you are interested in built-in heating radiators, you will also find information about them on our website.