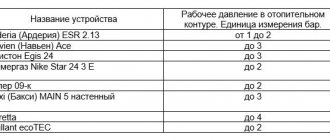

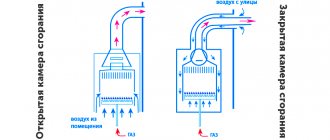

For heating networks in private houses and apartments, it is advisable to use boilers with closed coolant circulation, i.e. double-circuit. This design allows you to increase the pressure of the working fluid in the circuit.

High pressure in the heating system ensures safety and a higher boiling point of the coolant, therefore, the economic effect of the installation increases, and a decrease in pressure leads to problems in the system. Therefore, let’s look at why the pressure in the heating system of a double-circuit boiler drops and how to raise it.

The parameters of the boiler unit are monitored by measuring instruments - pressure gauges, main and additional. If a pressure gauge should be included in instrumentation and control measures, then choose models with electronic sensors.

Factors that affect the pressure inside the circuit:

- The impact of the coolant on the walls of the heating network elements;

- Height of laying pipes, hanging radiators and boiler unit;

- Design of main pipeline sections.

The pressure value for autonomous heating is not standardized. Acceptable values of network parameters are calculated based on the data of a specific object:

- Boiler type, pipe characteristics (diameter, presence of reinforcement, etc.), type and number of radiators;

- Equipment installation location, circuit length;

- Number of floors of the house;

- Parameters and condition of the external water pipeline.

Reasons for pressure drop in the circuit:

- Presence of leaks in the pipeline;

- Malfunction of the boiler, cracks on the surface of the heat exchanger;

- Malfunction of the membrane valve responsible for the safety of boiler equipment;

- Failure of the expansion tank membrane;

- Depressurization of the hot water supply circuit.

Leaks

Gaps are determined visually by pumping water into the pipeline to a predetermined level, and the cycle is stopped. The most susceptible to leaks are the joints of pipes, shut-off valves, radiator connections and the boiler itself.

One of the reasons for the pressure drop is a leak at the junction of the pipe and the radiator

- The presence of corrosion on metal pipes and connections;

- Poor quality pipeline installation;

- Weakening of joints;

- Damage to the pipe due to mechanical impact.

Troubleshooting

If the connection is damaged, replace the fitting or the connection itself. If a leak is detected (by a special scanner) in a pipe behind a decorative partition, wall or under the floor, it is necessary to dismantle the surfaces and make repairs.

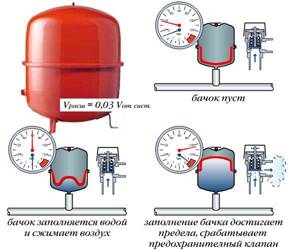

Expansion tank and its bleeding

In a closed-type system, the cause of a drop in pressure in the circuit may be the failure of the expansion tank.

- Frequent recharge of the system. If there is a need to additionally introduce coolant into the system at least once a week, without visible leaks, then the problem lies in the incorrect operation of the expansion tank;

- Dispersion of pressure gauge readings for different operating modes of the system. A sharp drop in coolant pressure in the system when using hot water supply also indicates a malfunction in the RB.

Pressure inside the expansion tank

To check its functionality, it is necessary to pump the tank and check that the pressure in it corresponds to the pressure in the heating system.

Sequence of pumping actions:

- Close the shut-off valves (direct and return water supply);

- Open the fitting, drain the water until the pressure in the boiler becomes zero;

- Take readings on the expansion tank in the “open” position. The presence of condensation on the RB should not be observed;

- Pump air into the RB until liquid stops flowing from the fitting. Allow the water to drain completely from the tank;

- Release the air;

- Repeat the procedure, keeping the pressure in the RB at 1.1...1.3 bar;

- Open the shut-off valve;

- Connect the coolant to the network. Set the pressure level to 1…1.1 bar.

Air injection

If there is no special pump for RB, you can use a regular bicycle pump.

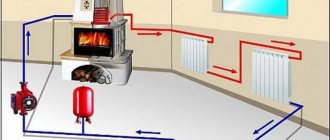

If there is no expansion tank

The expansion tank for a home heating network is the second most important element (after the boiler). Water, when temperature changes, changes in volume. The volume inside the circuit is always constant, so an expansion tank is additionally connected to the circuit, where excess coolant can be diverted, i.e. acts as a compensator. Consequently, the RB is a safety device that prevents emergency situations - increased pressure, depressurization of pipes, etc.

The use of boiler equipment without an expansion tank is highly not recommended.

For stable operation, the pressure of the RB must correspond to the system volume, because when replacing radiators with pipes, the volume of coolant must be increased. At the same time, a too large RB will not maintain the operating pressure in the circuit.

The standard is an expansion tank designed for 120 liters of coolant in the circuit (typical two-room apartment). If the tank is too small, then the water will be discharged when heating and expanding the volume through a safety valve. When the boiler is turned off, when the liquid temperature decreases, starting the boiler will be impossible, because its volume, and, consequently, the pressure will be insufficient. In such cases, additional network feeding is necessary.

Competent calculation of the heating system

In private homes, it is necessary to take a responsible approach to the choice of expansion tank. If the volume is insufficient and the system does not start, there is a high probability of pipes freezing.

Variety of expansion tanks

The installed equipment should be checked twice - immediately after installation and upon the onset of the cold season (at higher heating intensity).

Norm and control

We have already said that in a gas boiler the pressure should be within 1.5-2 atmospheres - this is the norm for a system that is put into operation and is in a heated state. In multi-storey buildings heated by centralized boiler houses, this figure is higher. Here, pipes and batteries must withstand not only high pressure, but also water hammer - this is an abrupt increase in pressure.

If drops are typical for centralized systems, then for autonomous heating they are rare - the volume of coolant here is not so large that serious jumps can be observed. In a cold state, the normal indicator is 1-1.2 atm., and in a warm state - slightly higher.

In private households, autonomous heating systems are used, powered by single-circuit and double-circuit boilers. The latter are becoming increasingly widespread. In addition to heating, they solve the problem of preparing hot water. One circuit in them heats the coolant circulating through the pipes, and the other ensures the operation of the hot water supply system.

What types of pressure are there?

A certain value is set to which the pressure must correspond. If it is below the specified value, then the entire heating device may break down. Let's look at what types of pressure there are.

- Dynamic pressure is the pressure in the coolant that passes through the pipeline and other elements of the heating system;

- Static pressure is the pressure of the coolant on the heating system. Moreover, the coolant is at rest;

- Maximum pressure. The device can operate at this operating pressure. If the arrow rises above the specified level, the equipment stops working.

Each device has its own minimum and maximum pressure values. The minimum pressure can only be when the gas boiler starts operating. As the coolant heats up, the pressure should be equal to normal operating pressure. If this value is underestimated or exceeded, the reasons for the incorrect pressure of the heating device should be considered.

Control devices

To control the water pressure in the heating boiler and heating system, pressure gauges and thermomanometers are used. The latter are combined devices for monitoring two parameters at once. After starting the circuit, it is necessary to monitor the indicators so that they do not go beyond normal limits.

Some double-circuit floor-standing and wall-mounted boilers do not have traditional dial pressure gauges. Instead, electronic sensors are installed here, information from which is transmitted to the electronic unit, after which it is processed and displayed on the display. Another approach is also possible - if the heating unit does not have a pressure gauge, it is provided by the safety group.

The security group itself includes the following nodes:

- Pressure gauge or thermomanometer - for monitoring temperature and pressure in the heating circuit;

- Automatic air bleeder – prevents the circuit from becoming airy;

- Safety valve - relieves coolant pressure when it increases excessively.

Be sure to provide this unit in a closed heating system.

Pressure drop and causes

In this section you will learn why the pressure in the heating system drops and how to deal with it. The reasons can be very different, so a comprehensive check of the entire circuit is practiced.

The pressure in the system drops when hot water is turned on

This problem is widespread, such complaints are received from many users. The bottom line is this: you open a hot water tap, and at the same time the pressure in the heating system drops. There is nothing wrong with this, since this phenomenon is associated with the design features of some double-circuit boilers. Experts say that in fact it does not fall, and the pressure gauge shows the wrong value.

When the pressure in a gas boiler drops, it goes into error and does not turn on - this scheme is implemented in many double-circuit units. If you open a hot water tap, and then the heating does not restore its operation, therefore, the pressure still drops - you need to deal with the reasons. For example, this may be caused by air leaks into the circuit or improper operation of the three-way valve.

Pressure drops due to leaks

A problem such as a coolant leak leads to a constant drop in pressure in the circuit. The user's task is to inspect the entire heating system - water can come out through literally every node. For example, leaks are often caused by poorly clamped connections, leaky heat exchangers, cracks in pipes and radiators. Typically, the tightness is checked during the initial startup of the circuit, but it can be broken later.

Let's look at what needs to be inspected and checked if the pressure in a closed heating system drops:

- Connecting fittings - the more connections, the less reliable the system;

- Heating batteries - even the smallest crack can cause coolant to leak out of it;

- Expansion tanks - make sure that their tightness is not broken;

- Double-circuit boilers - if the pressure drops due to a leak, puddles of water may form under them.

Any faults found are corrected, after which the system is refilled with water until normal pressure is restored.

Air jams

Cracks and lack of sealing in the heating system lead not only to leaks, but also to the opposite phenomenon - air being sucked into the circuit. As a result, air bubbles form in it. Some of them are eliminated by air bleeders, but they are not present in all systems. If the pressure in the system drops, there is probably a strong airing of the heating.

Air bubbles can also form as a result of improper filling of the circuit - air pockets form in it, due to which the pressure in the heating system drops. Airing causes many other phenomena:

- Gurgling and murmurs traveling through pipes are sound effects caused by air bubbles;

- Cold batteries and pipe sections - not only the pressure drops, but also the heating efficiency;

- Metal corrosion – the presence of air in the heating system leads to the thinning of metal components.

Thus, banal deaeration of the system will help to increase the pressure in the boiler.

Problem with expansion tank

The pressure drops in the Baxi boiler or in the Arderia boiler - quite common problems that plague users. This is usually caused by leaks in pipes and radiators, improper operation of the make-up tap, and leaky heat exchangers. But sometimes the problem lies in membrane expansion tanks. Somehow they cannot maintain the nominal pressure in the heating system - it drops.

What can lead to traffic jams in the circuit?

The importance of air vents cannot be overstated. Traffic jams in the circuit can lead to different processes:

- circulation disturbance;

- pressure surges;

- reduction in the efficiency of heating equipment;

- corrosion of metal.

Autonomous air vent

Installing an air vent in the heating system prevents the formation of plugs and pockets. When bumping into them, the coolant stops. Sometimes plugs cut off entire sections with radiators from the circuit. At the same time, the pressure in the system increases. When it reaches a critical level, an emergency release of coolant occurs. This, in turn, leads to a drop in pressure. At the same time, there are many cases when air collected in the batteries, the circuit continued to work, only half of the radiator became cold. This significantly reduces the heating efficiency and slightly increases the cost of its operation.

For open systems, one of the most serious threats is rust. At the same time, the question of how to remove air from the heating system arises only at the design stage. Such circuits are assembled at an angle from pipes with a large diameter, so there is a lot of water in the system. Considering the fact that the coolant is in contact with air and draws it into circulation, the oxygen level in the pipes is more than sufficient. Since it takes a long time to remove air from the heating system, oxygen reacts intensively with the metal. The result of the interaction is the formation of corrosion on the inner walls of the pipes. Rust sometimes eats up the tank so much that you have to replace it.

The direct consequences of traffic jams in the circuit entail indirect ones, which are no less dangerous:

Occurs if the valve for bleeding air from the heating system and all sensors are in good working order and working correctly. Due to the increase in pressure, an emergency release of the coolant occurs, which leads to a decrease in its quantity in the circuit. After cooling, there will not be enough fluid in the system, and the pressure will drop sharply. If it does not correspond to the minimum required to turn on the boiler, the heater will not turn on. And from this moment in winter, the countdown begins when the pipes defrost. Depends on how insulated the house is. Sometimes this happens in just three hours. In this case, unpleasant news awaits you at home from work;

This occurs if there is a malfunction of the valve for bleeding air from the heating system, or the temperature-controlling equipment. An unlikely situation, although possible. The results of this are very disastrous. At best, repair or replacement of the boiler; at worst, injury; rupture of the circuit and release of the hot water fountain.

A very likely situation is that the joints may not be tightened enough. As the pressure increases, they cannot withstand and crack. At the same time, hot coolant flows from the pipe like a fountain. Not only does the circuit need to be repaired, but the neighbors also need to repair the ceiling, since you flooded it thoroughly. This is the kind of chain that can be caused by simply airing the system.

How to increase the pressure in the boiler

If the pressure drops due to the expansion tank, it means that its volume is incorrectly calculated or the internal membrane is damaged. The situation can be corrected by more accurately calculating the required volume or by replacing the tank.

If the pressure in the heating system drops immediately after it is first started, then this is normal. The newly filled circuit, if it was filled with ordinary tap water, is full of air. As soon as it is converted into bubbles and removed from the pipes, the circuit parameters are normalized. You can also try removing the bubbles manually by using a manual air release.

The worst thing is if the pressure in the system laid inside the walls and floors has dropped - the pipes are often masked and completely recessed in building structures. If something happens to them, you will have to suffer thoroughly to localize the problem. The situation can be prevented by more careful selection of materials for the construction of the heating circuit.

Before increasing the pressure, it is necessary to check the tightness of the system. To do this you need to inspect:

- All heating devices - often leaks form where they connect to the pipes. Leaks between individual sections are also possible;

- Pipes - microcracks often lead to leakage of coolant, due to which the pressure gradually drops;

- Fittings are another common place for coolant leaks to occur;

- Boilers - double-circuit models have a complex internal structure; it is necessary to inspect the circulation pump, three-way valve and heat exchanger.

It is best if a specialist inspects the double-circuit boiler.

Increased pressure in the heating system causes unbalanced operation of the equipment and frequent boiler blockages. As a result, individual elements are subjected to increased load, which leads to circuit breakdowns and equipment failure. Why does the pressure in the heating system increase? There are several reasons for this phenomenon, most often these are leaks, unbalanced operation of individual elements, failure of automation or incorrect settings.

MF240F – Pressure has dropped: why and how to raise it correctly?

MF240F – Pressure has dropped: why and how to raise it correctly?

Post by Digika » 08 Dec 2015, 23:46

I woke up from a wild cold and saw E10 flashing on the boiler. I look at the barometer:

Everything seems ok.

I look at the instructions, it says that you need to increase the pressure with valve A:

Do I understand correctly that you need to COMPLETELY turn off the power to the boiler at 0 and then regulate the pressure? Or should I just turn it OFF? Is there a problem with the pressure at all, if it seems to be ok according to the sensor?

I found an article here, so according to it you need to bleed air and water in a bunch of places about which there is no mention at all in the manual.

Why might the pressure drop? The boiler has been working without any problems since February 2015, it was not used in heating mode all the time, it was switched to it only to heat the apartment, then switched to DHW mode.

For heating networks in private houses and apartments, it is advisable to use boilers with closed coolant circulation, i.e. double-circuit. This design allows you to increase the pressure of the working fluid in the circuit.

High pressure in the heating system ensures safety and a higher boiling point of the coolant, therefore, the economic effect of the installation increases, and a decrease in pressure leads to problems in the system. Therefore, let’s look at why the pressure in the heating system of a double-circuit boiler drops and how to raise it.

The parameters of the boiler unit are monitored by measuring instruments - pressure gauges, main and additional. If a pressure gauge should be included in instrumentation and control measures, then choose models with electronic sensors.

Factors that affect the pressure inside the circuit:

- The impact of the coolant on the walls of the heating network elements;

- Height of laying pipes, hanging radiators and boiler unit;

- Design of main pipeline sections.

The pressure value for autonomous heating is not standardized. Acceptable values of network parameters are calculated based on the data of a specific object:

- Boiler type, pipe characteristics (diameter, presence of reinforcement, etc.), type and number of radiators;

- Equipment installation location, circuit length;

- Number of floors of the house;

- Parameters and condition of the external water pipeline.

Reasons for pressure drop in the circuit:

- Presence of leaks in the pipeline;

- Malfunction of the boiler, cracks on the surface of the heat exchanger;

- Malfunction of the membrane valve responsible for the safety of boiler equipment;

- Failure of the expansion tank membrane;

- Depressurization of the hot water supply circuit.

The main reasons for increased pressure

Most often, the reason why the pressure in the heating circuit increases in a closed heating system is equipment failure due to which the indicators either jump up or drop sharply down. But apart from this, the reasons also include the following:

- A sharp increase in coolant pressure due to blocked shut-off valves. An increase in pressure is observed in the system, after which the boiler is blocked and the system stops. To fix the problem, you need to check the fittings for leaks, open valves and taps to relieve pressure.

- The reason for the increase in pressure in the heating system may be contamination of the dirt filter. Rust particles, debris, sand and slag accumulate on the surface of such a filter. As a result, the pressure increases greatly in the area between the boiler and the filter. To eliminate the cause, it is necessary to regularly clean the filters, at least 3-4 times a year. Also, a good solution would be to replace conventional mud filters with magnetic or flush filters. They cost more, but their maintenance is much easier.

- The operating pressure of the system may increase due to a malfunction of the heating boiler automation. This is a manufacturing defect, incorrect system settings, or a breakdown of the control board. All these problems require boiler repair, which can only be carried out by a master.

- There are leaks in the make-up tap, that is, water will constantly penetrate into the general circuit, which causes a pressure surge. The repair is usually quite simple, you just need to replace the rubber gaskets. But if there is a defect, the crane or equipment should be completely replaced.

Why does the pressure drop in a double-circuit or conventional boiler? This situation most often occurs when the expansion tank breaks down or the air valve leaks. To fix the problem, you may need to repair or completely replace the tank.

How to solve the pressure problem?

The very first thing to do in such cases is to check the valve. Before starting the test, make sure that the make-up valve is closed as tightly as possible. Check what happens when the gas boiler is turned off. To do this, disconnect it from the power supply. The same thing happens even when it is turned off - there is only one solution - call a service center that will replace the faucet for you. It is not recommended to replace the faucet yourself at home, as this work may require special equipment.

If the pressure drops only while the boiler is on, and this does not happen while warm water is being used, but only when the boiler is turned on and off, then the cause of the breakdown is most likely in the expansion tank. You can easily fix the problem yourself, at home. It is enough to find a fault by external inspection, most often it is some kind of scratch or small hole, then patch it with special glue. If the hole is large, then repairing it will require the help of specialists or a complete replacement of the expansion tank.

For heating networks in private houses and apartments, it is advisable to use boilers with closed coolant circulation, i.e. double-circuit. This design allows you to increase the pressure of the working fluid in the circuit.

High pressure in the heating system ensures safety and a higher boiling point of the coolant, therefore, the economic effect of the installation increases, and a decrease in pressure leads to problems in the system. Therefore, let’s look at why the pressure in the heating system of a double-circuit boiler drops and how to raise it.

Air lock as a cause of pressure increase in closed systems

When operating a closed system, it is not uncommon for the pressure to increase, which may be accompanied by a decrease in the overall coolant temperature and blocking of the boiler. All this leads to imbalance in the operation of the circuit and failure of its individual elements.

Why does the pressure increase in the system or is there a sharp increase in it? Typically, in closed heating circuits using gas equipment or other types of boilers, such changes occur due to airing. Air locks are a fairly common cause of pressure drop. Typically, the presence of such problems is determined in the following cases:

- equipment breakdown;

- incorrect system startup;

- automation malfunctions;

- presence of cracks in the boiler heat exchanger.

There are several reasons for such system failures:

- the contour is filled from the top point;

- upon startup, there is a very rapid filling of water in the system;

- Mayevsky valves or air vents are faulty;

- the heating radiators were not vented after their repair;

- The impeller of the circulation pump is loose, that is, air pumping occurs with disturbances.

Preventing the formation of air jams

Preventative measures against the occurrence of air locks are as follows:

- Pay attention to the correct installation of pipes and connections of heating devices. Many problems are caused precisely by mistakes made at this initial stage.

- To prevent air locks, proper commissioning of the equipment is necessary, before which it is important to first check all components and connections.

- Before putting devices into operation, check them for functionality. Using a compressor, you need to apply a pressure level that is ¼ higher than its normal operating value. If it does not weaken within 30 minutes, then everything is in order and the system is ready for operation. If the pressure drops sharply, then leaks are possible, which should be promptly identified and repaired before starting operation.

Official BAXI Forum in Russia

- Unanswered topics

- Active topics

- Search

- Users

- our team

- Acknowledgments

- 07/19/2019 – The BAXI seminar book 3Q was published. 2019 (119 MB). Download

- 06/20/2019 – BAXI Energy voltage stabilizers are on sale.

- 04/16/2019 – Sales of BAXI Eco Nova boilers have started.

- 11/16/2018 – The BAXI 4Q seminar notebook was published. 2018 (8 MB). Download

Optimal value for a private house or cottage

Any boiler operates at certain system settings, in particular, it is necessary to correctly calculate the water pressure. This value is influenced by the number of floors of the building, the type of system, the number of radiators and the total length of the pipes. Usually for a private house the pressure level is 1.5-2 atm, but for a five-story apartment building this value is 2-4 atm, and for a ten-story building it is 5-7 atm. For higher buildings, the pressure level is 7-10 atm, the maximum value is achieved in heating mains, here it is 12 atm.

For radiators that operate at different heights and at quite a decent distance from the boiler, constant pressure adjustment is required. In this case, special regulators are used to reduce it, and pumps to increase it. But the regulator must always be in good working order, otherwise sharp fluctuations and drops in coolant temperature will be observed in certain areas. The system must be adjusted so that the shut-off valves are never completely closed.

Pressure drop

An increase in pressure in closed heating systems is not the only problem; in some cases there is a sharp drop in operating pressure, and among the reasons why the pressure level drops, the following should be highlighted:

- hidden system leaks, corrosion, loose connections, leaking fittings;

- rupture of the tank membrane, which requires replacement or repair of equipment;

- pressure drops in the system are observed, if the nipple poisons, such an air leak leads to deflation of the tank, and this causes damage to the membrane;

- there are cracks on the boiler heat exchanger, which leads to coolant leakage;

- pressure drops associated with the appearance of air bubbles lead to a decrease in the overall temperature in the system and its shutdown;

- One of the reasons for the decrease in pressure may be a soured or slightly open tap used to discharge water into the sewer system.

Types of pressure

Why does the pressure drop in a wall-mounted unit? First, let’s figure out what types there are and how they affect the operation of the equipment.

- Static. The higher the height, the higher the performance. With every meter there is an increase of 0.1 bar.

- Dynamic. Forced operation of the pump creates the rated pressure in a closed system.

- Working. Includes the two options above.

- Excessive. Determined by a pressure gauge as the difference between atmospheric and fixed.

- Nominal. The one indicated by the manufacturer in the documentation for a specific model.

- Maximum. The maximum that is allowed to avoid breakdowns and accidents.

- Crimping. Used in production when testing equipment.

In the heating circuit, indicators are measured in atmospheres. They may vary; It is important that the value does not exceed the permissible maximum and minimum thresholds. A low value is only possible when coolant is pumped into the circuit. In other cases, it should not deviate from the norm.