How to tile a stove with your own hands

Decorating with tiles seems complicated. In fact, that's how it is. In the old days, two craftsmen were invited to lay tiles: a stove maker and a tiler. By doing the work at the same time, they created a beautiful and functional heating structure. Today, thanks to the fact that technology has stepped forward, it has become possible to finish the stove with tiles with your own hands.

Let us note right away that the work time from the moment the decision is made, development and approval of the stove/fireplace project to tiling is 3-4 months. And until the first full heating of the furnace is still 1 month.

Plus, a person who decides to make the cladding himself will be forced to play several roles: artist, designer, architect, ceramist and stove maker.

But, as they say, if there is a desire, step-by-step instructions for installing the tiles are attached.

Tiling - planning

Tiled stoves are a specific type of firebox arrangement. Its peculiarity is that construction and cladding are carried out simultaneously (classic method). There is also a modern one, for those who want to cover an already working (old) stove or fireplace.

Thus, first, let's consider the first option - simultaneous construction and lining of the stove with tiles. As a rule, two specialists perform such work at once - a stove maker and a tiler.

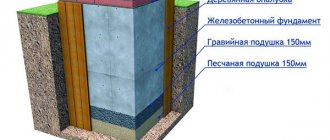

Based on the essence of the stage, we can conclude that the decision to cover the stove with tiles is made simultaneously with the idea of building it. Considering that the weight of the tile is quite large (2 kg), due to its greater thickness compared to ceramic tiles, as well as due to the installation method, the stove needs to be provided with a powerful base - the foundation. Its area should be slightly larger than the planned size of the stove or fireplace. This will allow the structure to stand firmly and support the weight of the tiles without distortion. When choosing the type of foundation, it is better to give preference to a slab foundation, and its thickness will be determined by the weight of the future furnace.

What it is?

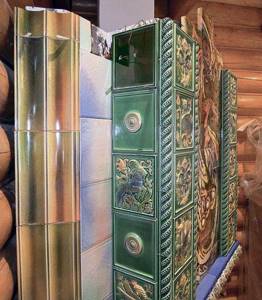

Tiles are traditional decorative tiles made from clay that were used to decorate stoves. Ancient art made it possible to create unique colored tiles with a special technology that made it possible to evenly distribute the heat of the oven and slow down the rate of its cooling. Most often, tiles have painting and relief decorations, but you can find smooth models with only painting or plain models with relief.

You can cover the entire stove with tiles or combine them with ordinary ceramic tiles and bricks. The use of tiles in decoration has the following advantages:

Such decoration will give your stove or fireplace a beautiful, original look and will diversify your interior. If you think that the decor in your home is too simple and boring, decorative tiles will help to significantly diversify it. Usually the stove is the semantic center of the room

In an interior design project, the semantic center should immediately stand out and attract attention. This is exactly the effect that bright tiles will allow you to achieve. Most of these tiles are coated with glossy enamels or varnish.

This is a very durable coating that will last a really long time. The glossy surface of the tiles will make it easier to clean the room: dust practically does not accumulate on such tiles, unlike brick, artificial stone or matte ceramic tiles. Tiles are made using a special technology, thanks to which they retain the heat of the stove longer.

Drawing and diagram of laying tiles

An accurate diagram is necessary in order to simplify installation and calculate the exact consumption of materials. Having at your disposal a detailed installation diagram, it is easy to determine what configuration of tiles will be needed for finishing and what order of their installation. Taking into account the cost of the tile, this is an important aspect.

Note. Users recommend creating an emergency supply of tiles. At least one piece of each type of tile should be available not only in case of unexpected damage during laying, but also in case of damage during use.

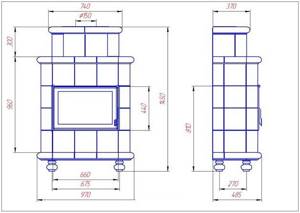

You don't need to have the skills of an architect to create a drawing of a tile slab. It is enough to indicate the dimensions of the stove and the location of the tiles.

Drawing of a tiled stove

Currently, 3D visualization of the project is popular.

Materials and tools

To work you need to prepare:

- tiled tiles for the stove - the main material;

- pins made of steel wire with a diameter of 5 mm. They are needed to connect the tiles to each other and the brickwork of the stove;

- soft wire;

- steel staples;

- clay for filling the tiller;

- filler: broken brick, river pebbles or gravel (for placing in the tiller);

Note. Refractory bricks are not suitable for filling the lump, but only ordinary stove bricks. The fact is that refractory brick expands under the influence of high temperature, which can lead to splitting of the tile.

- gypsum-based grout for joints.

The tools that every owner has will suffice: a building level, a plumb line, a square, a rasp, a spatula, an angle grinder.

Selection of tiles for cladding

Master tilers have created many different tile configurations, allowing for the construction of a beautiful and functional tile stove. So, for example, smooth tiles are used when finishing planes; for cladding corners, corner tiles with a rum of the appropriate configuration are provided. Curves and decor are made by shaped parts (border, straight and corner cornice, grate, relief inserts, cover shelf, firebox frame).

Not only the types of tiles can be different, but also the method of making the front surface. Here there are relief, smooth, with and without patterns, glazed and terracotta surfaces. The method of applying the design and its color scheme determined entire schools of ceramists. Dutch, Spanish, and Russian tiles have gained popularity.

But the sizes of tiles, on the contrary, are unified and regulated by GOST 3742-47. The document contains information about the geometry of the tile and permissible deviations from the norm. The latter are no more than 1 mm. Standardization made it possible to avoid the lengthy adjustment of tiles to each other, which significantly reduces the tiling time.

How to check the quality of a tile

When buying a tile, you need to be guided not only by its aesthetic properties, but also pay attention to such indicators as:

- raw materials. Masters claim that durable tiles can only be made from white clay. Colored clays contain various impurities that affect quality;

- presence and size of pores. You don't need to break the product to see the pores. They are clearly visible at the ends of the tile. The larger the pore size, the more moisture the product can absorb. The percentage of moisture absorption determines the tile’s resistance to temperature changes and mechanical damage. Accordingly, the larger and larger the pores, the lower the quality of the product;

- method of making tiles. In industrial quantities, tiles are made in two ways: punching, pressing and casting. In the first case, wet clay is used, which simplifies the production process, but increases the drying time of the product. In addition, during the drying process, a wet product may move, which will violate the specified dimensions. The second option is more labor-intensive, but the finished product is more durable and has identical dimensions. The third method is used to obtain “tiles for tiles”;

- number (number) of firings. They can be determined by the quality of the front surface. If it is slightly cracked and has a duller shine, it means that the tile was fired once.

Kinds

Stove tiles can be very diverse: with simple patterns or complex paintings, round or rectangular. If you are planning to decorate your hearth with them, you should first of all decide on the desired design. Consider the following possible options for traditional painting:

- Russian traditional tiles contain predominantly floral and plant patterns . Nowadays, products painted with Khokhloma are popular, although this color scheme was more typical for wooden utensils. Khokhloma can successfully fit into the Russian style in the interior, and it can also become an interesting accent in an eclectic and even modern interior. If you combine such fireplace tiles with high-tech style elements, you can create a very unusual design.

- The Russian stove was characterized by tiles with Gzhel decor - these are white relief tiles with simple blue ornaments . This type of cladding will also look great in almost any type of interior. Moreover, it is Gzhel, thanks to its exquisite laconic design, that fits perfectly even into the classical and baroque style. The subjects depicted in the pictures of such products are very diverse: they can be not only flowers, but also birds, houses, landscapes and images of people. Gzhel is often used in combination with regular tiles - corner tiles may be suitable for this.

- Dutch tiles also have a white and blue color scheme . At the same time, such tiles are distinguished by complex paintings - they depict not just simple ornaments, but entire scenes from everyday life, painted with a thin brush. Such tiles are made absolutely smooth so that nothing distracts the viewer from the painting. Very often, Dutch tiles depict the sea and ships, domestic animals, peasants at work or knights. Such tiles fit perfectly into Scandinavian-style interiors.

- Tiles with Italian decor are glazed very selectively - often untreated areas of red clay are deliberately left on them. Otherwise, the color scheme is predominantly warm - olive, yellow, red and bright blue tones are typical. The patterns on Italian tiles are usually very minimalist: often a large flower is simply depicted in the center. However, you can also find more unusual options - for example, images of branches with fruits or portraits of people in national costumes.

Preparing tiles for cladding

Considering the method of making tiles, it can be noted that all tiles will differ in size and shade.

It’s easier with the size - all the tiles are adjusted to the same size using a grinder and grinding with a rasp. Moreover, if you need to cut the product into pieces, you first need to cut down the front glazed surface.

Note. In order not to damage the surface of the tile during further grinding, you must first make a small bevel on the glazed surface. Thus, the tiles will rest on each other with an edge, and not as a decorative surface. This will not affect the quality of installation in any way.

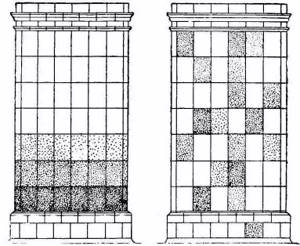

But if the size can be brought into uniform compliance, then attention should be paid to color. Products should be grouped in such a way that the transition between shades is as less noticeable as possible. At the same time, craftsmen advise laying tiles with dark shades at the bottom.

Products with detected defects (cracks, chips, design defects) may be useful for trimming. They can also be laid at the junction with the wall or other inconspicuous places.

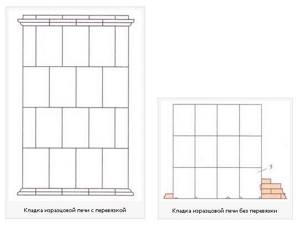

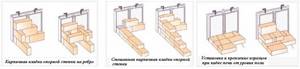

Options for laying tiles: the first pattern is with sorting, the second is without.

Furnace cladding with and without tile sorting

Scheme for laying tiles with and without bandaging. In addition, there are methods for laying tiles with and without bandaging.

The approaches to installation are not limited to this and are determined by the design, the relief of the tile and the imagination of the author.

Material prepared for the website www.moydomik.net

Layout of tiles

The sorted products must be laid out in accordance with the drawing on a flat surface.

Layout of tiles before and after

Note. Before laying out the tiles, it is convenient to mark the outline of the stove with masking tape.

If the dimensions of the tile exceed the dimensions of the stove, the edges of the tiles must be sanded (ground down) to the required size. If less, you can increase the thickness of the joint between the tiles. However, its thickness should not exceed 1 mm. for a vertical seam and 3 mm. for horizontal.

The laid tiles are numbered on the reverse side and proceed directly to the stove lining.

Layout of a set of tiles

Manufacturing technology

The production of tiles that you see in stores is organized in factories - glaze is applied to standard shapes by machine in the form of a print. Such modern products can be called imitation tiles, since the tiles were originally made by hand. Nowadays you can also buy handmade models, but they will cost more.

0e10de5d49706740d25e40a00d10103d.jpe 2b6f5a65ce6ab862853d74c78e0eba00.jpe

cf99d595752f06bf4e2a19f0192423db.jpe 9bd97202059e80b12eaa28436533330e.jpe b5a68f94b87f88f08133caa68ae98755.jpe

1c1ffce17dab52e53d165301a17ed1f3.jpe 57679aa83962094beff4fb7b3edc7553.jpe

The technology for producing tiles is relatively simple, although it is a labor-intensive process:

- First you need to sculpt the product with the desired relief. Ordinary sculptural plasticine may be suitable for this - if you want to make the tiles yourself, this material is the most accessible.

- The plasticine mold should be placed in a larger container or box. The front side of the tile should be directed outward.

- Carefully pour plaster into the container and allow it to harden.

- After this, the gypsum blank is turned over, and the plasticine is removed - it will no longer be needed.

- Clay is placed into the workpiece and fired. At home, the required temperature for firing cannot be achieved, but some workshops offer the service of using their kilns.

- After firing, the tile is covered with glaze; any patterns can be painted on it.

- Then, together with the glaze, the tile is fired again, and the product is ready. With one plaster mold you can make many standard tiles.

Cladding the stove with tiles - step-by-step instructions

The technology of finishing with tiles, like any construction process, is sequential and begins with the formation of the first row.

The first row of tiles or the so-called “hooves” set the tone for the entire construction. Their correct installation is the key to quick and high-quality further installation.

Installation of the first row

- tile preparation;

- selected and numbered tiles are immersed in water. This will avoid a situation where the clay of the tile will draw moisture out of the solution;

- After extraction, the rum of each tile is filled halfway with clay. Filling the pump increases the heat transfer of the furnace;

- then filler is packed into the clay. This can be brick, gravel, pebbles;

- the resulting voids are filled with clay;

Note. Many craftsmen use the ready-made mixture to fill the pump. Composition of the mixture: clay, quartz sand and brick in a proportion (ratio) of 1:2:2.

- laying tiles begins with the installation of corner elements;

- installation of central tiles. After the first row is laid out, it is necessary to tighten the tiles together with a steel pin. To prevent the tiles from sliding, it is recommended to bend the pin from above. Its lower edge will rest against the tiller;

- tiles in vertical and horizontal rows are connected to each other using steel brackets.

- a soft wire attached to a pin will allow you to connect a row of tiles to a row of stove bricks. The wire is tied to the pin. A loop is formed at its end, which is inserted into the brickwork. For a reliable connection, two wire loops should be tied to each pin.

Note. Hinges for connection with the furnace masonry are installed during the construction of the furnace. Installed in advance, they will interfere with work.

The procedure for attaching the tile is shown in the photo.

Methods of fixing tiles

After the first row has been laid, the seams need to be cleaned. This will help you apply the grout more accurately in the future. And also clean the tiled surface from washing.

Laying subsequent rows of tiles

After the first row is laid, another one is laid out in the same way. After this, the masonry of the stove or fireplace itself is carried out. After several rows of bricks have been laid, the space between them and the tiles is also filled with clay.

Tiling - order - 1

Tiling - order - 2 (legs)

Tiling - order - 3

Covering the stove with tiles - order - 4

Tiling - order - 5

Tiling - order - 6

Covering the stove with tiles - ordering - 7

Covering the stove with tiles - ordering - 8

Covering the stove with tiles - ordering - 9

Installation of tiles - order - 10

Installation of tiles - ordering - 11

Installation of tiles - order - 12

Installation of tiles - order - 13

Installation of tiles - ordering - 14

Cleaning the stove and grouting the joints between tiles

The tiling of the tiled stove is completed by cleaning the surface. To do this, use a soft cloth or paper. The final touch is to seal the seams (grout), if any were allowed during the work process. To grout the joints between the tiles, liquid gypsum dough is used, which is used to lubricate the joint spaces. After 10-15 minutes. After the dough has dried, remove any remaining residue with a soft cloth.

Note. No matter how much you would like to heat the built and lined stove, you should not do this earlier than a week after completing all the work. And even then, the trial fire lasts no more than an hour. A full check can be performed after the clay solution has completely dried - after 3-4 weeks.