Author: Yuriy Fedorovich Kolesnikov, thermal power engineer

When the stove smokes, it is dangerous for the life and health of people, the safety of the heated building and causes a large excess consumption of fuel. Even a slight smoke from the stove during lighting is literally the owner's money thrown away. In most cases, if you received the stove in good working order or the new one was accepted from the stove maker as expected, smoke from the stove can be completely eliminated on your own in a short time. You just need to know how fuel burns in a stove and how to heat it correctly and what can cause smoke during the operation of a working stove. The combustion of stoves has already been written in another material (and it is worth studying), and we will look for and eliminate the causes of smoking in a completely serviceable (running) stove in this publication. For the information of readers: even a black sauna can be heated so that the air in it will be clean, and a barely noticeable, non-vesting smoke will appear outside.

Smoke from stoves

Checking the draft quality in the chimney pipe

Smoke comes out of the house, and you need to start checking from the roof - from the chimney.

If the draft was good, but suddenly stopped, the cause may be an object that blocked the pipe. This happens especially often if there is no cap over the chimney and there are tall trees nearby. Any object can mechanically narrow the chimney channel: a nest made by birds, a brick falling out of the chimney, an accumulation of branches, debris. If there is no cap, the draft also disappears during strong winds. The air mass creates a turbulence in the pipe and blocks the path of smoke. It comes back and exits through the latches and doors. In calm weather there is no smoke in the house, and from this sign you can already understand its cause.

To determine further measures to eliminate smoke from the stove, it is necessary to check the quality of draft in the smoke exhaust system. Verification is carried out in one of the following ways:

- Using an anemometer. High-precision professional device for determining smoke draft.

- Ignition of flammable material. The burning material is brought to the chimney grate - with good draft, the flame is directed upward, with poor draft or its absence, it remains motionless.

- Visual check. If, when lighting the stove, the flame acquires a dark red tint, this indicates a decrease in draft. Good draft provides a light, almost white flame.

- Presence of a strong smell of smoke. If strong odors appear when the firebox is open, this indicates a mechanical blockage of the chimney system.

If the technology for arranging and lighting the stove is followed, the likelihood of smoke in the structure is minimal. But if a problem is still detected, then timely diagnosis and troubleshooting will ensure a long service life of the heating equipment.

There are many stoves in the modern world, but multi-variance is not suitable for a bathhouse; here, since ancient times, the first violin has been played by a wood-burning stove - brick or made of metal. Their internal structure is identical, and the problems that can arise are almost the same. The main thing is a “pillar of smoke” in the wrong direction.

User recommendations

Internet users who have encountered this problem and managed to solve it competently give several important tips regarding stove smoke:

- You should always pay attention to when the stove starts smoking. This almost always helps determine the cause of the problem.

- Do not use trash or damp wood for lighting. As a rule, such materials contribute to the rapid accumulation of soot on the walls of the chimney.

- At the first appearance of even a small amount of smoke, you need to think about it. If you do not pay attention in time, the soot will ignite and start a fire.

If you follow lighting and prevention technologies, the likelihood of smoke will be minimal. But if a problem is still detected, you should immediately carry out diagnostics or call a specialist, because only a timely solution to the problem will ensure a long service life.

The chimney is clogged

It also happens that for some time everything works flawlessly and suddenly one day the stove in the bathhouse starts smoking. What should you do in this case? The reason for this may be a chimney clogged with soot. The problem is solved by simple cleaning. You need to know how to clean a chimney in a bathhouse correctly. If the pipe has no bends, then this will be quite easy to do. Take a rope, attach a brush with a weight to it, and use this device to clean the chimney.

An overcooled chimney pipe can also cause poor draft. This happens in cases where the stove has not been used for a long time. To solve this problem, the chimney should be heated. This is done using a lit rag, which should be soaked in kerosene. The pipe will heat up and there will be no more problems with the operation of the furnace.

Due to the use of low-quality firewood, soot may settle on the inner walls of the chimney. To avoid this, you should first light the stove and then add firewood.

There are stoves in which the size of the blower is equal to the width of the stove. The air entering the furnace from the blower is pushed away from the back wall and goes out. To solve this problem, it is necessary to close part of the blower.

Prevention

The best method to get rid of problems with the stove is prevention:

- Timely cleaning of chimneys will protect you from blockages. It is recommended to do this at least once a year. When you use a lot of fuel, or if the fuel itself burns, producing too much soot, it is a good idea to have your chimneys cleaned twice a year.

- Monitor the condition of the chimney pipe. It is enough to do a visual inspection of its condition once a year. Secure the brick pipe parts using clay or cement mortar with sand. Use clay for work inside, cement for outside. Repair cracks. Monitor the condition of the insulation and insulation of the metal pipe. Strengthen it in a timely manner if you notice damage.

- Remember to maintain your oven when it is not in use. Try to paint all its metal elements with heat-resistant paint. This will extend the service life. Protects against corrosion. Examine the internal condition of the firebox of a brick kiln. If necessary, replace damaged bricks and grates with new ones. Check the condition of the welds on the metal stove and repair them if you see cracks.

With these simple tips, you can troubleshoot your stove and also keep it in working order so that it warms you with its warmth on cold winter evenings.

The video below shows the reasons why the stove smokes and how to fix it:

Pipe cleaning

Work should begin with cleaning the chimney. All doors in the stove and smoke ducts must be tightly closed and secured. If a large amount of soot falls from a height of 3-4 m, dust may be released into the house. A special brush is used for cleaning; if you don’t have a ready-made one, you can do it yourself.

The device will require a strong rope or cable. At one end you should attach a weight weighing 2-3 kg and a pair of old hard washcloths. You can use a fluffy ball of wire, stiff cord, or something similar. The fastening must be strong; parts that come off and get stuck in the pipe can cause a lot of problems.

You need to climb onto the roof with the brush, lower it into the pipe, pull it up and down several times, if possible, rotating and swinging it to the sides. Similar work needs to be done to understand why the fireplace is smoking. If after cleaning the operation stabilizes, the problem is solved. Otherwise, you need to look further.

If the stove is used for seasonal heating and cooking, the chimney should be cleaned once a quarter. This should be done more often if resinous or damp firewood is used. This causes excessive deposits and narrowing of the lumen. Mechanical cleaning can be done independently using traditional techniques that have not changed over the past centuries. Work is carried out wearing protective glasses and gloves. For activities at heights, you need non-slip shoes and insurance.

From the roof side

You will need a cable on which hard brushes are attached to clean the chimney from soot, and a heavy round weight with an eye. A brush can be made from an old plastic bottle.

Cleaning is carried out in five stages:

- To prevent soot from entering, cover the firebox and hatches with a wet rag.

- Remove the head and inspect the canal.

- Clean with a broom to remove cobwebs and debris.

- Use a weight to break through the blockage several times.

- Clean the chimney walls with brushes.

Finally, you will need to clean up the soot from the roof and inside the firebox.

From the oven side

Cleaning the chimney from the stove side

You need a special brush with a rigid but flexible fiberglass cable. It can be purchased at a hardware store.

Cleansing also takes place in five steps:

- Unscrew the hatch plug for cleaning,

- Clear the entrance of debris.

- Attach a suitable brush (for metal pipes only a plastic one).

- Clean the canal, slowly moving the instrument upward.

- The firebox is cleaned in the same way.

You can use traditional methods. Periodically complete the kindling with a few alder or aspen logs. This prevents the formation of soot. But you should not add any powders to the firewood, since some of these methods can lead to an explosion.

To prevent the stove from smoking, check the draft periodically. Do not use coniferous or wet firewood or garbage. From time to time, carry out preventive inspections of the chimney, because most often the stove smoke occurs due to its clogging. However, other problems can also lead to this. If you correctly determine the cause, you can quickly correct the situation yourself or with the help of a specialist.

Russian stove and its design

One of the reasons for insufficient traction may well be weather conditions. This applies to all wood stoves, regardless of their design.

This now seems implausible, but for many village families the stove was not only a “breadwinner”, but also a “meteorologist”. Based on the direction of the smoke column, the burning of coals, and the sounds that arise during the fire, experienced owners determined with a sufficient degree of reliability only the weather for several days.

Russian stove in the interior of a village house.

For example, if the atmospheric pressure is low, the stove takes a long time to light up, and the wood burns sluggishly, since the draft in the chimney becomes weaker. In this case, the smoke coming into the chimney from the fuel chamber often overflows onto the forehead of the stove.

If, due to poor draft caused by low pressure, damp firewood is also used, then acrid smoke can fill the entire room. All these manifestations together indicate that the next day the weather will be rainy and windy, and if it’s winter outside, then you should expect a snowstorm, which is very likely to bring a thaw.

But experienced owners, nevertheless, always knew how to distinguish external phenomena from malfunctions that arose in the design of the furnace itself. There are many other reasons that directly affect the level of draft and, accordingly, the efficiency of this heating structure.

And in order to deal with them, you need to know the internal structure of the furnace, at least schematically. Otherwise, it will be difficult to carry out repair work.

A Russian stove with an additional firebox allows you to use the structure for cooking food in the cooking chamber located in the front part of the hearth, without heating the entire structure.

The structure of a Russian stove is somewhat more complex than many other heating brick structures. And, by the way, there is no single, “dogmatic” scheme - even for one master stove maker, different stoves laid out can differ quite significantly. So, for example, a stove may have an additional firebox located under the main mouth or on the side, or do without it, have a different number of stoves, differ in size and location of the stove, etc.

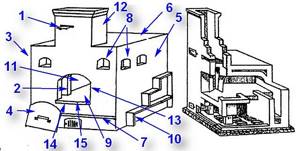

In order not to get confused in the furnace sections, you need to know their location and names:

One of the most common design schemes for a Russian stove

So, the design of a Russian stove consists of the following elements and sections:

1 - A view or valve that blocks the chimney pipe.

2 - Bend - the second wall in front of the entrance to the chamber, located under the arch.

3 - Oven - the surface of the oven, turned towards the wall of the house.

4 - Damper - a removable steel or cast iron door that closes the mouth of the oven during heating, cooking or baking bread. She is pressed against the walls of the bracket.

5 - The mirror is the front surface of the stove, reflecting heat into the room.

6 - Bed - a sleeping place heated from the inside, from the roof of the cooking chamber.

7 - Ward - the lower part of the furnace located immediately on the foundation.

8 - Stoves - blind niche openings that allow you to retain and distribute heat throughout the room for a longer time. Cooking utensils are often placed in them to keep cooked foods warm.

9 - Under - the base of the cooking chamber. Usually done with a slight slope towards the mouth.

10 - Pre-stove - a wooden extension to the outside of the stove - a mirror. It is used as a ladder for climbing to a sun lounger, and also as a shelf for drying shoes.

11 - The vault is the ceiling of the cooking chamber laid out in the form of an arch.

12 - The lower part of the chimney pipe.

13 - The mouth is the area of the hearth located at the front of the hearth, which can serve as a cooking chamber.

14 - The head is the end of the hearth, that is, the lower part of the cooking chamber.

15 - Pole - part of the hearth protruding forward from the general surface of the wall.

Russian stove in the process of being laid. The bottom of the main hearth is lined. A special section at the bottom is clearly visible - the baking area.

In addition to the departments listed above, the “classic” of the Russian stove is usually the oven space, which is called the oven area. The necessary equipment is stored here, and firewood brought in from the street is also dried.

Causes of smoke in new heating stoves

What to do if a newly installed stove smokes? Often the cause of smoke is structural inconsistencies, non-compliance with the technology of the masonry process, insufficient ventilation, and the absence of a distribution box.

Incorrect chimney height

The main reason for smoke in new stoves is a miscalculation of the height of the chimney pipe. Heating equipment for a Russian bathhouse and a private house must meet the following parameters:

- The size of the stove pipe opening depending on the type of fuel: 140×140 mm (coal) and 140×270 mm (peat briquettes, firewood).

- The height of the chimney above the roof is 75 cm, the elevation above the ridge is 50 cm. If the ridge is more than 1.5 meters away from the chimney, then the chimney can be of a similar height.

If the height of the chimney is not sufficient to prevent smoke, then you can increase it yourself.

Why does the stove smoke when the door is opened during the lighting process? A similar problem arises when there are serious design miscalculations: incorrect cross-section of the exhaust pipe, low location of the inlet channel, unswept chimney. To eliminate the shortcomings, a major overhaul of the heating equipment will be required.

Violation of stove and well construction technology

The required clearance of the chimney pipe ensures quick and safe removal of fuel combustion products. The minimum pipe diameter for a house is 15 cm, for a bathhouse – 10 cm. The height of the pipe and its installation location on the roof must correspond to the chosen design of the heating stove.

In addition, the inlet to the first well (in the combustion chamber) must be located no lower than the top of the door, otherwise this may lead to smoke every time the stove is lit. The shortcomings can only be corrected by rebuilding the furnace structure.

When assembling the chimney, you should avoid using elements of different sections, which can be the main cause of smoke in the stove. The best option is a round pipe. Rectangular smoke exhaust channels can create unnecessary air vortices and increase soot deposition.

Poor ventilation

Another reason why a new furnace starts to smoke is poor ventilation. As a rule, when installing a forced-type ventilation system, building owners provide exhaust hood only in functional rooms - a sanitary unit, a kitchen or a dressing room. However, a separate smoke channel must also be equipped in rooms where normal movement of air masses is required: in the steam room and washing room.

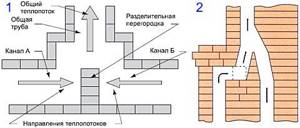

No distribution box

If there are two heating stoves installed in a building, for which a common smoke exhaust system is provided, then smoke occurs as a result of the absence of a distribution box.

To eliminate this problem, it is enough to make a distribution box with two separate channels or operate the furnaces alternately.

The distribution box is a special brick partition located inside the common chimney.

How to solve a problem

Once the cause of the problem is determined, you can begin to fix the problem. In addition, you can handle the repairs yourself, if the matter does not involve global relocation.

Clean the chimney

Chimney cleaning must be carried out regularly, even if expensive firewood is used. To carry out the procedure, use a brush with a weight (no more than 2 kg) on a strong cable. A weight helps knock pieces of brick to the bottom, and a brush cleans soot from pipes and wells.

We suggest you familiarize yourself with how lining is processed in a bathhouse

Important! If the owner leaves the house for a long time, it is necessary to close the pipe damper, which will prevent the deposition of soot inside the structure.

When craftsmen make design inconsistencies, the stove quickly fails and begins to smoke. Such violations are costly for the owner, since correcting the problem requires relocating the stove. Only a specialist can perform such complex work.

Cracks that appear as a result of overheating or long service life can be repaired yourself. To do this, use stove mortar, which is usually used for laying Russian brick stoves.

The procedure is as follows:

- Make a solution of sand and clay in a 1:1 ratio. You need to add a few teaspoons of water to the mixture. The solution should be thick.

- Moisten each crack with water before sealing.

- You should seal the gap inside the stove with your hand so that the mixture does not spill inside the structure. You can use a piece of metal for this.

- From the outside, the gap is sealed with mortar using a brush and spatula.

Clean the oven

The easiest way to clean the unit is not with a brush, but with special products that are sold in hardware stores. The Smoke log works well.

Before use, you only need to remove the film. The log is placed in the fired oven. The desired cleanliness effect is achieved in 2 hours.

Technical nuances

Overheating is equally dangerous for both metal and refractory brickwork, especially in the seams. Metal parts are prone to warping, bending, directional twisting, and burning. This is especially true for lightweight steel stove models. A few subtle but serious defects are already enough to cause a headache like why an iron stove smokes in a bathhouse. And if burnouts can, in most cases, be melted by inverter welding with repair heat-resistant electrodes or eliminated by applying patches, which is more correct, then warping and other linear deformations must be straightened, often painstakingly embroidering problem areas using an angle grinder cutting disc, and then restoring and strengthening the damaged geometry of various kinds of inserts, scarves, segments and other additional elements.

A few words should be said about why there is poor draft in the furnace, which is associated with the production culture determined by the construction of the furnace and the technical arrangement of smoke channels. Like any heating device whose operation involves burning fuel, the stove emits combustion products, both solid and gaseous. The dynamics of gases is associated, first of all, with the presence of certain obstacles in their path. It is not without reason that when constructing a chimney, responsible executors use such a technological technique as “scraping”, the essence of which is to eliminate various types of irregularities and obstacles in ducts, chimneys, distributors, and outlets. In metal single-wall pipes, a mandatory element is a condensate receiver glass, the purpose of which is to collect and remove condensate from the zone of movement of flue gases, preventing them from being moistened and cooled. The presence of these elements, as well as a sufficient number of service doors, will help to avoid an unpleasant situation when the stove in the bathhouse smokes, what to do, where to run.

The occurrence of backdraft in the furnace

Diagram of normal draft in a chimney

Reverse thrust can be detected with the naked eye. If the stove smokes when lighting, then this effect occurs. In theory, smoke should rise upward, since it has a lower density relative to cold air. If the stove smokes into the room, it means that something in these processes has broken down and does not allow the smoke to comfortably leave the stove space. There are several reasons that, to one degree or another, affect the release of smoke into the chimney. It’s worth talking to us in more detail.

In cases where the stove has not been used for several days, backdraft may form in the chimney. This means that air flows do not move outside, but into the room. This phenomenon quite often becomes the reason why the stove smokes when lighting.

Please note that weather conditions have nothing to do with this phenomenon - reverse draft appears in both warm and cold seasons

It is worth noting that draft overturning is possible even in stoves with an ideal design, assembled by experienced stove makers.

So, the answer to the question of what to do if the stove smokes into the house is to increase the air temperature inside the chimney. Moreover, these manipulations can be performed independently.

Warming up the chimney can be done in the following ways:

- Treating the internal surface of the chimney using a hair dryer through the open door to remove soot.

- Gaining access to the chimney by dismantling or opening the hog in the attic and further heating it with a hair dryer or other devices.

- The cap is removed from the top of the chimney and lit paper is thrown into the chimney.

Ventilation

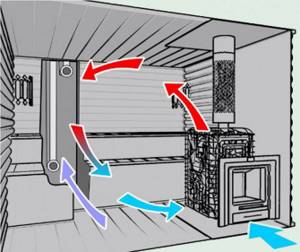

The chimney itself is a natural exhaust hood. In order to create upward movement of warm air, a full influx from the outside must be ensured.

Oven ventilation

However, often, when installing a forced ventilation system, owners only perform forced exhaust (in the kitchen and bathroom, for example). If some factors have influenced the reduction in draft in the chimney, powerful forced exhaust through a separate channel will become an additional obstacle to the normal movement of smoke from the stove.

The second floor may compete with the chimney. If there is a staircase nearby and an opening to the top, air sometimes rushes there more readily, especially if at those moments when a window on the second floor opens.

Temporarily turn off the hood, close the windows on the second floor, open a window or door at the level of the stove so that fresh air enters the room. However, the other extreme should not be allowed - drafts.

Why does the new stove smoke?

Design flaws

What to do if a new stove smokes? In most cases, the cause is design miscalculations and violations of masonry technology. The heating furnace must have the following parameters:

- The chimney opening is 14*27 cm (firewood, peat) or 14*14 cm (coal).

- The height of the chimney is 6 cm from the stove grate to the top.

- The height of the pipe above the roof is at least 70 cm, but at least 50 cm above the ridge. The exception is when the ridge is located at a distance of more than 1.5 meters - then the pipe can be made of the same height.

The cause of smoke may be a pipe that is too narrow

If the internal dimensions of the chimney can only be corrected by a professional stove maker, then you can try to solve problems with the pipe yourself:

- Explore the area surrounding the house. If there are tall trees or walls nearby, the wind can blow into the chimney and drive smoke indoors. In this case, you need to put a cap on the top of the pipe, and with a 90% chance the problem will be solved.

- A stove in a house or bathhouse may smoke due to insufficient chimney height. Ideally, it needs to be increased, but this is not always realistic. If the heating season has already begun, you can lengthen the pipe using improvised means by placing one or two metal buckets without a bottom on it. This design does not look very aesthetically pleasing, but it will last through the winter.

Scheme for determining the height of the chimney

Putting a new furnace into operation

The service life of the furnace and its uninterrupted operation depend on how correctly it was put into operation. After completion of the masonry, a lot of moisture remains in the materials, which must be removed before the start of the heating season. The drying period lasts 7-10 days in the warm season and up to 3 weeks in the cold season. The process takes place in several stages:

- Open all valves and constantly ventilate the room in which the oven is located. Drying should continue until wet spots disappear from the walls and condensation stops appearing on metal parts.

- After 5-6 days, light a small fire in the morning and evening. Gradually increase the volume of firewood.

- Do not try to speed up the process by using too active a firebox. Overheating can lead to cracks and crevices in the masonry.

The stove in the bathhouse can also smoke due to improper kindling. To avoid smoke, just follow these simple rules:

- Clean the ash pan and firebox. This must be done before each use of the oven.

- Open the valve and place the kindling on the grate. A splinter, birch bark or dry wood chips will do.

- Open the ash door slightly and light the kindling. After this, load the firebox with firewood. Lay them in tight horizontal rows.

- Close the firebox and open the blower door completely.

- Reload the firewood after 30-40 minutes. During this time, the previous batch should burn down to large coals. Try not to open the firebox between fills to prevent cold air from entering the oven.

- Regulate the combustion process using a blower and valve. The flame should be calm and straw-colored. If the fire turns pale, you need to close the ash door - this will reduce the air flow. If it gets dark, you need to open the door.

- For the last stack, it is best to use aspen firewood. They create a long flame and burn off accumulated soot.

- After the last batch of wood has burned through, rake the remaining coals onto the grate. The valve can be closed when the coals darken and no bluish lights appear above them.

Many people believe that heating can be done with any materials. If only they burned. With this approach, sooner or later the question arises as to why the stove smokes when the door is open or when lighting is started. The reasons may be as follows:

- Small debris does not burn through completely. Light particles are picked up by the air flow, and they settle on the walls of the chimney.

- Remains of glossy paper clog the grate.

- Damp firewood causes excess soot formation.

It is best to use dry birch firewood, approximately equal in size, as fuel. Other hardwoods found in the middle zone are also suitable - aspen, ash, alder, poplar, oak. Willow produces little heat and burns unevenly.

If you have eliminated all possible causes and the stove continues to smoke, do not be a hero and contact a specialist. Malfunctions in the operation of the stove can lead not only to the appearance of a specific odor, but also to carbon monoxide poisoning or a fire. Be careful!

Typical cases of stove smoking

Now we can move on to analyzing the typical cases of smoke listed above. But first, the golden rule: before eliminating the smoke, look outside or send someone - is there a strong stream of smoke coming from the chimney? Are sparks flying? Did a flame appear? Doesn't it smell like burning outside? If so, immediately extinguish the stove and the chimney from the roof: soot is burning! Fire! The best extinguishing agent is a carbon dioxide fire extinguisher of at least 2 kg: it will immediately extinguish the fire and will not damage the stove. But by no means powder! These are intended for extinguishing ignited flammable liquids. If the extinguishing powder gets on a hot hard surface, it can explode!

Case 1

Smoke when kindling. Checking the traction. If it capsizes, we return it, see above. It’s just not there or weak – we check where the obstacle is. We inspect the chimney and stove inside. Free - we remove the traffic jam. If the stove has not been cleaned for a long time before and was heated with random fuel, a lump of fluffy soot may collapse. In the case where a full load of fuel was immediately placed into a stagnant furnace, it is likely that bricks or mortar dust will fall out of the seams. A stagnant stove (especially a systematically stagnant seasonal dacha stove) is brought to full speed during 3 fires: 1/3, 1/2 and 3/4 of the full fuel load. Since problems with starting seasonal stoves in the spring arise systematically, watch another video about lighting a country stove after winter:

Video: how to light a country stove after winter without smoke

Case 2

She worked and worked, and little by little she began to smoke. It burns poorly and has become gluttonous. Add more air and draft - it doesn’t flare up; There may be a buzzing and/or popping sound. The probable cause is cracks in the masonry (casing), through which cold air penetrates into the furnace, knocking the furnace out of operation.

Cracks in the stove causing it to smoke

If cracks are noticeable on the external finish of the stove (on the left in the figure) or along the seams of its lining, carefully inspect the stove from the inside. Harmless and safe non-through cracks quickly become overgrown with dense graphite soot or carbon deposits (coked). But suspicious clean cracks (shown by red arrows on the right in the figure) need to be covered up. But not with stove mortar: it takes a long time to dry, it won’t adhere properly to the old one, and the pressure of the outside air will soon blow it out again. You need heat-resistant oven glue at a temperature of at least 1300 degrees with a complete hardening time of no more than 4 hours, the so-called. repair Now on sale there are heat-resistant quick-hardening adhesives for temperatures up to 1700 degrees. It is also highly advisable to update the external finish of the stove (re-sort the lining) and thoroughly coat the “bare” stove with ordinary heat-resistant plaster of 140 degrees or more (clay, cement).

Note: also check the firebox door - a gap between it and the frame of just 1 mm will give the same effect.

Case 3

Suddenly it began to smoke strongly and evenly. The probable cause is a mechanical obstacle in the chimney: a lump of collapsed soot, fallen brick, construction dust, etc. We stop the oven, open (remove) the cleanouts (see also below), find the obstacle, and remove it. The furnace may need to be repaired.

Case 4

It smokes when it gets hot, and the stronger the more the vent is open. We cover the gate - there is less smoke. First of all, we open the window and the door - perhaps the oven simply does not have enough air. It didn’t help - the chimney was overgrown with fluffy soot from bad fuel or improper combustion. It is necessary to inspect, make sure and clean, see below.

About the smoking of fireplaces

Fireplaces often smoke due to lack of air. The relatively good efficiency of an English fireplace is achieved by its huge air consumption, and a modern living room is not the hall of a knight's castle with a ceiling higher than 20 feet (6 m).

The causes of smoke in the fireplace and how to eliminate it are shown in pos. 1-3g rice. But, firstly, if the fireplace does not have a smoke tooth (top right in the figure), then it will spit smoke, as they say, from a sparrow’s sneeze above the chimney.

Why does the fireplace smoke and how to fix it

Secondly, a traditional English fireplace is built on a 3/4 foot (22.9 cm) high podium. If the fireplace insert is level with the floor, it will smoke from the excess influx of cold air, just like a cracked stove. To check, place a row of bricks (bottom right) or something else non-combustible in front of the firebox. Doesn't it smoke? The fireplace needs a solid or very thick grate. Just don’t lift your feet up on it like a lord after a fox hunt—you’re not wearing natural chevron boots with soles made of raw buffalo leather.

Case 4a

The stove smokes while running, but less and less. Perhaps in half an hour or an hour it will “heat up” altogether - deposits of “normal” dense graphite soot in the chimney or in the furnace. Needs cleaning, see below.

Case 5

The iron stove smokes until it warms up. We check the chimney, the stove is clean. Most likely, the indoor hog, the horizontal elbow of the steel chimney in the room, has sagged. An indoor hog allows you to make a stove-type stove very economical, up to an efficiency of 85%. But the far end of the hog should rise 3-6 cm above the one closest to the stove. If during operation the far end of the hog sags, the stove will smoke until the entire chimney warms up. If the sagging is more than half the height of the section of the hog, a permanent air plug will appear in it and without its acceleration the stove will not start running at all.

Case 6

An old running stove smokes smoothly, if you open the door a little - most likely, the stove stroke is set incorrectly: there is too much air, but the draft is less than optimal. We check the temperature at the cut of the view - if it is less than 140, you need to open the damper slightly and close the vent. The temperature on the view is normal - the chimney, which has an extremely small cross-section, begins to become overgrown with fluffy soot and needs to be cleaned. And quickly: the likelihood of soot igniting in such conditions is greatest.

Case 7

The stove spits smoke when you open the door - most likely it is overheated (forced). Look into the firebox - it is either completely filled with white flame, or yellowish-red flames are going up in waves. The temperature on the view is higher than optimal. You need to cover the air, and then the damper.

Quite a rare case - the flame in the firebox is beating, the temperature on the view is normal or lower. Then - an inspection of the structure of the stove from the inside: one of the channels is covered with soot, or it is littered to the point that its clearance has become smaller than the cross-section of the chimney. If there is at least one place in the entire smoke duct whose cross-sectional area is smaller than the chimney, the combustion will definitely escape from the firebox and become pulsed.

Case 8

The new stove smokes when the door is opened. The most likely reason here is its incorrect structure.

The lower edge of the firebox heater should be located at least 3 cm above the upper edge of the firebox door, pos. 1 in Fig. Only then will the flue gases rush into the haylo due to natural thermal convection. For reference: the calculation is based on the Reynolds number Re.

Why does a new stove smoke when the door is opened?

In a bell-type furnace, the fireplace is most often horizontal and located on the roof of the firebox, i.e. in any case completely above the door. But the high point of a channel furnace can be at any height, depending on where the exit to the first well is structurally located. If the openings of the door and the heater overlap each other in height, when the door is torn off, part of the flue gases will be forced out (positions 2 and 3) and will immediately cool down, which is smoke. Very dangerous, by the way: a lot of carbon monoxide is also released.

In a properly designed and built stove, if the door openings and the heater overlap in height, there should be a pass between them (do not confuse it with a smoke tooth) the same 3 cm above either the upper edge of the firebox opening, or the same – the heater, depending on which one is higher, pos. 4 and 5.

How to fix the matter? Only prevention, because in a good stove there is no extra combustion space. First, look at the design or layout of the stove and make sure it meets the specified conditions. Secondly, according to the ethics of the stove business, the stove maker himself, without waiting for a reminder, must say when the stove is dry and he will come to start it. Arriving at the launch, the master must, in the presence of the owners, light the stove, put it into operation, show that it does not smoke with the door closed and open, and only after that receive the due reward. And then from the understanding owners - a set table to wash the stove.

Case 9

The stove started smoking after repair or reconstruction. Most often - when installing a “new, good” branded firebox with glass. To avoid this, before purchasing a firebox, make sure that: a) the firebox is a stove firebox, capable of working with a smoke duct system, and not a fireplace fireplace, designed only for a direct chimney; b) the thermal power of the furnace is not greater than that of the old furnace - the flow of flue gases from an excessively powerful furnace will not completely pass through the furnace smoke path, and a systematic underload of fuel will cause its overconsumption.

Case 10

The stove smokes if something else (stove, fireplace) on a common chimney is started. If everything worked as it should before, but now it’s smoking, you need to check each device for all the cases described above. On a common chimney, a malfunction of any of them can cause the good one to smoke, while the “bad” one will seem to be working.

If the common chimney is new, then, most likely, the pairing of the outlets into it was done incorrectly. Correctly, the outputs of heat-generating devices are discharged into a common chimney through a separation and distribution box, the cross-sections of the arms of which are proportional to the thermal power of the devices. For example, at pos. 1 pic. Below is shown the design of a box for devices of approximately equal power. In this case, any malfunction (except for foreign objects getting into the chimney) will seem to go towards the device that caused it and can be clearly localized.

Correct and incorrect connection of the outputs of heating devices to one chimney

In everyday life, if you need to attach a stove or fireplace to an existing stove, you often simply cut out a window in its chimney, trim its lower edge onto a wedge to form a dividing tooth, and attach a new device, pos. 2. In this case, a number of malfunctions are possible that are “transmitted” to an innocent device. For example, a column of soot from waste fuel will grow on the tooth, which can fall in any direction. And the plug from a stagnant, unclogged stove will slide down to the stove, etc., etc.

Causes in the stove

The draft of the furnace depends on many factors, ranging from design solutions, the quality of the masonry, to meteorological factors and the need for periodic maintenance of the entire furnace system. Let's take a closer look at why there is poor draft in the furnace and what the possible reasons may be due to the design features:

- chimney design,

- pipe size,

- brick falling into the chimney,

- the chimney is clogged with soot.

Chimney design

The simplest chimney design is straight. Exit outside the premises occurs directly through the pipe. This can be observed in the example of simple “stove stoves” in temporary premises, tourist stoves and in the case of fireplaces.

The straight design provides the best draft, which is what is used for open fireplace fireplaces and temporary stoves. The draft in such a pipe near the stove is almost ideal and is less dependent on external factors.

But in stove heating systems of a home, the chimney is arranged through a heater. The purpose of such a stove is to heat the room and retain heat for as long as possible.

Pipe size

How to increase draft in a stove if the chimney design is with a heater? All things being equal, the higher the pipe, the better the traction. But it's not that simple. A pipe that is too high will be affected more by winds, and if the pipe is too high, the draft may be unnecessary. Excessive draft leads to faster combustion of fuel and an increase in the combustion temperature in the furnace, which is unfavorable for masonry.

At the same time, rapid combustion does not have time to heat the entire heater array.

The optimal height of the chimney is about 5 meters or slightly above the ridge of the roof, in order to avoid exposure to air turbulence from it.

By the way, according to fire regulations, the length of the chimney above the ridge of the roof allows you to place the exit at any distance from it. Whereas, the lower pipe should be located from the edge of the roof and the ridge at a certain distance. These reasons must be provided for when laying the furnace; they cannot be corrected during operation.

Brick collapse

The draft of the correct chimney for your stove may also depend on temporary factors. One of these is the collapse of a brick inside a chimney. This happens most often due to poor quality material, but it may also be due to the reason mentioned above. Burnout of bricks at high temperatures of fuel combustion is one of the main causes of premature breakdowns. Pieces from cracked bricks clog the chimney where it turns and interfere with the free passage of gases. Clogging with foreign objects and soot is the main temporary problem when operating any furnace.

In this situation, you will have to redo the chimney.

The chimney is clogged with soot

There are several reasons for this problem. First of all, the possibility of clogging is affected by the design of the chimney. The more turns, the more opportunities for soot from combustion products to settle.

The more “wells” there are in a heater’s design, the more often it is necessary to clean the chimney and pipe due to a decrease in the speed of smoke passage and a decrease in draft. In this case, a vicious circle results - soot reduces thrust, and as thrust decreases, soot is deposited even more intensely.

Lots of soot

How to improve draft with such a problem in the oven without cleaning it in the standard way?

There are several methods - heat the stove for 24 hours with dry wood with a low resin content, briefly create a high combustion rate when burning flammable materials. Often, soot deposition also contributes to the formation of frost on the inner surface of the pipe.

To prevent this, if you leave the house for a long time, you need to close the pipe damper in time, which will prevent hot air from coming into contact with environmental humidity. If the chimney is neglected and clogged with foreign objects, cleaning is essential.

Elimination of these causes is carried out:

What to do if the fireplace smokes

Stovemaker Master

Understanding the reasons why a fireplace smokes and then eliminating them can be difficult. Below we will consider the most likely of them. These may be design and installation errors, as well as improper operation.

Design errors

- – Poor design of the smoke collector. If the volume of the smoke collector, or hail, is small, the smoke does not go completely into the chimney. The same thing happens if the cross-sectional area of the chimney is insufficient. If the volume of the high is too large, insufficient vacuum is created. The smoke collector needs to be modified.

- - Firebox. The depth of the firebox should have a ratio with the height of the fireplace portal from 1/2 to 2/3. If the firebox is too deep, you can lay it down; if it’s shallow, you can increase it. If the smoke tooth is positioned too low, the fireplace may also smoke. An additional row of bricks placed on the smoke tooth may solve the problem.

- – Chimney design. The height of the chimney for a fireplace should be higher than for a conventional stove. The cause of smoking may be a narrowed pipe head, or the lack of wind protection on it. The cross-section of the chimney must correspond to the size of the fireplace. If the damper narrows the passage for smoke, it should be replaced.

The fireplace pipe can be connected to an existing chimney. In this case, all connections and turns should not have right angles, thereby creating additional resistance.

To eliminate smoke, the chimney needs to be modified. In this case, joints made at right angles are disassembled. It is recommended to make vertical pipe joints at an angle of 60° from the horizontal.

It may be necessary to install additional purifiers to remove soot.

Poor vent design can also be the reason why the fireplace smokes. It's all about the reverse thrust that the blower can create. In this case, it will be enough to close it.

If there is insufficient oxygen supply, the combustion of wood will be sluggish and the flame will have a dark color.

Poor quality installation

The use of low-quality materials for masonry mortar can cause the formation of cracks in the chimney, or burnout, especially in the attic. Air leaks will worsen traction. The chimney may be clogged with construction debris and mortar.

Uneven chimney walls will additionally collect soot. Insufficient chimney insulation in the attic can also cause smoke. To eliminate it, you need to carefully examine the pipe and seal the cracks.

Plastering the pipe will additionally insulate the chimney.

Operational reasons

The cause of smoking will be damp, rotten and dirty firewood, or drafts. Avoid opening windows and slamming doors excessively. Perhaps the chimney has not been cleaned for a long time, and it is clogged with soot.

Practical tips for eliminating smoke

If the size ratio of the fireplace portal and chimney is not met, you can try the following. An asbestos-cement strip is taken, the width of which is slightly greater than the width of the fireplace portal, and is applied on top of the smoking fireplace. The area of the portal decreases and the fireplace stops smoking.

Now you should lift the strip up, gradually increasing the area of the portal until smoke appears. Thus, the optimal position of the strip is found when there is no smoke and the portal has the largest cross-section.

Now all that remains is to install a stationary decorative curtain made from a strip of metal instead of a strip of asbestos cement.

It is possible to eliminate smoke by changing the upper section of the smoke collector, or by installing a metal plate on the smoke tooth. It is possible to install a metal heil of appropriate dimensions.

To increase the cross-sectional area of the chimney, you can try to saw off the edge of the tooth - this technique is quite risky and is used as a last resort. To determine where the smoke goes during combustion, use a mirror.

If the room has supply and exhaust ventilation, this may cause smoke. Turn off the ventilation and look at the result.

This solution can be effective if the pipe height is insufficient, but it has a number of disadvantages. The danger is that in the event of a power outage, a non-working fan will create additional resistance to the exit of flue gases.

Rollover traction

This process can occur after a long period of absence of heating in the stove. Simply put, it hasn’t been drowned for a long time. The chimney and stove cool down to a temperature comparable to the street temperature. As a result, warm air cannot leave the chimney, since there is no heat-conducting flow. To eliminate rollover, there are several proven folk methods. All of them are aimed at increasing the temperature in the chimney area. Here are a few of the most obvious ones:

- Every stove contains a door for cleaning the chimney. It is worth trying to heat the air here by setting fire to paper or any readily available fast-burning material;

- the previous point can be repeated for a hog in the attic. That is, open it and warm the air in this area;

- Well, the most emergency way is to throw burning materials inside the pipe. This method is worth using if others have not helped.

Main causes of smoke

If the stove smokes into the house, and not out into the street through a pipe, then this is a good reason to look for breakdowns in the heating system and to carry out timely repair work. There are a huge number of reasons, but eliminating them requires various efforts, tools, and knowledge.

Reduced traction

It happens that smoke starts inside the house the first time the system is started. And then the owners wonder why the new stove, installed in accordance with all the rules and recommendations, smokes. Usually the main reason in this case is the loss or weakening of draft, which plays an important role in the operation of the entire heating structure.

Bringing power above normal

In duct, bell-type and other brick stoves, there is a certain power level that should not be exceeded, overheating the system to excessive heat generation capacity.

When you try to boost the power of a brick system, smoke almost always begins in the room, since the structure cannot cope with the smoke escaping into the chimney.

Don't squeeze the maximum out of the stove

Insufficient air flow

For good combustion, fire needs oxygen - everyone knows this, but few people understand that for the proper functioning of the stove and its chimney, a sufficient amount of air is also required.

Even in severe frost, you should not tightly close all the doors and windows, but if you have forgotten about this and the stove is smoking into the house, then you can try to save the situation by opening the window or the entrance doors - perhaps the heating system has simply begun to “suffocate.”

Open the window

Rollover traction

A virtually uncontrollable process is the reverse draft of the heating system. It happens that even a new stove smokes if there is strong windy weather outside. Do not panic if smoke begins to occur for this reason - usually the wind subsides quickly, and operation of the stove can continue as usual.

Structural violations

The most unpleasant reason for the stove to smoke into the house may be improper installation, installation or construction. If there are violations in the design, the stove usually does not heat well, often smokes small doses of toxic air, and over time begins to emit large clouds of smoke.

If it turns out that the cause was an incorrectly installed structure, then the heating system will have to be redone, often completely.

In some cases, you can get by with partial relocation, usually with the following structural damage:

- Brick splitting in the firebox

- Small crack in chimney

- Disabling the blower,

- Collapse of solution inside the firebox.

If destruction has begun in the structure, then it is better to completely rebuild it, since partial repairs may not help, and the system will continue to collapse in the future.

Furnace wear

Incorrect operation of the heating system may result from wear and tear of the furnace, due to improper operation or frequent boosting of the furnace power. When the structure wears out, various damage occurs on it, from which smoke often pours out.

It should be understood that too large cracks or breaks can lead to a fire, so if they are detected, repair work must be carried out immediately.

Large cracks

Soot in the chimney

The most common reason for the malfunction of the chimney and the emission of toxic smoke into the room is poor draft due to a pipeline clogged with soot.

Soot

If such a problem occurs, it is very important to promptly clean the chimney from the accumulation of soot; this is done using various devices: a hammer, a brush with a weight or other tools. For preventative purposes, once a week it is necessary to heat the stove with aspen logs, which, when burned, can release soot along with smoke through the chimney to the street.

For preventive purposes, once a week it is necessary to heat the stove with aspen logs, which, when burned, can release soot along with smoke through the chimney into the street.

Preventing blockages in the chimney

Video.

There is no draft, the stove smokes, and, as a result, condensation forms and the casing begins to collapse. Both the stove maker who made a mistake when laying the stove, and the owner of the house due to inept handling of it, may be to blame for these troubles. Indeed, such a situation for a rural resident living in a house with stove heating in the winter turns into serious problems. In order for the stove to work properly, you need to know what causes the “whims” of the stoves.

The oven with hob heats up slightly

.

Check whether the valves are opened correctly when firing the stove in summer and winter.

The stove burns sluggishly and smokes

.

Check that the oven cleaning holes are properly sealed. The lack of good draft is observed when burning with damp wood, when the pipe is poorly heated, when the chimney is narrowed, or when the chimney has right angles.

The chimney needs to be expanded.

If the narrowing is caused by soot deposits, clean the chimney.

Cut right angles in the path of hot gases.

The stove smokes during the summer fire

.

Violation of draft on a hot day causes cold, compared to outside, air filling the pipe.

It is necessary to preheat the pipe with a bunch of burning paper or wood chips, placing them into the pipe through the view doors.

If there is a summer operation, you must first heat the stove in summer mode.

The stove begins to smoke some time after the fire starts

. Often a similar problem occurs in homes due to a lack of outside air flow. When fuel burns, air is consumed, its pressure in the room decreases, and draft is disrupted.

To equalize the pressure in the room with outside atmospheric pressure, open the window.

Formation of condensation in the pipe

.

When any fuel is burned, the water contained in it turns into steam and rises along the chimney along with the flue gases. When the flue gases are cooled to a temperature below 100 degrees, the steam condenses, the resulting liquid, mixing with soot and resins, flows down the pipe. During the cold season, moisture freezes and gradually destroys the brickwork. With proper combustion in a properly built stove, the temperature of the flue gases at the view should be about 240 degrees.

What are the reasons for the low temperature of flue gases in the chimney and how to eliminate them?

Use of fuel with high ash content

(peat). A large amount of ash generated during fuel combustion clogs the grate, which leads to a decrease in air flow. The fuel burns poorly and the temperature drops.

For efficient combustion of fuel, you need to reduce its layer and periodically remove ash from the ash pit.

Obstructed passage of flue gases

. A similar problem is typical for stoves with a long narrowed hog and with turns at right angles.

Errors made when laying the stove are eliminated.

A short pipe impairs traction

. The rate of fuel combustion and, accordingly, the temperature of the flue gases decrease.

The chimney should be extended.

The internal diameter of the chimney has been increased

. The slow rise of gases through such a pipe leads to the entry of cold outside air into it and cooling of the flue gases.

The chimney outlet should be narrowed.

The grate is not completely covered with fuel

. The bulk of the air passes by the fuel, which leads to cooling of the flue gases.

Distribute the wood evenly on the grate and stack the logs tightly together.

A decrease in the temperature of the flue gases can be caused by the influx of air through loosely closed combustion doors and stove burners, through cracks in the stove, and dampers.

Proper care and timely cleaning of chimneys from soot is a guarantee of stable operation of the stove in the coming winter season. In addition to the mechanical method of removing soot, chemical means are currently used, for example, “Jolly Chimney Sweep”.

After using this product, after some time, the soot separates from the walls of the chimney and settles at the bottom of the well. All that remains is to remove the soot through the cleaning doors.

The case is a pipe

. This expression, taken from V. Dahl’s dictionary, perfectly describes the situation when the stove, which has worked faithfully for you for several years, suddenly begins to “shoot” smoke, smoke, and does not melt well... What should you do in such situations? Remember the last time you looked into a chimney? And did you look at all? Meanwhile, all more or less reputable publications on the stove business recommend periodically inspecting the masonry and cleaning the pipes and chimneys at least once a year.

It is best to do this “dirty” work in early autumn. It’s not cold yet, and you can carefully, slowly, inspect all parts of the pipe in the attic and above the roof. If you find slot holes in the masonry or signs of destruction of the fluff, hog, riser, otter and head, immediately eliminate all defects and flaws and begin cleaning the inner surface of the pipe. It’s ideal if you can find tools for cleaning soot from a friend of yours. If there are no such items, make something like a brush yourself. It can be successfully replaced with a nylon washcloth made of thick threads, placed in a string bag with a cobblestone. But the best choice for this purpose is the used brushes that are equipped with garbage collection machines. If you have a coil of steel wire, cut it into pieces so that they completely cover the cross-section of the chimney. Next, drill holes in a piece of duralumin tube around the circumference and insert the cut wire into them. Fill the cavity of the gravity tube with molten lead, inserting a wire loop for garter to the “ruff” of the rope.

Having completed cleaning the central chimney outside the house, quickly clear the surface area of ash and soot from the layer of ash and soot. This can be done without even lifting the cast iron stove - through the burner.

There is more hassle with cleaning the smoke ducts. It's good if they have cleanout doors

, and when instead of them halves of bricks with mortar are inserted into the masonry? You need to know these walled up holes and carefully use a chisel or small spatula to pick out the seams and remove the insert to get to the clogged channels.

In summary, all other reasons that the stove smokes are as follows.

1. The weather is windy and the pipe is not equipped with a windproof cap. Wait for the wind to stop or climb onto the roof to install the cap.

2. The pipe is below the roof ridge. It is necessary to extend the pipe as soon as possible.

3. Rains, frosts and winds partially destroyed the outer masonry. Wind blows into holes and cracks, forming air plugs that interfere with normal traction.

Without delay, begin restoration work.

Remember that any crack in ovens can cause a fire. This is especially true for old furnace structures with flue ducts lying in the attics.

4. The cleaning door turned out to be defective and does not cover the cleaning hole tightly. In such cases, it is better to temporarily block it (the window) with a piece of brick coated with clay mortar.

5. If you heat your stove with firewood, remnants of vegetation from the site, brushwood, straw, then the length of the blower should be reduced by placing half a brick flat or on a spoon at its end.

6. After kindling, when you open the door, you notice smoke as if stuck to it. Look for a defect in the combustion chamber. If a welded oven is installed next to it, place bricks along it on spoons flush with the top of the door frame. If the gas outlet channel is made below the combustion door or flush with it, insert a brick jumper at the back wall of the firebox at the level of the top of the combustion door (Fig. 2). The smoke will then begin to “bounce”, contributing to the draft.

7. Smoke seeps in whitish streams through the summer valve that is not completely closed. It is necessary to determine whether a foreign object has fallen into the chimney and whether the chimneys are clogged with soot.

8. If the underground is damp, the chimneys may become saturated with moisture over the summer. They should be dried thoroughly by opening the bottommost cleaning and making a small fire of dry wood chips in it. You can use dry alcohol tablets for the same purposes. At the same time, start heating the stove itself. When the traction is restored, wall up the cleaning again.

9. The cause of smoking can be a burnt-out oven wall, a ash chamber clogged with ash, the small size of the gas collector, or an incorrectly selected cross-section of the main chimney.

10. If you have a fireplace attached to a stove with gases escaping into one chimney, you must start heating from the fireplace.

11. If chimneys from two stoves are connected to the same pipe at the same level, a cut should be made between them (the chimneys), or one of the stoves should be connected to the riser through an inclined chimney at a different level - higher or lower.

12. Resinous soot is burned directly in chimneys using dry splinters or special stove matches that have appeared on the Russian market.

Category: Stoves

Smoke when lighting

The stove smokes when lit in the cold season. This problem often occurs with ovens that are not used regularly. For example, the unit is located in a bathhouse or country house. A column of cold air forms a plug in the chimney that blocks the draft. Stove makers advise getting rid of it in the following ways:

- bring a burning torch to the smoke collector,

- burn a piece of paper directly next to the smoke collector.

These techniques allow the plug to warm up, rise up and come out. The problem of cold plug occurs not only with brick, but also with metal stoves that are installed in bathhouses and saunas (heaters). If the house is 2-story, you should know that the plug often collects in the horizontal part of the chimney, if it is on the 2nd floor. According to masonry technology, the length of this section (box) should not be more than 2 m.

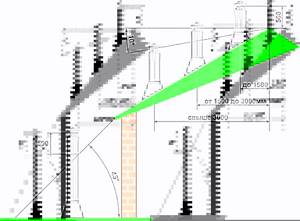

Smoking from the stove due to incorrect chimney height

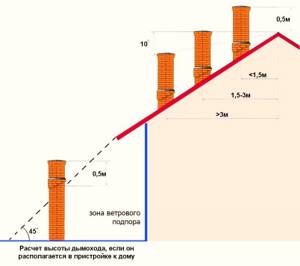

Often the outside of the pipe is built of insufficient height. There is a rule according to which it must exceed the height of the roof ridge by an amount depending on the distance to it:

- by 0.5 m at a distance from the ridge of up to 1.5 m;

- not lower than the level of the ridge, if the distance from it is 1.5-3 m;

- not less than an angle of 10° from the ridge level at a distance of more than 3 m.

If these conditions are not met, the stove will smoke due to insufficient draft and wind currents from the street. This error can only be corrected by extending the chimney. In case of severe wear, a major overhaul is carried out. It involves restoring the masonry and lining it with a metal pipe.