Everyone is familiar with Buleryan long-burning heating stoves. Having read so many positive reviews about them, I would like to add a little “from myself.” In addition, the heating theme is especially appropriate for the winter season.

The peculiarities of the Brenerans’ work are known to many. Having supported their knowledge about the furnace with positive reviews, our compatriots are happy to purchase this result of engineering. Expecting too much from him.

What is a Buleryan stove

History says that the device was developed by technologists, and it was intended for mobile teams of lumberjacks. The Buleryan stove is a convection-type solid fuel device for autonomous heating. The Bulerjan stove is produced in Germany. There is also a Russian analogue - the Breneran oven. There is no functional difference, their structure is identical. There are variations of the stove with a hob for cooking, which makes it even more comfortable for home use. The device is suitable for heating residential private houses, bathhouses, and garages.

Device

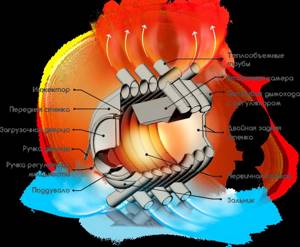

The wide, sealed firebox door has a blower (throttle) to regulate power. The chamber has curved walls in which batteries of pipes are placed at 2/3 of the diameter (pipes can be round or square). This Buleryan device provides high heat transfer in smoldering mode. At the bottom of the firebox there is a tray in the form of a grate made of cast iron or steel. The upper partition has holes.

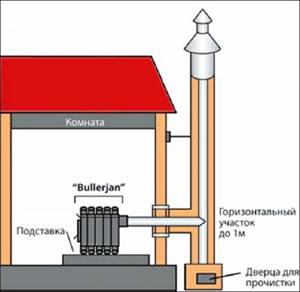

The space above the upper partition is an afterburning chamber in smoldering mode. Flue gases from this cavity exit into the horizontal zone of the chimney - the hog. The chimney for buleryan has a damper; it is installed where the pipes turn upward. This smoke choke can control the combustion mode. The fumes always fly out through the pipe and do not enter the room due to the fact that the throttle and damper are not able to block the draft.

The heater economizer is located above the damper. This vertical section has good thermal insulation and is intended for combustion of flue gases. In the economizer, the gas flares up and forms a plug - the intensity of the flame in the firebox subsides. When the plug cools down and slips through, the combustion intensifies again. The presence of an economizer increases the efficiency of the stove to 80%; without it, this figure does not exceed 65%. Using diagrams and drawings, you can make a stove from a cylinder yourself.

Principle of operation

The stove can operate in two modes: kindling and gasification. The operating principle of Buleryan depends directly on the mode. In the first mode, the stove quickly heats up to maximum temperature with a minimum amount of fuel. The room is heated quickly, because the stove is capable of producing 4 cubic meters of hot air per minute. In the gasification mode, the air warms up evenly, and the solid fuel smolderes. In this case, the maximum amount of fuel is added, and the damper is closed to a minimum. In this mode, the oven can operate for up to 12 hours.

What is buleryan?

The relatively new device is called differently - buleryan, bulerian, buller or breneran. This is not an ordinary stove, which was invented in the 1970s, and immediately became a leader in two “categories” - efficiency and productivity. A lot of water has passed under the bridge since then, but even now Buleryan has no serious competitors-stoves. If we talk about appearance, many compare this heating device to a potbelly stove, but with an unusual design.

You can be convinced that they are right just by glancing at photographs of a strange, unusual, unique design. Canada is traditionally considered to be the birthplace of the device, but this is not true. It was invented by the American Eric Darnell. He lived in Vermont, but right on the northern border. For some reason, production was established in cold Canada. The future Buleryan, which was then called “Free Flow,” was intended for heating residential and non-residential premises.

The Canadian device is designed to use solid fuel - firewood, but can also work on other types of fuel - compressed wood waste, brushwood or coal. However, the manufacturers of these devices prohibit the use of the latter type. The reason is the risk of destruction of the steel structure, since this fuel requires high temperatures (800-900°) for combustion.

Despite the comparative simplicity of the device, buleryans are characterized by high efficiency. This same relative simplicity of design makes it possible not to buy a heating unit, but to first try to make it yourself.

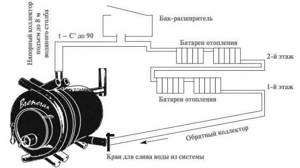

Buleryan with water circuit

The presented unit can be used for water heating, then the heat exchanger will contain liquid, not air. The Buleryan boiler has the same efficiency as gas heating devices. The Buleryan stove with a water circuit is relevant in dachas and industrial premises. Main features of aqua-buleryan:

- The surface of the stove with a water circuit does not heat up very much, so it can be installed in a small room.

- The boiler can be used provided there is natural circulation of the coolant.

- For most models, a concrete base-stand is made for installation.

- Inside the casing there is a combustion chamber. The pipes containing the liquid fit tightly around the chamber, which results in rapid heating.

Advantages and disadvantages

- The air warms up quickly and is distributed through air ducts.

- The room warms up evenly.

- Ease of operation and installation, minimal fuel consumption.

- High efficiency of furnaces.

- The oven can operate at full capacity for up to 12 hours.

- The oven body heats up less than other types of ovens.

- An insulated pipe is required.

- Fire safety requirements complicate the location. There must be at least 1 meter from the body to the wall.

- Condensation from soot, water and tar forms on the pipes. When burning, an unpleasant odor enters the room.

The advantages and disadvantages of Buleryan indicate that an effective device needs to be monitored. Pipes must be cleaned of condensate at least once a year. The placement features of a convection type oven will not cause any particular difficulties during installation. Thanks to the fast heating of the room and the low price, many are ready to buy a Buleryan stove. The Canadian stove is an inexpensive option and fits into any interior.

Buleryan stove and its application features

Buleryan is a heating stove, which is an all-metal body with pipes welded into it, providing forced convection, thanks to which the air in the room warms up very quickly.

The Buleryan stove was invented by Canadian lumberjacks, and later underwent modern modifications for more comfortable operation.

This device is a heat-resistant metal structure. This type of stove is intended for heating private houses, various workshops and premises.

Buleryans quickly gained recognition from buyers, displacing other types of stoves and various heating systems on the market. Such excitement and sympathy among consumers is due to the impressive characteristics of the stove, among which we can immediately note the high efficiency of 75-80%.

Consequently, fuel consumption will be less, while the heated air will spread over the entire area. An important feature is also that the stove does not heat up.

Another advantage is the low prices for such stoves, all thanks to the fact that it consists entirely of metal, without any engines or additional parts.

There are rows of pipes protruding from the top of the furnace, and pipes are also located below. Due to these pipes, convective heating occurs - cold air, entering the lower pipes, passes into the combustion chamber, and at the outlet the air comes out of the upper pipes already heated.

There are two cameras in Buleryan.

One of them is filled with solid fuel. namely: firewood, peat briquettes, brown coal, cardboard and various types of paper industry.

In this chamber, the presence of air is minimal, due to which the wood does not burn immediately, but gradually, in addition, this smoldering firewood produces flammable gas, which burns in the second chamber.

The Buleryan stove is aimed at heating air, which, due to convection, can warm up the room faster.

The unique design of Buleryan allows you to simultaneously perform the functions of such devices as:

- bake;

- heater;

- gas generator.

This stove is used to heat rooms:

- residential building;

- unfinished house at the time of construction;

- dachas;

- enterprises;

- in a greenhouse, etc.

The Buleryan stove can operate in two modes:

- Stove firing mode – brings the stove to the desired operating temperature.

In this mode, the room is rapidly heated using intense convection. To quickly ignite the stove, you should first place small dry firewood (chips) with paper in the firebox, which are then set on fire.

After this, the firebox door closes and the damper opens to the maximum, providing intense air draft into the firebox. In the kindling mode in the furnace, the temperature rises to +700-800°C, which warms up the heat exchange pipes well, through which air begins to move intensively. At the exit from the heat exchange pipes in the kindling mode, the air temperature reaches +130-140°C.

When the Buleryan stove operates in the kindling mode, the efficiency of the boiler is very low, which is not beneficial, therefore, when the desired temperature is reached, the stove must be switched to gasification mode (long-term burning mode).

- The stove gasification mode is the subsequent mode to which the stove can switch after the kindling mode (approximately 30 minutes from the moment of kindling).

After the first batch of firewood has burned, to switch to gasification mode, you need to completely load the firebox with a new batch of firewood, then close the door and close the dampers to limit air access into the firebox.

In this mode, the wood practically does not burn, but only smolders, which leads to a decrease in the outlet temperature to 55-60°C. In this mode, when the firebox is fully loaded with wood, the Buleryan stove can operate for 10-12 hours.

We can highlight the main functions and features of using Buleryan stoves:

- Warming up the room in a short period of time;

- Operation independent of communications (gas, electricity, water, etc.);

- Uniform heating of the room;

- Ease of use, operation on almost any solid fuel;

- Economical operation;

- Easy to maintain;

- High efficiency rate (80%);

- Ability to maintain a stable temperature for up to 12 hours from one load of fuel.

The miracle stove is very economical. Fuel is burned in it in two stages.

In the first chamber, the process of smoldering and the formation of furnace gases occurs, and in the second, these gases are burned to completion due to the supply of air to the secondary chamber. As a result, complete combustion (or so-called clean combustion) is achieved. The temperature of the flue gases, in this case, reaches 200 - 300 C, and the efficiency increases to 70 - 75%.

Thus, with a full volume, Buleryan can work for 8-12 hours, and sometimes more depending on the quality of the fuel.

In a day, it is enough to give him attention three times, and the rest of the time he works unattended. Since the combustion door closes very tightly, and the temperature of the furnace itself is low, Buleryan meets fire safety standards, which is confirmed by a test report.

In addition to heating housing, industrial and warehouse premises, it can also be used for drying wood and lumber, which, when used as fuel, waste from sawing wood leads to a very low cost of dried lumber.

If you have a built-in chimney, you can install Buleryan in an apartment with stove heating.

If you are satisfied with Buleryan's design, it will fit into your apartment, cottage or cottage in its original form. If not, you can design it as a fireplace.

Moreover, as noted, the efficiency of the best open fireplaces reaches 35%, and closed ones up to 80%. By the way, when designing country cottages, you can provide an air duct system for separate rooms on the 1st and 2nd floors.

Buleryan can also be used as backup heating. Its installation is quite simple. It is necessary to connect to the chimney or install a new one.

The use of Buleryan is especially important where there are no other energy sources (energy supply, central heating, gas) or heat is supplied inconsistently.

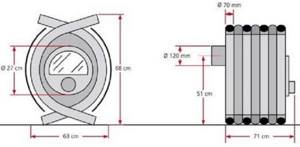

There are five types of units, differing in their power. Each of them is designed for a certain room volume: 100, 200, 400, 600, 1000 and 1200 cubic meters.

Solid fuel burns completely in Buleryan in two stages, each of which occurs in one of two combustion chambers.

This process begins with the traditional placement of wood, peat or other suitable combustible materials into the furnace firebox and lighting it. Placed in this way in the first chamber, the fuel begins to smolder and release a large amount of furnace gases.

Next, these gases enter the second chamber, where they are mixed with air entering the same chamber, after which the resulting mixture burns.

Thus, the process of complete or clean combustion of the fuel is realized, due to which a large amount of heat is released. At the same time, the temperature of the exhaust gases reaches 200-300°C, and the efficiency of Buleryan increases to the level of 70-75%, which is higher than the same coefficient of ordinary stoves and fireplaces.

The described principle of operation provides the Canadian stove with an important advantage - the ability to work on one full load for up to 8, and sometimes up to 12 hours, depending on the quality of the fuel burned.

Accordingly, it will have to be loaded 2-3 times a day, which is significantly less than when using a classic solid fuel boiler, the firebox of which must be filled every 4 hours. Accordingly, Buleryan using wood is much more convenient and economical.

Additional advantages of Canadian bullers are a fairly low body temperature and the presence of a sealed combustion door.

Thanks to this, these heat generators comply with fire safety standards, which is confirmed by relevant tests. In addition to private houses, dachas and cottages, Buleryan can also be installed in shops, greenhouses, production, repair and warehouse premises.

Such heaters are suitable for drying wood and lumber products. And the use of waste from the wood processing industry as fuel for buleryans can significantly reduce the cost of heating such production workshops and warehouses.

The presence of a built-in chimney makes it possible to install a buller stove even in apartments without centralized heating. For those who are not satisfied with the specific appearance of such a heat generator, there is a technology for turning it into a fireplace using a special finish. In this case, the efficiency of the resulting heater will be twice as high as that of a classic open fireplace.

It is also important that with the help of a wood-burning buller boiler you can heat several rooms at once, using flexible metal hoses placed on the outlet ends of the pipes and distributed in different rooms.

There are special models of Buleryans with a flat surface that can be used for cooking or heating water, which makes them especially convenient in everyday life.

How to properly drown Buleryan

The manufacturer recommends using linden or poplar firewood, peat briquettes, cardboard or shavings as fuel. The moisture content of firewood should not exceed 25%. Intense combustion is not a priority operating mode; it is only relevant for quick warming up. At the first stage, the air is heated to 120°C and the room is intensively heated. After the start of smoldering, the body of the structure cools down to 55°C, and air comes out of the batteries at a temperature of up to 70°C. You should not try to increase the combustion temperature with coal or coke; this will not only harm the metal, but will also reduce efficiency.

Heating with Buleryan should be carried out according to the instructions:

- We light the stove using flammable fuel: cardboard, paper, wood chips. The volume of the bookmark should be enough for 15-20 minutes. The fuel should turn into coals 2-3 minutes before the room is completely warmed up, this requires skill.

- When burning, you need to close the door, but the throttle and gate remain open.

- Firewood is laid on the coals until it stops. You can also put whole logs.

- We set the throttle to the desired position, and the gate must be closed all the way.

The heating system based on a steel, tightly welded Buleryan stove attracts summer residents , owners of private baths and garages with its high efficiency and speed of heating the room.

Visually, the stove looks like a horizontally mounted metal cylinder (furnace part) with a chimney and resembles a regular cast iron stove. At the top and bottom of the firebox there are several rows of pipes that help quickly warm up the room.

The unit works as a gas generator . The fuel burns in the lower chamber, releasing gas that enters the upper chamber, where it finally releases heat.

Thanks to the two-chamber design, the construction of additional tubular convectors on the stove, with the correct selection of fuel, the stove flares up well and the gas released quickly and for a long time provides heat to several rooms at once. You can find out more detailed information about the operating principle and design of the Buleryan stove from the following article.

Below we will look at the basic rules for using the Buleryan stove, the features of kindling and maintaining a fire, and also tell you how to light the stove and how best to do .

How does buleryan work?

The Canadian “answer to the potbelly stove” is a steel barrel with air ducts, which differs from a classic stove precisely in the presence of pipes. Their holes are located at the bottom and top of the structure. This convection heater is not as simple as a conventional device; it uses a pyrolysis type of combustion. The generated heat immediately enters the air ducts, which provides the furnace with an efficiency of at least 80-85%.

Buleryans are very different from the usual potbelly stoves. They come in two forms. Those intended for heating small areas are cylindrical in shape. High-power designs are produced in teardrop-shaped shapes. A classic buller consists of a certain number of elements, which are more than a traditional oven has.

- Primary combustion chamber. This is the largest part of the device: the main fuel chamber occupies up to 85% of the total volume of the structure. Primary ignition occurs in it, and pyrolysis products are generated.

- Secondary compartment designed for afterburning fuel. It “takes away” only 25% of the volume from the oven. Pyrolysis products enter the upper chamber: the residues burn in it, forming a flame that increases the temperature.

- Pipes made of metal. This is the “brand name” of the devices. They are recessed into the walls of a large chamber by 2/3 of the diameter. These elements play the role of air ducts: cold air enters the firebox through them from below, and heated masses exit from above.

- Injectors are narrow tubes connecting the primary compartment to the afterburning chamber.

- The chimney and ash pan are traditional elements that perform a familiar role in the stove.

- Throttle and damper. Their task is simple: it is to regulate the air supply.

This is not to say that such a design cannot be “repeated” on your own, since the structure of the Buleryan is quite simple. The disadvantage of the operation is a large number of different elements that must be connected as accurately as possible. This option can be considered if the price of purchased models seems somewhat overpriced, and the master has experience working with welding equipment.

Description of the furnace design

The firebox of the product is divided into three parts. Cast iron grates are installed at the top and bottom - special grates on which firewood and other fuel are placed, and ash spills down .

In this main part of the structure, fuel is ignited and burned . In a secondary chamber built on top, separated by a sheet of steel with holes, smoldering and post-burning of gases released during combustion in the main block occurs.

The firebox is closed with a door with a lock and a power regulator . A chimney consisting of prefabricated pipes begins with a horizontal part of at least one meter in length. It is brought outside through the wall or ceiling.

You can purchase a Buleryan stove with a water circuit combined with a circulation system, and use such an installation to organize a water heating system .

You may also be interested in an article on how to make a diesel drip stove with your own hands: //6sotok-dom.com/dom/otoplenie/pech-kapelnitsa-svoimi-rukami.html

At the turn of the chimney, a heat exchanger , which ensures the process of post-burning of the resulting gases. For efficient operation of the device, the pipes are well insulated with heat-insulating materials, which also helps reduce unpleasant consequences in the form of condensation .

Combustion adjustment is carried out using the main damper located at the bottom of the door and a gate valve - a valve with a metal plate located at the outlet of the firebox.

Features of operation

In order for the buller to work with maximum efficiency, it should be heated with completely dried firewood - the humidity should not exceed 10%. Raw wood can be dried directly on the stove.

Buleryan drowns himself like this:

- Having fully opened the ash flap and damper, well-dried flammable material is loaded into the firebox - small brushwood, wood chips, or even paper.

- Now you need to set fire to the bookmark and close the door. At this stage, the stove operates in combustion mode and intensively warms up the cooled room. Experienced users select the volume of the first bookmark so that it turns into coals just by the time a comfortable temperature is established. If the door is not transparent, you should monitor the combustion through the ash pan.

- After the first filling burns down to coals, the main fuel is placed on it - wooden logs, peat briquettes or pellets. The door is closed and the blower valve is turned to the position corresponding to the desired power. The gate must be completely closed. In this case, the furnace will go to the main mode: smoldering fuel with partial pyrolysis.

The temperature in the firebox is 550–650 degrees, the air coming from the heat exchangers will heat up to 60–70 degrees. The body will be at 50-55 degrees and the exhaust will be around 120 degrees.

Possible mistakes

Attempts to operate the Buleryan stove with increased power are extremely irrational - due to the low heat capacity and thermal conductivity of the air, most of the heat generated will go into the chimney.

A branded buller cannot be heated with coal - this fuel, when burned, gives a temperature of 800–900 degrees, from which the walls of the furnace quickly burn out. Constant operation of this unit in combustion mode with a flame for which it is not designed will lead to the same result. True, sometimes users still go for it, since with this operating mode, condensate is formed in a smaller volume and, most importantly, it is much less toxic.

As for homemade bullers, it all depends on the materials used. Thick walls made of heat-resistant steel will withstand any operating mode and any fuel. If the stove was made, as often happens, from scrap metal, that is, ordinary structural steel, then the rules for operating branded boilers apply to it as well.

Basic rules of use

To avoid unnecessary problems, you should carefully study the operating instructions for the Buleryan stove and follow its recommendations . So:

- For better air circulation a foundation with a height of 20 centimeters ;

- The distance from the outer surfaces of the chimney to the rafters and other roof elements must be at least 10 centimeters ;

- Before lighting, the power regulator is set to the fully open position;

- After intensive heating of the fuel during the first 15 minutes, it is necessary to close the regulator at least halfway;

- It is prohibited to light the stove with flammable liquids and operate it with an open firebox.

Fuel for Buleryan

The reliability and efficiency of depends on the correct :

- First of all, the raw materials for kindling must be well dried . Its humidity should be less than 20 percent ;

- Do not coal or chipboard waste into . Chipboard and its analogues, when burned, release that are harmful to health. Pine and other conifers, during the process of burning and smoldering, release a lot of resin into the air;

- It is best to use dry oak, poplar, aspen and birch pieces, wood or cardboard waste, and peat briquettes;

- Firewood made from ash or hazel is more difficult to melt , but it is less humid and easier to dry;

- Cedar logs are good for a long smoldering process ;

- Expensive beech , which has excellent calorific value, burns quickly and emits a pleasant aroma, is more suitable for bathhouse owners who use the unit only on weekends;

- Dried poplar and birch burns well and will allow you to sleep peacefully at night for six hours without monitoring and adjusting the operation of the stove;

- Alder burns beautifully, emits little smoke, has a pleasant smell, but is more expensive;

- Aspen also does not emit much soot and serves as a good fuel;

- The optimal heating option for Buleryan is charcoal .

How do experts overcome the disadvantages of the furnace?

Experienced users of the Buleryan stove advise :

- Construct a chimney from easily dismountable pipes and direct them against the movement of gas that occurs during combustion and smoldering in the firebox. In this case, the accumulating wood resins will flow down into the firebox and gradually smolder and burn out there, rather than pollute the floor around the stove;

- The stove should be installed at a distance of at least a meter from the wall. With a diameter of more than two meters, flooring on an asbestos cushion is constructed before installing the device

- A brick pipe or a ceramic chimney is better suited for the exit of burnt gases ;

- Once every three months of intensive operation of the device, the chimney is thoroughly cleaned .

The Buleryan stove is a heating device that requires observation and patience to maintain. If you have these qualities, you will be able to master this capricious “device” and it will serve you for a long time and properly.

Buleryan talks about the rules for firing a stove in the following video :

Buleryan is a long-burning stove, one load of firewood is enough for several hours, the fuel smolderes for a long time, which maintains the temperature in the room until the next load of firewood. It is important to learn how to properly heat a boiler. How and what is the best way to heat such a stove is explained in this article.

General instructions

Buleryan's kindling scheme:

- Open the chimney gasifier regulator.

- Open the blower damper.

- First, lay down wood chips or medium/large-sized firewood, add some crumpled paper/newspaper;

- Light the wood, check combustion and close the stove door;

- Check for traction after 15-20 minutes;

- Approximately every 5 minutes you need to close the damper a little, but you cannot close it completely;

- Do not move away from the stove while lighting;

- When the temperature decreases, you can add the next batch of firewood (use only large, dry firewood);

You can also watch detailed video instructions on kindling Buleryan:

After some time of use, you will gain the necessary experience and melting buleryan will become a simple task.

What kind of wood to burn?

Before using the stove, you should figure out how to properly heat Buleryan with wood, because not everyone is suitable for this purpose. Any hardwood firewood is suitable for heating.

It is not recommended to use coniferous varieties ; they quickly clog the chimney. If you heat the stove with apple, pear, cherry, etc., little heat will be released.

Can I use other fuel?

- Coal. Buleryan stoves come with special operating and fire safety instructions. If you follow these instructions exactly, it is prohibited to heat the stove with coal alone; a large amount of heat from burning coal can melt the metal. You can use brown coal, but only together with firewood. Many sources on the Internet describe many ways to heat Buleryan with coal, but you should not rely on them, these methods may not be safe.

- Workout. According to the instructions, the waste cannot be used as fuel. Its use will lead to burnout of the pipes and failure of the furnace.

- Briquettes. Peat briquettes are an ideal type of fuel; they have good heat transfer and do not impair the performance of the stove. Briquettes are difficult to purchase in a store; they are usually ordered on the Internet, but suppliers mainly sell only in large quantities, which is inconvenient for personal use.

- Sawdust, wood chips and tree bark. Kindling with sawdust, wood chips and tree bark is not prohibited - this is a good way to save money, allowing you to reduce the use of good firewood. In order to use this type of fuel, you must first light the stove with wood, and then add wood waste.

- Pellets. The method of melting with pellets is similar to that used when melting with sawdust, wood chips and bark. Since pellets are made from wood, they are also suitable for buleryan, but before that a special mesh is installed.

How to properly stack firewood?

First of all, wood chips are laid for kindling. You can set fire using different ignition means. Afterwards the firewood is stacked. The furnace operates in normal mode or in gas generation mode. Continuous operation in normal mode reduces the service life of the boiler. It is important not to use wet firewood, as this will damage the chimney over time.

For a longer service life of the stove, it is necessary to periodically clean it; to do this, it is enough to burn special briquettes if the chimney begins to clog.

How to reduce consumption?

- Use dry firewood.

- Clean the chimney regularly.

- Heat the stove with wood from acacia, oak and aspen - they are the hardest.

- Insulate the chimney.

Optimal temperature

Before purchasing a Buleryan stove, you need to decide on its size. This affects how much area the boiler can heat. The period between laying firewood is long - 8-12 hours. To always maintain a comfortable temperature, it is enough to periodically add firewood.

The optimal temperature depends on the size, power of the stove and the volume of the firebox. The principle of operation is similar to a conventional potbelly stove, but the efficiency is higher, so the bullerian will quickly warm up a large room.

General fire safety rules

- Do not add too much firewood.

- During heating, do not move away from the stove, constantly check for draft.

- Do not use only coal as fuel, this may cause the metal to melt and spread the fire.

- Watch the stove closely while it is burning.

- Clean your chimney regularly.

- Please read the instructions carefully before use.

Conclusion

The Buleryan stove is very convenient and useful if you use it correctly. It does not accumulate heat near itself, but distributes it throughout the room. Such boilers can be used in a home, garage, industrial premises or greenhouse. All the tips presented in the article are most useful for people who use the stove all winter.

When choosing a stove, pay attention to the fact that Buleryan has a number of useful advantages - easy installation, cost-effectiveness, long service life, good heating (it is easy to maintain a comfortable temperature). To heat several rooms at once, it is necessary to lay additional pipes. But don’t forget that the Buleryan stove does not run on coal, only on wood fuel.

Combustion depends on many factors - outside temperature, fuel quality, wood moisture content, chimney height, so there cannot be exact instructions for heating. The main thing is to follow the instructions exactly so as not to harm people in the room and not damage the boiler.

Useful operating tips can be found in user reviews, but do not trust them 100% if they are completely at odds with fire safety rules and do not comply with the instructions.

Common Operation Problems

The main problem when operating a buleryan is the release of flammable gases, which cannot burn due to the moisture of the wood and are released in the form of condensate. To solve all operational problems, it is enough to use exclusively dry firewood, otherwise the released gases will settle on the surface of the pipes and form growths, leading to blockages.

Why does Buleryan smoke?

Buleryan may smoke due to the fact that there is no draft or the stove has not been serviced for a long time, i.e. the chimney was not cleaned; similar situations occur if the stove was still heated with wet wood. These problems can be eliminated by mechanically cleaning the pipes with a special metal rod or by cleaning with special chemical briquettes. After cleaning the chimney and if there is draft, smoke will not come out.

It can also smoke due to the fact that the damper is completely closed, i.e. there is simply nowhere for the smoke to escape. As stated in the instructions for heating the stove, the damper should not be closed, only slightly closed.

Can't melt it

At the beginning of operation, using Buleryan is a pleasure - it does not take up much space, warms the room well, and saves firewood. But, if over time the stove becomes more and more difficult to light, this means that the chimney may be clogged and needs to be cleaned. There are two ways to clean the stove: mechanical (use a special metal rod to break through the build-up that has formed in the chimney), chemical (heat the stove with special brackets, which remove the blockage during combustion).

When installing a stove, proper installation of external chimney pipes is necessary. If the pipes are installed incorrectly - there are hills nearby (trees or buildings), or the pipe does not rise enough above the roof of the house and the ridge, the smoke will not be able to escape through them, but will go into the room. It is impossible to light the stove under such conditions. Check that the chimney pipes are installed correctly.

Other problems

According to user reviews, the main problems with Buleryan stoves are the emission of smoke into the room and the release of carbon monoxide, which is harmful to health. Other problems may arise due to improper operation, use of wet firewood, or failure of the stove. As stated above, you cannot use coal as fuel to avoid burning the walls of the boiler.

At the beginning of use, smoke will be emitted from the paint, but after a few fires this problem will disappear by itself. In addition, external pipes have to be insulated for better heat transfer.

The Buleryan stove is very convenient and useful if you use it correctly. It does not accumulate heat near itself, but distributes it throughout the room. Such boilers can be used in a home, garage, industrial premises or greenhouse. All the tips presented in the article are most useful for people who use the stove all winter.

When choosing a stove, pay attention to the fact that Buleryan has a number of useful advantages - easy installation, cost-effectiveness, long service life, good heating (it is easy to maintain a comfortable temperature). To heat several rooms at once, it is necessary to lay additional pipes. But don’t forget that the Buleryan stove does not run on coal, only on wood fuel.

Combustion depends on many factors - outside temperature, fuel quality, wood moisture content, chimney height, so there cannot be exact instructions for heating. The main thing is to follow the instructions exactly so as not to harm people in the room and not damage the boiler.

Useful operating tips can be found in user reviews, but do not trust them 100% if they are completely at odds with fire safety rules and do not comply with the instructions.

Author: Igor Vernikov, published 07/03/2012

More articles from the section All about stoves

Everyone is familiar with Buleryan long-burning heating stoves. Having read so many positive reviews about them, I would like to add a little “from myself.” In addition, the heating theme is especially appropriate for the winter season.

The peculiarities of the Brenerans’ work are known to many. Having supported their knowledge about the furnace with positive reviews, our compatriots are happy to purchase this result of engineering. Expecting too much from him.

Operating principle of the device

The new heating device can be used for industrial premises or shops, for heating residential buildings, houses still under construction, cottages, greenhouses, garages or workshops. Another potential area of application for buleryan is drying lumber. This option for using units allows you to achieve a reduction in production costs thanks to waste-free production (sawdust goes into the firebox).

How does buleryan work?

The peculiarity of the buleryan is the maximum possible heat transfer, and this result is achieved thanks to the operating principle, which differs from the functioning of a classic potbelly stove.

- First, the required volume of firewood is loaded into the firebox. After ignition, the flow of fresh air into the chamber is limited using a special mixture or paper.

- If there is a lack of oxygen, the firewood does not burn instantly, but slowly smolders, producing flammable gas that enters the upper compartment.

- In the second chamber, the pyrolysis product is “refined”—the gas is ignited due to the secondary air flow.

- The heat generated during the process of smoldering and residual combustion of fuel enters the room.

The efficiency of a well-made buleryan can reach 90%. If the unit's power is correctly calculated, the owners will only have to add fuel a few times a day (2-3). The uniqueness of the Canadian device is that it can work as a replacement for several devices. Buleryan can perform the functions of a conventional furnace, gas generator or air heater.

Device operating modes

Such devices belong to a separate category - “long-burning stoves”. Heating devices can operate in two modes - kindling and gasification.

Kindling mode

In this case, the main task is to heat the device to the required temperature. Thanks to intense convection (movement of heated/cooled air), the room warms up very quickly. After filling the firebox with fuel, its door is closed and the damper is fully opened, ensuring air flow.

The temperature in the combustion chamber rises to 700-800°, warming up the built-in air ducts. At the outlet, the temperature of the air masses reaches 130-140°. This mode has a drawback: it is not high enough efficiency. Therefore, immediately after kindling, the buleryan is transferred to a long-term burning mode.

Gasification mode

The transfer to this type of work usually occurs half an hour after lighting the stove. After the first batch of fuel burns, firewood is loaded into the chamber again, but now as densely as possible: small elements are placed between large logs. The door is then “sealed” and the air flow is restricted while the damper is closed.

In this mode, fuel combustion almost completely stops: it begins to slowly smolder, releasing gases that are sent to the second chamber. In it they mix with the incoming air and ignite. The temperature in this compartment is low: it is 200-300°, at the exit from it the value drops to 55-60°.

With a full, dense load of the compartment, the Buleryan is able to work for 10-12 hours without a new portion of “food”. The time depends only on the type of fuel - on the type of wood: the harder it is, the less often refilling is required.

Furnaces with water circuit

Not so long ago, buleryans could only be used as local heating devices. One device was capable of heating only one room. To fill the gap, devices with a water circuit were invented. They are called aquabullers. When making your own, you can use two solutions:

- “repurpose” all the Buleryan pipes, completely remake the stove for water heating: there are eight air ducts in the classic version;

- prefer combined equipment: make only part of the pipes a water circuit, and leave the rest “as is”.

Another alternative is to add an additional circuit, so there is no shortage of solutions. It is logical to use such units if:

- the building has several rooms or floors that cannot be heated with one or two devices;

- the house does not have access to a centralized heating system;

- the cost of heating is high, but the price of fuel is acceptable;

- problems often arise with central heating;

- the house is not intended for permanent residence.

The use of such combined devices is permitted, but this option remains not very popular. An exception is equipment operating in summer cottages.

Combustion theory and disadvantages of the Buleryan firebox

If you understand the operation of heating stoves with long-term heat release, the so-called Buleryans (Brenerans). These are simply ordinary, unremarkable potbelly stoves with increased efficiency due to the large heat transfer area. Firewood in Buleryan does not burn, but rather rots, and this process has a lot of disadvantages - more on that later.

At the moment the device is ignited, the wood flares up, warming itself up, it heats the chimney pipe, thereby, as it were, “turning on” the draft in the stove. When wood burns, volatile gases immediately begin to be released. It is these gases that ensure a constant combustion temperature of the firewood in the firebox.

With further combustion, heavy fractions of flammable gases are released. In a good way, these gases should burn in the afterburner. But in practice, due to the humidity of the firewood, there are too many of these gases and they cannot burn, because there is simply no air, and without it there is no combustion. You need to buy dry firewood - this is the first disadvantage.

Many believe that the problem is solved with the help of afterburning tubes, but designers design the furnace so that it saves fuel and does not burn the stacked stack in minutes. This means the tubes are ineffective.

If you do not use dry firewood, then the second disadvantage follows from the first. Rising up the chimney, oily gas fractions adhere to the surface of the pipe. In the cavity of the pipe, drops of condensate flow down and form peculiar growths of tree resin. Which, without burning, freeze and “block” the path of rising exhaust gases until they completely block the chimney. This means the second disadvantage is that the oven often gets clogged.

What not to drown

Those people who have not previously dealt with a Buleryan stove often have questions about other types of fuel.

For example, can you burn with coal or waste oil? Unfortunately, the answer is no. As for coal, the problem lies in its excessive heat transfer. The metal from which the Buleryan stove is made will simply burn out under such a powerful influence. This is especially true for coal, since it is the most efficient fuel.

However, if you take brown coal and add it to firewood, you can get the desired effect without fear of somehow damaging the device. Some craftsmen also manage to remake the device itself by adding grates that protect the metal from burning. But keep in mind: if you perform this operation on a new stove, the manufacturer’s warranty on it will automatically end once changes are made to the design.

Using waste oil as a fuel can lead to the same unfortunate consequences as with coal. In general, for the efficient operation of the Buleryan stove, an ash bed is required. If the oil is ignited, there will be no oil, so the lower pipes of the device will burn through.

We fight the problems of Buleryan stoves

During the first time of use, any smoker is a pleasure. Small sizes. Heats up the room quickly. Convenient door for storing fuel. There is enough firewood for a long time.

But, over time, the stove begins to melt worse and worse, the draft disappears, and the shutter refuses to close. So it's time for the first cleaning.

The first thing that comes to mind is to heat the stove with aspen wood. But their effect is weak. If the stove is clogged, this will no longer help.

Next, it comes to mind to burn the stove with the ash drawer completely open. The pipes must be heated to very high temperatures, literally red hot, for the resin to burn. One of my friends slipped a hose from an oxygen cylinder into the ash pan, and the stove heated up almost to red. But this is a huge risk. Although there was a result.

Unfortunately, there's not much you can do about the smoker. But you can get along with capricious heaters.

Practical advice - how to use Buleryan

Guided by experience in use and, moreover, production, I would like to give some recommendations:

- Assemble chimney pipes against the flow of gases, and not along the flow, as the manufacturer advises. This will help keep your flooring safe from the wood resins leaking from every hole in the stove. Then they can return back to the chimney and burn.

- Follow fire safety rules and do not neglect them when organizing a room near the stove.

- Follow the instructions and ensure easy disassembly and assembly of the pipe for easy access when cleaning soot and resins.

- Customize the work of your Buleryan to suit you. Determine the acceptable combustion temperature. Periodically inspect the top of the pipe for resin build-up.

- Select the heating mode that suits you. The longest burning time multiplied by the minimum degree of chimney blockage. The optimal ratio is achieved if you clean the oven twice a season.

- Dry the wood over the stove before putting it inside.

In addition to logs, use briquettes made from wood chips and sawdust as fuel. They will make the stove a little easier to use. They will make the firebox cheaper.

Finally…

The article was written for people who heat Buleryan around the clock in winter. The article will not be useful for weekend summer residents. All my observations and advice are personal opinions and do not claim to be official instructions on how to drown Buleryanchik.

Engineers are constantly introducing something new into heaters. Devices that distribute flammable gases evenly throughout the furnace. The Brenerans also have individual precise adjustment of the wood burning mode.

If there are any innovations in your favorite, be sure to write your comment under the article, I think it will be very useful.

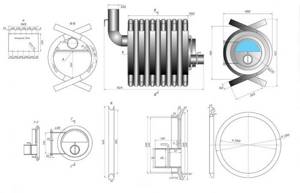

How to make buleryan?

If, after getting acquainted with how the Buleryan works, the owners concluded that it is better to try the design in action, then the most logical solution would be to assemble it yourself. However, to work, the master will need welding equipment and skills to work with it.

Since the Canadian design can hardly be called elementary, a drawing of the furnace will be required. If desired, the finished project can be found on the Internet: if previously the device diagram was kept secret, now all the secrets have already been revealed.

Materials, tools

Basic materials for making a buller:

- sheet metal: its thickness is 5-6 mm;

- the same pipes: wall thickness - 5-6 mm, outer diameter - 50-60 mm.

For high-quality cutting of parts, you will need to use patterns. To give the elements a curved shape, you need to purchase or find a hydraulic (electric) pipe bender. To check the location of elements relative to each other, it is recommended to use a building level. But this is not the whole list; it includes:

- ruler, marker;

- tape measure, square;

- pipe cutter;

- clamps;

- grinder (circular saw);

- asbestos cord;

- Grinder; hinges, eccentric latch.

A beam, the cross-section of which is equal to the outer diameter of the pipes, is useful for fixing structural elements during assembly.

Making buleryan

They begin work by preparing materials: cutting pipes and cutting sheet metal parts. After this, they move on to creating the furnace, collecting and welding all the elements in order.

Creating a Corpus

When working, focus on the drawing.

- After cutting the pipes (the minimum number is 8 pieces, the optimal length of each is 120 mm), they proceed to bending them. The radius should be 225 mm. Then blanks for the back and front walls, doors, strips for the body, as well as regulators, narrow strips for sides, etc. are cut out of the metal.

- The remains of the metal sheet are used to create small parts for the door, ash pan, etc. At the same stage, blanks are made for the upper compartment: the partition is made V-shaped. The metal strips for the body are made slightly wider than the outer diameter of the pipes. Oval cuts are made at the ends of the elements, which will simplify welding to the air ducts.

- The finished pipes are laid on a flat surface in a checkerboard pattern, using bars for secure fixation. The lower element will become part of the back of the stove, the upper - the front. Then these elements are welded, after which a V-shaped tray is attached between them, inside, separating the primary chamber from the secondary one.

- In one of the pipes located at the top of the front side, a hole is cut for the injector, which is designed to supply air to the upper combustion chamber. A narrow injector tube is welded to it. Strips of metal are welded to the body, which for now consists only of pipes.

The inlet and inlet pipes can be made in two ways. The first is to cut pieces from a pipe with a larger diameter than were used in the design. The second is cutting out strips of metal and bending them into a ring.

Making the front wall

This operation is a rather complex stage that will take a lot of time.

- First of all, a hole for the door is made in the blank intended for the front wall. It should be quite large for ease of loading fuel. A low side made of a strip of metal is welded to the edge of the hole.

- A hole is also cut out in the door part: it is intended for the blower. Then a pipe is welded to it. It will contain a damper that will be used to regulate the air supply to the primary compartment. A side is welded to the edge of the door.

- A second one is welded at a short distance from it. The side-collar of the wall should fit into the free space between the elements (“like a glove”). It is recommended to lay asbestos cord there. Its task is to guarantee the tightness of the structure.

- Then they make a damper: a round part is cut out of a metal sheet, which corresponds to the internal diameter of the pipe. Then axial holes are drilled in it. A pin is threaded through them, then it is welded to the damper.

Since the front wall with a door with a rotary flap is a rather complex element, it is recommended to order it. The final “stage steps” are adding a cam latch and hinges to the door on opposite sides. Hinges and a pin for the latch are welded to the body.