Heating boilers using waste oil - operating principle, do-it-yourself installation diagram

There is a huge variety of heating equipment on the domestic market. Here, buyers are offered heating units operating on different types of fuel, including heating boilers using waste oil. You can see what they look like in the photo. Their main purpose is to heat not only residential premises, but also small offices and industrial premises.

Depending on the tasks that need to be solved with their help, waste oil heating boilers operate on the basis of various technologies and using different types of fuel:

- Waste oil heating boilers operate on waste generated as a result of transportation and are an ideal solution when it comes to heating a car service station. In addition, the waste oil heating system also operates on diesel fuel;

- thermal energy sources using natural gas are in stable demand;

- electric heat units.

Gas and electric appliances have long been used for domestic purposes, but oil heating at home is rare.

Where to apply and how to modify?

Due to a significant list of disadvantages, waste oil heaters are rarely used in housing. Their use is possible only in utility rooms and in the case of trouble-free supply and exhaust ventilation. But they are widely used for heating technical and production areas.

Motorists use them as heaters for garages, and only if they have a good exhaust hood. Gardeners install them in greenhouses, livestock farmers install them in outbuildings. There is always a place for them at car washes, service stations, and warehouses where there are no flammable materials.

Often basic designs are subject to various kinds of modifications. For example, a water jacket or water heating coils are used for these purposes. Such equipment is included in water heating. Furnaces of this type must operate using automation, otherwise their functioning will have to be closely monitored.

Waste oil heating boilers

Used oil is distinguished depending on its purpose and use.

- hydraulic;

- transformer;

- transmission;

- of plant origin.

According to calculations carried out at one time by specialists, the economic effect obtained from the use of this type of waste for heat supply needs is considerable.

When buying a heating boiler using waste oil, you should definitely inquire about the quality certificate for the product. It also doesn’t hurt to purchase another (spare) burner, as it often becomes unusable. In case of breakdown in the cold season, it will not be superfluous.

Frequent misconceptions about waste oil boilers

There are a number of misconceptions regarding equipment operating in mining:

- There is an opinion that used oil is unsuitable for use and should be disposed of, which is absolutely false.

- Work is hard to find. But in reality, oil is drained during repairs of railway and road transport, in woodworking, clothing and other industries. There is a lot of it in public catering establishments - restaurants, cafes and fast foods.

- You can also hear that a homemade waste oil boiler emits harmful substances in large quantities during operation. But modern heating units produce emissions, but their amount is several times less than that of cars.

- Steam heating using waste oil can be considered as one of the possible heating options for detached service stations or garages. Such premises are not considered residential. This is also a misconception.

Waste oil heating for a private home

Waste heating oil was initially used together with diesel fuel. This method has proven its effectiveness and cost-effectiveness. Then they decided to reduce the cost of the product even more and removed diesel fuel from the composition. Used oil resembles diesel fuel in its characteristics , but is much cheaper.

Photo 1. This is what used oil looks like, which is used for heating. The liquid is dark brown in color.

Features of use

The waste is used as fuel in a special boiler or furnace. Only this guarantees complete combustion of the product without the formation of fumes. Re-equipment of the heating system or installation of a new circuit pays for itself in the first year of use of the product.

Types of fuel. How much heat is produced by burning one liter?

Burning one liter of such fuel produces 10-11 kW of heat per 60 minutes. The pre-treated product has more power. Its combustion produces 25% more heat.

Types of used oils:

- motor oils and lubricants used in various types of transport;

- industrial products.

Advantages and disadvantages

Pros of fuel:

- Economic benefit. Consumers save money on fuel, but businesses benefit the most. The implementation of processing eliminates the costs of storage, transportation and disposal of the product.

- Conservation of energy resources . Refusal to use gas and electricity for heating prevents the depletion of sources.

- Environment protection . Due to the high cost of disposal, business and vehicle owners disposed of oil by dumping it into waterways or into the ground. This had a negative impact on the environment. With the beginning of the use of waste as fuel, such manipulations stopped.

Disadvantages of fuel:

- poses a health hazard if the product does not burn completely;

- large dimensions of the chimney - 5 m in length;

- difficulty of ignition;

- the plasma bowl and chimney quickly become clogged;

- The operation of the boiler leads to the combustion of oxygen and evaporation of moisture from the air.

How is oil processed?

Processing is obtained by burning any type of oil, but for heating the premises, oil refining products from internal combustion engines .

Also from industrial mechanisms, compressors and power equipment.

What does not apply to such fuel?

List of products not related to waste:

- processed oils of vegetable and animal origin, which are used for household needs;

- solid waste with processing;

- solvents;

- products that are not subject to the same processing as waste;

- natural petroleum fuel from the spill;

- other unused petroleum products.

Advantages and disadvantages

Among the advantages of heating with waste oil, the following points can be noted:

- Fairly low cost of equipment. In addition, you can even make the equipment yourself.

- Availability of fuel. Sometimes used oil can even be obtained for free. And for those industries where there is a lot of such oil, this is an ideal solution.

- Efficiency and functionality of devices.

Let us note one drawback: some systems are demanding on the quality of the oil used.

How to choose a heating device?

The choice of device for the heating system depends on the area and shape of the room.

Fireproof furnaces for mining, device with water circuit

It is recommended to install such a stove in a one-story building without walls or other partitions . The unit guarantees fast and economical heating of the building.

The device operates on the principle of supplying the product in drops onto a hot bowl or plate of the combustion chamber. So the product ignites and heat is transferred to the walls of the firebox, and from them the air is heated.

An exhaust furnace rarely fails. The device is easy to make with your own hands. The unit is small in size, so it does not take up much space in the room and is easy to transport. The oven is suitable for heating food on top of the device.

It is allowed to combine the return furnace with water heating. For such a circuit, a metal tank is placed at the source. The return flow is diverted at the bottom of the tank, and the supply from the structure is connected at the top.

Instead of working off, it is prohibited to use any kind of flammable substances. Such elements should also not be kept near a heat source during its operation.

Attention! Do not allow oil to come into contact with water, otherwise a fire will occur. If a fire occurs, do not use water to extinguish it. The flame can only be knocked down with a fire extinguisher , which is installed near the stove.

During operation of the source, the ventilation system must not be closed. This will cause carbon monoxide poisoning.

How to weld a simple stove

Then the heat is released in greater quantities into the room, rather than being “thrown out” to the street.

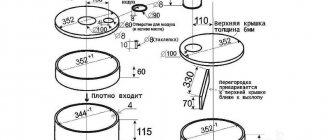

Another upgrade is to make an iron drawer. Oil is poured into it. With this design, the stove is easier to maintain. The drawing contains all the necessary dimensions. Before assembling a homemade oil stove, it is necessary to select the correct diameter of the firebox and body. Here everything depends on the volume of the room that needs to be heated. If it is a garage of 3 by 6 meters, take a profile of 80x80x4 mm. The fuel box is made of metal 60x60x4. It is more difficult to work with round rolled metal.

The step-by-step instructions look like this:

- Cut the metal according to the drawings to make a casing, drawer, afterburner. If the latter has a bend, the tube is cut at an angle of 45 degrees.

- For a profile of a smaller standard size, one wall is cut out with a grinder. Plugs are welded to the sides. The result is an open container to which you need to attach a handle.

- The structure is welded. It is necessary to drill an air hole at the top of the fuel chamber. The pipe is perforated. At this point the work is completed.

It should be taken into account that you need to calculate the number and diameter of holes in the afterburner. If you use a profile of 80 by 80 mm, then the cross-sectional area will be equal to 6400 square millimeters. This value is divided in two

Pay attention to the markings of the drill used. If it is 8 mm, then the hole area will be 50 sq. mm

Now 3200 must be divided by 50. The result is that 64 holes will be required to work effectively. However, as a result of customization, their number can be increased.

It is important that the chimney is of sufficient length. The elevation of the chimney outlet must be at least 5 meters

Then the operation of the stove during testing will ensure the highest possible efficiency even without supercharging. Otherwise, the pipe will have to be extended to this mark. But you can further increase productivity if you organize an inclined chimney running along the wall. The heated metal will release heat into the room. Only in this case is it important to follow fire safety rules. There should be no wooden shelves above the pipe, and no wallpaper on the walls. Even better is to cover the wall with a metal sheet.

Making a drip heater

Professionals who have assembled more than one “dripper” use old propane cylinders with a diameter of 200 mm. Oxygen ones are also suitable, since their cross section is 220 mm. the latter benefit due to thick walls. They serve for a long time, do not burn out, and accumulate heat. Pipe C-10 is also suitable if it has a wall thickness of 5 mm. An excellent option for a durable housing is pipes made of heat-resistant stainless steel alloys, alloyed chromium, molybdenum or nickel (for example, 15X1MF or 12X18H12T) with a wall no more than 3 mm. However, it is not advisable to specifically purchase this raw material due to its high cost.

Technologically, the manufacturing process is as follows:

- A flame bowl is made using a piece of pipe or ready-made steel containers. This one is pulled out through a rubber hatch, so it is not made too big.

- The openings necessary for connecting the chimney pipe and the cleaning service hatch are cut out in the body. The latter is framed and closed with a door. Bolts can be used for fastening.

- An afterburner is being made. All holes are not made at once. Usually the bottom 2-3 rows are drilled, and the rest are drilled during the setup process. If you do everything at once and there are too many of them, you will have to make a new one.

- Weld the cover with the air duct and flange. The latter is necessary for installing the fan. The fuel supply device is connected. Photo and video instructions will help here.

Now assemble all the components and connect the electrical wiring. The structure will be more stable if you make a metal frame. A heavy metal profile is suitable for this.

Features of arranging heating using waste oil using stoves and boilers

Any prudent owner strives to reduce the costs spent on organizing heating of residential and utility rooms. It is possible to achieve this goal by arranging heating using waste oil with your own hands by installing special furnaces and boilers. This space heating option is only beneficial if you have access to free waste oil. This raw material accumulates at service stations, repair shops that restore the functionality of oil-containing devices, and other enterprises faced with the problem of disposing of waste of this kind.

Construction of a homemade stove during development

This video presents the design of a furnace that can operate on mining, wood, and sawdust.

A furnace operating on waste oil consists of two containers connected to each other by a pipe. The design also includes a chimney through which combustion products are discharged into the atmosphere. For the manufacture of containers, metal is taken, the thickness of the sheets is 4 mm. The top cover of the second container is cut out of a 6 mm steel sheet. This is done in order to prevent its rapid burning, thereby increasing the service life of the entire heating structure.

Rating of the best coolants for heating systems

| Nomination | place | Name of product | rating |

| Rating of the best coolants | 1 | DIXIS-65 | 4.9 |

| 2 | Warm House Eco | 4.8 | |

| 3 | THERMAGENT-65 | 4.8 | |

| 4 | RODA | 4.7 | |

| 5 | AMT-300 | 4.7 | |

| 6 | Hot Stream | 4.7 | |

| 7 | Teplokom | 4.6 | |

| 8 | WARME BASIC-65 | 4.5 | |

| 9 | Thermagent Eco 30 | 4.5 | |

| 10 | FTX-30 | 4.5 | |

| 11 | PRIMOCLIMA ANTIFROST | 4.4 |