Which boiler elements depend on electricity?

Power outages to houses not only in the outback, but also in cities occur quite often.

They happen due to emergencies, planned repairs and technical work, and breakdowns on the line. And the most unpleasant thing is that when the electricity is turned off, the operation of the gas boiler is paralyzed if it is of the volatile type. The non-volatile gas boiler continues to function as usual, even if there is a power outage on the power line. The only exception is if a pump works in conjunction with it, and a gravitational coolant circulation system is not provided.

Non-volatile boilers have the simplest, basic set of functions. They are less comfortable to use than their energy-dependent counterparts. But their operation is absolutely independent of energy supplies to the home electrical network, and they are less likely to fail

In a heating circuit with a boiler of the simplest type, the set of basic elements is something like this:

- smoke removal system with natural draft;

- heat exchanger;

- gas burner with nozzles for supplying gas, which is located in the combustion chamber;

- gas supply and ignition unit;

- expansion tank;

- mechanical temperature sensor;

- control module, which includes a boiler ignition system (mechanical or piezo), temperature control;

- safety group (safety valve, pressure gauge, air vent).

Volatile devices are more complex in design. But is electricity really necessary and important for the operation of a gas boiler?

Depending on the model and brand, in addition to the same basic set of elements, in some cases electronic and automatic, they may provide such functions as:

- forced ventilation system;

- built-in circulation pump;

- electronic system control module;

- shut-off and control valves with electric drive;

- various sensors - water flow, temperature, flame supply, water pressure in systems, manostat, emergency complexes;

- piezo ignition unit with electric drive;

- automatic temperature regulators;

- notification and remote control system;

- display showing the current performance indicators of the device

Units of this type are more reliable and much more convenient to use, and in addition, they are economical. You can set the automation to turn on and off, reducing fuel consumption, create a comfortable microclimate at home, and not worry about safety and performance.

Modern boilers are crammed with electronics. When choosing a device, also install a voltage stabilizer to protect against surges in the network

The only negative is that after a power outage, the volatile gas boiler will not be able to fully operate. It is difficult to say which functions will be completely absent; it depends on the boiler model. Some units have a combined control system - mechanical and electronic.

It is certain that forced ventilation, automatic adjustment of the flame supply to the burner, pump, display, electronic control module, in general, all devices operating on an electric drive and a constant current supply will not function.

But is everything so scary?

Solid fuel boilers

Without a doubt, these units (as well as fireplaces with a water circuit) can be called the least protected from troubles associated with a power outage. True, as practice shows, it is precisely this type of equipment that is most often used in open or gravitational, that is, completely energy-independent heating systems. However, this heating method has not become widespread due to a number of serious disadvantages, among which are the large diameter of the pipes and the complete inability to supply heat to rooms located below the boiler room. Well, when using circulation pumps, a power outage for a solid fuel unit is like death. If, as can be seen from the above, devices of any other type can be stopped quickly enough to prevent overheating of the liquid in the heat exchanger, then wood or pellet analogues do not allow anything like this to be done. Even by closing the corresponding damper and stopping (or rather, limiting) the air supply to the firebox, it will not be possible to quickly extinguish the fire, and basic common sense dictates that it is impossible to douse the flame with water. As a result, the owner of the unit will have to at least replace the heat exchanger, and experts say that it is almost impossible to prevent such an outcome.

The conclusion from all that has been said suggests itself: while there is no centralized power supply, it is necessary to provide for the possibility of autonomous power supply for the elements of the heating system, organized on the basis of a gasoline or diesel generator or an uninterruptible power supply (UPS).

Electric boilers.

Everything here is quite obvious: the unit turns off simultaneously with all auxiliary devices. No problems arise in this case, which distinguishes this type of heat generator from other analogues from the point of view of safety during operation.

Liquid fuel boilers.

Theoretically, they also do not pose any threat, even taking into account the disabling of all automation. The fuel pump will stop functioning, which will stop the supply of diesel fuel (fuel oil, waste oil, etc.) to the burner, which will quickly exhaust the remaining fuel and go out. In practice, this inertia of the device can lead to overheating of the liquid in the heat exchanger and cause its damage, albeit minor, but which will affect the efficiency of the boiler in the future.

Gas boilers.

The main difficulty that awaits such equipment during a power outage is that the supply of natural gas to the burner is an energy-independent process. That is, the control and safety automation becomes completely incapacitated, and the fuel continues to flow and burn in the corresponding boiler chamber; after such words, some people have a desire to buy a non-volatile boiler .

What could this lead to? Let us remind you that the circulation pump, as well as the flow sensors, water temperature and flame presence, do not work. The liquid inside the heat exchanger quickly heats up and is brought to a boil, while literally tearing the tubes of the device, entering the combustion chamber under pressure. If an atmospheric burner is installed here, then it will most likely be flooded, that is, the flame will go out, the de-energized controller will not be able to issue a command to re-ignite, and in the meantime, the gas supplied to the burner will freely penetrate into the room where the boiler is installed.

A somewhat less catastrophic situation will arise in the case of a supercharged (fan) model. Without the air flow necessary to prepare the gas-air mixture and provided by electric fans, the fire will quickly die out (however, it will probably have time to damage the heat exchanger). However, a closed combustion chamber will not allow uncontrolled gas to leak into the boiler room: it will be discharged through the chimney to the street, which, however, can also have the most negative consequences.

To avoid them, the security automation includes only one device, which is perhaps the most important element of this system. We are talking about a gas cutoff

, also called a shut-off valve. If the slightest malfunction occurs (including a power outage), this device instantly cuts off the fuel supply to the burner. The design is truly elementary: the shut-off valve, which is normally closed, consists of an inductive coil with a core on which the valve cover is fixed. The magnetic field generated in the coil by the applied voltage causes the core to move upward, lifting and holding the valve cover in the “open” position. As soon as the voltage disappears, for any reason, be it a command from the controller or a general power outage, the core, under the action of the return spring and the valve cover’s own weight, falls down, pressing it to the saddle and cutting off the gas supply to the burner.

The device does not require maintenance and must be replaced only upon failure, however, during each maintenance (MOT) of the system, the shut-off device must be checked for the speed of operation and the tightness of the valve cover to the saddle. Simply put, it turns out how quickly and effectively the device in question can shut off the fuel supply.

UPS for a gas boiler and its power consumption

If there is a loss of electricity in the network, the gas unit will switch to emergency operation, which threatens the breakdown of expensive components. And a UPS (uninterruptible power supply) will come to the rescue in such situations.

How long a gas boiler can operate in the absence of electricity depends on the capacity of the battery pack. Choose either a UPS with a built-in battery, or a UPS with the ability to connect the required number of battery sections to it

The “line-interactive” type is the most popular UPS, according to numerous customer reviews. They contain a voltage stabilizer, which is able to respond to voltage drops in the network within 10%; if this value is exceeded, a switch to power from the battery follows.

The “off-line” type is an uninterruptible power supply without a voltage stabilizer. They help out in case of a sudden power outage, but do not protect against mains voltage fluctuations.

“On-line” type - the most advanced UPS. They smoothly switch from mains power to battery power and vice versa. The only drawback is that not everyone can afford their price.

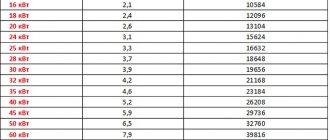

At the moment the gas boiler is started, electricity consumption increases by at least two, or even three to four times. Even if this is a short-term moment, lasting a second or two, we still take a UPS for a gas heating boiler to the maximum and with a power reserve. For a gas boiler with an electric power of 100 W, you need a UPS with a power of at least 300 W (with a reserve of up to 450-500 W).

As for the battery capacity, let’s say one battery with a capacity of 50 Ah is enough for 4-5 hours of operation with an electrical consumption of 100 W. To ensure 9-10 hours of operation, you need to have two such batteries, etc.

This table shows the battery life of a gas boiler in hours depending on the power consumption of the gas boiler (electrical power in W), battery capacity (capacity, Ah) and the number of simultaneously connected batteries (one, two, three or four)

And finally, will the UPS consume electricity for its needs? It all depends on efficiency. If we take efficiency = 80%, then for our 300 W UPS the consumption together with the load will be:

300 W / 0.8 = 375 W, where 300 W is the load, the remaining 75 W is the consumption of the UPS itself.

The given calculation example is conditional and is applicable for simple uninterruptible power supplies, namely for the moment when mains voltage surges become above a certain level - more than 10%. When the network has standard 220 V, the UPS consumes almost nothing.

It is better to entrust detailed calculations for calculating the power of the UPS, the capacity of the batteries and the additional costs of electricity in connection with the installation of a UPS in the heating network to an electrician.

Are power outages dangerous?

Sellers of non-volatile appliances and uninterruptible power supplies tell customers chilling stories that look quite plausible. A person who does not understand anything at all about the design of a boiler will believe that if the current is lost, the gas supply to the burner continues.

What's really going on? When the temperature sensors, electronic control unit and pump are turned off, uncontrolled combustion of fuel occurs in the combustion chamber, which means overheating of the liquid in the heat exchanger.

Accordingly, the tubes cannot withstand, they become deformed, burst, and the water from them extinguishes the burner of the atmospheric gas boiler. Gas enters the room and creates an explosive situation or simply poisons people and animals. And if a forced-air ventilation system is installed in the boiler, go outside. This is also unsafe and not environmentally friendly.

Do you agree that it sounds plausible and scary? Have you already decided to run for a non-volatile boiler? But in vain!

Do not avoid performing maintenance on gas appliances and their components. Checking will show their performance, especially after power outages

In fact, electrically dependent boilers occupy a leading position in the sales market. They are installed in holiday villages, private houses, with owners spending half a day at work, and in non-residential premises where long-term repairs are being carried out.

Power outages, as mentioned earlier, are quite common. And for some reason there is no data on hourly large-scale tragedies of carbon monoxide poisoning or explosions.

Moreover, such a dangerous device would not be certified and could not in any way comply with GOST, which means that gas workers would not allow it to be used.

And now the technical details. In fact, the devices have a reliable system that ensures that the boiler is turned off in the event of force majeure, including a power outage.

What happens after power supply is restored?

One of the most pressing questions for consumers is whether a volatile gas boiler will turn on automatically after a power outage?

Depending on the boiler model, after the electricity is reconnected, it may ignite automatically or only after manual starting. Devices with piezo ignition will require mechanical activation.

Devices with an atmospheric burner, as well as units with the above-mentioned pressurized system, are able to turn on independently, and even without losing the set automatic parameters, if they are equipped with electric ignition and a pressure switch.

However, auto-start does not always work either. After a large number of subscribers have lost power, when electricity is restored, the pressure in the gas pipeline may drop for some time; accordingly, the pressure switch is triggered, the equipment does not turn on, and then it can only be started manually.

For those for whom this issue is relevant, it is enough to install a delay relay or, as it is also called, a “time relay”. Then your boiler will not start immediately, but after some time, when the pressure in the gas pipeline is likely to equalize.

A time relay allows you to delay the automatic activation of electric ignition until the gas pressure is expected to equalize

In some cases, the electronic control module displays an error after power is supplied. This means that a minor emergency occurred before the shutdown. The decoding of the code can be found in the instructions for the heating device.

By the way, not all of them can be fixed on their own; to solve certain problems, you will need to call a specialist from GorGaz or the service department.

Rating of the best UPS for a boiler

The compiled rating is based on the overall functionality of the UPS, which ensures long-term and stable operation of the gas boiler.

1 place

The best option for a gas boiler would be an uninterruptible power supply with continuous operation and an external battery with a capacity of 50Ah or more.

It will ensure round-the-clock stable operation of heating equipment and its autonomous operation for 3-5 hours. Good models in this category are Legrand DAKER DK 1kVA, LogicPower LPY-WPSW-1000VA, CyberPower OLS1000E, Luxeon UPS-1000LE and Delta Amplon N1K.

The LogicPower LPY-WPSW-1000VA uninterruptible power supply is a device with double voltage conversion and will be an ideal solution for boilers with power consumption up to 500 W

2nd place

The middle of the rating is occupied by linear-interactive devices with a wide range of operating voltages, a smooth sine wave at the output and the ability to connect an external battery. The cost of devices that will be sufficient to operate a gas boiler is within $100.

Typically, such UPSs already contain a battery that will provide 5-20 minutes of operation of the heating equipment. For longer operation, you can connect an additional battery to the UPS, the capacity of which is limited only by the size of the wallet.

The best models in this category are REALEL HOME UPS-1000, Luxeon UPS-1000ZY, PowerWalker VI 1000PSW, APC SmartUPS XL 1000VA and LogicPower LPY-BPSW-800.

The Luxeon UPS has a minimalist design and is suitable for most indoor gas boilers. An external battery can be connected to it

3rd place

It housed backup-type devices with minimal power, small capacity of built-in batteries and an approximate sinusoid.

Sudden voltage rises can be transmitted through such UPSs to the heating boiler circuit board and lead to its breakdown. And the battery capacity of such uninterruptible power supplies is only enough for 10-30 minutes of continuous operation of the heating equipment, after which it will still turn off.

Popular models in this category are the FSP DP 450VA, CyberPower Value500EI, Powercom WOW-500U and Mustek PowerMust 424EG SVEN Pro+ 400 devices. You can buy these devices for a gas boiler only if you do not have enough funds to purchase a more suitable device.

A small backup UPS is more suitable for autonomous operation of a computer than a gas boiler. Therefore, such devices are rarely recommended to ensure the operation of the heating system

When purchasing a UPS, you should pay attention to its release date, because the battery located inside loses capacity over time. But equipment can lie in a warehouse for several years before hitting the shelf. You should not neglect the seller’s advice, especially if it is based on the experience of previous buyers.

How to deal with periodic power outages?

In regions remote from large cities, this is a common problem. And in order not to worry about what will happen to the boiler if the power goes out, there are two solutions.

Solution #1. Generator

This option is more suitable for country houses and in general is not particularly convenient. Yes, generators provide good autonomy, but they are inconvenient. It is imperative to take care of proper exhaust gas removal. Plus, generators make a lot of noise during operation. Therefore, we cannot recommend this solution to everyone.

Solution #2. Uninterruptable power source

Modern UPS models allow the boiler to operate autonomously from 1 hour to several days. Plus, they act as a stabilizer, which also solves the problem of power surges. The built-in stabilizer evens out even minimal surges, and thanks to the ability to connect multiple batteries, very high autonomy can be achieved. Plus, the stabilizer ensures safety for the batteries themselves during charging. Thus, the service life of the system is significantly increased.

How to choose a backup power source?

The most popular option is an uninterruptible power supply, abbreviated as UPS. It provides a secondary power supply to the device in case of a short-term power outage on the line.

Most often, it is used to provide power to a computer so that a person has time to finalize, save information and exit the system in normal mode in the event of a power outage from the main source.

Of course, a regular uninterruptible power supply from a computer is not suitable for a gas boiler. The maximum that he can do is extend the functionality of the device by 2-3 minutes, since the output produces an approximation of a sine wave or a square wave, and the boiler requires a pure sine wave. Please take this into account when purchasing a device.

A competent choice of UPS for the boiler will allow you to ensure fuel supply even when there is a power outage on the line

Ideally, an uninterruptible power supply with a power of 300-600 W is suitable, with the ability to connect a battery up to 600 Ah. The capacity of such a battery will last for 3 days.

But if for some reason you want to save money, keep in mind that:

- 50-100 Ah, will extend the operation of the boiler for a period of 3 to 8 hours;

- 200 A*h is enough for about a day of uninterrupted functionality.

Outages longer than a day require a more powerful power source. And here it is best to choose an inverter gasoline generator, which also has a pure sine wave. With the help of these devices, the gas boiler will operate in a stable mode after the load is turned off.

Types of independent gas boilers

The following types of boilers operating without electricity can be distinguished:

- single-circuit

- apply only to the heating system; - double-circuit

- these are devices that, in addition to heating, also provide hot water for household needs.

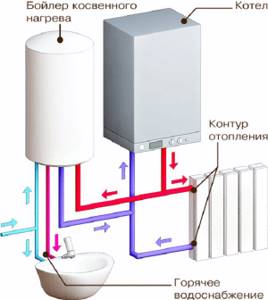

1 Double-circuit boiler with a boiler connected to the system Double-circuit gas boilers, in turn, provide hot water in 2 ways: flow-through and storage.

Operating principle of the boiler

Due to the lack of access to energy supply, two-chamber boilers are equipped with special thermogenerators, which are responsible for the state of the burner by stopping the gas supply to it. This process is ensured by the influence of the coolant on the regulator. The automatic system provided in the boiler restarts access to gas as soon as the coolant has completely cooled down. Ignition for this purpose is provided by the operation of a piezoelectric element, the task of which is to ignite the pilot burner. if necessary, the piezoelectric element starts ignition of the main element, which in turn is responsible for heating the liquid in the entire heating system.

Selecting an independent boiler model

Gas boilers operating without electricity must fully correspond to the area of the heated room. That is, the power must match the load.

Double-circuit models from foreign manufacturing companies are often more expensive than domestic ones, as they are more advanced and have an attractive design. The manufacturer of the gas boiler must be chosen carefully; it is important to make sure that this company has a service center in the city or nearby. Since, if necessary, you can find spare parts for repairing the device there.

The most popular manufacturers of such equipment are Alphatherm, Beretta - Italy, Attack - Slovakia, Protherm - Czech Republic, Electrolux - Sweden.

Rice. 2 Boiler without electricity from Protherm

Domestic models of independent boilers are cheaper than foreign ones, but are considered less reliable. But we should pay tribute that such devices are already adapted to our weather conditions and the parameters under which they must operate.

A gas boiler without electricity can be chosen with a steel or cast iron heat exchanger. The most popular are cast iron devices. This is explained by the service life: cast iron will last 30 years, and steel 15-20 years.

Cast iron is not only stronger, but the design also means that the walls of such a heat exchanger are thicker. This prevents the walls of the heat exchanger from burning through. This device has been tested in practice.

The heat exchanger may also be subject to corrosion. A cast iron appliance is much less susceptible to such damage than steel. Corrosion on the heat exchanger appears if the temperature drops to the point that condensation appears. And this very moisture leads to corrosion processes.

Also, the cast iron heat exchanger, by its design, consists of sections. If necessary, you can change a section, not the entire device. Nowadays, impurities are added to the cast iron alloy, which make it even stronger. This means that it will not crack if transported incorrectly.

Determining the appropriate model for an installation such as a gas boiler without electricity

The main guideline for determining the appropriate model of such an installation as an autonomous gas boiler without electricity is the correspondence of its heating power to the required area, and this characteristic must also correspond to the load on the installation. The double-circuit type of boiler, manufactured mainly by foreign companies, is often determined more serious price category. This is explained by the increased quality, design and more advanced functionality of the device compared to domestic analogues. At the same time, the manufacturer of the gas installation should be determined with special diligence; it is especially worth considering the presence of service centers of the represented company in the city or nearby, because the device requires maintenance and sometimes repair.

The most popular and high-quality manufacturers of gas autonomous boilers include the following companies: Italian manufacturers Alphatherm and Beretta - Italy, Slovenian company Attack, Czech-made Protherm and Swiss-made Electrolux.

Although models from domestic manufacturers are more attractive in terms of price, their reliability does not always correspond to the level of foreign analogues. Although they have their own special advantage - the models are produced according to all parameters corresponding to the use of boilers under local temperature conditions.

It is better to give preference to a gas boiler with heat exchangers for the manufacture of which cast iron or steel was used, and special attention should be paid to the first version of the material

In addition, after many years of using a gas boiler, the heat exchanger tends to corrode. At the same time, cast iron is more advantageous than steel. Corrosion on this element of the device can occur as a result of a drop in temperature, which leads to the formation of condensation. Corrosion processes in such cases are provoked by released moisture.

In addition, the design of the heat exchanger provides for the presence of sections. If one of them is unsuitable, it is not advisable to change the entire heat exchanger; replacement is sufficient. At these production stages, all sorts of impurities are added to the cast iron, which significantly increase the strength characteristics of the boiler as a whole, which provides it with additional safety during transportation.

Advantages and disadvantages

The advantages of non-volatile boilers include:

- there is no dependence on the availability and quality of power supply;

- simplicity of design, absence of minor parts;

- guaranteed continuity of the home heating process;

- the cost of the boiler and repair work is significantly lower than that of energy-dependent models;

- You can do maintenance and cleaning yourself.

Disadvantages are considered to be:

- the protection system is limited to several sensors;

- there is no possibility of remote control;

- The operation of the boiler depends on external factors that cannot be adjusted.

IMPORTANT!

Despite some disadvantages, non-volatile boilers are a practical and reliable solution. In some settlements they have no competitors due to power outages.

TOP 5 double conversion voltage stabilizers

The highest quality and most reliable types of stabilizers include double conversion devices. Let's look at the most notable models:

Calm IS550

Low power voltage stabilizer (400 W), designed to work with one consumer. Compact, lightweight device. Designed for wall-mounted installation. The output is single-phase voltage, the error is only 2%.

Device parameters:

- input voltage - 90-310 V;

- output voltage - 216-224 V;

- Efficiency - 97%;

- dimensions - 155x245x85 mm;

- weight - 2 kg.

Advantages:

- high stabilization accuracy, w

- wide input voltage range,

- compactness and light weight.

Flaws:

- low power,

- the price is too high.

Calm IS1500

Household voltage stabilizer with double conversion. Power is 1.12 kW. Designed to work with single-phase current with a frequency of 43-57 Hz.

Main parameters:

- input voltage - 90-310 V;

- output voltage - 216-224 V;

- Efficiency - 96%;

- dimensions - 313x186x89 mm;

- weight - 3 kg.

Advantages:

- compactness,

- attractive appearance,

- light weight.

Flaws:

noise from a running fan, for which there is no data on service life in the data sheet.

Calm IS350

300-watt stabilizer with double voltage conversion. It has a high stabilization accuracy of 2%.

Device parameters:

- input voltage - 90-310 V;

- output voltage - 216-224 V;

- Efficiency - 97%;

- dimensions - 155x245x85 mm;

- weight - 2 kg.

Advantages:

- compactness,

- light weight of the device,

- able to work with different sources,

- has high accuracy.

Flaws:

- low power,

- The price of the device is too high.

Calm IS1000

Stabilizer with a power of 1 kW. A device with double voltage conversion, designed for wall mounting. It is compact, the low weight of the device does not create unnecessary load on the supporting structures.

Stabilizer characteristics:

- input voltage - 90-310 V;

- output voltage - 216-224 V;

- Efficiency - 97%;

- dimensions - 300x180x96 mm;

- weight - 3 kg.

Advantages:

- high performance,

- reliability,

- the range of input voltages is very large, which gives no reason to worry about household appliances and electrical appliances.

Flaws:

- short power cord length,

- slight fan noise

- inconvenient placement of plugs for consumers.

Calm IS3500

Double conversion stabilizer with a power of 2.75 kW. Designed for wall-mounted installation, it has high operating accuracy (only 2% error).

Main parameters of the device:

- input voltage - 110-290 V;

- output voltage - 216-224 V;

- Efficiency - 97%;

- dimensions - 370x205x103 mm;

- weight - 5 kg.

Advantages:

- high accuracy,

- reliability,

- wide range of input voltages.

Flaws:

- excessive cooling noise,

- relatively high cost.

Rating of TOP-5 energy-independent gas boilers

Let's look at the features of some models of non-volatile units:

Lemax Premium-12.5

Non-volatile floor-standing boiler of domestic production. The power of the unit is 12.5 kW, so the area of the room should not exceed 125 square meters. m.

The model is equipped with a steel heat exchanger, overheating protection and a gas supply controller.

Main performance characteristics:

- Efficiency - 90%;

- maximum heating water temperature - 90°;

- pressure in the heating circuit (max) - up to 3 Bar;

- natural gas consumption - 1.5 m3/hour;

- dimensions (W-H-D) - 416x744x491 mm;

- weight - 55 kg.

Lemax provides a long-term warranty on its boilers - the user receives technical support for 3 years.

Lemax Premium-20

Another floor-standing, non-volatile gas boiler, manufactured in Taganrog.

Its power is 20 kW, which is optimal for most private two-story houses. The maximum area for this unit is 200 sq. m.

Boiler parameters:

- Efficiency - 90%;

- maximum heating water temperature - 90°;

- pressure in the heating circuit (max) - up to 3 Bar;

- natural gas consumption - 2.4 m3/hour;

- dimensions (W-H-D) - 556x961x470 mm;

- weight - 78 kg.

The single-circuit design is designed to heat the coolant, but if necessary, you can connect an external indirect heating boiler .

Lemax Patriot-12.5

Energy-independent parapet model from Taganrog. A boiler with specific capabilities.

Non-volatile unit, but the combustion chamber is of a closed type. Boiler power 12.5 kW, suitable for heating 125 sq. m.

Main technical characteristics:

- Efficiency - 87%;

- maximum heating water temperature - 80°;

- pressure in the heating circuit (max) - up to 2 Bar;

- natural gas consumption - 0.75 m3/hour;

- dimensions (W-H-D) - 595x740x360 mm;

- weight - 50 kg.

The main advantage of parapet boilers is their low fuel consumption - almost half that of conventional models.

Siberia 11

Products of Rostov manufacturers of heating equipment. And the units are available in single- and double-circuit versions, which expands the possibilities of choice .

The power is 11.6 kW, allowing you to heat a house up to 125 square meters. m.

Main settings:

- Efficiency - 90%;

- maximum heating water temperature - 90°;

- pressure in the heating circuit (max) - up to Bar;

- natural gas consumption - 1.18 m3/hour;

- dimensions (W-H-D) - 280x850x560 mm;

- weight - 56 kg.

Rostov units are positively assessed by specialists and ordinary users.

MORA-TOP SA 40 G

The Czech gas non-volatile boiler with a power of 35 kW is designed for use in rooms up to 350 sq. m. m. The massive structure is equipped with a cast iron heat exchanger.

Options:

- Efficiency - 92%;

- maximum heating water temperature - 85°;

- pressure in the heating circuit (max) - up to Bar;

- natural gas consumption - 3.9 m3/hour;

- dimensions (W-H-D) - 630x845x525 mm;

- weight - 151 kg.

The cast iron heat exchanger has a sectional design of 5 sections . There are pressure and temperature sensors.

Design features of a non-volatile installation

Gas boilers of this type are distinguished by the following equipment:

- A pair of gas burners, pilot and main purpose;

- Open combustion chamber;

- A system that ensures automatic operation of the device;

- Thermal sensors to ensure installation safety, backdraft valve;

- Heat exchanger.

Important!

Features of the non-volatile gas boiler system include the operation of an open, expanded tank, due to which the liquid expands when the coolant is heated. This process ensures the circulation of the coolant. The expansion of water is accompanied by the formation of excess liquid, which goes to the tank itself. Ignition of such an installation is provided by a piezoelectric element, which starts working a second after the button is turned on. Its purpose is to heat the pilot burner, which in turn ignites the main gas burner. Thus, a heat exchanger is activated, which is responsible for maintaining the required water temperature. Over time, the gas supply stops, the heat exchanger parts cool down, therefore, all stages are repeated.

Installation

Any gas equipment can be installed and put into operation only if there is an installation project and after agreement with the gas service. If the project is completed with errors, or if they were made during installation, the boiler will not be allowed to be used.

In order for the boiler to operate normally, a number of conditions must be met:

- The boiler room must constantly maintain a positive temperature;

- During the installation of the boiler, fire safety instructions must be observed (for example, the walls near which the boiler is installed must be protected with non-combustible materials);

- When installing the boiler yourself, for its first start-up, you must invite a specialist who can, with an experienced eye, make sure that the boiler is installed correctly and that there are no errors in its operation.

When designing a boiler installation scheme, you need to think not only about the unit itself, but also about the installation of the chimney system. The chimney must be installed in accordance with a number of requirements, which depend on the characteristics of the boiler and the characteristics of a particular building. Each individual boiler must have its own chimney, but if necessary, several boilers can be reduced to one flue channel, the cross-section of which corresponds to the sum of the cross-sections of the outlets of each boiler.

According to the standards, if the chimney is installed on the roof and is installed at a distance of 1.5 meters from the ridge, then the height of the pipe must exceed 0.5 meters. If the distance between the ridge and the edge of the pipe is from 1.5 to 3 meters, the chimney must be installed at least on the same level as the ridge.

It is recommended to make the chimney completely straight, but if this is not possible, then you can make several turns (no more than three along the entire length of the chimney channel). The total length of the chimney must exceed 5 m. The top of the chimney is closed with a metal fungus, which prevents dirt and moisture from entering the structure.

A private option for a chimney is coaxial pipes, the possibility of using which is determined individually (it is advisable to consult a specialist). Coaxial chimneys can be installed at a low height and lead directly into the wall. Installation is inexpensive, and its technology is extremely simple.

Among the disadvantages of coaxial chimneys, one can note some dependence on forced air draft, which is created by an electric fan. When installing such a chimney in combination with a non-volatile gas boiler, the reliability of the system will be reduced. In addition, condensation constantly appears in coaxial chimneys, and the difficulty of removing it is also a disadvantage.

Sources:

https://sovet-ingenera.com/otoplenie/kotly/rabota-gazovogo-kotla-pri-otklyuchenii-elektrichestva.html https://www.teplodvor.ru/articles/otklyuchenie-elektrichestva-i-ego-posledstviya .html https://teploknam.ru/stati/chto-delat-s-kotlom-esli-otklyuchili-svet.html https://livelyday.ru/kotlomaniya.ru/gazovye/gazovyy-kotel-bez-elektrichestva.html https://expert-dacha.pro/otoplenie/kotly-ot/gazovye-k/top-5-energonezavisimyh.html https://teplospec.com/gazovoe-otoplenie/kakie-energonezavisimye-gazovye-kotly-otopleniya-luchshe -vybrat-kak-ustanovit.html

[collapse]

Where to buy a gas non-volatile heating boiler

In Moscow and Moscow Region

- MirCli (https://mircli.ru/kotly-otopleniya/napolnye-gazovye-kotly/energonezavisimye/) – 8 (495) 666-2219.

- Teplodvor (https://www.teplodvor.ru/kotly-otoplenija/napolnye-gazovye-kotly/energonezavisimye.html) – +7(495)48-132-48, Balashikha-1 microdistrict, st. Sovetskaya, 35 143902 Balashikha.

In St. Petersburg

- Gas boilers St. Petersburg (https://spb.kotel-gazoviy.ru/energonezavisimiy/) – +7 (812) 923-18-67, St. Petersburg, 5th Verkhny Lane, 15.

- Teplodvor St. Petersburg (https://spb.teplodvor.ru/kotly-otoplenija/napolnye-gazovye-kotly/energonezavisimye.html) –, st. Vitebsky Avenue, 3 196105 St. Petersburg.

In conclusion, we can say that energy-dependent models are more advanced and functional. If there are no problems with power supply, then the choice is obviously in their favor. Non-volatile analogues are an excellent solution in situations where there is no uninterrupted and high-quality power supply, and there is no desire to equip the boiler room with a voltage stabilizer and generator.

Gas boilersEnergy independent