Operation of the Stropuva boiler

You are no longer a fireman! Having flooded Stropuva once, you can forget about it and go about your business, without constant checks and refilling of fuel

This is very important if there is no one to monitor the operation of the system in your absence. The boiler operates autonomously, without the use of electricity*

*Pellet and universal versions of Stropuva use mains-powered fans or batteries (about 15-20 W/h for the air supply unit to the firebox)

Unlike conventional solid fuel boilers, Stropuva does not require frequent cleaning. Due to its high efficiency, the fuel burns almost completely.

Unlike boilers using electricity, gas and diesel fuel, where there is always a danger of a short circuit in the electrical network, a gas explosion or a diesel fuel fire, the STROPUVA solid fuel boiler is absolutely safe in principle. The boiler is designed in such a way that if the permissible load is repeatedly exceeded, it will not explode, but will shrink inward.

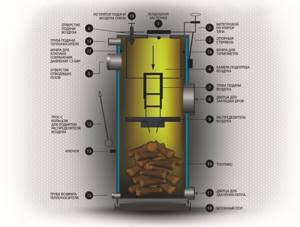

Due to constant modernization of production, the final version of the boiler may differ slightly from that shown in the photo.

Principle of operation

The Stropuva hot water boiler is a long-burning mine boiler. A special feature of the boiler is the top combustion technology, in which only the top layer of the loaded fuel volume burns.

This allows fuel to be consumed gradually, depending on the intensity of heat loss from the heating system. The maximum operating time of Stropuva on one tab reaches 120 hours. In this case, the thermal energy goes directly to maintaining the temperature of the coolant, and does not fly away into the chimney.

The combustion of wood and briquettes in Stropuva is supported by natural draft, so wood-burning versions of boilers are energy-independent. The pellet and coal versions use a fan for the air supply unit, powered by mains power or batteries (about 15-20 W/h).

How to start a Stropuva boiler

First, you need to purchase a piping kit to connect the equipment to the heating system. We recommend purchasing a kit with the ability to connect an indirect heating boiler. It includes a set of pipes, a safety group, an expansion tank and a circulation pump. Also on sale are kits for connecting underfloor heating.

It is not recommended to use damp firewood - this will interfere with the normal operation of the boiler.

Ignition is carried out in the following way - here are brief instructions for use:

- We load the wood combustion chamber full with the air distributor raised.

- We fill the finished masonry with sawdust.

- Open the flap for switching to wood.

- Open the air damper 3-5 cm.

- We light the top layer, close the loading door, leaving a gap 3-5 cm wide.

- We wait for reliable combustion, close the loading door and immediately lower the air distributor.

Please note that the cleaning door must be closed. A new portion of firewood can be added to the Stropuv boiler at any time, but doing this with coal is dangerous. In any case, the manufacturer recommends that you always wait until the fuel burns out completely before adding a new portion.

In any case, the manufacturer recommends that you always wait until the fuel burns out completely before adding a new portion.

A new portion of firewood can be added to the Stropuv boiler at any time, but doing this with coal is dangerous. In any case, the manufacturer recommends that you always wait until the fuel burns out completely before adding a new portion.

How to put the Stropuva boiler into operation

First of all, the air distributor rises, and the combustion chamber of the boiler is completely loaded with firewood; chips, sawdust, etc. are poured on top. For quick and guaranteed ignition, it is recommended to pour them with flammable liquid. Next, the flap for switching to wood opens, as well as the air damper by 3-5 cm. As soon as the fuel is fully ignited, close the door tightly and immediately lower the air distributor.

For efficient operation of the boiler, the temperature of the coolant entering the return must be at least 55 degrees. Otherwise, aggressive condensation will appear on the inner surface of the boiler, corroding the metal and turning into a crust when cooling. As a result, the transfer of thermal energy decreases, and the efficiency drops to 15%. This is usually observed in fuel saving mode, when wood burns for a long time and there is a lack of air masses.

The Stropuva solid fuel boiler can operate on one fill from one to two to three days. The duration of burning of one bookmark depends on many factors. This includes the area of the room, the quality of the fuel (for example, the firewood must be very well dried), the power of the heating unit, and the selected operating mode of the boiler. You also need to properly organize the heating system.

The cost of Stropuva boilers is considered high, but this heating equipment is in great demand among consumers. The reason for this is its energy independence, the ability to use various types of solid fuel, as well as the availability of a model range with certain power characteristics.

How do Stropuva boilers work?

Let's see how it is customary to start a traditional solid fuel boiler. First, we ignite small chips, and when they take up the flame, we begin to throw full-fledged firewood into the firebox. Our heat source is located below, under the wood stack. This is where the combustion spreads. As a result, the firewood burns out in a matter of hours, and a lot of thermal energy often flies away into the chimney.

Stropuwa boilers are built on the top combustion principle. In this way they are similar to Bubafonya wood stoves - here the wood is lit from above, not from below. The prototype of these furnaces were Stropuva boilers, which have a similar operating principle. Depending on the power of the selected unit, the combustion duration can be up to several days.

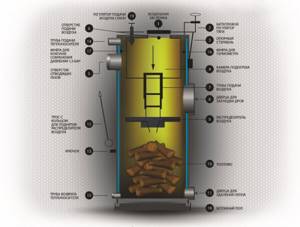

The Stropuwa boiler consists of the following elements:

- Combustion chamber – starts from the very bottom of the equipment.

- Heat exchanger – here a “jacket” of the “pipe-in-pipe” type is used. The coolant flowing through it ensures efficient heat intake and transfer to the heating system.

- Air distributor - it is located above the combustion zone and supplies air to it.

- Draft regulator – allows you to adjust the heating temperature of the coolant.

- Air heating chamber - it is responsible for heating the air masses supplied to the combustion zone. This design ensures efficient combustion of wood.

Air is taken in through a damper, combustion products are removed through a pipe in the rear (the chimney is connected to it). There are two doors in the front part - for loading fuel and removing ash.

The Stropuva solid fuel boiler has a long burning time. On one load it can work for up to several days - it all depends on the heated area, the current operating mode and the thermal power of the unit. Dried firewood, pellets, fuel briquettes or coal are used as fuel. According to the manufacturer, the burning time on coal is up to 5 days.

Patented combustion scheme ↑

The long-burning solid fuel boiler under the Stropuva brand is well-deservedly popular in the country due to its certain fuel versatility and affordable price.

Heating boilers using solid fuels are widely used when there is no possibility of connecting to a gas main or in places where there are problems with the electricity supply. In such cases, wood, coke or coal can be used as fuel. Also, these devices are in demand as a backup (additional) heat source.

The manufacturer of Stropuva products is a Russian-Lithuanian company that produces solid fuel boilers, the operating principle of which is based on a patented top-down combustion scheme. The long period of fuel combustion ensures continuous operation of the boiler for up to several days.

Stropuvo boilers offer such advantages on the heating market as a unique (up to 5 days!) combustion duration on one load of solid fuel, as well as energy independence and simplicity of design

Saving on heating with Stropuva

Layer-by-layer combustion allows you to use the fuel supply much more economically. That is, in 120 hours, Stropuva will burn 5 times less fuel than in a conventional bottom-burning solid fuel boiler. The duration of combustion directly depends on the quality of the fuel and compliance with the operating technology of the boiler and the heating system as a whole. You can independently calculate the cost of heating for your home. With Stropuva boilers it is much easier to ensure continuous operation of the system without loss of power. The graph shows the operating cycle of the Stropuva boiler in comparison with conventional solid fuel boilers. The efficiency remains constant over the entire period of time.

How to light a boiler

The most difficult thing in cycling is not to ride, but to start and finish the movement. It’s the same in the operation of a boiler - the most difficult thing is to light it. Do not expect that lighting the boiler will take you little time: you will have to allocate about an hour for this procedure.

Firing a wood-burning boiler is a responsible task

The beginning of the firebox is removing the ash and preparing the boiler for operation. After the ash pan and combustion chamber are cleaned, you can proceed to kindling.

Warming up the boiler firebox and chimney

For your own comfort and proper startup of the boiler, you need to warm up its firebox and chimney. If the heating device is not equipped with a forced smoke removal system, in order for the fuel to start burning, it is necessary to create draft. The formation of thrust is based on Archimedes' law: heated gases become lighter and tend to “float”. For their movement and removal, heating devices that burn fuel are equipped with a chimney.

Boiler diagram. Photo from the site www.viessmann.ru/

The design of the boiler is such that the path for smoke is difficult: in its path there is a heat exchanger and a complex convective surface, which reduces the speed of movement of combustion products. And the chimney pipe is usually located horizontally, which also makes it difficult for smoke to move. Therefore, if the boiler is not heated up, combustion products look for the easiest way. And most often the smoke begins to seep into the room.

In some cases, the vertical part of the chimney is equipped with a firebox (a small firebox used to warm up the chimney) with a door, by opening which you can burn a small amount of flammable fuel (for example, paper) directly in the chimney itself. When used, the heating element warms up the inside of the chimney duct.

If this possibility is not provided, then kindling is placed in the firebox - crumpled paper, birch bark - something highly flammable. On top of the kindling are chips and splinters, then logs of small thickness. The combustion chamber must be filled with firewood to no more than half the calculated volume.

At the moment of kindling, you need to open the chimney damper and the blower valve, ensuring the flow of air for combustion.

There is advice before starting the fire to open the window in the boiler room, if there is one: do not forget that the physical and chemical process of combustion requires oxygen.

How to properly heat a boiler with wood

To burn a kilogram of wood, about 5 cubic meters of air are required. If the air flow into the boiler furnace is from the boiler room, then it is necessary to arrange supply ventilation - especially if the boiler room does not have windows or they are sealed (with double-glazed windows).

After laying the logs, the kindling is ignited. When a stable combustion appears, the firebox door must be closed and the filling should be allowed to burn out.

Output to design power

As soon as the combustion chamber and chimney have warmed up sufficiently, you can proceed to the main stage of boiler operation. To do this, repeat the kindling process using well-burning materials. Now the main load of firewood is already complete, in order to fill the combustion chamber, according to the instructions for the device.

After the fuel has ignited, the boiler will reach its design capacity after some time. Now the combustion process will occur independently for some time. How long depends on the volume of the combustion chamber and the operating principle of the boiler. After the stack of firewood burns out, you will need to make a new one.

A properly functioning boiler is a source of heat and comfort in a country house

Important! When lighting, do not use lighter fluid or flammable gasoline, diesel fuel, etc.

Design and principle of operation

The body of the Stropuva boiler consists of two main parts: a cylindrical container placed in another container of the same shape, which are “clad” in thermal insulation. The coolant circulates in the space between the containers. The firebox is located inside a small container.

Boiler design

The bi-thermal draft regulator allows the stove to independently, without human intervention, regulate the volume of air supplied to the firebox. The principle of its operation is based on the fact that when heated, the boiler body expands and the bithermal regulator automatically closes the damper. If the combustion in the firebox slows down, the reverse process occurs, the housing cools and contracts and the regulator opens the damper.

Just like with the Bubafonya stove, the combustion process occurs only in the upper part of the stack, into which a controlled amount of oxygen enters through the air distributor pipe (also often called a piston or heel), this has a positive effect on the burning duration of the unit. Before entering the furnace, the air is preheated in the air heating chamber, which is located in the upper part of the boiler.

The air distributor is always located on the bookmark and as the fuel burns, it moves down.

Note! The efficiency of the boiler can be increased or decreased by changing the volume of air supplied.

Depending on the boiler model, the fuel used is wood, coal and pellets. To operate on coal and pellets, universal Stropuva boilers with a U attachment are used, which are equipped with a grate and a damper.

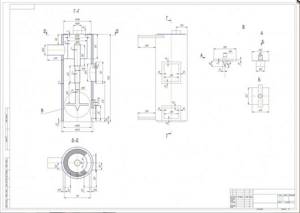

DIY Stropuva boiler drawing

The boiler design provides two doors:

- for loading fuel (top door);

- for removing ash (lower door).

At the back there is a hole for the chimney pipe. The coolant inlet and outlet are also located there. All boiler models use a 32 mm pipe for supply and return.

Safety

Buyers choose the Stropuva boiler also for the reason that it is safe to use. If severe overheating occurs, which causes excessive loads, the boiler cannot explode; its design is made in such a way that it “shrinks” inside. This heating equipment has a large volume firebox, which allows you to add fuel in the appropriate quantity. It will gradually burn out in thin layers, as the air distributor lowers and the heated gas rises into the chimney. During the process, heat will be transferred to the inner walls.

Advantages and disadvantages of Stropuwa mine boilers

The principle of top combustion and Stropuv boilers made on its basis have their pros and cons. Let's look at the main advantages:

- The duration of work on one load can range from several hours to 5 days. How long it will supply your home with heat depends on many factors, such as: type and quality of fuel, room insulation, quality of piping. If you use high-quality, dry fuel and properly configure the boiler, you will not need to frequently visit the boiler room.

- The efficiency of long-burning shaft-type boilers is comparable to gas boilers. Thanks to the top combustion and the special design of the boiler, fuel is burned very economically. Your money does not go down the drain, and every penny goes towards heating your home.

- The Stropuva wood-burning boiler does not require power supply. It can be used even in remote regions where there is no power grid. However, they are universal and require a small amount of electricity to operate the air supply manifold.

- Due to the efficient fuel consumption of Stropuwa boilers, very little waste remains. It is enough to remove ash only a couple of times a month, and resin deposits can be avoided if you use the right fuel.

- Unlike electric boilers where a short circuit is possible or gas boilers where there is a possibility of gas leakage, solid fuel boilers are absolutely safe. Even if it overheats, it will not explode, but will shrink inward like a tin can.

- What can we say, many long-burning boilers are extremely bulky and look angular. The Stropuva boiler, on the contrary, is very elegant and takes up little space in the boiler room.

To be fair, it should be admitted that there are some disadvantages:

- Only fuel with a moisture content of no more than 20% can be burned in the boiler. When using a more humid one, its effectiveness is significantly reduced and soot and soot are formed. It is also not advisable to use coniferous wood for the same reasons.

Inconvenient loading

For the longest possible operation of a solid fuel boiler, the fuel must be packed as tightly as possible. In the case of homogeneous coal or pellets, this is not a problem, but with firewood you have to tinker. And the windows in the boiler do not allow you to reach the lower level of firewood.

As you can see, Stropuva has many advantages, but is not without minor disadvantages. In terms of burning duration, mine fires can only be competed with completely and the like.

When constructing any building, residential or industrial, heating is a very important element. It is not always possible to connect a gas or electric boiler, then a long-burning solid fuel boiler would be an excellent solution. It allows you to save money throughout the entire life of this device. Long-burning boilers provide good savings not only in money, but also in time. You can refuel once every 12 hours, and there are also boilers that operate for up to three or even seven days absolutely without outside intervention.

Stropu va boilers are a good option for any building; the shape of the boilers allows them to be installed even in small rooms. The height of the unit can reach two meters, but its diameter will be no more than seventy centimeters. The boiler does not require any additional connections for automation or heat accumulators.

These are top combustion boilers, which gives them a lot of advantages. The fuel in this boiler is ignited from above and burns in thin layers, gradually falling down, this allows you to significantly increase the combustion duration

one load of fuel. This technology also allows for the release of much more heat, even during long-term smoldering.

The advantage of this boiler is that it can show high efficiency,

operating at 15% of maximum power level.

The advantages include the fact that the combustion center inside the boiler does not remain in one place for a long time. Thanks to its unique design, it moves inside a cylindrical shape from top to bottom, eliminating the constant heat load

on one place.

This also made it possible to reduce the thickness of the boiler walls and, accordingly, reduce its weight, which is important. These boilers help you save money

and time, many of them require very infrequent human intervention.

Long-burning boilers operating on wood need to be loaded with fuel once every 30 hours;

when using briquettes, loading is done every two to three days, and when operating on coal, the boiler can maintain heat for up to five days without adding fuel.

Advantages and disadvantages ↑

Sectional diagram of the Stropuva boiler

It is worth briefly listing the main advantages of Stropuva boilers:

- Cost-effectiveness and convenience - their installation does not require an expensive gas supply, and the long duration of work on a one-time fuel supply saves money and time.

- Energy independence - there are no electronics in the design, so wood-burning boilers, when used in a gravity heating system, do not require electricity.

- Safety and reliability - one of the advantages is control using a bimetallic valve - a simple and trouble-free draft regulator.

- Aesthetics along with simplicity - STROPUVA boilers differ from similar types of devices in their elegant appearance and compact placement. The clear design of the unit eliminates any difficulties during operation.

Among the disadvantages, the following can be noted: their performance is greatly affected by the humidity of the loaded fuel. But this is rather a minus of all solid fuel boilers, and not of a specific brand in particular. The solution here is simple - keep firewood or coal in a dry place.

Stropuva – long burning boiler

The top combustion principle ensures gradual combustion of the fuel. The full volume of fuel is loaded into the boiler, which is enough for the entire combustion cycle of the boiler (in Stropuva S20 P this is 72 hours). But only the top layer will burn at the same time - there will be enough thermal energy to maintain the set temperature without loss of power.

In conventional solid fuel boilers (not shaft type), the entire volume of fuel after ignition releases the maximum amount of thermal energy depending on the heat capacity (as in a regular fire). Afterburning pyrolysis gases can extend the time of efficient operation of the boiler, but will not ensure fuel combustion for more than 6-8 hours, since any volume of fuel burns simultaneously. In Stropuva, thanks to the vertical design, only part of the fuel burns, releasing the energy necessary to maintain the temperature of the coolant and no more. Heat does not escape into the chimney.

Design and principle of operation of the Stropuva boiler

The design of the Stropuva boiler consists of two cylinders of different diameters, inserted one into the other, and in the space between them there is a coolant: in most cases it is water. The combustion chamber is located in the inner cylinder, above which there is a telescopic cylinder at the top for supplying air to the firebox. In turn, air enters the telescopic cylinder through a damper made in the form of a thermocouple, which opens and closes the air supply, depending on the combustion temperature.

The difference between the STROPUVA heating boiler and other solid fuel boilers is the use of the “top-down” combustion principle

A large amount of fuel is placed in the boiler, which, unlike other solid fuel boilers, burns not at the bottom, but at the top. It should be noted that the fuel is not in the combustion chamber, but under it. To service the boiler, there are two doors: one in the middle for storing firewood, the other at the bottom for removing ashes. After the upper part of the fuel burns, the air distributor moves down and is constantly located above the burning fuel, in the center of combustion. Thus, the efficiency of Stropuva boilers increases to 90%.

If the boiler is fired with briquettes or coal, a grate is used, which is included with the boiler when it is sold.

To better understand the principle of operation of the Stropuva boiler, we will give a common example of the combustion of a simple match. If we light a match and turn it over, it will burn twice as fast as the one that burns with its head up. Moreover, both matches emit the same amount of heat, but in the second case the match will burn twice as long.

Description of the unit with boiler connection, without heated floors

The coolant heated in the boiler passes through steel pipes d 25 mm for boilers. Air is removed from the boiler through an automatic air vent (3). A safety valve (0) of 1.5 atmospheres is installed on the external circuit of the boiler. The coolant is directed along the external circuit through the valve to the hot water boiler (3). After heating the boiler, the coolant flows back into the outer circuit of the piping unit.

After the boiler (3), a selection is made to an additional radiator, which, in the event of a power failure, can operate as a gravity radiator. The additional radiator (2) must be connected independently. It is necessary to prevent overheating of the boiler when the circulation pump is turned off.

The radiator system (1) is connected at the top of the small circuit through a valve d 25 mm. The return line of the radiators is supplied to the circulation pump through a valve d 25 mm. The heated coolant from the boiler enters the heating system manifold and then into the radiator system (1).

The cooled coolant flows from the return manifold to the circulation pump (5).

The balancing valve (8) regulates the flow of coolant passing through it so that there is enough coolant to heat the radiators, and at the same time, so that it is sufficient for the boiler itself. The total volume of coolant flow through the balancing valve depends on the power of the circulation pump and on the selected heating system design.

The flow rate through the balancing valve should be within 16 l/min. The three-way mixing valve (6) is connected to the circulation pump (5) and to the common return line. A three-way mixing valve (6) is necessary to mix the coolant in the return and supply lines and regulate the temperature of the boiler in order to prevent the formation of condensation.

In the return line after the balancing valve, drain valves are installed to recharge and drain the system, as well as an expansion tank (9).

The pressure in the expansion tank should be 0.5–0.7 atmospheres.

If necessary, an electric boiler can be installed instead of a boiler.

Design and principle of operation of the Stropuva boiler

The heating unit is based on two cylinders, one of which is placed inside the other. The outer cylinder is made of steel. Wall thickness up to 4 mm. The inner cylinder, whose wall thickness ranges from 4-6 mm, can be made not only from steel, but also from cast iron, which improves its operational and technical characteristics. There is water between the cylinders. This is precisely the area of the boiler water jacket. This is where heat is taken in and distributed throughout the heating system. The heating of the coolant is easily regulated using the draft regulator.

The inner cylinder is the combustion chamber. Here the design also provides a telescopic distributor, which touches the fuel and, as it burns, moves down. Air is also supplied through it to support the combustion process. Air masses are taken in through the damper. It is noteworthy that air is supplied only to the combustion zone. It's already warmed up enough. This is ensured by the air heating chamber included in the design of the Stropuva boiler.

So, the intensity of combustion and, accordingly, the temperature of the coolant depends on the volume of supplied air. A strong draft is created in the boiler as it is connected to the chimney. The smoke from the boiler practically does not enter the room; it is drawn out of the room by the chimney. The boiler design has a door for loading fuel, it is located in the upper part. At the bottom of the boiler there is a door for removing ash.

Advantages and disadvantages

Reviews from owners indicate that heating boilers from this company have many advantages. Stropuva is better than its counterparts in many ways. The main advantage, of course, is continuous combustion and the ability to use one bookmark for a long time. For example, if you choose coal as fuel, then one load will last for almost a week, and briquettes will last for two days. If you have to heat the room with wood, then the stash will last for thirty hours. Standard models can function on one tab for no more than eight hours. According to users, the device is very easy to use and there are no loading issues with it.

Stropuva boilers are also quite economical. They themselves are relatively inexpensive, as well as the fuel used, which can be ordinary wood, coal, wood chips or other common materials. If we compare Stropuva products, which are solid fuel devices, with a conventional pellet boiler, the benefits will be obvious. There will be no unnecessary fuel consumption - only as much as needed. You can change the mode depending on changing conditions and thereby extend the burning hours of one bookmark. For example, if it gets warmer outside, less energy will be required, which means the boiler will run on fuel longer. When switching to Stropuva, heating costs are reduced by approximately half.

The boiler from Stropuva always works in the best mode. A conventional boiler operates until all the fuel is burned, and in a short period of time produces a huge amount of heat. Therefore, you have to either constantly update the bookmark, or supplement the design with a heat accumulator that will store heat. In Stropuva, only a small part of the fuel is burned and no additional devices are required. The efficiency of the boilers reaches 90%, and the boiler itself is non-volatile and can work with almost any solid fuel. Even if there is no electricity in remote areas, Stropuva will still be successfully operated. It is also worth mentioning that the boiler itself is quite compact and does not take up much space, it is very easy to clean, and it can function for up to 5 years.

Boilers of this type are distinguished by their safety for users. The device is made of steel, characterized by increased heat resistance and heat resistance. If there is a fire, the boiler will not explode anyway. In addition, the design is equipped with a special protection valve, which in case of danger activates the extinguishing mode. Stropuva can be easily equipped with radiators and boilers, connected to underfloor heating, as well as any heating system. You can set different temperatures for different connections. For example, the heated floor will maintain a temperature of 33 degrees, and the radiators will maintain a temperature of 55 degrees.

The main disadvantage of such boilers is still considered to be the price - you will have to pay more than 80 thousand rubles. It is also bad that the device reacts extremely sharply to changes in the quality of the coolant, most often liquid. Some aspects of operation also differ in complexity. For example, if fuel is burned with insufficient air, condensation will begin to appear from inside. The metal, exposed to aggressive influence, will begin to corrode, and then a crust will appear, inhibiting the transfer of heat.

Finally, Stropuva is picky about the choice of fuel. The humidity of dry firewood cannot exceed 15%, otherwise condensation will begin to form inside again. It is also bad that during operation a lot of waste is generated, that is, ash. When fuel is mixed with ash, an unnecessary layer is formed, thereby reducing the combustion temperature.

Some users point out such a disadvantage as the inconvenience of loading. Fuel needs to be formed in the most dense rows, which is not very easy when choosing firewood. In addition, the design is made in such a way that it is not always possible to reach the lower fuel level.

Next, see a review of the operation of the Stropuva boiler.

Pros and cons of Stropuva boilers

pros

- Duration of combustion. Depending on the type of fuel, they can operate without additional fuel loading from 1 to 5 days.

- High efficiency. In terms of efficiency, the boilers are close to gas boilers.

- Does not depend on power lines. And therefore, they can be used to heat even in the remote taiga.

- There is no need to spend a lot of time and effort to clean the ash pan, since the fuel burns almost completely, leaving little ash.

- Exceptional security. Electrical short circuits and gas leaks are excluded. And if for some reason the coolant overheats, the boilers do not explode, but collapse like tin cans.

- Elegant appearance.

Minuses

- High demands on fuel quality. If the firewood has a moisture content of less than 20% or is of coniferous origin, the efficiency of the boiler decreases and soot and soot form in the lower part.

- Small windows for loading fuel complicate this process.

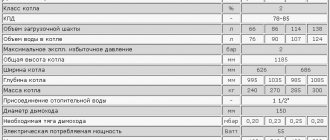

Types and technical characteristics

At the moment, Stropuva is available in three varieties: wood-burning, pellet and universal. Each of these three varieties is designed for a specific type of fuel, but can work on any other, albeit with less efficiency. In total, the line includes 4 standard sizes: 10, 15, 20, 40 kW and a Mini version with a power of 8 kW.

The Stropuva wood-burning boiler is equipped with a special air distributor, which allows efficient burning of wood, and has the following characteristics:

| Model | Mini S | S10 | S15 | S20 | S40 |

| power, kWt | 8 | 10 | 15 | 20 | 40 |

| Room area, m² | 30-80 | 50-100 | 75-150 | 100-200 | 200-400 |

| Efficiency, % | 86,3 | ||||

| Firewood capacity, dm³ | 120 | 150 | 200 | 230 | 360 |

| Chimney diameter, mm | 160 | 180 | 200 | ||

| Burning duration, h | 31,5 | ||||

| Price, rub | 65 000 | 87 150 | 92 348 | 97 545 | 107 730 |

The pellet version is equipped with a distributor for fuel pellets and an air supply manifold. Boilers operating on pellets have the following data:

| Model | Mini SP | S10P | S15P | S20P | S40P |

| power, kWt | 8 | 10 | 15 | 20 | 40 |

| Room area, m² | 30-80 | 50-100 | 75-150 | 100-200 | 200-400 |

| Efficiency, % | 86,3 | ||||

| Pellet capacity, kg | 50 | 70 | 110 | 120 | 200 |

| Chimney diameter, mm | 160 | 180 | |||

| Burning duration, h | 72 | ||||

| Price, rub | 65 000 | 91 350 | 97 072 | 102 795 | 112 980 |

The last representative of solid fuel boilers is universal. These devices can operate on coal, wood, fuel briquettes and pellets. The delivery set includes distributors for all types of fuel, as well as an air supply manifold. They have the following technical characteristics:

| Model | Mini SP | S10P | S15P | S20P | S40P |

| power, kWt | 8 | 10 | 15 | 20 | 40 |

| Room area, m² | 30-80 | 50-100 | 75-150 | 100-200 | 200-400 |

| Efficiency, % | 86,8 | ||||

| Pellet capacity, kg | 50 | 70 | 110 | 120 | 200 |

| Chimney diameter, mm | 160 | 180 | 200 | ||

| Duration of coal combustion, h | 130 | ||||

| Price, rub | 65 000 | 102 700 | 114 608 | 121 380 | 127 995 |

As you can see, from the presented model range you can choose a solid fuel boiler for any room, type of fuel and available budget.

Boilers Stropuva Mini

STROPUVA boilers are modern units that have a unique design designed to ensure the longest possible combustion. We bring to your attention boilers MINI S8, MINI S8P, MINI S8U.

- The MINI S8 boiler can operate on wood and fuel briquettes. Has a power of 8 kW. Designed for heating an area of up to 80 square meters. m. With one load of 32 kg it can heat for 18 hours.

- The MINI S8P boiler can also operate on both wood and fuel briquettes. Like the MINI S8, it has a power of 8 kW. Designed for a heated area of up to 80 square meters. m. With one stack weighing 80 kg, it will generate heat for 32 hours.

- The MINI S8U boiler differs from the models described above in that it can operate on wood, pellets, fuel briquettes and even coal. With a power of 8 kW and a load of 61 kg of fuel, it is capable of maintaining combustion for 72 hours.

The design of the boilers has a round shape. The body is coated with yellow powder paint. The manufacturer's warranty on devices is five years. The user has the ability to adjust the temperature. One adjustment is enough for the boiler to maintain combustion automatically by opening and closing the damper.

You can purchase any of the above models at Thermo-Mir. If you have any questions, please contact our specialists. Solid fuel boilers STROPUVA – time-tested reliability!

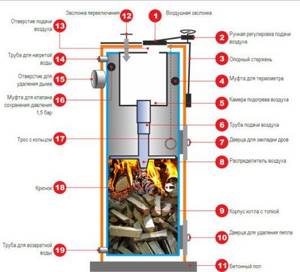

Boiler design

The boiler is a steel cylinder surrounded by a second steel cylinder of larger diameter, the structure is insulated. In the gap between the cylinders there is a heated coolant. At the front of the boiler there is a bi-thermal draft regulator (2). The design has a door for storing fuel (8), a door for removing ash (11) and an exhaust gas hole (5). There are also coolant supply and return pipes (14, 15) and a coupling for installing a thermometer (16). To improve the quality of combustion and heat transfer, an air heating chamber (4) is installed in the upper part of the combustion chamber. The boiler may include a grate and a bottom air supply regulator (19) for firing with peat and sawdust briquettes, or coal.

To achieve optimal heat removal, between the air heating chamber and the walls of the boiler combustion chamber, there is a gap along the entire perimeter through which smoke, washing the air heating chamber, enters the exhaust gas hole. A telescopic air supply pipe (7) is lowered into the combustion chamber, at the end of which an air distributor (9) is attached.

At the top of the air heating chamber there is an opening for air intake and an air damper (1). On the right side of the boiler there is a cable for lifting the air supply mechanism with a ring (12) and a fixing hook (13).

The purpose of the air distributor is to correctly distribute air in the combustion zones. The air distributor moves down as the fuel burns under the force of gravity.

It is not recommended to lift the air distributor during combustion: after lifting, the distributor may rotate around its axis and, when lowered, go deeper into the combustion center. As a result of turning and deepening of the distributor, the efficiency of the boiler decreases and the wear of the distributor increases.

* The diagram is shown conditionally; the actual location as well as the type of parts and components of the boiler may differ from the image in the figure.

| Wood-burning version of Stropuva | Universal version of Stropuva |

|

|

What does a solid fuel boiler consist of?

In the upper part, solid fuel heating boilers have an air damper that regulates the pressure inside the device. Next to it is a bi-thermal draft regulator. This, in turn, is connected to the support rod. Inside the cylinder there is a large air heating chamber. There is also a hole on the boiler body designed specifically for the removal of gases. There is a switching damper at the bottom of the air heating chamber. Next comes the air supply pipe.

On the front panel of the boiler there is a door for storing firewood. Behind it there is an air distributor. The fuel itself is located there. At the bottom of the boiler there is a special door for removing ash. The cable with the ring is designed to lift the air distributor. Below it there is a hook and a coolant pipe. On the left side, heating boilers have a coupling for a thermometer. Manufacturers also provide a mechanism for the valve, which is responsible for pressure. A lever is installed near the base of the boiler to switch the damper. It is located near the air supply pipe. With its help, you can easily choose between loading coal and firewood.

Reservation of work

The Stropuva boiler will delight you with long-lasting fuel combustion. But even in this case, you can miss the moment of the next bookmark. As a result, the temperature of the coolant in the heating circuit will begin to fall. To prevent this from happening, we recommend installing a backup electric boiler in the circuit. If it detects a temperature drop below the set limit, it will turn on and maintain the set temperature.

Electricity consumption will be small if you don’t forget to add firewood for 2-3 days. The vast majority of the time the boiler will burn, providing heat to consumers. Therefore, you should not expect huge expenses. In addition, the auxiliary boiler does not have to be as powerful as the main one - a model with a power 2-3 times lower is quite enough so as not to make your teeth chatter in the morning. We also recommend working on insulating your home so that it retains the accumulated heat longer.

Recommendations for operating a long-burning solid fuel boiler in Stropuva

- When filling the firebox with firewood, it is recommended to place larger logs in the upper part of the stack along the edges, and smaller ones (no more than 0.5 kg) in the central part. This is necessary to prevent the formation of a large amount of smoke during kindling.

- It is necessary to fill the firebox completely, this will allow the boiler to operate longer on one fill.

- When using firewood, the ash should be cleaned out once a month. When using coal, the ash is removed each time before adding a new batch of fuel.

- Air penetration into the firebox through the ash cleaning door is not allowed. The lower door must be closed while the unit is operating.

- The humidity of the firewood should not exceed 30%, otherwise, most likely the fuel will not burn at all, or will not burn enough, which will not allow the required coolant temperature to be reached.

- The air distributor should not be lifted during combustion, as Most likely, after lowering, it will take an incorrect position and sink deep into the combustion zone, this in turn will affect the service life of the boiler.

Reservation of work

The Stropuva boiler will delight you with long-lasting fuel combustion. But even in this case, you can miss the moment of the next bookmark. As a result, the temperature of the coolant in the heating circuit will begin to fall. To prevent this from happening, we recommend installing a backup electric boiler in the circuit. If it detects a temperature drop below the set limit, it will turn on and maintain the set temperature.

Electricity consumption will be small if you don’t forget to add firewood for 2-3 days. The vast majority of the time the boiler will burn, providing heat to consumers. Therefore, you should not expect huge expenses. In addition, the auxiliary boiler does not have to be as powerful as the main one - a model with a power 2-3 times lower is quite enough so as not to make your teeth chatter in the morning. We also recommend working on insulating your home so that it retains the accumulated heat longer.

Stropuva – long burning boiler

The top combustion principle ensures gradual combustion of the fuel. The full volume of fuel is loaded into the boiler, which is enough for the entire combustion cycle of the boiler (in Stropuva Village V30 - this is 31 hours). But only the top layer will burn at the same time - there will be enough thermal energy to maintain the set temperature without loss of power. In conventional solid fuel boilers (not shaft type), the entire volume of fuel after ignition releases the maximum amount of thermal energy depending on the heat capacity (as in a regular fire). Afterburning pyrolysis gases can extend the time of efficient operation of the boiler, but will not ensure fuel combustion for more than 6-8 hours, since any volume of fuel burns simultaneously. In Stropuva, thanks to the vertical design, only part of the fuel burns, releasing the energy necessary to maintain the temperature of the coolant and no more. Heat does not escape into the chimney.

Product Features and Benefits

A solid fuel heating boiler of the STROPUV brand has obvious advantages that not only justify its purchase, but also bring numerous advantages during operation.

- This is the most economical and efficient heat source for batteries.

- STROPUVA heaters have a reliable design; the stove will serve you faithfully for many years.

- This heating device has high technical characteristics.

- Quick payback due to affordable fuel prices.

- Adequate cost of the installation itself, made in Russia.

But the main highlight of products under the STROPUVA brand is the top combustion of fuel. It's simple - fuel is loaded into the boiler and ignited. Fire moves from top to bottom. This greatly increases the combustion reaction time and reduces the temperature. You yourself will feel how convenient it is to use this boiler when one load of firewood or coal will last for several days.

The boiler is a double barrel, firebox in a water jacket. The material is steel, 6 mm thick. Long-lasting combustion is achieved through the movement of a special round steel plate up to 20 mm thick. It is this that, when moving, prevents the flow of air to the fuel and ensures gradual combustion. A cable is attached to the plate, by which it must be lifted before loading again. In addition, the plate creates a kind of afterburning chamber above itself, where the flammable gas released by the coal, usually emitted into the atmosphere, burns. This property makes the STROPUVA furnace even more productive and efficient - approximately 1%-3% is added to the efficiency. Strong heating of the fuel is also facilitated by protection from a flexible bimetallic plate, which changes shape when heated, closing the air damper.

The company produces three models of furnaces with a capacity of 8 kilowatts. The STROPUVA boiler, which you can buy in our online store at the most affordable price, operates on one full load of coal for up to 120 hours (depending on the model)! Briquettes and firewood burn for up to 2 days. The stove will be a great addition to your home. We also sell wholesale - we invite various commercial organizations in the regions of Russia to cooperate, we have special offers for you. Call the numbers listed on the page for more information.

Boiler design Stropuva

To answer the question of whether it is possible to make a Stropuva cauldron with your own hands, you must first honestly determine the degree of your skill. If you are a jack-of-all-trades with a lot of ingenuity, then the process may be within your power. If you are a homemade DIYer, then most likely there will be no point, because the task is really not an easy one. To see this, let’s look at the design of the Stropuva boiler. It consists of the following main structural elements:

- double body;

- telescopic air duct;

- air distributor;

- automatic air supply control system.

Of course, long-burning boilers in Stropuv are equipped with doors and pipes for supply and return coolant. There will be no difficulties with simple elements, but it is simply impossible to make basic ones at home. Let's start with a telescopic pipe, how to make it yourself? This is unrealistic without factory equipment. In principle, we can end this here; the attempt failed. Hypothetically, let's say that you managed to make a telescopic duct that can be folded by pulling a cord.

The layout of the unit is really complex. You need to do the following:

- connect two pipes of different diameters;

- cut in pipes for supply and return coolant in the outer pipe;

- attach a chamber for heating the air in the inner pipe from above (exactly in the middle);

- in the chamber from below, fix an already manufactured telescopic air duct with an air distributor at the end;

- You should also make a pipe to remove smoke from the inner pipe;

- install doors;

- install an air supply control system.

In this case, everything should be as airtight as possible. Can you cope with such a difficult task? Most likely not. So Mr. Afanasy Budyakin from Kolyma thought that this task was impossible, so he came up with an analogue of the Stropuva boiler. He didn’t call him anything, but simply posted it online under the nickname “bybafonja.” That’s how the name “Bubafonya” stuck to the domestic long-burning stove. We'll tell you about it a little later.

Design of Stropuva boilers

An important advantage of all Stropuva boilers is their very pleasant appearance. The design of these devices is very simple. Essentially, this is a regular cylinder without any extra parts. Additionally, manufacturers use discreet neutral colors that do not irritate. The absence of many elements on the boiler makes it simple and at the same time safe to use. It is also worth noting its compactness. All this allows you to experiment with the installation location. In some cases, the boiler can be mounted directly in the center of the room. However, it can also occupy a small space in the corner of the room. The price for a long-burning Stropuva boiler is 50,000 rubles.

Stropuva boiler: chimney

To a greater extent, the efficiency of the boiler will depend on the draft in the chimney pipe. With low draft, combustion products will not have time to escape through the chimney, and as a result, the boiler will begin to smoke, so the room will gradually fill with smoke, and the combustion process in the firebox will slow down.

Typically, lack of traction occurs for the following reasons:

- The chimney height is insufficient. It should be 50 cm higher than the ridge;

- The chimney pipe is filled with combustion products (soot, tar, etc.);

- The chimney diameter is not wide enough;

- Incorrect dimensions of the horizontal chimney area (length should be at least 20 cm, but not more than 150 cm).

Increased traction leads to:

- increased combustion temperature;

- excessive fuel consumption;

- high noise during boiler operation.

When installing a chimney, special attention should be paid to fire safety. The chimney connection to the boiler must be made of metal

All joints must be tightly sealed. And one more thing - you need to regularly clean not only the chimney pipe, but also its horizontal part, because accumulations of resins and soot can ignite and cause a fire.

Operating principle of the Stropuva boiler

Once the flame is sufficiently hot, it will burn from top to bottom.

Both the original and the analogue of the Stropuva boiler work on the same principle. First you need to load the firebox with bitters. Let us immediately make a reservation that this can only be done after the boiler has completely burned the previous fuel supply, since the source of smoldering must be at the top. To start the boiler you need:

- pull the ring and lift the telescopic air duct;

- remove ash through the bottom door (1-2 times a week);

- fill the firebox with wood or coal, depending on the model of the unit (there are wood-burning and universal ones);

- Set fire to paper or cloth soaked in gasoline on top;

- lower the air duct and close the doors.

From one load of firewood the boiler works for a little more than a day, from a briquette - up to two days, and on coal - for five whole days.

As the fuel burns out, the air distributor moves down until it reaches the bottom. The air supply is controlled by a bimetallic plate. The developers have increased the efficiency due to the fact that an air heating chamber is built into the Stropuva boiler design. The latter enters the furnace at a temperature of about 400 degrees. At this temperature, pyrolysis gases ignite. But, unfortunately, the plate loses its properties and every month you need to make adjustments to the settings, and after a year, completely replace it with a new one.

Boiler duty cycle

The entire volume of fuel is poured into the boiler and ignited from above (see lighting instructions).

As the top layer of fuel burns, the boiler power increases to that required to maintain the set temperature of the system.

The fuel in the boiler burns slowly, the burning layer of fuel slowly sinks down. The air supply pipe also lowers under its own weight, supporting combustion.

As soon as the fuel has burned out, the cycle can be repeated again.

Firewood

Maximum combustion up to 18 hours.

STROPUVA S8

- Firewood / Briquettes

- Heating area: 50-80 m²

- Power: 8 kW

- Burning up to: 18 h

- Fuel capacity: 163.15 dm³

- Firewood capacity: 37 kg

53,000 rub. / piece RUB 75,715 / PC

Firewood

Maximum combustion up to 31 hours.

STROPUVA VILLAGE V30 kW

- Firewood / Briquettes

- Heating area: 200-300 m²

- Power: 30 kW

- Burning time: 31 h

- Fuel capacity: 341.88 dm³

- Firewood capacity: 78.43 kg

80,000 rub. / piece 89,000 rub. / PC

Firewood

Pellets

Coal

Maximum combustion up to 120 hours.

STROPUVA S20 U

- Coal / Firewood / Briquettes / Pellets

- Heating area: 100-200 m²

- Power: 20 kW

- Burning up to: 120 h

- Fuel capacity: 234.31 dm³

- Firewood capacity: 60 kg

101,000 rub. / piece RUR 148,850 / PC