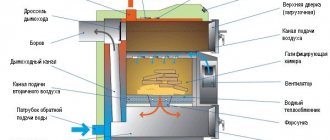

Dakon KP Pyro pyrolysis boilers are known in the countries of the Union of Independent States (CIS), that is, throughout the entire former USSR, precisely because of the two-chamber heat exchanger located both in the loading (upper) chamber and in the combustion chamber (lower).

The ceramic nozzle is located between these two chambers. The upper chamber is intended for gasification of fuel using hot gases, which are pumped by a fan. Through a ceramic nozzle, the released wood gas sequentially enters the lower chamber, where it is burned.

Dakon long-burning boilers are of very high quality, since the firebox is lined with fireclay lining and heat-resistant ceramic segments, which increase the efficiency of fuel combustion, while at the same time serving as a catalyst.

Table of characteristics of the Dakon Pyro pyrolysis boiler:

- Electrical supply: frequency 50 Hz, voltage 230 V.

- CO heating circuit temperature: from 65 to 95 degrees Celsius

- Operating pressure of the heating circuit CO: up to 2 bar.

Dakon KP Pyro boiler – pros and cons

The positive aspects of this rather well and neatly made boiler (this is a nod towards some domestic products - they could do the same):

- The Dakon boiler has a large fuel loading chamber, which immediately increases the operating period without attention from the owner or the stoker.

- The Dakon Piro boiler is designed for burning logs whose diameter does not exceed 130 millimeters. The maximum length of logs is directly dependent on the size of the combustion chamber in the boiler used.

- The Dakon KP Pyro boiler has a ceramic nozzle, which significantly improves combustion processes by burning pyrolysis gases in the upper combustion chamber.

- The Dakon heating boiler is very easy to regulate - for example, adjusting the primary air does not cause any problems even for beginners who are not familiar with the processes.

- The Dakon Piro pyrolysis boiler has a unique modern design.

- You can remove ash from this heat generator once over a period of time from 3 to 7 days.

- The large loading chamber allows you to increase the time intervals between fuel loadings.

As you can see, there are quite a lot of advantages. The downside is that the price is not the most humane, especially now when dealers are forced to increase prices for their boilers due to the difficult economic situation in the industry.

Dakon KP PYRO 24 Pyrolysis boiler 25 kW

Heating and hot water boiler power: 12-25 kW.

Fuel type: Solid (wood, briquettes)

Heated area: up to 250 m2

KP PYRO hot water boilers with a power from 18 to 40 kW are designed for burning wood with a maximum humidity of up to 20%. Pyrolysis combustion in a chamber with a special ceramic nozzle guarantees economical and environmentally friendly operation with high efficiency.

Solid fuel gas generator boilers Dakon KP Pyro 24 Solid fuel steel wood boilers with pyrolysis combustion.

Dakon KP Pyro pyrolysis boilers are highly efficient - fuel combustion is ensured by environmentally friendly decomposition of wood into a small amount of ash and wood gas

Advantages of DAKON KP PYRO boilers:

- a large fuel loading chamber ensures long-term operation;

- the boiler can burn logs with a diameter of up to 130 mm, the length depends on the size of the combustion chamber of a particular boiler;

- ceramic nozzle with hot combustion chamber ensures perfect combustion;

- simple adjustment of primary air;

- removing ash once every 3-7 days;

- modern design.

The stationary boiler KP PYRO is a gasifying heating boiler for family homes, workshops, temporary facilities with a heat loss of 10-40 kW. The heating system can be opened or closed by a pressure expansion tank with self-regulating or forced circulation of heating water.

Description of the boiler

The boilers are designed to burn wood logs with a maximum length of 430 – 580 mm in accordance with the given boiler type. For heating, you can use wood chips and briquettes, but only in combination with lump wood.

The boiler body is welded from steel 4-6 mm thick. At the top there is fuel loading. At the bottom there is a combustion chamber with ceramic blocks. The upper part is separated from the lower by a ceramic nozzle. At the rear there is a combustion products collector with an exhaust fan. In the front part there are upper (loading) and lower doors. The outside of the boiler body is thermally insulated - mineral wool, which is placed under the frame. On the top panel there is a control panel with adjustment elements.

The main air supply is ensured using adjustable segments in the side panels. Secondary air is heated at the rear of the combustion products manifold and piped to the injector.

Combustion of various types of fuel.

Recommended fuel is dry split wood and logs with a diameter of 100 mm and a maximum humidity of up to 20%. The length of logs and chips is from 430 to 580 mm (according to the type of boiler) and the heating value is from 15 to 17 MJ.kg

The tree must be dry! As the humidity of the boiler increases, its power decreases, the formation of tar increases, and its service life decreases. The power and operation of the boiler is guaranteed at a maximum humidity of up to 20%.

Wood briquettes

Wood briquettes have a higher heating value than wood logs, so it is necessary to reduce the amount of main air. The adjustment segments in the side panels must be adjusted to the 75% open position.

In the production of wooden briquettes, material with varying degrees of grain size is used. Under the influence of heat and raking, they can crumble and clog the nozzle. When heating with wooden briquettes, do not use a poker while loading the backfill into the loading chamber, only add the appropriate number of briquettes or lay it with lump wood.

Manufacturer: Bosch Termotechnika sro / BBT Thermotechnology CZ

Manufacturer: BOSCH GROUP

A little more theory from dealer brochures

As noted above, the Dakon boiler is very easy to operate - the power indicators are adjusted due to the special design of the combustion chamber with the ability to supply secondary and primary air, as well as suction - for this, a blower fan with an adjustable rotation speed is used.

For this heat generator, it is possible to connect external control devices - a programmer or a thermostat regulated by room temperature.

There is another big plus - a well-thought-out system for retaining flue gases when opening the combustion door. When you need to add firewood, the movement of flue gases in the firebox is such that there is no emission of smoke into the boiler room. Naturally, the chimney for the TT boiler must meet the manufacturer’s requirements.

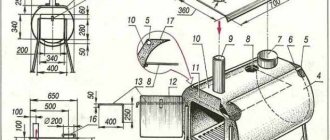

Steel solid fuel boiler Dakon DOR

Out of production

Main advantages:

Water heating boilers type DOR

- These are modern products of a new design, designed to operate on solid fuel. Combustion efficiency is ensured by the use of a new grate system and a new design of the combustion chamber using primary and secondary air together and with the ability to adjust the supply of additional air.

Advantages of DAKON DOR boilers:

- large loading funnel with an expanding entrance to the firebox;

- a new grate system that allows you to burn even lower quality fuel in a continuous cycle, with dust-free sifting of ash, with joint regulation of primary and secondary air;

- use of new non-asbestos materials for boiler thermal insulation;

- automatic power control with a direct-acting draft regulator;

- modern design.

- equipped with a thermomanometer to monitor temperature and pressure in the heating system.

- complete autonomy (independence from electricity)

- use of alternative fuels.

Hot water boiler DAKON DOR D

- designed for burning wood.

The main advantages of DAKON DOR D boilers:

- possibility of using alternative fuels.

- use of firewood with humidity up to 35%.

| Boiler name according to the manufacturer's catalog | DOR 12 | DOR 16 | DOR 20 | DOR 24 |

| Rated power, kW | 7-13,5 | 6-16 | 6-20 | 7-24 |

| Length, mm | 691 | 691 | 730 | 730 |

| Width, mm | 424 | 424 | 526 | 526 |

| Height, mm | 920 | 920 | 1040 | 1040 |

| Weight, kg | 158 | 166 | 200 | 215 |

| Prescribed fuel | Brown coal diameter 2-3 cm | Brown coal diameter 2-3 cm | Brown coal diameter 2-3 cm | Brown coal diameter 2-3 cm |

| Fuel consumption, kg/h | 3,2 | 4,7 | 6 | 7,6 |

| Chimney pipe diameter | 145 | 145 | 145 | 145 |

| Efficiency % | 78-84 | 74-78 | 74-78 | 74-78 |

| Out of production | ||||

| Boiler name according to the manufacturer's catalog | DOR 25 MAX | DOR 32 | DOR 32 D | DOR 45 D |

| Rated power, kW | 8-27 | 9-32 | 9-28 | 18-45 |

| Length, mm | 830 | 830 | 830 | 864 |

| Width, mm | 526 | 526 | 526 | 688 |

| Height, mm | 1040 | 1040 | 1060 | 1045 |

| Weight, kg | 232 | 240 | 240 | 320 |

| Prescribed fuel | Brown coal diameter 2-3 cm | Brown coal diameter 2-3 cm | Firewood | Firewood |

| Fuel consumption, kg/h | 7,9 | 8,9 | 8,4 | 14 |

| Chimney pipe diameter | 145 | 145 | 145 | 180 |

| Efficiency % | 78-84 | 74-78 | 75-82 | 76-82 |

| Out of production | ||||

Pyrolysis boiler Dakon KP Pyro owner reviews

Dakon solid fuel boilers receive fairly decent reviews. There is no sharp negativity or general admiration. Normal workhorses.

There are the following reviews for this pyrolysis Dakon:

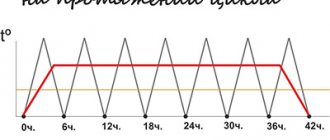

Valentin Sapko, Kaluga: I read reviews about Dakon on the Forumhouse and decided to purchase a boiler of this brand. And in order not to add firewood every 3 hours, I chose the Piro pyrolysis machine. The power of 18 kW is enough for me; we heat a house of 80 square meters. Why did you take such power? And you can’t buy less, we don’t have less. This is the smallest power that the supplier company has. They did the installation too. Everything was told by, I must say, smart guys. This is the first heating season. But immediately after the KChM you feel that you bought and installed the thing. Burning of one bookmark is 6-8 hours. There is no stated 12 hours. I don't need it.

There are also reviews on Dakon KP Pyro pyrolysis boilers:

Avtandil Zvigoev, Mokva: We had Dakon Kp Pyro 18 installed in the fall of 2013. Just when we finished closing the outline of the house. We installed a box under the roof, installed windows and doors, installed electricity throughout the house - the most basic lines. Then they installed a chimney and dragged the boiler into the boiler room. They then placed it on a temporary stand with a few bricks. And since then he has stood on these bricks. Because there are a lot of other more important concerns. And the Dakon boiler calmly copes with its responsibilities; we heat it 2 times a day. They wrote here that it doesn’t last for 12 hours. Well, yes, there is no combustion for 12 hours, but the house keeps the temperature calm. Why burn wood in vain? Insulate your home!

Here is such an interesting pyrolysis Dakon - it keeps itself warm and warm. Know, throw some firewood. It’s a pity, you can’t insert a “good-natured smiley” here, the site engine doesn’t allow it.

If you have any feedback on the Dakon boiler, please write it below in the comments form. There you can also chat about this boiler model.

Specification. The Dakon Piro boiler is supplied fully assembled, with lining and installed thermal insulation.

More on this topic on our website:

- Coal and wood boiler Dakon DOR - characteristics and reviews The coal and wood boiler Dakon DOR is manufactured by DAKON in the city of Krnov (Czech Republic). The boiler is intended, first of all,…

- Solid fuel boilers Dakon Dor 16 - reviews and installation examples We wrote a review about Dakon Dor solid fuel boilers produced in the Czech Republic on the pages of this site. Also published...

- Scheme of a simple pyrolysis boiler - making a pyrolysis boiler with your own hands The energy market has never been highly stable. Constant fluctuations in the prices of major fuels such as oil and natural gas…

- Solid fuel boiler ZOTA Mix - review and reviews from owners ZOTA boilers are produced at the Krasnoyarsk Heating Equipment and Automation Plant. The plant specializes in the production of solid fuel and electric heating boilers….

Solid fuel boilers Dakon - Dakon

| Name | Price | |

| Solid fuel heating boiler with top loading Dakon - DAKON DOR 12 (12 kW) | RUB 65,700.00 | Add to Basket |

| Solid fuel heating boiler with top loading Dakon - DAKON DOR 16 (16 kW) | RUB 69,120.00 | Add to Basket |

| Solid fuel heating boiler with top loading Dakon - DAKON DOR 20 (20 kW) | RUB 83,250.00 | Add to Basket |

| Solid fuel heating boiler with top loading Dakon - DAKON DOR 24 (24 kW) | RUB 86,040.00 | Add to Basket |

| Solid fuel heating boiler with top loading Dakon - DAKON DOR 25 MAX (25 kW) | RUB 89,100.00 | Add to Basket |

| Solid fuel heating boiler with top loading Dakon - DAKON DOR 32 (32 kW) | RUB 89,100.00 | Add to Basket |

| Solid fuel heating boiler with top loading Dakon - DAKON DOR 32 D (32 kW) | RUB 102,150.00 | Add to Basket |

| Solid fuel heating boiler with top loading Dakon - DAKON DOR 42 D (42 kW) | RUB 129,420.00 | Add to Basket |

Coal and wood boiler Dakon DOR pros and cons

The main advantages of the Dakon DOR solid fuel boiler include the following factors:

- The boiler is quite reliable, many users note this. Most users of Dakon DOR boilers are satisfied with their choice.

- Well-thought-out design for regulating draft and fuel combustion process.

- Quite affordable prices for Dakon DOR boilers. The cost of the “junior” boiler in the line is only 30,000 rubles from an official dealer who is ready to provide installation and service.

The main disadvantage of the Dakon DOR boiler is the insufficient volume of one fuel load. Initially, these boilers were intended for European countries, where winters are quite warm.

In the case of Russia, when in the Siberian expanses -40C is quite common and when -50C is also a normal phenomenon, such boilers have to be heated often. The frequency of the owner's approaches to the boiler is the biggest disadvantage of the Dakon DOR boiler.

More on this topic on our website:

- Wood and coal boiler Viadrus Hercules U22 reviews and table Boilers, which are produced under the Viadrus brand at Czech and Slovenian factories, in the Hercules modification with a capacity of 11 to 58 kW,…

- Pyrolysis boiler Dakon KP Pyro - review and reviews Today we have “for starters” pyrolysis boilers under the Dakon brand. And, since this is a well-known brand in the “solid fuel environment”, then...

- Solid fuel boilers Dakon Dor 16 - reviews and installation examples We wrote a review about Dakon Dor solid fuel boilers produced in the Czech Republic on the pages of this site. Also published...

- Solid fuel boiler KChM 5 - technical characteristics and reviews KChM 5 boilers are produced by the Kirov plant, founded in the 18th century. Over the years of operation, the boiler has proven itself to be very reliable and…

Solid fuel steel boilers Dakon DOR F

Hot water boilers of the DOR F type are modern products of a new design, designed to operate on solid fuel. Combustion efficiency is ensured by the use of a new grate system and a new design of the combustion chamber using primary and secondary air together and with the ability to adjust the supply of additional air.

Advantages of solid fuel boilers DAKON DOR F:

- large loading funnel with an expanding entrance to the firebox;

- a new grate system that allows you to burn even lower-quality fuel in a continuous cycle, with dust-free sifting of ash, and joint regulation of primary and secondary air;

- use of new non-asbestos materials for boiler thermal insulation;

- automatic power control with a direct-acting draft regulator;

- modern design.

- equipped with a thermomanometer to monitor temperature and pressure in the heating system.

- complete autonomy (independence from electricity)

- use of alternative fuels.

Water heating boiler DAKON DOR D is designed for burning wood.

The main advantages of DAKON DOR F boilers:

possibility of using alternative fuels.

use of firewood with humidity up to 35%.

Technical parameters of DOR boilers:

| Unit | DOR F 12 | DOR F 16 | DOR F 20 | DOR F 24 | DOR F 27 | DOR F 32D | DOR F 45D | |

| Rated power | kW | 13,5 | 16 | 20 | 24 | 27 | 28 | 45 |

| Efficiency | % | >76 | 82 | 82 | ||||

| Pressure permissible excess operating pressure/maximum test pressure | bar | 2 / 4 | ||||||

| Attach. input T1 and output T2 | — | G 1 1/2″ male thread | G 1 1/2″ male thread | DN70 external thread | ||||

| Height | mm | 920 | 875 | 990 | 990 | 990 | 1060 | 1045 |

| Width / total width | mm | 425/600 | 425/600 | 535/700 | 535/700 | 535/700 | 535/700 | 688/770 |

| Depth/total depth | mm | 691/730 | 691/730 | 730/770 | 730/770 | 830/870 | 830/870 | 864/980 |

| Combustion chamber volume | l | 26 | 26 | 46 | 46 | 61 | 63 | 115 |

| Boiler weight without water | kg | 155 | 160 | 200 | 215 | 230 | 240 | 320 |

| Boiler water volume | l | 46 | 46 | 56 | 57 | 63 | 64 | 73 |

| Main fuel | Brown coal - (nut 1) | firewood | ||||||

| Fuel consumption | kg/h | 5,3 | 6,4 | 8,5 | 10,0 | 11,2 | 8,8 | 13,8 |

| Reserve fuel | Firewood, brown coal - dia. more than 5 cm (walnut 2), brown coal briquettes, hard coal, coke, compressed fuel | brown coal - dia. more than 5 cm (walnut 2), brown coal briquettes, hard coal, coke, compressed fuel | ||||||

| Chimney pipe diameter | mm | 145 | 180 | |||||

| Weight flue gas flow (at minimum/nominal power) | g/s | 6,4/12,4 | 5,5/13,2 | 6,1/20,5 | 7,0/24 | 6,0/23,2 | 7,1/22,1 | 15,0/37,7 |

| Minimum operating traction | Pa | 18 | 18 | 30 | 30 | 30 | 26 | 36 |

| Operating temperatures | OS | 65 — 95 | ||||||

| Flue gas temperature | OS | 260 | ||||||

For all solid fuel boilers, it is recommended to install a heat accumulator and a Laddomat mixing device into the system.

Buy DAKON solid fuel boilers in the Comfort-Eco online store.

Maintenance of solid fuel boilers