The Siberia gas boiler has left its competitors far behind in many respects. Having recently appeared on the market, the products are popular, occupying the first lines of ratings in positions related to quality and reliability. The equipment, differing in technical characteristics, is used for heating premises of any size - from residential buildings to industrial enterprises. Consumers are attracted to Siberia boilers by their stylish design, innovative solutions and impeccable technical characteristics.

About company

The owner of the Siberia brand is ZAO Rostovgazoapparat. This is a large company producing gas equipment. The year the plant was founded is 1888. Location is Rostov-on-Don. The first in the USSR, in 1959, began to produce gas boilers - AOGV-80. Today the enterprise is an example of automation and robotization of production processes. Products produced by the plant last 20 years or more.

Device

• Heat exchanger material - carbon structural steel.

• Automatic SIT unit consisting of a magnetic valve, a modulating thermostat for on-off switching and a thermoelectric device that controls the flame. There is a re-ignition and fuel pressure stabilizer, piezo ignition and a gas filter.

• Atmospheric burner. Material: heat-resistant steel. Can operate on reduced fuel pressure.

• Powder coated housing.

• Foil heat insulator – to reduce heat transfer and increase efficiency.

• Capillary type thermometer.

Floor-standing gas boiler Siberia 11K

Rostov-on-Don, Lenochnaya, 3

+7+7

Purpose: home water heating and hot water supply. Siberia boilers are resistant to significant changes in gas pressure, are completely energy independent, and have increased efficiency. The design uses basalt fiber - a key element of thermal insulation for spacecraft.

Technical equipment:

- Heat exchanger made of carbon structural steel;

- Automation unit (SIT): magnetic valve, modulating thermostat with active instant on/off function, thermoelectric flame control device with re-ignition lock, pressure stabilizer, piezo ignition, gas filter;

- Atmospheric burner made of heat-resistant stainless steel (Polidoro);

- Capillary thermometer with increased capillary volume;

- Thermal insulation foil using basalt fiber;

- Powder enamel coating of the body.

| Model | power, kWt | Peculiarities | Chimney diameter, mm | Dimensions, mm (HxWxD) | More details |

| 11 | 11,6 | heating only | 130 | 850x280x560 | |

| 17 | 17,4 | heating only | 130 | 850x280x560 | |

| 23 | 23,2 | heating only | 140 | 850x380x560 | |

| 29 | 29 | heating only | 140 | 850x380x560 | |

| 35 | 35 | heating only | 140 | 850x380x560 | |

| 11K | 11,6 | heating + hot water | 130 | 850x280x560 | |

| 17K | 17,4 | heating + hot water | 130 | 850x280x560 | |

| 23K | 23,2 | heating + hot water | 140 | 850x380x560 | |

| 29K | 29 | heating + hot water | 140 | 850x380x560 |

| Model | 11 | 11K | 17 | 17K | 23 | 23K | 29 | 29K | 35 |

| Rated thermal power, kW | 11,6 | 11,6 | 17,4 | 17,4 | 23,2 | 23,2 | 29 | 29 | 35 |

| Reduced gas consumption | |||||||||

| natural, m3/h | 1,18 | 1,18 | 1,76 | 1,76 | 2,3 | 2,3 | 2,94 | 2,94 | 3,75 |

| liquefied, kg/h | 1 | 1 | 1,21 | 1,21 | |||||

| Approximate heating area, m2 | up to 125 | up to 125 | 100–200 | 100–200 | 100–250 | 100–250 | 150–300 | 150–300 | 150–400 |

| Flue gas efficiency, % | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 | 90 |

| Water temperature setting limit, °C | 90±5 | 90±5 | 90±5 | 90±5 | 90±5 | 90±5 | 90±5 | 90±5 | 90±5 |

| DHW at Δt=35°C, l/min | 3,8 | 5,5 | 7 | 8 | |||||

| Connecting thread of fittings, inch | |||||||||

| for gas supply | G½ | G½ | G¾ | G¾ | G¾ | G¾ | G¾ | G¾ | G¾ |

| Inlet/outlet | |||||||||

| to the heating part | G1½ | G1½ | G2 | G2 | G2 | G2 | G2 | G2 | G2 |

| to the water heater parts | G½ | G½ | G½ | G½ | |||||

| internal diameter of the chimney, dm, not less | 1,25 | 1,25 | 1,25 | 1,25 | 1,38 | 1,38 | 1,38 | 1,38 | 1,38 |

| Overall dimensions, mm | |||||||||

| height | 850 | 850 | 850 | 850 | 850 | 850 | 850 | 850 | 850 |

| width | 280 | 280 | 280 | 280 | 380 | 380 | 380 | 380 | 380 |

| depth | 560 | 560 | 560 | 560 | 560 | 560 | 560 | 560 | 560 |

| Weight, kg | 52 | 56 | 56 | 59 | 65 | 70 | 70 | 76 | 90 |

terma.su

Series from Siberia

The manufacturer offers three series:

- Premium Topline-24. Premium models are designed for small buildings. Double-circuit - you can heat water for domestic needs. A special feature of the series is electronic ignition. There is ionization control of fire and exhaust gas. There is an anti-scale function. Efficiency 90%.

- Comfort Siberia. Modifications 23, 29, 35, 40, 50 (heat output, kW). Any option is offered - single-circuit or double-circuit. Designed for large rooms.

- Economy Siberia. Produced since 2005. Four models, differing in the number of circuits and power - 11.6 kW and 17.6 kW. The letter “K” in the marking means two circuits. It is possible to switch to liquefied gas - you can insure yourself in case of an accident in the gas pipeline. The cases are covered with enamel, which protects from mechanical damage.

Characteristics of the floor-standing gas boiler Siberia 11

___________________________________________________________________________

The floor-standing gas boiler Siberia 11 (AOGV-11.4) is intended for water heating of residential premises. The device is not intended for collecting water for domestic needs.

The Siberia 11 floor-standing boiler operates on natural or liquefied gas with a nominal pressure of 1274 Pa or 2940 Pa, respectively, and ensures stable operation at natural gas pressure in the range of 65 mm water column. ... 280 mm water. Art.

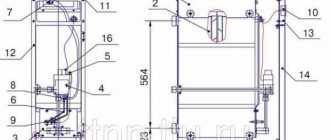

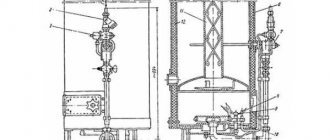

When natural gas pressure drops below 130 mm water. Art. The thermal power of the unit decreases proportionally. The vacuum in the chimney for normal operation of the device is from 2.94 to 29.4 Pa (from 0.3 to 3.0 mm water column). The operating water pressure of the heating system is 100+20 kPa (1.0+0.2 kgf/cm2), in a closed heating system it is necessary to install a safety valve at a pressure of no more than 150 kPa (1.5 kgf/cm2). Main technical characteristics of gas boilers Siberia 11 (AOGV-11.4) Thermal power: 11.6 kW Heated area: 125 m3 Number of circuits: single-circuit Efficiency: 85% Automation: 630 EUROSIT Combustion chamber: open Heating system type: open+closed Heat exchanger material: steel Installation type: floor-standing Dimensions: 850x280x560 mm, (HxWxD) Net weight: 52 kg Construction of the Siberia 11 floor-standing boiler The boiler unit consists of the following main parts (see Figure 1): heat exchanger, cover, gas exhaust device, walls, ignition burner, main burners, frames, gas block. Automation 630 EUROSIT provides: stabilization of gas pressure on the main burner, maintenance of the set water temperature, turning on the main burner when there is a flame on the ignition burner, turning off the device when the ignition burner goes out, in the absence of vacuum in the chimney.

Fig.1. Floor-standing gas boiler Siberia 11 with water circuit

1 - gas exhaust; 2 - heat exchanger; Z – main burner; 4 – gas valve; 5 — cover with piezo ignition; 6 - thermocouple; 7 — traction sensor; 8 — thermal breaker; 9 — ignition burner (pilot burner), 10 — thermometer; 11 - cover; 12 – left/right side wall; 13 - panel; 14 - anterior wall; 15 - frame; 16 – thermostat indicator knob (magnetic valve button). Automation 630 EUROSIT consists of: a gas unit, a draft sensor, a thermocouple, an ignition burner (pilot), a piezo ignition, a thermal breaker. The gas block consists of: a thermostat, a magnetic valve, a stabilizer.

Fig.2. Gas block

1- thermostat indicator knob; 2- magnetic valve button; 3-piezo ignition.

Fig.3. Gas block (shown without cover)

1- pointer handle (magnetic valve button); 2- gas flow adjusting screw; 3- adjusting screw of the ignition (pilot) burner; 4-screw pressure stabilizer. Conditions for installation and connection and installation of gas boilers Siberia 11 The device is installed in the kitchen or other non-residential premises at a distance of at least 15 cm from the walls. The premises must meet the requirements of the current “Safety Rules for Gas Distribution and Gas Consumption Systems”. The temperature of the room in which the boiler is installed should not be lower than +5°C. A gas valve is installed on the gas supply pipe in front of the unit, blocking gas access to the apparatus. The gas pressure in front of the boiler must correspond to the gas pressure indicated on the plate. The unit can be connected to the heating system on the left and right, since the fittings are located on the rear wall. An approximate open diagram of the heating system is shown in Figure 5 and Figure 6, an approximate closed diagram of the heating system is shown in Figure 7. To improve the operation of the Siberia 11 gas boiler in a closed system, it is necessary to install a circulation pump in the heating system. In a closed heating system, it is necessary to install a safety valve for a pressure of no more than 150 kPa (1.5 kgf/cm2). The pipeline couplings must be precisely adjusted to the location of the inlet fittings. The voltage transmitted to the assembly units of the device can break the tightness of the heat exchanger and supply pipelines. The chimney structure to which the device is connected must comply with SP42-101-2003 “General provisions for the design and construction of gas distribution systems.” When connecting the device to a chimney, fire safety requirements must be met. An approximate diagram of connecting the device to the chimney is shown in Figure 4.

Rice. 4. Connecting the Siberia 11 floor-standing boiler to the chimney and gas pipeline

1 - gas tap; 2 - gas supply pipe; 3- smoke exhaust pipe; 4 – apparatus; 5 - gas filter The installation of the Siberia 11 (AOGV-11.4) boiler and heating system is carried out by a specialized organization that has the right to carry out this type of work in accordance with the project, in accordance with the current rules and regulations and approved by the gas management department. After installing the boiler to the heating system and gas pipeline, the latter must be checked for leaks and tightness. Pipeline connections are checked by soaping. Any gas or water leaks detected during testing should be eliminated before turning on the device. After checking the device and system for leaks, it is necessary to check the operation of automatic and locking devices. The pilot burner flame must intensively wash the thermocouple and ensure ignition of the main burner. When operating floor-standing gas boilers Sibiriya 11, at the initial stage of commissioning, drops of water may appear from under the bottom of the heat exchanger - this is the result of condensation of water vapor due to the temperature difference. When the entire heating system warms up, condensation will stop.

Fig.5. Approximate open diagram of a heating system

1 - signal pipe; 2 - main riser; 3 - expansion tank; 4 - apparatus; 5 - radiator; 6 - return water pipeline; 7 - drain line; 8 — make-up water supply.

Fig.6. Approximate open diagram of a heating system using a pump

1 - signal pipe; 2 - main riser; 3 - expansion tank; 4 - device; 5 - radiator; 6 - return water pipeline; 7 - drain line; 8 - make-up water supply; 9- tap; 10- filter; 11- pump.

Fig.7. Approximate closed diagram of a heating system

1 - main riser; 2- boiler; 3- radiator; 4- return water pipeline; 5- drain line; 6- make-up water supply; 7- membrane expansion tank; 8- automatic air release valve; 9- pressure gauge; 10-safety valve 150 kPa (1.5 kgf/cm2); 11- tap; 12- filter; 13- pump.

___________________________________________________________________________

___________________________________________________________________________

___________________________________________________________________________

___________________________________________________________________________

___________________________________________________________________________

___________________________________________________________________________

wssm.ru

Technical design features

High-strength heat exchanger. In its manufacture, practical materials were used - steel or cast iron, and automatic welding. Service life – 25 years.

- Devices with two circuits heat water in a flow-through copper radiator.

- Thermal insulation layer protects users from burns.

- They are used in any water supply systems - both forced and natural water circulation are suitable.

- Energy independence. Not connected to electrical networks.

Features of wall modifications

They are in high demand - functional, practical, compact. Advantages:

- Gianoni bithermic radiator made of copper.

- Polidoro is an alloy steel burner.

- Honeywell - automatic flame modulation.

- Anti-freeze function.

- LCD display with current information and error codes that occur during failures.

By connecting a room thermostat, you can reduce fuel consumption.

The lineup

The manufacturer offers several lines:

• AKGV and AOGV. Accordingly, double-circuit and single-circuit. Installed on the floor. Heating capacity 11-35 kW. The material of heat exchangers is most often carbon steel. They heat areas of 125-400 square meters. Water consumption - 4-8 l/min at 35°C.

• KCHGO. Powerful devices 16-50 kW. They heat large buildings, warehouses, and production workshops. The radiator is cast iron.

• Top Line. They hang it on the wall. 24,000 W. Copper heat exchangers. Designed for simultaneous servicing of several water intake points. Designed for houses up to 200 sq. m.

• Aqua. 18,000-23,000 W. This is more of a water heater than a heating boiler. Ignition – piezo/electronic.

The best and most famous models: characteristics and prices

Classic floor-standing boilers Siberia

Classic, inexpensive and most popular boilers with a steel heat exchanger. They are distinguished by their compact size, heat exchanger steel thickness of 4 mm, reliability and reasonable price. Efficiency is 90%, gas consumption of the 11.6 kW model is only 1.18 m3/hour. Available in 11, 17, 23, 29 and 35 kW versions. There are also double-circuit models; they come with the prefix “K” (for example, Siberia 11K) and cost only 5-15% more than single-circuit ones.

Otherwise, after more than 12 years of operating experience, there are practically no serious service complaints; the model is considered the most successful and most reliable of domestic gas boilers. It has almost all the previously described disadvantages - sensitivity to clogging, noisy ignition. Please note that the maximum permissible operating pressure is only 1 bar, so it is not recommended to use the model in closed systems, where the operating pressure is usually 1.5-2 bar.

KCHGO series

One of the best Siberia gas boilers for heating a private home. This is a larger and heavier model with a durable cast iron heat exchanger. Cast iron is practically not subject to corrosion, so such heat exchangers last 30 years or more, although they are much more expensive. Unlike the previous model, the permissible operating pressure is now 3 bar, which allows the boiler to be used in any domestic closed heating systems with forced circulation of coolant. Available in 16, 25, 40, 50 kW versions.

The burner and automation of the boiler are still the same - the famous Italian EuroSit and Polidoro, so the gas consumption remained at the same level - 1.7 m3/hour for the 16 kW model. Otherwise, everything is the same as with classic steel floorplates. A significant drawback is the lack of dual-circuit versions. Prices for cast iron models, although quite high, are much lower than foreign analogues and are among the lowest among domestic ones

Top Line Series

A mounted model, the body of which already contains all the necessary modules of the heating system (expansion tank, circulation pump, safety group, etc.). It is distinguished by the presence of a smoothly modulated burner, which is reflected in the maximum gas consumption - 2.65 m3/hour with a power of 24 kW. The copper heat exchanger is more resistant to corrosion than steel and more thermally conductive. But in dual-circuit models it is bithermic (double), which means almost zero results when washing it and vulnerability to scale accumulation. Therefore, it is imperative to use soft purified water as a coolant and change it as rarely as possible.

Among other things, there is protection against overheating and freezing, and the ability to connect an external thermostat. The model is quite new and has only been in use for a few years; during this time there have been no serious service complaints. A significant drawback is the difficulty of acquiring it, since it is still rarely found in the assortment of online stores. First of all, this is due to the lack of versions of other power: only Top Line 24 kW (single-circuit) and Top Line 24C (double-circuit) are available.

Cost: 21,500-26,000 rubles.

Criterias of choice

• Power – the higher it is, the larger the heated area. It is stated in the labeling.

• Dimensions of the room. The calculation of the required heating capacity is carried out taking into account the dependence: for 10 sq. m. – 1000 W. It is not recommended to operate the device at maximum - this increases the wear of its elements. The value needs to be increased by adding 30%.

• Climate.

• Insulation of the building.

• DHW (hot water supply).

• Boiler type. In an apartment it is more convenient to use a wall-mounted version, in a private house - a floor-mounted one.

Installation

The kit comes with a passport and instructions. The latter is necessary to familiarize yourself with the device, operating principle and rules for using the boiler. After reading the instructions, the user will be able to find out how to turn on the device. It is advisable to entrust the installation to specialists. Installation features:

• Registration of permission for installation - from gas workers.

• Installation is carried out by specialists with a license for the relevant work.

• The kit does not include an expansion tank and a circulation pump - you will have to buy them additionally.

• The device is placed against the wall, so you must leave a gap - at least three centimeters.

• For surface mounting, the device requires a foundation. Usually it is made of brick. Wall-mounted models are firmly fixed.

• There must be no gas leakage during connection. Connections must be carefully insulated.

• If you start the device for the first time, condensation will accumulate on the heat exchanger, which will disappear when the system warms up.

How to use the equipment?

Without violating the operating rules, you can significantly extend the service life of gas appliances:

• Do not turn on the boiler with a broken burner or a clogged chimney.

• The chassis must be grounded.

• When using antifreeze as a coolant instead of water, you need to purchase only a certified product. Containing ethylene glycol is prohibited.

• Water should not heat above 95 degrees.

• When installing the device near a wall that is covered with a fire-hazardous material, it is necessary to make a gasket made of steel or asbestos.

• The device may only be turned on after the system has been filled with water/antifreeze.

• Clean your chimney and filters annually. Make sure all connections are tight.

Owner reviews of Siberia gas boilers: advantages and disadvantages

| Advantages | Flaws |

| Reliable, practice-tested design and clear operating principle | Owners often note noisy ignition and pilot burner operation. |

| The cost of both steel (from 19 thousand rubles) and cast iron (from 33 thousand rubles) models is lower than foreign analogues and lower than many domestic market leaders such as Lemax | Requirement for cleanliness in the boiler room and regular maintenance (cleaning the heat exchanger, burner, igniter, solenoid valve and thermocouple) |

| High technical characteristics and efficiency | Sometimes mediocre build quality, typical of domestic technology |

| Availability of both single-circuit and double-circuit models | According to reviews from owners of dual-circuit models, the performance of hot water supply is often insufficient during long-term use, which is why it is necessary to reduce the volume of consumption by only slightly opening the hot water tap |

| Availability of models with durable cast iron heat exchanger | Due to the simple design and principle of removing combustion products, an incorrectly designed chimney causes backdraft, extinguishing both the burner and the wick |

| Energy independence - all floor-standing models do not require connection to the electrical network | |

| Compact size, nice design | |

| Adaptability to unstable gas pressure, hard, not the purest water used as a coolant | |

| The presence of a layer of thermal insulation |

Model overview

Siberia17К

Floor installation. Simple design. Minimum functions. Having found out how much the 17 K modification costs, as well as technical parameters, consumers willingly purchase it. Two circuits. Heating capacity 17.4 kW. Heats an area up to 200 square meters. Efficiency 90%. Open combustion chamber. Fuel consumption – 1.21 kg/h and 1.76 m3/h – liquefied and natural gas, respectively. Mechanical control type. Protection – gas control. Weighs 59 kg. Width 28 cm. Height and depth are standard for Siberia - 85 and 56 cm, respectively.

Siberia KCHGO-25

Single-circuit floor-standing convection boiler. Heating of an area up to 270 sq. m. Estimated price 37,700 rubles. 25,000 W – heat output. Cast iron heat exchanger. 2.45 m3/h of natural gas. Mechanically controlled. Gas control. 115 kg – weight.

AOGV-17.4

Floor installation. Does not respond to pressure changes in gas pipes. Non-volatile. Thermal insulator with basalt fiber. Auto control. Steel radiator. Heats up to 180 sq. m. SIT. Equipped with a magnetic valve that resists contamination. Piezo ignition.

TopLine 24

Wall-mounted version. Copper heat exchanger. Capacity 12 l/min at 25 °C - it decreases with increasing temperature. Depending on the power of the device, you can heat an area of 30-200 square meters.

AOGV 11.6

Budget modification. Approximate price – 10,000 rubles. One circuit. 11.6 kW – heat output. Efficiency – 87%. Floor installation. No auto-ignition. Open camera. Non-energy independent, like all Siberia gas devices.

Gas boiler SIBERIA 11 (AOGV-11.6/3)

Description

Gas single-circuit boiler Rostovgazoapparat series Siberia 11 (AOGV-11.6-3) (Siberia) is intended for floor installation, manufactured in Russia, intended for water heating of a country house, cottage and office premises. Siberia boilers operate on main (natural) gas (methane) and are designed for constant operation, are resistant to significant changes in gas pressure, are completely energy independent (do not require connection to a 220 Volt electrical network), and have increased efficiency. The heating device can be converted to work with liquefied gas (propane-butane). The design uses basalt fiber - a key element of thermal insulation for spacecraft. Features and advantages are the reliability and durability of the gas boiler, which especially sets the device apart from its competitors.

The fully automatic control system of the device allows you to regulate the gas pressure on the burner, in case of pressure drops in the main line, safely turn on the boiler burner in the presence of a pilot flame, and automatically turn off the boiler when the pilot goes out and there is no vacuum (draft) in the chimney. The gas valve allows you to maintain the specified temperature of the coolant in the heating system.

The power of the gas single-circuit boiler Rostovgazoapparat Siberia 11 (AOGV-11.6-3) (Siberia) is 11.6 kW, effective operation in rooms whose area does not exceed 115 sq. meters with ceiling heights up to 3 meters. The total volume of the room should not exceed 230 cubic meters. meters. You can view the full parameters of the gas boiler on our website in the technical specifications section.

The store warranty for this type of equipment is 12 months.

Distinctive features:

- Efficiency of the device: efficiency, workmanship and reliability of the device;

- Convenient installation and safe operation;

- Available service and repair parts;

- Intuitive controls and low noise operation;

- Aesthetic design and compact dimensions;

- The body is coated with powder enamel;

- The heat exchanger is made of heat-resistant carbon steel of a cylindrical shape;

- Gas valve EUROSIT 630, made in Italy;

- Polidoro atmospheric burner, made in Italy, made of high-alloy heat-resistant stainless steel;

- Capillary type thermometer;

- Execution in foil thermal insulation;

- Non-volatile, does not require connection to a 220 Volt network;

- Piezo ignition;

Lemax or Siberia - which is better?

When choosing a domestic inexpensive boiler, the consumer has to compare it not only with European analogues, which are superior in price, but also with products manufactured in Russia. Siberia and Lemax are products of domestic enterprises. Lemax is a trademark of the Taganrog plant. This is a young production that has been supplying its products to all regions of the Russian Federation since 2002. Both brands have an efficiency of 90%. Siberia outperforms Taganrog competitors in the ranking of demand - consumers are attracted to the products of Rostovgazoapparat CJSC by efficiency, heat transfer, appearance and ease of operation. Both plants produce energy-independent models with steel and cast iron heat exchangers. Reviews about Lemax products are neutral - not “premium”, but quite reliable and unpretentious for their cost - a steel device with a power of 10,000 W costs 13,000 rubles, a cast iron device 19,000 W costs 30,000 rubles.

Siberia or Lemax: which is better

Floor-standing gas boilers have a similar, slightly more complex design, but similar automation and burners. The efficiency of almost the entire Lemax model range is also 90%, but gas consumption is on average 10% higher. For example, Lemax Premium-16 kW has a maximum gas consumption of 1.9 m3/hour. Lemax boilers are quieter, and even steel models are designed to operate in a circuit with a pressure of up to 3 bar. However, their cost is 10-20% more expensive.

Siberia is more reliable, more economical, simpler and cheaper. But it is deprived of the above-described advantages inherent in the Lemax model range. In general, both manufacturers are worthy of attention and it is not for nothing that they are sales leaders among domestic manufacturers of gas boilers.

Review of Lemax gas boilers The most famous and widespread among domestic models