What is corrugation and why is it needed for exhaust devices?

In kitchen exhaust systems, corrugated pipes are used as air ducts through which combustion products and evaporations resulting from cooking are evacuated into the ventilation shaft. The devices differ in diameter, length and material from which they are made. Corrugation is made from galvanized and stainless steel, aluminum, and various polymers. Products for exhaust gas removal have a round or square cross-section. It is selected taking into account the shape and size of the hood neck, as well as the ventilation duct itself. Corrugated pipes are also used to remove burnt gases in columns and mounted boilers.

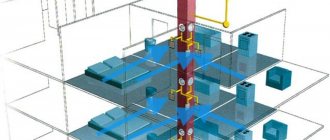

Gas water heater exhaust system

Forced exhaust systems prevent the spread of unpleasant odors that form in the kitchen during the combustion of organic compounds. In addition, there is no need to open windows to check the kitchen, and grease vapors do not settle on the cladding, furniture and ceiling, so the room is always kept tidy and clean.

Corrugated pipe and its scope of application

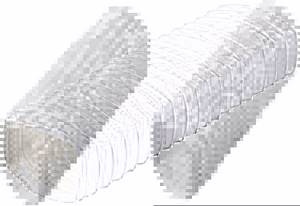

Corrugation is a hose or pipe that can stretch, compress and rotate in any direction without compromising the internal diameter. It consists of a frame, usually wire, and a sheath made of PVC, steel or aluminum foil and other materials. It is used for the installation of various engineering systems: water supply, heating, gas communications, heated floors, ventilation, etc. In everyday life, a corrugated pipe is mainly used to connect a kitchen hood to a general house ventilation system. Thanks largely to the corrugation, various odors and vapors that are formed during the cooking process are removed from the kitchen.

A corrugated pipe is needed to remove steam, odors and combustion products into the ventilation duct PHOTO: mssupply.com

Classification and use of corrugation

Corrugated pipe is presented on the building materials market in a wide variety of versions - these are small-diameter colored models made of plastic and serious water-permeable corrugations made of stainless steel. Material, size, color, price - all this for any buyer.

It is difficult for a novice home handyman to choose exactly what is ideal for solving the problems that arise.

Types of corrugated pipes

One of the convenient and simple solutions for the kitchen is to use a corrugated pipe to connect the hood to the ventilation system.

In order to buy exactly what you need, not to get lost among a large number of offers and not to overpay for an air duct, you need to understand a little about the main types and purpose of corrugations.

Due to inexperience, you can choose a completely different type of pipe for ventilation, choosing a color or material that will harmoniously fit into the interior

Corrugation is actively used by builders and home craftsmen as an important element in arranging communications.

Its popularity is due to its high strength, variety of sizes and materials, and long service life.

Large diameter corrugated pipes of 3.0-3.6 m can often be seen under roads and railway tracks. They are installed to perform a culvert function

In appearance, corrugation can be rectangular or round. For a kitchen hood, buy a round air duct.

Corrugated versions with a rectangular cross-section are more often used in production and warehouse premises

You can often find corrugated pipes made from the following materials:

- Cink Steel;

- stainless steel;

- aluminum;

- textile;

- high and low pressure polyethylene;

- polyvinyl chloride

The scope of application depends on the type of material and diameter of the finished product. For the installation of domestic ventilation, corrugated aluminum and stainless steel are often purchased.

The plastic corrugation connecting the hood to the ventilation duct creates more noise than its aluminum counterpart

According to the manufacturing method, corrugated pipes are divided into:

- frame;

- spiral-wound.

The first type of product is a metal frame covered with aluminum foil or polymer film.

These are flexible air ducts. They have the ability to return to their original appearance without deformation after stretching the corrugation to its full length.

Spiral-wound corrugation is made from stainless and galvanized steel and aluminum. It costs significantly more than frame analogues

The second type of air ducts is made from metal strips. The finished product is half flexible - it can stretch 2-3 times, but cannot return to its original state.

You will have to make an effort to give such a pipe the desired shape, and traces of deformation will be clearly visible.

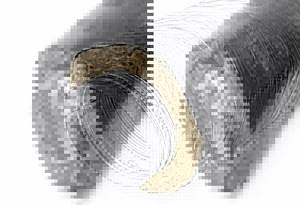

Many manufacturers offer flexible corrugation with and without thermal insulation. The first option allows you to expand the scope of use of the products.

Thus, with the help of four-layer flexible pipes, ventilation ducts can be laid both indoors and outdoors. And the distance will not be of fundamental importance.

In the manufacture of thermally insulated products, mineral wool or glass wool is used

Scope and nuances of using corrugation

Different types of corrugated products, which stand out for their size and type of material, clearly indicate the areas of application of this material. In addition to electrical and sewer systems, corrugations are widely used in everyday life. Here, pipes with a diameter of 100-150 mm are mainly used. But sometimes models with a cross-section of 200 and 300 mm are required.

Textile ventilation ducts are used mainly in production workshops. It is precisely because of the textile material that such corrugations are used in meat processing premises, in public canteens and other similar enterprises.

Sometimes during installation non-standard cases arise: connecting two corrugations or hiding it for external viewing in the kitchen.

Connecting two parts of a pipe

If the area for laying a corrugated channel is slightly more than three meters, it becomes necessary to attach an additional element. In this situation, special plastic inserts are used, on which the pipe is tightened with clamps. If such pipes are not available at the moment due to the non-standard dimensions of the channel, then the connection can be made using adhesive tape.

Invisible corrugation gasket

There can be many options for making the air duct invisible, here are just a few of them:

- in a hanging cabinet;

- facing slab;

- due to appropriate painting;

- behind the suspended ceiling.

In any case, in order not to disturb the interior of the kitchen, an extraordinary approach and ingenuity of the homeowner are required.

What is corrugation for hood: structural features

Corrugation gained its popularity due to its high efficiency as a connector between the ventilation duct and the ventilated device. It is characterized by ease of installation, which can be carried out even by an inexperienced technician without special tools. The desired size and shape can be easily created due to the flexible properties of corrugated pipe.

The corrugated pipe serves to connect the ventilation duct to the hood

The corrugated pipe for ventilation has a fairly simple structure: it consists of metal rings that are covered with a thin layer of insulating material. Most often, this covering is made from several layers of laminated foil. The pipe in most cases has a cylindrical shape. There are types of products where the strips of the base material are simply twisted in a spiral. Depending on the type of model, the thickness of the strips can be 100, 120, 150 ml. They are securely connected to each other by special locking seams, forming a hermetically sealed connection.

Thanks to the compression of the links, the flexible outer layer folds into an “accordion”, and when they are stretched, the pipe can increase several times. The softness of the frame allows you not only to stretch the structure, but also to bend it at the desired angle. A long pipe can be given a snake-like appearance, which makes it possible to use it in the most difficult to reach places. Corrugation is an ideal option for inconvenient placement of the ventilation system or in a small apartment.

Fundamental factors for the classification of corrugated pipes

Corrugated pipes are made from a variety of materials in varying lengths, basic shapes and diameters. Plastic pipes come in different colors. The price range is also quite wide. These basic differences form the basis for the classification of corrugations. Manufacturers of the product offer a variety of models - from colored and thin ones made of transparent plastic to special culverts made of stainless steel. When choosing, you must be guided not only by external features, but also by the production characteristics and purpose of the product.

The scope of application of corrugated pipes is very wide. Models with large diameters (more than 3.5 m) are laid under highways and railways, where they act as reinforcement walls on culverts under embankments. Radically opposite thin models are used as insulation or to drain water. An example would be a corrugation for an air conditioner.

Corrugation can be made from a variety of materials, different colors and diameters

Helpful advice! When choosing corrugation, you should pay attention not only to its color and harmony with the interior, but also to the appropriate type of pipe, which has a narrow purpose.

Structure and dimensions of metal, textile and plastic corrugations for hoods

According to the external structure, the corrugation can have the shape of a circle, rectangle or square. A variety of materials are used in the production of corrugated pipes. Their list is very wide:

- Cink Steel;

- stainless steel;

- aluminum foil;

- textile fiber;

- polyethylene of varying degrees of pressure, HDPE;

- polyvinyl chloride fabric.

Each type deserves special attention, since its direct purpose depends on the structure of the material and the dimensions of the pipe. The most popular corrugation in this list is made of stainless steel or aluminum, which is most often used in the installation of home ventilation. Based on production methods, corrugated pipes are divided into the following types:

Plastic corrugation is used both for hoods and plumbing installations

- Frame. They are a metal frame covered with foil or film. The flexibility of such air ducts allows you to restore the original, undeformed appearance.

- Spiral wound. They look like metal strips with medium flexibility. The product can be stretched twice as much, but after that it cannot be returned to its original position.

Polyethylene or plastic corrugation is applicable in plumbing installations, for example, for supplying water to various types of household appliances. In addition, corrugation is widely used in the installation of indoor sewer passages, in particular under the bathtub or sinks.

Scope of application of corrugation: for ventilation, heating, chimney ducts

The different materials from which the product is made and the dimensions of the corrugation indicate its wide purpose in various fields. Thin, inflexible, but long plastic or polymer pipes are used in the installation of various networks. These can be electrical, telephone, television wires, power and fiber optic Internet cables. To insulate electrical wires, corrugated wires with a diameter of 15 to 40 mm are used.

Less flexible metal corrugated pipes are used in heating systems because such pipes are quick and easy to install. A piece of the required length can be easily bent in the right place without changing the diameter inside, which makes it possible to create a heating system in complex and hard-to-reach areas.

Large diameter corrugated pipes are used for arranging chimney ducts

Pipes with great flexibility are suitable for ventilation systems. The diameter of the corrugation for the hood corresponds to sizes from 10 to 15 cm. Sometimes these figures reach 20 and even over 30 cm. Such options are rather an exception, although they can be easily found in the trade sector. The most common material used for making corrugations used in kitchen ventilation systems is aluminum foil. Less commonly used in domestic conditions are plastic or stainless steel pipes.

Textile ducts are used for arranging communication systems in industrial premises because they do not interfere with the free circulation of air. They are widely used in meat processing plants or catering establishments.

Materials

And finally, the cherished question: how to insulate the ventilation pipe? Let's take a short review of modern insulation materials that can be successfully used for ventilation ducts.

Requirements

Let's start by stating our wishes.

- Thermal insulating qualities will, of course, be a priority characteristic of insulation.

- Fire safety. In the event of a fire, the insulated ventilation pipe should not become a conduit for the spread of flame.

- If possible, the price should not be exorbitant.

Mineral wool

Unsurpassed cheapness. Any other insulation will cost more.

Mineral wool 50 millimeters thick is supplied in rolls.

Absolute fire safety.

- Quite labor-intensive installation. The ventilation duct is wrapped in a layer of mineral wool; then it is wrapped in foil (which is only permissible in interior spaces) or protected with galvanization. From the outside, the structure is tightened with bandages.

- The need to protect the respiratory system and eyes when working with the material. Anyone who has ever worked with mineral wool (or glass wool, which differs only in the thickness of the fibers) probably has the most unpleasant memories of it.

- The material cakes over time. Gaps appear in the insulation.

- Humidification leads to loss of thermal insulation qualities.

Some of the shortcomings are devoid of a ready-made solution based on mineral wool - an insulated corrugation for ventilation, which is a two-layer sleeve made of aluminum foil reinforced with steel wire. However, it involves laying ventilation from scratch.

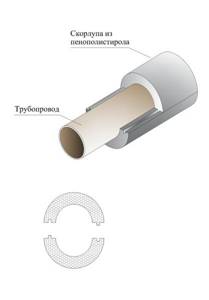

Styrofoam

A ready-made detachable shell made of dense foam plastic (expanded polystyrene) is in many ways more convenient.

The insulation process is not associated with health risks and is relatively simple. How to insulate a ventilation pipe with foam shell? Just put two halves of detachable thermal insulation on the ventilation and squeeze them so that the tongue-and-groove connection is fixed.

The diagram makes the connection method clear.

- The material provides excellent thermal insulation and practically does not change its thermal insulating properties over time, regardless of humidity fluctuations.

- Styrofoam is cheap. It is precisely because of its low cost that it is the main candidate among insulation materials if you are planning to insulate a loggia or the facade of a private house (for more details, see the article How to insulate a loggia and what is required for this).

- Polystyrene foam burns well, releasing toxic combustion products.

- The shell is easy to use only on straight sections of air ducts.

Polyurethane foam, polypropylene foam

The shell can be made not only from polystyrene foam. The other two foam plastics are similar in application to foam insulation.

- Both materials have slightly greater mechanical strength.

- They are more expensive.

- To fix it, you have to apply a bandage. Ordinary knitting wire is often used as it.

Shell made of polyurethane foam.

Foamed polyethylene

This material can be found on sale in the form of split tubes of various diameters. They are put on the ventilation pipe - and, in fact, the thermal insulation work is completed.

The material is cheap and is not afraid of moisture, mechanical impacts of moderate force and rodents.

However, in cases where it is necessary to insulate ventilation in a cold climate zone, you can pay attention to two other types of insulation based on polyethylene foam

- Penofol and its analogues are polyethylene foam coated with a layer of aluminum foil. In our case, it is useful because the insulated pipe will collect less dust: the porous surface of polyethylene foam tends to accumulate dirt.

- Self-adhesive insulation based on the same polyethylene foam is equipped with a sticky layer that simplifies work. If you have ever insulated plastic windows or steel doors with a rubber or foam seal, you have already come across a method for fixing it: simply remove the protective glossy paper and press the material to the surface (see also the article How to insulate windows - getting ready for winter).

The material is very convenient for insulating pipes of square or rectangular cross-section.

The thickness of the insulation can reach 10 millimeters; if necessary, it can be laid on ventilation pipes in several layers.

Types of ventilation ducts

Installing a ventilation system in a house is not an easy task. And the main mistake is the inequality of power to remove polluted air and fresh air coming from the external environment.

There are known cases where simply replacing traditional window frames with sealed plastic ones led to poor combustion of stoves and difficulty breathing for residents. The whole point is that the balance of air inflow and outflow is disturbed.

To properly arrange the exhaust system, various channels are used:

- corrugated plastic pipes;

- plastic boxes of square or rectangular cross-section;

- metal boxes made of galvanized steel;

- corrugated metal pipes made of aluminum.

What should you choose? It all depends on where the ventilation is installed. For example, plastic products are not suitable for installing an air duct from a kitchen hood. In conditions of hot gas removal, their service life is extremely short. Galvanized boxes are expensive and difficult to install on your own; this requires professional skills of a tinsmith.

And the appearance of such an air duct leaves much to be desired. Currently, air ducts made of aluminum corrugated hoods are popular, the diameters of which are available in a wide range, allowing the installation of ducts of any degree of complexity. The material can withstand temperatures up to 300 degrees, which allows them to be used not only in ventilation, but also as chimneys in geysers and boilers.

What are the diameters of the corrugations for the hood? Such systems use pipe sizes:

- 100;

- 120;

- 125;

- 150 millimeters.

The most popular size of corrugation for hoods is 120 mm; the diameter of 125 millimeters is almost as popular. Often, consumers simply do not differentiate between these parameters, especially since they can be mounted on the same additional elements. This is facilitated by the plasticity of the material when using special connecting elements - clamps.

The production form of corrugated pipes is individual pipes, which in the delivery state have a length of 65-100 centimeters, and during installation it can be extended up to three meters without changing the diameter size.

Features of thermal insulation

The technology for protecting ventilation pipes from cooling depends on the type of insulation and its performance properties. In this case, it is necessary to follow the sequence of work and carefully perform all operations.

Insulation with mineral wool

It happens as follows:

- the surface of the ventilation pipes is cleaned of dirt and dust;

- a strip of the required size is cut from the roll, which depends on the diameter of the air duct;

- thermal insulation of ventilation pipes made of mineral wool is carried out in one layer, while you need to ensure that the material adheres tightly to the surface;

- The air duct is wrapped with foil insulation over the mineral wool;

- glue the resulting seams with aluminum tape.

- The pipe is wrapped in one layer of mineral wool insulation.

- On top of a layer of cotton wool, wrap the pipe with foil insulation (4 mm thick), which will help retain heat and prevent cold air currents from entering.

Particular attention should be paid to sealing the structure, since mineral wool, when interacting with moisture, deteriorates its thermal insulation properties

Polyethylene foam insulation

This method is one of the most popular because it combines ease of implementation and efficiency. For insulation, foamed polyethylene is used in the form of shells, with which the following actions are carried out:

- measure the insulation of the required size;

- cut the shell along a special seam;

- install the resulting elements around the pipe;

- glue seams and joints using glue or mounting adhesive tape.

For pipes with a square cross-section, it is much more convenient to use polyethylene in rolls.

Polyethylene foam shells

Expanded polystyrene insulation

In this case, the insulation resembles a shell, and the insulation of ventilation pipes is carried out as follows:

- measure out the shell halves of the required size;

- cut polystyrene foam along the marked lines;

- The shell halves are placed on the pipe, shifting them by 20-30 cm.

- close the side connections, ensuring tightness.

Protective shells made of polyurethane foam with foil outer layer

Polypropylene and polyurethane foam insulation are a similar form but have lower thermal conductivity and fire resistance. Fixation of individual parts is carried out using special bandages. Polyurethane foam can also be sprayed onto the pipe surface.

Air duct protection has a significant impact on its service life. By correctly selecting the material for insulating the ventilation pipe, and following the technology for carrying out thermal insulation work, you can ensure the effective functioning of the system for a long time without damage or repair.

Pros and cons of corrugated pipes for exhaust hoods

Before purchasing a corrugated exhaust pipe, you should familiarize yourself with its advantages over other types of air ducts, as well as some disadvantages.

Among the advantages of corrugated pipes, it is worth noting the following:

- lightness and simplicity of installation, due to the fact that the air duct can bend in any direction;

- the ability to adjust the pipe to the required size using ordinary scissors;

- length 1-3 meters. The air duct when folded resembles an accordion and, if necessary, it can be stretched or, conversely, folded. If the distance from the hood to the ventilation hole is large, corrugated pipes can be connected to each other using special clamps, adapters or inserting their ends into each other;

- light weight and availability of different diameters;

- heat resistance and corrosion resistance;

- flexibility;

- long service life;

- low cost.

However, despite so many advantages, the corrugated exhaust duct also has its disadvantages, albeit few.

- When subjected to strong compression, dents appear on aluminum corrugation due to the softness of the metal. Therefore, such a pipe should be installed very carefully.

- Due to the design features of corrugated pipe, it is difficult to maintain.

- Masking is required due to the external unaestheticness of the air duct.

Rules for laying the air duct from the hood to the ventilation shaft opening

The quality of the hood’s operation directly depends on how correctly the air duct is laid to the ventilation hole.

When planning your route, remember:

- The bending angle should only be obtuse (more than 90º). A right angle bend will take about 10% of the hood's performance. If the duct has bends less than 90º, this can create backdraft.

- The more bends, the more performance drops. If you get a lot of bends (3 or more), you should make them as smooth as possible.

- The length of the air duct should ideally not exceed 3 meters. Each meter will take 5-10% of the hood’s performance.

Installing an exhaust duct (video)

Corrugated pipe for exhaust: advantages and disadvantages of the device

Related article: Plastic air ducts for ventilation. From our review you will learn the types of devices, sizes, classification, popular manufacturers, average prices, how to calculate an air duct based on the area of the room and other parameters, installation secrets.

Let's look at the advantages and disadvantages of corrugated air ducts for exhaust hoods. First of all, it should be noted the ease of installation and the ability to bend the structure at a certain angle. In addition, you can simultaneously connect several sections using clamps.

The air duct stretches freely and can return to its original state. The flexibility of the design provides some reduction in noise level during operation of the hood. Due to these properties, corrugated ducts are used in rooms with non-standard layouts and in conditions of limited space for arranging ventilation systems.

Please note that aluminum corrugated duct can be easily divided into sections of the required length using scissors. Compared to plastic and metal counterparts, the price of the device is significantly lower. It should also be noted that the corrugation is resistant to high temperatures. The aluminum duct can withstand up to +300°C, so its fire is completely excluded.

Table 1. Disadvantages of aluminum ducts

| Disadvantage of the device | Description |

| Difficulty in cleaning | Since the corrugated surface has a textured surface, soot and fatty deposits accumulate on it (in comparison with smooth types of air ducts). This makes cleaning the device difficult. |

| High noise level | Compared to exhaust ducts (smooth-walled) made of plastic or steel, the noise level of aluminum corrugation during operation is significantly higher. |

| Unattractive appearance | Corrugated air ducts, in comparison with plastic channels, have a less attractive appearance. For this reason, some difficulties arise when decorating the kitchen interior (you need to figure out how to close the corrugation). |

Types of corrugated pipes for exhaust according to material

Modern manufacturers offer corrugated pipes for ventilation from a variety of materials: aluminum, steel, PVC, etc. Each of them has its own advantages and disadvantages. Let's look at them in more detail.

Steel and aluminum corrugated pipe

Aluminum corrugated air duct is the most common type of air duct that can be used in a ventilation system. This product has many advantages:

- corrosion resistance;

- withstands a wide temperature range;

- moisture and air tightness;

- light weight;

- no grounding of the structure is required;

- convenience and ease of installation.

Aluminum corrugated pipe PHOTO: binimare.ru

Pipes made of steel tape, unlike aluminum corrugated ventilation, can withstand fairly strong air flow and high temperatures. However, they are distinguished by significant mass and more complex installation.

The disadvantage of steel and aluminum corrugated air ducts is that if a high-power fan is installed, there is strong noise and increased vibration. Also, aluminum corrugations are subject to mechanical damage, so you need to work with them very carefully.

Plastic corrugation for ventilation

Very often, corrugated spiral-wound PVC pipes are used to connect kitchen hoods to general house ventilation. This is due to the fact that such corrugations differ:

- Low price.

- Ease of installation.

- Light weight.

- Large selection of diameters and colors.

Rectangular PVC pipe for exhaust hood PHOTO: aireng.ru

However, before you buy a plastic corrugated hood, you should also be aware of its disadvantages, namely: fire hazard, toxic emissions during combustion, low strength, poor tolerance to low temperatures.

Other types

There are other types of corrugated pipes for ventilation, which are used less frequently due to objective reasons. For example, corrugation with thermal insulation is used to protect air ducts with high operating temperatures. As a rule, such structures are installed outside the building, which can significantly reduce the formation of condensation inside the pipe.

Corrugation with thermal insulation PHOTO: klimatlab.com

Corrugated pipe with polyester film is a metal wire frame wrapped in several film layers. The design is lightweight and can be used to work with low pressure and temperatures. The disadvantage is that the thin film walls of the corrugation are easily damaged, so it is better to use it for hidden installation

Pipe with a metal frame and polyester film PHOTO: solana.ru

Choosing a corrugated pipe: expert advice

A person who has never encountered the installation of a hood and air duct before will find it quite difficult to choose a suitable corrugated pipe. Therefore, our editorial experts decided to collect some practical tips on what you need to pay attention to when buying corrugation. When purchasing a flexible air duct, you should focus on the following main characteristics:

- diameter and length;

- material;

- appearance;

- price.

The diameter of the flexible air duct is usually indicated by the manufacturer of this or that equipment in the instructions. To insert corrugations into the air duct, as a rule, a special ventilation grille is required. In any case, you need to measure the outlet of the hood and select the diameter of the corrugated pipe in accordance with it.

The length of the corrugation is 1-3 meters, so measure in advance the distance from the ventilation grille to the installation site of the hood, taking into account all bends and angles. You shouldn’t buy a pipe with a large supply and overpay. The corrugation must be stretched so as not to reduce the performance of the system.

The material from which the corrugated pipe is made is very important, especially if the air duct is mounted on a kitchen hood. Corrugations made of steel or aluminum tape are usually used. Plastic structures are best used in ventilation with cold air circulation, since the material easily heats up and loses its qualities.

When purchasing corrugation, you need to carefully inspect it for mechanical damage: dents, cracks, abrasions and other defects. It is also recommended to ask the seller for a quality certificate and a passport for the product, which should indicate a warranty period of at least 12 months.

Price. Before you go shopping for corrugated pipes for exhaust hoods, it is advisable to monitor prices in your city, depending on the manufacturer and seller. This will help you save a lot and choose a product with the best price-quality ratio.

Exhaust duct: main criteria for successful selection

Choosing the right pipe model requires an individual approach and careful study of all the features. In this case, the following basic criteria should be taken into account:

When choosing an exhaust duct, you need to pay attention to the pipe material, its dimensions and quality.

- dimensions of the pipe, in particular its diameter and length;

- production material at the base of the corrugation;

- product quality;

- price.

In order not to make a mistake with the diameter of the connecting pipe, you must carefully study the instructions that come with the hoods. To be sure, you can measure the diameter. Failure to comply with recommendations can have irreversible consequences, when even very expensive equipment will not function properly. The standard diameters of pipes installed on hoods are 10, 12, 12.5 and 15 cm. Other sizes are much less common, but are still available for sale. Most often, manufacturers of hoods provide parameters corresponding to 100 and 120 mm, and these are indicated in the equipment installation and operation manual.

Often, the manufacturer also sells an air duct along with the ventilation equipment. This is an ideal option if the length of the pipe matches the dimensions of the kitchen. Otherwise, you will have to buy a product of the appropriate size. It is advisable to measure the length before purchasing the pipe. A regular tape measure is suitable for this purpose. The measurement is carried out from the exhaust pipe to the entrance to the ventilation shaft, observing the strict trajectory of the future route of the pipe.

In order not to make a mistake with the diameter of the pipe, you need to study the instructions for the hood

We should not forget that corrugation can stretch and bend. For some models, this parameter corresponds to 180°, which allows you to choose the optimal route for the ventilation path. It is also worth considering that the pipe is installed in a stretched form.

Quality and material as criteria for choosing corrugations: metal or plastic

The material from which the ventilation duct is made is very important. In particular, the advantages and disadvantages of metal and plastic products listed above should be taken into account. In particular, it is necessary to remember about the high noise production of plastic products, but it is also necessary to emphasize their high aesthetic characteristics, which allow the installation of a pipe when its masking is difficult.

Related article:

Plastic boxes for ventilation: the key to efficient operation of the entire system

Types of products and their advantages. Features of the choice of polymer air ducts and shaped elements for them. Installation of a plastic box.

The most acceptable option is aluminum corrugation for hoods, which is a multilayer product made from layers of polyester and aluminum. The reinforcement is steel in the shape of a spiral, which sets the desired degree of rigidity and direction of the pipe. Aluminum products can be smooth or corrugated on the inside. The smooth surface creates an increased level of aerodynamics, which makes it advisable to install them in long routes with a small number of bends, but this material is less flexible. A pipe corrugated inside is less aerodynamic, but more flexible, which allows it to set the most complex trajectory.

Helpful advice! When purchasing, you should take into account that the initial length of the ventilation corrugation is 60-70 cm, but when stretched it reaches three meters.

A plastic pipe looks more presentable than a metal one, but it is less resistant to temperature influences

When choosing a pipe for exhaust hood, you need to pay attention to the manufacturer and the quality of the material. For this purpose, it is worth inquiring about the availability of a quality certificate for the product and the warranty period. It is also necessary to visually examine the purchased material, eliminating the presence of dents and other visible damage. It is better to refuse to purchase a questionable product and look for a more acceptable option.

Technical characteristics of corrugated pipe for ventilation

Article on the topic: Kitchen hoods with ventilation outlet. Which hood is best to choose from a wide range, how to install and operate this device, advice and recommendations from experts - in our material.

Before purchasing corrugated exhaust pipes, you should carefully study their technical characteristics and properties. Air ducts for domestic use are flexible and semi-rigid (semi-flexible). The first type of device withstands bending and tensile deformation well with the ability to restore its original state. Using a flexible pipe, you can build an air duct of any configuration and a large number of angles.

The basis of flexible corrugation is a spiral-type wire frame onto which aluminum foil, polymers, or combinations of these materials are stretched.

The main characteristics include:

- device diameter – 100−500 mm;

- resistance to temperatures up to +100°C;

- bending amount equal to half the diameter.

Flexible air ducts come with or without thermal insulation. Filler (glass wool, mineral fibers) is used to suppress the noise level in the house during operation of the hood.

Table 2. Technical characteristics of semi-rigid corrugated pipes

| Device Parameter | Image | Description |

| Material |

|

Select and buy exhaust pipes (air ducts) online

We have agreed on DISCOUNTS for our readers in the LEROY MERLIN store.

Buying online is cheaper than buying in a store (lower prices)! It is very profitable, convenient and safe: you can buy air ducts without leaving your home or visiting a store. All purchases will be delivered to your home.

In addition, in the online store, on each product page you can see the exact characteristics and real customer reviews.

To select the air duct model you need, follow the link>>>

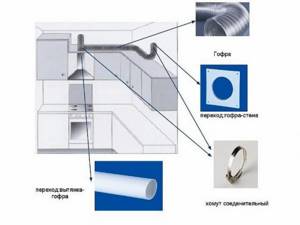

Installing corrugations on a hood - simple installation rules

Installation of corrugation is not as complicated as it might seem at first glance. Simple instructions will help you easily cope with this task.

For work we will need:

- clamps for fastening the air duct;

- the ventilation corrugation itself;

- exhaust grille, which we will install on the ventilation shaft.

Important! Each hood has a plastic flange installed at the outlet. Before purchasing a corrugation, be sure to measure its outlet diameter.

| Illustration | Description of action |

| The first stage is marking the place where you will strengthen the hood. Remember that the minimum height that is allowed when installing equipment from the work area is 75 cm. Study the location of the suspension points and the distance. | |

| We fix the device in the place allocated for it, having previously removed the filters so as not to jam them during installation. |

| We connect one end of the corrugation to the outlet at the top of the device using a clamp. In some cases, a hood adapter can serve as a fixing element. |

| We attach the second end to the flange that connects the air duct to the ventilation shaft. |

Advice! Remember that unnecessary turns and bends impair the draft of the hood.

Watch this video on YouTube

Some features of corrugated pipe installation

Installing a corrugated pipe in the kitchen does not require any special skills. All work can be done independently. However, in order for the system to function for a long time and efficiently, several important points must be taken into account during installation.

- If it is not possible to select the diameter of the corrugation for the hood, use a product with a larger size, connected through a special adapter. For a kitchen hood, this will only be a plus: as the size increases, the air flow speed decreases, which means the noise will decrease.

- Before installing the corrugation, a special platform with a grille, flange and check valve is installed on the ventilation hole. It is used to avoid completely blocking the hood with a pipe. The grille serves for natural ventilation, the flange for forced ventilation. Then the air in the kitchen will be constantly renewed, regardless of whether the forced draft is working or not.

- If your kitchen has a second ventilation hole, you can connect the pipe to a flange without a grille.

How to increase the length of a corrugated pipe for exhaust hood if the dimensions do not match

It often happens that the length of the corrugation is not enough and needs to be increased. The problem is that corrugation does not withstand mechanical stress quite well. To “extend” the corrugation, we will need thin aluminum sheets approximately 5 cm wide, the length is selected depending on the diameter.

The sheets are rolled into a ring so that they fit freely into the corrugation, the joints are connected with rivets

The ring is inserted into the corrugation, which must be pressed against the ring. It is important to first bend the edges of the ring inward to increase strength and prevent its deformation during compression.

The result should be some narrowing of the diameter of the corrugation, which will be enough to insert one end into the other.

The connection point can also be tightened and secured with masking tape, or twisted with copper wire

Tips for choosing the right one

A large selection of corrugated pipes leads to certain difficulties for buyers when choosing. However, there are parameters that you can pay attention to in order to make the right choice. These should include the following indicators:

- length and diameter;

- material of manufacture;

- product quality;

- cost of goods.

When choosing the appropriate diameter, you should look at the recommendations specified in the instructions for the hood. If you choose a material that deviates more or less from the declared standard, then, at a minimum, the equipment will not cope with its function. Odors, grease and soot will not be removed from the room. But another option is also possible, when the device simply burns out from overvoltage.

Depending on the external appearance of the object, as well as the features of the interior, it becomes necessary to hide the element and the surrounding fastening. If you want to add more aesthetics to the interior, a white design is suitable.

Before purchasing, you can even ask for measurements of the product you are interested in. Under no circumstances should you ignore the manufacturer's recommendations. Sometimes you can get an air duct complete with a hood. It’s good if the material turns out to be suitable and the length matches the required one. If the opposite situation arises, a person will have to independently go to the building materials market and look for a suitable solution.

We recommend that you read: How to choose and install a ventilation grill for a window sill

Another situation may arise when a seller insists on purchasing a hood and corrugation. Here you need to show maximum attention, since not all sellers care about the client’s benefit. It is quite possible that a person is offered an expensive product or product that has been in the warehouse for a long time. Measurements will help you avoid adverse consequences. Thanks to this, you will be able to avoid buying extra meters, trusting solely in the opinion of the seller.

How to hide the corrugation from the hood in the kitchen: options

Usually the corrugation is “sewn up” or simply laid on kitchen cabinets. There are other options that we are ready to talk about.

Plastic box for kitchen hood - cheap and cheerful

One option is to use an aesthetic plastic box. However, this option “steals” usable space. They can be either plastic or metal.

“Box” made of plasterboard - the choice of experienced finishers

Drywall is one of the options for solving the problem. However, it is more labor intensive. In addition, drywall is afraid of moisture. Before using in the kitchen, plasterboard sheets must be pre-treated.

Application of kitchen furniture or suspended ceilings

A special mezzanine in the kitchen where you can hide the corrugation. Most often, such hidden cabinets are ordered simultaneously with the purchase of the entire set.

Aluminum corrugation 3m.

To select and buy an air duct, you need to understand for what purpose you need it. Discerning clients are satisfied with cooperation with our online store. You will have no complaints about the quality of the products.

Air duct production technology

Aluminum corrugation is produced from metal foil of a certain thickness. Thanks to the special processing of the aluminum sheet, the resulting pipe is flexible and durable. It can be installed in hard-to-reach places. The product can withstand sufficient stretching and compression. Main characteristics of corrugation:

- aluminum foil thickness – 0.12-0.15 mm;

- maximum operating temperature – +250°С;

- pressure in the system – up to 2000 Pa.

The standard length of the air duct is 3 m when stretched. When compressed, the length of the supplied products is approximately 1 m. The aluminum foil is processed in a special way to ensure that the resulting products are durable. Corrugation is used when installing a ventilation system. It is in demand among private clients who want to improve the air exchange system in a private home. Large corporate clients also often turn to our online store to buy air ducts.

Features of the process of purchasing aluminum duct

Durable aluminum corrugation for ventilation perfectly performs its functions. It can be securely attached to a round or oval duct. It is better to entrust the installation of the air duct to professionals. They can also give recommendations regarding the purchase of specific products.

All that remains is to buy the corrugation in our online store, wait for the product to be delivered, and make sure of its high quality. The trading company's employees are well aware of the entire range of products. They can give their advice regarding the choice, having previously clarified exactly where the elements will be used. Often a decision is made based on data from project documentation. Large wholesale clients of our store make purchases on special terms. You can also count on pleasant bonuses when purchasing aluminum corrugation for the ventilation system.

Other nuances

In its original form, the object has a length of 60 to 70 cm. However, it can be stretched up to 3 m. This point must be taken into account when purchasing. To correctly measure the length of the product, use a regular tape measure. Take into account the points from the entrance to the hood pipe up to the wall surface. The path must fully correspond to the one that follows the product itself. We must remember that the corrugation is flexible in accordance with the technical parameters specified by the manufacturer. For example, it can bend 180 degrees.

Flexibility ensures the ability of the pipe to adapt to any interior features. You can choose the most optimal route for the channel. The product is installed in a stretched form. Another parameter that is important to consider when purchasing is the material of manufacture. Sometimes people choose plastic models because they suit their color scheme. But we must not forget about the noise that the air duct makes. He can be quite impressive at times. If this issue is not important to the consumer, he will be able to expand the list of available models.

It is not customary to use polyethylene corrugation for ventilation. They are selected depending on the diameter in order to pump substances in bulk and liquid states and transport them from place to place. In order not to be disappointed in your own purchase, you should check the documents that confirm the quality of the product. Do not hesitate to ask sellers if there is any warranty from the manufacturer.

In addition to documents, a visual inspection of the corrugation is also important. There should be no scratches or dents on it. If they are present, this should raise suspicion. Don’t be afraid to stretch the pipe to its full length. It has the necessary flexibility for this. By stretching it, you can see holes and gaps in the structure, which should not exist in the normal case. You should not purchase materials of questionable quality. The presence of defects is unacceptable, since corrugation is used for the ventilation system.

We recommend that you read: Plastic pipes for air ducts: features, application and installation

Cost also matters . In order not to overpay, it makes sense to familiarize yourself with offers from various manufacturers. Also, knowing the appropriate length of the air duct, you can save a certain amount. It also wouldn’t hurt for the buyer to know where he is going to install this object. If you plan to place it outside or in supply ventilation systems with cooling and heating modes, then it is more advisable to buy models with thermal insulation. It is more convenient to purchase ready-made pipes than to insulate them yourself later.

Corrugation is most often used in domestic conditions for laying ventilation ducts, which are responsible for removing various fumes, soot and grease from the kitchen. They are indispensable for the full operation of exhaust devices.

Comparison of flexible corrugation for ventilation with a rigid air duct

If we compare flexible air ducts with rigid ones, the former have a number of undeniable advantages, which include the following indicators:

- elasticity and flexibility allow them to be used in complex areas of ventilation systems, in different placement planes, with a minimum number of fastening elements;

- lightness of structures and, at the same time, strength;

- ease of installation work;

- small overall dimensions in transport position (compressed state);

- functionality that allows installation indoors and outdoors.

Air ducts can be made of heat-resistant polymer materials