The chimney is one of the most significant and important elements of boiler room equipment. The efficiency of the heating system, the nature of fuel combustion and the removal of combustion products largely depend on it. Modern chimneys are made from different materials. There are metal, ceramic, brick, and even glass pipes. For a chimney of complex configuration, it is best to use a metal corrugated duct.

Corrugated pipes can be used to construct new chimneys and modernize existing ones

Technical parameters of corrugated stainless steel pipes

Among the important technical indicators of corrugated stainless steel pipes are:

- operating temperature: -50 °C – +110 °C;

- pressure at an operating temperature of +110°C: 15 bar;

- possible bending radius of the product depending on the pipe diameter: 25-150 mm;

- thermal conductivity coefficient: 17 W/(m*K);

- linear expansion: 17;

- roughness coefficient: 0.008.

The corrugated pipe is resistant to pressure changes (limit value 50 atm). The maximum pressure for destruction is 210 atm. Other pipe indicators are given in the table.

Table 1

| Index | Meaning | |||||

| steel grade | 304 | |||||

| Diameter in mm | 12 | 15 | 18 | 20 | 25 | 32 |

| Outer diameter in cm | 1,62 | 1,81 | 2,0 | 2,56 | 3,2 | 3,76 |

| Inner diameter cm | 1,18 | 1,41 | 1,78 | 2,1 | 2,7 | 3,2 |

| Wall thickness in mm | 0,3 | |||||

| Weight of one l.m. corrugated pipes, kg | 0,13 | 0,156 | 0,164 | 0,2 | 0,23 | 0,28 |

| Corrugation pitch in cm | 0,425 | 0,476 | 0,5 | 0,5 | 0,526 | 0,56 |

Installation

When installing corrugated pipes, a number of rules must be followed:

- The installed equipment must comply with fire safety regulations.

- The structure must be sealed.

- The dimensions of the chimney are determined by the number of sources of combustion products.

- The inner diameter of the pipe, the seat, is equal to or greater than the corresponding size of the firebox.

- Try to maintain the maximum position of the pipe close to vertical.

- It is advisable to make the internal cross-section of the chimney the same size.

- A geometric figure for the exhaust system - a circle, square or rectangle with rounded corners.

- The minimum height of the chimney should not be less than 3.5 meters.

- At a distance of 20-50 cm from a metal chimney, flammable materials and products made from them should not be located.

- Do not install the chimney next to a gas pipeline.

To install a corrugated pipe, in addition to itself, you will need:

- clamps for joining along the length;

- mounting brackets for external installation;

- heat-resistant sealant;

- hammer drill (impact drill), hammer, pliers, screwdriver;

- set of hardware;

Depending on the installation conditions, two installation methods are used:

Internal method - used when installing a corrugated pipe inside a brick chimney:

- The finished product is lowered into the existing channel. The process must be carried out without jerking, with smooth movements. If counter-resistance occurs, under no circumstances should you use excessive force - the corrugation may become wrinkled.

- When the receiving hole is reached , its neck is covered with heat-resistant sealant, and the pipe is fixed to the firebox.

- The part of the pipe in contact with the atmosphere , for example, in an unheated attic or above the roof, is insulated with stone wool.

- The headband is installed above the upper cut of the chimney.

External method - used in the case of using a corrugated system as an independent chimney, without connection to a permanent structure:

- Markings are made along the location of the chimney, and marks for the location of the mounting brackets are applied.

- Brackets are installed.

- The pipe is extended to the required length.

- The metal chimney is mounted on the outlet neck of the firebox, which is pre-treated with a heat-resistant sealant.

- The corrugated pipe is being installed. If the size of the exhaust system is larger than the maximum size than that of a single pipe, the pipe is extended in the necessary places and secured with a clamp. The joint itself is coated with thermosealant.

- The outer part of the corrugated pipe, above the roof, is passed through a product of larger diameter, for example, an asbestos pipe. The top of the new chimney is attached to the outer protection pipe.

- The headrest is installed.

- The outer parts of the chimney are covered with thermal insulation.

Types of flexible pipes for smoke exhaust ducts

The modern market for corrugated pipes offers various types of these products. But not all of them meet safety requirements and can be used for a chimney. There are designs made of aluminum and stainless steel.

A safe chimney for a fireplace or stove can only be built from stainless pipes and components

Some time ago, aluminum pipes were used for the chimneys of water heaters and gas heating appliances. This multilayer corrugation is a pipe made of laminated foil with a diameter of 10-15 cm. It is durable and inexpensive. In order to give the required shape, a steel wire is inserted inside.

When compressed, the aluminum pipe has a length of 650 mm, and when stretched, it is up to 3 meters. You can use metal tape to extend the air duct.

Note! Boilers and fireplaces that burn solid fuel do not have an aluminum pipe installed, since it is not able to withstand high temperatures.

Currently, such corrugation is not recommended at all.

Stainless steel corrugated pipes are structurally similar to aluminum ones, but their characteristics are much better. The material can withstand temperatures up to 900 °C without damaging the duct structure and at the same time effectively remove combustion products from devices using liquid, solid and other types of fuel (boilers, fireplaces, stoves).

Corrugated chimney pipe for a gas boiler: options

There are several types of flexible corrugations that are acceptable for use as chimneys:

1. Flexible chimneys made of stainless steel . The most acceptable option in terms of price-quality ratio for connecting to high-temperature equipment. If installed correctly and sufficiently sealed, such chimneys can withstand flue gas temperatures reaching 400 degrees. In addition, a steel chimney duct can also be used with some solid fuel boilers.

Corrugated stainless steel pipe is characterized by the following qualities:

- for steel flexible chimneys, sheet steel is used, the thickness of which will be from 0.12 mm to 1 mm;

- corrugated pipe has a high ability not only to bend, but also to compression and stretching; manual bending is possible, without the use of additional means. In this case, the shape given to the corrugation will be maintained for a long time, and the cross-sectional diameter will not change.

- resistance to high temperatures, temperature changes and aggressive acidic environments. This property is provided to stainless steel products by a significant concentration of alloying elements (nickel - about 14%, silicon - about 18%). Also, there will be no acid residue left on the inner wall of the corrugated pipe.

- Due to the thinness of the steel walls, the channel is heated quickly and evenly. And provided that insulating materials are used for insulation, heat loss from the chimney will be minimal.

- flexibility without loss of integrity: it is possible to install without a large number of fittings, angles (rotary elbows), adapters and adapters.

Chimney pipes made of stainless steel are more durable and stronger than aluminum products

2. Flexible chimney for a gas boiler made of aluminum. The design of this type of corrugated pipes completely coincides with the design of stainless steel products. The difference is that aluminum is inferior to stainless steel in its ability to withstand high temperature loads, it is less durable and impact resistant.

Important! A corrugated aluminum pipe is not able to withstand temperatures above 500 degrees - its walls can melt and collapse, and soot particles and other gas combustion products will enter the living room. But if the power of your gas boiler is low, then the aluminum pipe is quite suitable for use.

Technical standards do not prescribe a ban on the use of aluminum pipes in the installation of chimney systems. But in some regions of the Russian Federation there is an unspoken ban on the use of pipelines made of aluminum for gas equipment. Therefore, when inspecting your system or registering your boiler, the inspector may recommend that you replace the aluminum hose with pipes made of a more durable material.

Construction of corrugated products

A corrugated stainless steel pipe for a chimney is made from multilayer foil. Its strips (0.12-1 mm thick) are connected using a special locking method and secured to a spring made of stainless steel. This design allows the pipe to be bent by 120-180° and stretched to a length exceeding the original by more than 3 times. The stretching/compression procedure can be repeated several times without compromising the integrity of the pipe.

Depending on the power of the boiler or furnace, a corrugated pipe of larger or smaller diameter is selected

For chimneys, corrugated stainless steel is produced in various diameters, which allows you to select the required size that matches the outlet pipe of the heating device.

In order to increase the service life of the chimney, it undergoes treatment with a special solution both from the inside and outside. This manipulation protects the channel material from chemically active substances and aggressive environments. The minimum service life of a metal corrugated chimney pipe is 20 years.

Installation of chimney corrugated ducts requires insulation. The insulation for such pipes is basalt wool, produced in rolls. It is suitable for both internal and external installation. The insulated corrugated stainless steel pipe does not heat up from the outside.

Application of corrugation

Corrugated stainless steel chimney is used in devices with high operating temperatures. They can be installed in private homes to remove combustion products from kitchen gas water heaters. In them, the outlet gases are heated to 300°C. Steel pipes are used for chimneys of heating units, in which temperatures up to 900°C are reached.

This material can be used for repairing old chimneys, as well as as adapters when installing smooth steel pipes. Stainless steel corrugation is also used as a connection for household appliances in the house. In this case, it is necessary to install fittings made of brass and stainless steel with linings of dielectric material to avoid sparks. In stores you can find connecting devices covered with polyethylene and painted yellow. The internal diameter of the corrugation does not exceed 20 mm.

Main characteristics of corrugated pipes

Stainless steel corrugation for chimneys has a round cross-section. Its standard length in many cases makes it possible to obtain a smoke exhaust duct without unnecessary joints.

Note! The tightness of the chimney pipe directly depends on the number of joints that are used to assemble it: the fewer joints, the better.

Corrugated pipe is very flexible, it can be given any shape without special corners and bends

Stainless steel is the main material for the manufacture of corrugated chimneys. It is durable, has anti-corrosion properties and is heat-resistant, which increases the service life of products. During the heating of a boiler or furnace, condensate containing a certain amount of H2SO4 (sulfuric acid) forms inside the channel, which damages many chimneys made of other materials. Therefore, this type of pipe is used more often than others.

The stainless steel pipe design increases the mechanical strength of the entire channel by compensating (up to 50%) for the linear expansion of the initial pipe size when exposed to temperatures and vibrations.

An important thing when choosing the type of pipes for a chimney is the ability to take them into different shapes and configurations. The corrugation allows for repairs and installation in a channel that has a large number of bends. When purchasing a corrugated pipe, you need to check it for mechanical damage or kinks so that no problems arise during installation.

Advantages

With the help of a flexible chimney, you can independently install smoke exhaust channels even in difficult conditions when it is necessary to make several turns of the pipe. This does not require a special tool or the help of a professional technician. The use of metal corrugated chimneys has the following advantages:

- Flexibility. The main difference between corrugated pipes and ordinary straight pipes is flexibility and elasticity, thanks to which they can easily be rotated at any angle, taking the desired shape. Installing a flexible chimney does not require additional elements (bends, rotary elbows), due to this the cost of work is reduced.

Important! Perhaps the main advantage of corrugated stainless steel pipes is versatility. They are used as a chimney for a stove, fireplace, gas boiler, boiler, water heater or as an air duct. Flexible pipes have many uses, and their properties can be improved by using thermal insulation winding.

Pros and cons of corrugation

The corrugated pipe is suitable for any smoke exhaust systems, even at very high flue gas temperatures.

Another advantage of a corrugated pipe is the ease of connecting two sections together

It is resistant to:

- humidity;

- high temperatures;

- chemically aggressive environments.

This pipe is used not only for the chimney, but also in air conditioning and ventilation systems. Its flexibility allows you to easily install a chimney in the presence of complex architectural structures: sloped ceilings, floor beams, built-in columns, etc. This feature of stainless chimney corrugations reduces the cost and complexity of installation work.

Installation does not require expensive components (adapters, angles, elbows); this is important if the budget is limited. Among other advantages, we can note the possibility of connecting pipes of different diameters into one design. For this, special adapters are used.

Corrugated pipes have few disadvantages: short service life and the need for insulation to combat the formation of condensation. In addition, the draft in a corrugated pipe is much lower than in a smooth pipe, so it is not recommended to make a vertical channel along the entire length from such a product.

The diameter of the boiler pipe must match the size of the pipe being installed

Advantages and disadvantages

The main advantage is elasticity. It is easy to build (connect) a smoke exhaust system of any complexity and configuration from them. They easily turn in a given direction and bend at the desired angle. When working with them, bends, flanges and other rotating elements are not required. All this has a positive impact on the final cost of the work performed.

Round walls facilitating the rapid removal of decomposition products Source cloud.maxni.ru

In fact, the advantage of using them can be characterized by the following list:

- The favorable rounded shape of the pipe cross-section is considered optimal for the unhindered passage of gases. The flow rises in a spiral, as a result of which a stagnant zone is formed in the corners of rectangular pipelines, in which destructive condensate settles. Moisture traps fine particles of unburned fuel, which settle on the walls and form soot.

- Simple installation and connection to other sections of the duct and heating equipment.

- Low cost. This is the cheapest option for installing a smoke exhaust system.

- If damaged, it can be easily removed and a new one installed in its place.

- There is no need to purchase additional components: corners, bends and other accessories.

- The aforementioned ease of laying at different angles and directions.

Requirements for installing smoke exhaust ducts

When installing flexible chimneys, it is necessary to comply with some important requirements that will ensure reliable and efficient operation of the channel. Among them are:

- performing fastening using an adapter;

- correspondence of the diameter of the smoke exhaust duct to the cross-section of the outlet opening of a particular heating device;

- placing the corrugated pipe in a fireproof case when passing through the interfloor ceiling;

- ensuring double thickness of the walls of the outer protective casing in order to ensure the safety of the structure in case of possible damage to the outer layer;

- hermetically sealing the corrugated pipe to the heating system, preventing gas leaks;

- the length of the channel section from the bottom of the pipe to the horizontal section of the flexible chimney is not less than 50 cm;

- ensuring the radius of curvature of the installation of a corrugated pipe is not less than its diameter;

- the distance from the wall or ceiling to the connecting pipe is not less than 50 mm if they are made of non-combustible material;

- if the wall is made of another material, this distance must be at least 250 mm;

- providing a vertical connection to the boiler;

- the total length of the installed horizontal sections is no more than three meters;

- installation of a flexible chimney with a slope towards gas equipment of more than 0.01 degrees.

All materials used to secure the pipe and come into contact with it must be non-flammable

Pipe installation

Before installing a corrugated chimney, it is necessary to prepare all the material and tools. These include:

- directly the corrugation itself of the required section and length;

- metal brackets;

- metal tape;

- adapters;

- rubber seals;

- roller pipe cutter or grinder.

Despite the ease of installation of chimney corrugations, its installation requires compliance with certain rules. After all, it serves as a channel for the removal of carbon monoxide generated during combustion.

- The diameter of the pipe must correspond to the diameter of the outlet of the heating device.

- When moving between floors, it is necessary to use a fireproof case.

- The fastening must be made hermetically. All parts are tightly connected to each other, gaps are unacceptable.

- Chimneys cannot be installed in residential premises. It is also prohibited to display these channels on closed loggias or balconies.

- When running a pipe through the walls or ceiling, an apron made of a metal plate laid on an asbestos sheet must be installed.

- If the wall or ceiling is made of fireproof materials, the distance between their surfaces and the pipe must be at least 5 cm. When using flammable materials in the construction of a house, this parameter increases to 25 cm. A distance of 10 cm is allowed, but in this case the wall surface must be insulated with a steel plate laid on a three-millimeter thick asbestos sheet. In this case, it should protrude 15 cm beyond the edges of the pipe.

- It is prohibited to install an umbrella on the chimney of a gas heating appliance.

- Sagging of the corrugation is not allowed.

Installation begins with attaching the corrugated structure to the output channel of the heating device using rubber seals. Its edge should be smooth without burrs.

The corrugation is attached to the wall in a vertical position with metal brackets. The elements are secured to each other with metal tape. For different pipe diameters, special adapters are used during connection.

Installation of corrugated stainless steel pipes

The corrugated pipe is applicable for installing adapters that connect the outlet pipe of the device with the main chimney channel, repairing (lining) brick chimneys with bends. Both external and internal installation are possible for them.

The stainless corrugation for the chimney is secured with special metal brackets. They are either included with the pipe or sold as a separate holding element. Fixation is ensured by conventional clamps, which are tightened with an open-end wrench.

Note! When installing horizontal sections of corrugated pipes, it is necessary to prevent their sagging.

During installation, no more than three turns of the corrugated chimney are allowed. To join two pipes, metal tape is used, which ensures high tightness of the joint and prevents leakage of combustion products. During installation, the use of sealant to seal the joints of the chimney elements is not required.

A corrugated stainless steel pipe can be a good alternative to using rigid flue ducts, despite its shorter service life.

Can a chimney corrugated pipe be used for gas?

The chimney for a stove or boiler is, in fact, a very vulnerable part of the structure. Due to constant temperature fluctuations and the presence of toxic substances in fuel processing products, there is a high probability of destruction of the chimney walls. Brick systems are especially susceptible to this phenomenon. The only way out is to install steel chimneys, which are more durable and easier to install.

There are no obstacles to installing corrugated flexible products as a gas chimney. With proper installation and operation, such systems can function no worse than smooth steel or asbestos-cement pipes.

Corrugated pipe is durable, which is achieved thanks to the following design features:

- its body looks like a cylindrical tube twisted in a spiral. The spiral strips are firmly connected using a lock seam;

- The reinforcing wire creates a body - the basis for the pipe, protecting it from mechanical damage and shock. At the same time, the flexibility of the metal pipe does not decrease.

Good to know! The possibility of using corrugated stainless steel pipes for gas is also mentioned in regulatory documents SP 42-101-2003, as well as in DBN V 2.5-20-2001, currently in force in Ukraine.

Flexible corrugated pipes can be used with different types of heating appliances, including gas

Cost and recommendations

Average price for corrugated pipe from domestic manufacturers:

- at 100 mm it will be 3100-3400 rub/m;

- 120 mm = 3300-3950 rub/m;

- 150 mm = 3700-4200 rub/m;

- 200 mm = 4700-5100 rub/m;

- 300 mm = 6400-7100 rub/m;

Adviсe:

- Under no circumstances should you use a corrugated aluminum pipe to remove combustion products from stoves, fireplaces, boilers, or heating boilers using solid, liquid or gaseous fuels.

- When pulling a stainless pipe through a stone chimney, it is advisable to attach it to the bottom of the ring, to which, in turn, a rope is tied. With its help, acting together from above and below, it is more convenient and reliable to lay the corrugated pipe.

- In the case of external installation of a chimney made of a stainless pipe, it is allowed to make one or two transitions with a deviation from the vertical of up to 45°.

- Be sure to use heat-resistant sealant in the area of all joints - this will increase the reliability of the connections and protect against leakage of exhaust gases and smoke.

- In the upper part, where the temperature of the combustion products does not exceed 150-200°C, it is allowed to fasten pipe joints using metallized tape.

- When repairing an old exhaust system made of brick, it is necessary to close all openings leading into the chimney - this will protect against crumbling soot from entering the premises.

The quality of operation of the entire heating system depends on the proper functioning of the chimney: combustion of fuel and removal of combustion products. The chimney can be made of metal, ceramics, brick and even glass. If it has a complex configuration, many convolutions, the best option would be to use a flexible chimney - a channel made of a corrugated metal pipe.

Features of flexible chimneys

The flexible chimney is a round hollow profile. To make such a pipe, sheet metal rolled into a spiral is joined using a locking seam.

The structure of the product differs in that steel wire is inserted between the metal layers, thanks to which the pipes acquire properties such as flexibility and strength. They have different cross-sectional sizes, but the most common are pipes with a diameter of 110 - 300 mm.

Each part of the pipe is 65 centimeters long, but it can easily be extended to 3 meters. Flexibility allows you to install a chimney with various bends and many turns. The wall thickness varies from 0.25 to 1 mm.

A corrugated pipe can be used for arranging part of a chimney (passage through a wall or ceiling, as well as when reconstructing a chimney made of indirect brick construction) or for installing the entire chimney duct.

Note! It is recommended to install a corrugated chimney to a heating system operating on different fuels with flue gases of high or low temperature.

Reliability is ensured due to the following properties:

- cylindrical spiral shape with interlocking connecting seam;

- a reinforcing layer in the form of wire, making the body more resistant to mechanical damage, but maintaining the flexibility and elasticity of the product.

According to the type of strength, light, heavy and super-heavy pipes are distinguished.

How to choose a corrugation for a chimney

Is it possible to use corrugation to make a chimney and what should you consider when choosing?

The possibility of its use and the main selection criteria are determined by:

- NPB 252–98. The document regulates the requirements for heat-generating devices, their testing methods and fire safety rules;

- SP 42-101-2003, which defines the rules for the construction and design of smoke exhaust systems;

- SP 60.13330.2012, which establishes the rules for the manufacture and use of air vents, heating and air conditioning systems.

So, in accordance with the specified documents, in order to choose a stainless corrugated chimney, you must consider:

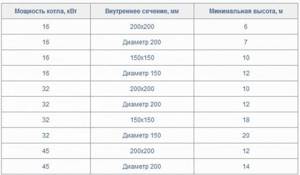

- diameter. For maximum removal of combustion products, it is necessary that the diameter of the hood be no less than the corresponding parameter of the outlet pipe of the installed equipment;

- equipment power. The parameter affects the determination of the length and diameter of the chimney;

Dependence of exhaust parameters on boiler power

- tightness class.

How to choose the right chimney pipes, watch the video.

Types of flexible chimneys

The flexible corrugated chimney is divided into two types depending on the material from which it is made: aluminum or steel.

Aluminum corrugated chimney

Previously, pipes made of aluminum multilayer corrugation with a diameter of 10 to 15 centimeters, made of laminated foil, were used everywhere for chimneys. This is a durable and inexpensive material.

But for fireplaces and boilers operating on solid fuel, such a pipe is not suitable, since it cannot withstand high temperatures. Moreover, at present, even gas workers do not recommend using it for the corresponding boilers and water heaters. The reason lies in the fact that when heated, the walls are deformed and there is a risk of fire.

This is interesting! In some regions, the use of aluminum corrugation is prohibited by law. This decision was made due to the fact that burnouts of the hose often occurred, and, as a result, gas poisoning of people who were in the room.

Stainless steel chimney

The design of chimneys made of stainless steel is the same as that of aluminum pipes. However, the technical characteristics of stainless steel differ significantly. Stainless steel chimneys are capable of functioning in systems operating on liquid and solid fuels at temperatures reaching 900 degrees, and effectively cope with the removal of combustion products.

Flexible steel chimneys are used for various types of heaters, boilers, boilers and fireplaces due to their excellent tightness and heat resistance.

But high security also comes with a high price. It is approximately three times higher than the cost of aluminum chimneys. When choosing steel corrugation for arranging a chimney, you need to choose only certified products. Service life is also important. For example, Lex Flex brand corrugations last at least 40 years.

Note! If funds allow, it is preferable to use a steel corrugated chimney, as it has improved characteristics compared to an aluminum chimney.