Updated: 02/19/2021 18:42:50

Expert: Andrey Nikolaevich Kuznetsov

*Review of the best according to the editors of expertology.ru. About the selection criteria. This material is subjective in nature, does not constitute advertising and does not serve as a purchase guide. Before purchasing, consultation with a specialist is required.

An integral part of heating appliances is the chimney. Brick buildings were replaced by lightweight and compact steel structures. The domestic market offers a wide range of both foreign and Russian smoke removal systems. They offer products of different prices and quality, which differ significantly in service life. Making the right choice without the help of experts is quite difficult. Therefore, you should listen to the following recommendations from experts.

Brick chimney and sandwich chimney: design features

- What does this have to do with a sandwich? — a buyer once asked. And really, what does a sandwich have to do with a chimney? The fact is that the sandwich contains several layers of bread and filling, and this structure perfectly suits the description of modern chimney systems (DS). The role of bread here is played by steel, and the filling is thermal insulation.

For a very long time, the traditional solution was a brick chimney. However, technologies evolve, solutions are optimized and improved, and the chimney eventually became round.

This approach allowed:

- significantly reduce the shaft;

- reduce the time for cleaning the chimney, since there is no need to clean the corners;

- reduce fire hazard - in round chimneys the accumulation of soot, which can ignite, is significantly reduced.

And also in a round pipe there is better draft, and this makes the fuel burn evenly. Simply put, heat will not escape into the chimney through a round chimney, as happens in brick chimneys.

It is important to know! The chimney must be cleaned thoroughly, that is, soot must be removed, and not just loosened. Loosened soot can easily ignite from any spark.

Range

Installing a stainless steel chimney is a rather difficult task, and therefore many people need to use a solution that is ready for installation. Many models include various parts of the pipe, so it is quite possible to install the structure yourself.

Let's consider all these elements.

- Straight pipes. Their length, as a rule, is from 33 to 100 cm. The bell joint is what firmly connects the pipe elements to each other.

The pipe does not require additional fasteners - Bends at an angle of 45°. They are best used when there is a need to deviate from the vertical.

- Bends at an angle of 90°. Thanks to them, it is possible to make transitions between the vertical and horizontal sections of the place where the pipes are laid.

Bends at 45 and 90 degrees - Condensate collector. It is placed at the lowest point of a vertically running pipe. It is used to collect water that appears when smoke cools.

- Tee at 45° and 87°. With it you can assemble pipes where you plan to collect condensate. In addition, such a tee is useful when connecting two heating devices connected to a common chimney.

- Revision element. The inspection is placed where soot is most likely to accumulate. Its use is to check and clean the chimney.

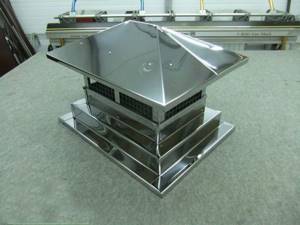

Chimney inspection - Penetrations. This element provides insulation of the structure for fire protection, sealing the roof, and also guarantees an improvement in the design of the pipes.

- Additional accessories. To protect against precipitation inside the chimney structure, against back draft and against sparks, a number of accessories are installed on the roof, including a cap and a spark arrestor.

Chimney cap

Stainless steel - why are chimneys made of it?

Improvements in technology have made it possible to create new materials that have given impetus to the development of the industry. For this reason, choosing stainless steel for the chimney shell became as logical a decision as giving it a round shape.

But thin-walled stainless steel did not immediately begin to be used for chimneys. The development of metallurgy has made it possible to improve the characteristics of steel and give it the necessary properties. In the case of steel chimneys, the main requirement is heat resistance.

Flue gases heat up to 800–1000 °C. A steel chimney can withstand high temperatures, but it is also a good heat conductor. And since a hot pipe can cause a serious burn, they decided to cover it with a protective heat-insulating layer.

But the thermal insulation layer also requires protection from atmospheric and other external influences. Therefore, they began to make a metal casing on top of the insulation, but not from heat-resistant steel, but from less ordinary steel, which does not need to withstand extremely high temperatures.

What should you consider when installing a chimney?

- How fast does free fall accelerate?

- What is the length of the chimney?

- Average external/internal temperatures.

- Height.

- Sectional shape of the structure.

- Total channel area.

- How smooth the walls are (measured in coefficient of friction).

- What is the speed of the flue gas?

Which chimney is considered reliable and safe?

Reliability and safety are the most important qualities of a chimney. If the chimney system does not meet these requirements, it is strictly forbidden to use it. And it doesn’t matter what material it’s made of. Here we can draw an analogy with construction: a house without a foundation will not stand, no matter how beautiful it is. Likewise, an unreliable chimney will not last long.

The chimney system is, first of all, a utility network and its selection and installation should be carried out exclusively by professionals. The same as with heating devices. Of course, a choice can be made based on its spectacular appearance and “reasonable” price, but the result of such a choice can be a fire or carbon monoxide poisoning.

The main thing when buying a steel chimney is the quality of the materials. Be sure to ask the seller for system test certificates, and also ask what fireproof clearances need to be made from flammable materials.

It is important to know! A reputable manufacturer will have test certificates for the chimney system and will inform the buyer of installation requirements and minimum clearances for flammable materials.

According to SP 7.13130.2013 Heating, ventilation and air conditioning clause 5.27 , the dimensions of the grooves and offsets for heat-generating devices and factory-made smoke ducts should be taken in accordance with the technical documentation of the manufacturer.

Simply put, your chimney manufacturer should guarantee your safety. If the cuts are not indicated, the manufacturer is confused about the values, which means that certification was not carried out and there were simply no tests. And, accordingly, no one guarantees your safety.

SP (set of rules) is a kind of law for builders. This document specifies and recommends standards for construction, design, production of building products and their operation. In other words, the joint venture is a kind of analogue of the administrative and criminal codes in construction.

If the equipment does not comply with the SP, it can be fully considered questionable, and therefore potentially dangerous to life and health.

Features of operation

A stainless steel chimney is quite popular today, but, like other chimneys, it needs to be checked from time to time and generally taken care of. Below we will talk about how to do it correctly.

- The first thing to do when using a steel chimney is to carefully inspect the heating apparatus before each season. From time to time it may need to be cleaned to remove soot and other dirt.

- Next, you need to check the draft when the time comes for the first ignition. If it’s not there, then you need to find out what’s wrong. As a rule, simply warming up with improvised means and then checking the traction with a match is enough.

Important! The draft is checked with the regulator valve or gate open.

- You need to inspect the chimney duct to see if it is clogged with soot. You can get rid of it using a soft stainless steel brush and a plaque softener.

- From time to time you can add aspen firewood, which can be used to remove soot from the chimney.

- Proper use of the stove involves the use of resin-free wood from deciduous trees. It should also be noted that it is impossible to use cuttings of plywood and chipboard for ignition.

It is necessary to take into account the presence of a number of operating features that determine the service life of the chimney

You might be interested in knowing which air conditioners are worth purchasing.

What secrets do steel chimney manufacturers hide?

Any engineering system consists of nuances and the chimney is no exception. We will tell you what pitfalls you can stumble upon when choosing a DS.

Steel

The steel for the chimney must be extremely heat-resistant. In addition, the steel must withstand the negative effects of condensation - it falls out when cooling flue gases or moisture in the fuel.

Do not confuse condensation that forms in the chimney with drops on windows that appear in cold weather. Condensation in the chimney is far from water, but an aggressive acid, the effect of which only intensifies with each subsequent kindling.

If you see a steel chimney with traces of corrosion on the facade, it means that it has been exposed to condensation. But if the chimney rusts on the outside, what happened to it on the inside? It's simple: if corrosion has reached the outer shell, then the inner circuit is already rusted, the insulation is broken, and users of this sandwich chimney are exposed to mortal danger - carbon monoxide poisoning or fire.

It is important to know! Low-quality steel of the internal chimney pipe may rust within the first year of operation. This is called money down the drain.

How thick should the steel be for a chimney?

Many believe: the thicker the steel, the better and more reliable the chimney. But this is far from true.

Throughout the civilized world, steel with a thickness of 0.5-0.6 mm is used for the production of DS. If a manufacturer uses thicker metal, it means that he is trying to compensate for its poor quality. In chimney steel, the composition of the alloy is important, not its thickness!

Any conscientious manufacturer, be it Russian or European, meets these standards. The specified steel thickness allows the steel chimney to heat up quickly and evenly in order to create the necessary draft. Thinner metal reduces the weight of the structure, which saves on fasteners.

It is important to know! If a seller advises you to buy a steel chimney made of thick steel, ask him what additives are in the alloy? The fact is that the heat resistance of steel and its ability to withstand condensation directly depends on alloying additives (titanium, chromium, nickel, molybdenum), and not on the wall thickness. Choosing a chimney based on thickness is like judging the quality of clothing by its size.

When choosing a DS, always check the steel grade! For the inner pipe, the most reliable and safest grades are: AISI 316 (AISI 316L and AISI 316Ti can also be found, carbon and titanium are additionally added to these types of steel, which increases their corrosion resistance and makes them more durable), AISI 321 and AISI 444.

The use of these steel grades will allow the chimney to serve reliably and safely for up to 20 years. If other alloys are used, a steel chimney may fail after a couple of years of operation - the inner shell will simply collapse from condensation.

The outer shell does not need to withstand high temperatures and aggressive condensation, but this is not a reason to make it from low-grade steel. It should still protect the system from precipitation and mechanical influences. For the outer shell, AISI 304 or AISI 441 steel grades are used. Some manufacturers offer a painted outer shell made of galvanized steel. The paint must be heat-resistant and applied in several layers.

It is important to know! A well-painted shell indicates high quality production and reliability of the chimney.

Steel summary:

- the inner shell must be made of durable steel grades: AISI 316 (AISI316L or AISI 316Ti), AISI 321 or AISI 444. Other steel grades AISI 430, AISI 439, AISI304, AISI441 may become unusable in the first year;

- the outer shell can be made of lower quality steels;

- the steel thickness for a high-quality steel chimney should be 0.5-0.6 mm;

- For steel to be of high quality, it must contain alloying additives (titanium, nickel, chromium, molybdenum, etc.).

Installation recommendations

The recommendations below will help you install the chimney correctly so that it functions without any difficulties.

- If you install a pipe with a height of five meters or higher, you can achieve good traction.

- The length of horizontal sections should be up to one meter, no more.

- Installing a chimney outdoors or in an unheated room requires the installation of thermal insulation material.

- If the chimney passes through a roof built with flammable materials, a spark arrestor must be installed.

If you strictly follow the proposed recommendations, you can install a chimney without any problems

Important! Joining uninsulated pipes in the wall is prohibited if the chimney ducts are not insulated.

Welds

The weld seam is one of the most vulnerable places in a chimney. Welding destroys the protective layer of metal and this is where the chimney is most susceptible to corrosion.

A poor-quality seam may not be airtight and, as a result, flue gases will escape. An unacceptable option for a chimney sandwich is spot welding or an overlap connection. The best and most reliable connection is a continuous butt seam.

Important! Always look at the welds. First of all, the seams of shaped elements - tees, bends, support plates. Here, welding costs an order of magnitude more than on straight pipes, and unscrupulous manufacturers can save on it.

Maintenance and cleaning

The chimney must be periodically cleaned of soot. Better 2 times a year. It can be cleaned mechanically and chemically. The choice is yours. After cleaning, be sure to check the traction.

In winter, sometimes condensation or precipitation freezes in the upper part of the pipe - it is necessary to ensure that the channel is not blocked - this reduces draft and creates a danger of poisoning residents with combustion products.

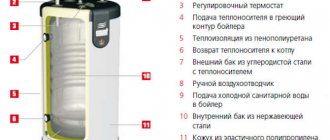

Thermal insulation layer

Thermal insulation plays an equally important role in DS. She must:

- maintain the temperature in the inner pipe so that working draft is created in the chimney and flue gases are removed from the firebox;

- do not transfer high temperature to the structures enclosing the chimney to prevent fire.

Low-quality thermal insulation loses volume, settles, forming voids through which high temperatures will be transferred to the outer shell and, accordingly, to flammable materials. This is fraught with fire.

And also low quality insulation can absorb moisture, bake or coke. In these cases, it immediately loses its characteristics, forms cavities and exposes the outer shell to high temperatures.

The best option for a chimney would be a heat insulator that does not contain adhesive binders that burn out at temperatures of 500–600 °C.

Important! Ask the seller to show the insulation in the pipe. If it is printed from individual fibers, then within the first six months or a year it will lose its characteristics. High-quality insulation will be wrapped around the pipe like a blanket or consist of 2-3 segments.

Unscrupulous manufacturers use a trick - they create an illusion: they install rings consisting of high-quality segmented thermal insulation into the edges of the chimney, and fill the main space with low-grade material.

How to calculate the dimensions of a chimney

To build the correct chimney for a solid fuel boiler, you must maintain its main dimensions:

- height;

- length of the acceleration section;

- hole diameter.

It is important to make the chimney for a solid fuel boiler insulated in order to shift the dew point. In thin-walled chimneys, cold and heat “meet” inside the pipe, condensation forms. It promotes the adhesion of soot particles to the walls, clogging the outlet channel with soot. Moisture reduces fuel combustion efficiency and impairs traction.

The minimum chimney height for a solid fuel boiler is indicated in the technical data sheet. It is advisable to make it higher; you cannot reduce it. The greater the length of the vertical section of the exhaust system, the greater the difference in the pressure of the air leaving the firebox and that located outside at the end of the pipe.

It is also impossible to make a very high chimney for a solid fuel boiler. The air leaving the combustion zone and rising upward gradually cools down.

Cold masses can begin to sink, bringing soot and carbon monoxide back into the room. The intensity of fuel combustion at this moment decreases due to the limited supply of oxygen. The diameter of the chimney for a solid fuel boiler must be the same as the smoke outlet on the heating equipment. If the exhaust duct is square in shape, then the diameter size is the determining factor between the walls of the pipe.

The golden rule for choosing stainless chimneys

A good chimney is also judged by its installation. When installing a steel chimney, the use of sealants, hammers, nails and screws is unacceptable. The chimney is assembled by inserting one element into another, and the joint is crimped with a clamp. This connection ensures high tightness and reliability.

The golden rule for buying a chimney is never take the price of one item as a guide. For example, the cost of a meter of pipe. Ask the manufacturer or retailer for a comprehensive quote to install the entire system. This way you can avoid pitfalls and compare real prices from different suppliers.

For example, cheap systems may have more fasteners and more expensive installation. Without paying attention to the comprehensive offer, which includes turnkey installation, you can get a low-quality chimney system at a good price.

What materials should exhaust pipes be made of?

With a wide variety of materials, only a few types can be used to operate a chimney. The main ones are:

- Brick.

- Metal.

- Ceramics.

They are able to withstand very high temperatures. Its maximum reaches 1000 degrees. Today, on the roof of modern expensive cottages you can see an original chimney made of eurobrick. However, upon closer examination, you can see pipes inserted inside the brick chimney. They can be steel or made of ceramic. This is explained very simply. One brick is not suitable for normal operation. In other words, it will work, but not for very long. It will quickly be destroyed by caustic condensation. Therefore, a liner is inserted into the brick pipe. Free cavities are filled with insulating material. Sandwich pipes made of ceramics can withstand very high temperatures. It can exceed 1200 degrees. This value is much higher than the maximum smoke temperature after coal combustion.

Such a pipe is not afraid of condensation and any atmospheric phenomena. Condensate is drained through a special drain hole. Sometimes for this purpose an additional container is made at the end of the watering can. A ceramic chimney pipe is installed on the facade or inside the building.

A chimney of the Schiedel Uni brand, if a soot fire occurs, is able to cope with such a thermal load. When burning, soot heats up to a temperature of 1100 - 1200 degrees.

Disadvantages of ceramics

They do not have a beautiful appearance. Their cost is much higher than their steel counterparts. Installing these pipes requires construction skills and experience. These pipes remain popular among consumers with low incomes.

Metal chimney

For its manufacture, ordinary steel or stainless steel is used. Unfortunately, steel chimneys cannot withstand

aggressive environment. When the boiler operates continuously, the pipe will become unusable in a very short time and may cause a fire.

The composition of the stainless steel used includes special additives consisting of several chemical elements

- Titanium.

- Nickel.

- Molybdenum.

They are the ones who save stainless steel from corrosion. For installation

The following steel grades are used in boilers:

- 316.

- 316 L.

- 321.

They contain substances that allow steel to withstand temperatures within 700 - 800 degrees. These grades of steel are not afraid of condensation, they are neutral to acids, and do not react with other aggressive substances.

The cost of a chimney made of stainless steel is affordable to the average buyer. It is considered most suitable for installation in a solid fuel boiler.

Glass chimney

Very rare. Its positive qualities include:

- Low thermal inertia.

- Corrosion never occurs.

- Original look.

The cost of such a design is very high. Therefore it is very rare. In addition, its installation is very labor-intensive and costs a lot of money.

Types and differences

All types of sealants for use at high temperatures are divided into two large groups - heat-resistant (silicone) and heat-resistant (silicate). They differ in chemical composition and permissible operating parameters.

Heat resistant

Heat-resistant sealants are made on the basis of silicones - organosilicon oxygen-containing compounds. They can withstand temperatures up to 300 °C; at 100 °C and above, heat-resistant silicones are superior to all traditional elastic materials.

Silicones are durable, elastic, chemically inert, waterproof, resistant to biological influences, and ultraviolet radiation. They can operate under rapid temperature changes, are non-toxic, and environmentally friendly.

Heat-resistant silicones are available in the form of a reddish-brown paste. The color of the sealant is given by iron oxides. Operating temperatures can range from 170 to 300 °C, this information is indicated on the packaging.

Areas of application of silicone: sealing the outer surfaces of a chimney, the junction of a pipe and a roof, sealing blind cracks on brick surfaces of fireplaces and stoves, sealing pipes of gas boilers with high efficiency and low heating of flue gases.

Silicone seals

For the convenience of consumers, the industry produces a huge range of silicone seals - gaskets, membranes, cords, tubes, seals of various configurations. They are used for sealing windows and doors, in household appliances, cars, and electrical equipment.

Master flush is made from silicone - an elastic seal for the passage of pipes through the roof. They produce special heat-shrinkable tapes - they are used to wrap the joints of chimney modules; when heated, they melt and tightly fill the joint being sealed.

Heat resistant

To seal and repair the internal surfaces of chimneys, combustion chambers, solid holes in brick pipes, joints of cast iron and steel elements with the furnace masonry, assemblies of sandwich chimneys, fire-resistant silicate polymers are used that can withstand temperatures up to 1200 °C (for a short time - even up to 1500 °C ).

Silicate sealants have a black or black-gray color and a viscous consistency, and harden within 15 minutes after application. The thickness of the seam can reach 15 mm. Heat-resistant silicates form an inelastic joint. Work is carried out at temperatures from 1 to 40 °C.

Adhesive facing compositions

The industry produces special heat-resistant compounds for cladding stoves, fireplaces and chimneys with tiles (regular, fireclay, clinker, porcelain stoneware), natural or artificial stone. They are usually made on the basis of silicates and contain liquid glass, kaolin, cement, plasticizers, and polymers.

Such mixtures can withstand temperatures from -30 to +170 °C and even higher. Other high-temperature adhesive compositions are also used in industry, the drying of which requires strong heating, but they are not widespread in everyday life.

How to carefully and correctly apply sealant

When working with both types of polymers, it is necessary to prepare the surface of the chimney: clean, remove dust and dirt, and degrease. It is advisable to sand the steel with fine sandpaper to improve polymer adhesion.

The surface under the heat-resistant sealant must be completely dry. The tube is inserted into the gun and a small amount of silicone is squeezed onto the joint to be sealed. Allow to harden (approximate time is indicated on the package).

The base for the heat-resistant silicate polymer is prepared and slightly moistened. Apply the sealant and let it harden. Excess heat-resistant mass is removed before the sealant hardens. You can apply masking tape along the joint in advance and remove it after application.

It is advisable to carry out work in warm weather.

Features of sealing sandwich chimneys

Sandwich pipes have a metal surface. Both silicate and silicone polymers are used to seal them.

A characteristic feature of sealing sandwich pipes is the need to seal both the inner and outer pipes. In addition to the general safety considerations that were given at the beginning of the article, it is very dangerous for a sandwich to get atmospheric moisture from the outside or condensation from the inside into the insulation.

The outer layer should be coated with silicone - it has excellent hydrophobic properties. For the internal joint, a heat-resistant sealant is selected depending on the type of heating device and the smoke temperature.

The sealing process itself is not particularly difficult - a bead of sealant is applied to the joining surfaces of the outer and inner layers and carefully spread with a layer of 1-2 mm using a spatula or a flat steel plate, then the chimney modules are joined together.

Pipe height

Its minimum permissible value can be recommended by manufacturers of heating units and depends on the power of the manufactured devices.

Consider a table of the dependence of the height and diameter of the chimney on the boiler power:

| Power, kWt) | Diameter (mm) | Height (m) |

| 18 | 130 | 7 |

| 28 | 150 | 8 |

| 45 | 150 | 9 |

| 65 | 200 | 10 |

| 90 | 250 | 11-13 |

But this indicator can also be calculated using the formula:

H = P x TG x TV/3459 x (TG – 1.1 x TV), where:

- P – traction force, in Pa.

- TG and TV are the temperatures of the outlet gas and outside air, respectively, attention, in Kelvin.

- H – required height.

In this case, the pipe in any case must rise at least 1.2 m above the flat roof, 0.5 m above the ridge (if located closer than 1.5 m, on the same level with it, if located at a distance of 1, 5-3 m, or at an angle to the horizon of 10 degrees, if further than 3 m).

Device and installation

When installing a metal chimney, work starts from the bottom, gradually moving upward. Pipes can be connected in several ways:

- By the movement of smoke.

- For condensate

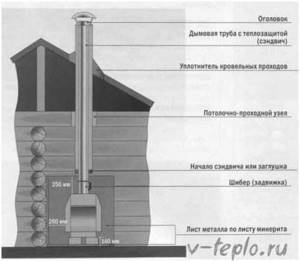

When the boiler is connected to the chimney according to the first option, installation occurs from the boiler. The second option, on the contrary, goes to the boiler. The metal structure consists of several parts:

- Cup.

- Pipe sandwich.

- Condensate collector.

- Spark arrestor.

- Header.

- Cleaner.

To create a reliable connection, establish:

- Adapters.

- Tees.

The joints are fastened with clamps from the outside.

Installation of a brick chimney

Brick, being a traditional material for laying chimneys, is valued for its high resistance to high temperatures. Laying out the structure while maintaining complete sealing of all joints requires certain skills, so competent craftsmen are needed. Due to the fairly large weight of a brick chimney, a foundation will be required.

Basic rules for installing a chimney for a solid fuel boiler

Experts note that the rectangular shape and rough surface of the brick contribute to significant soot settling and make it difficult to clean the chimney. One of the positive aspects is the fact that the high intensity of fuel combustion in a solid fuel boiler prevents the accumulation of condensate with subsequent destruction of the chimney walls.

Types of steels used for the manufacture of pipes (chimneys):

Stainless steel is a complex alloy steel (an alloy of iron with carbon 0.02-2% by weight), containing various additives and at least 10% chromium, which is resistant to corrosion in the atmosphere and aggressive environments to varying degrees.

Steels and alloys with special chemical properties (corrosion-resistant, heat-resistant, heat-resistant) are designed to work in aggressive environments and at high temperatures.

It should be remembered that not all stainless steels are both heat-resistant and heat-resistant: an increase in heat resistance t (scaling t) to the maximum indicators always leads to a decrease in fur. strength - here an increase in the thickness of the inner sheet is a good sign. Chimneys are offered in abundance on construction markets, but it is always necessary to check the grade of steel. In the domestic classification (according to GOST), resistant stainless steels include grades with a high percentage of chromium, titanium and nickel, for example, such as 10Х18Н9Т, 12Х18Н10Т, 10Х23Н18. In the USA - these are steel grades AISI 316L, AISI 310S, in Europe - classes EN 1.4404, EN 1.4539, EN 1.4845

The resistance of steel to corrosion depends on the chromium content:

– 13% and higher - alloys are stainless under normal conditions and in slightly aggressive environments (ferritic steels); with aggravation of chemical Due to the parameters of the diesel generator, corrosion occurs in different types. – more than 17% are corrosion-resistant in aggressive environments (oxidative, etc.).

Corrosion resistance is provided by a film of chromium oxides that forms on the surface of the metal when it interacts with atmospheric oxygen and is capable of self-healing after damage. The higher the chromium content, the greater the corrosion resistance of the steel. Corrosion is the process of destruction of metal under the influence of the external environment.

Stainless (corrosion-resistant) steels according to their structure are divided into:

Flame characteristics and properties

The flame is a hot gaseous medium and spreads from bottom to top. This happens because warm air becomes less dense. When heated, it rushes upward and carries the fire with it. Therefore, lighting the fire (stove) starts from the bottom. Because a torch set on fire at the very top will not spread the fire down, and it will die out.

Flame behaves completely differently in zero gravity. Due to the lack of gravity, it spreads in all directions at once and therefore has the shape of a ball. Moreover, it glows with a bright blue color, but only as long as there is oxygen nearby. As soon as the latter burns out, the fire goes into a “cold” stage, invisible to the eye. And it lasts for several minutes. And if oxygen is supplied to the invisible source, the bright combustion resumes.

On the ground, the height of the flame will depend on how hot the flame temperature of a wood fire is. This is directly related to the intensity of combustion. And the phases stretch: from slow smoldering to explosion. But the greater the strength of the fire, the faster the fire burns out.

High flame of a fireSource goodfon.ru

The flame can change its color, and this is also affected by power. During the combustion process, the fire passes from red to violet spectra and back. But the palette also depends on the impurities in the fuel. If you throw ordinary table salt into a burning hearth, the flame will turn yellow. Sodium is to blame. And boric acid causes a turquoise tint.

Therefore, when firewood burns bright orange, it means that it contains a lot of sodium salts. And the blue color of a fire comes from incomplete combustion of fuel. This releases carbon monoxide. So it gives a similar spectrum.

But it happens that the flame is almost impossible to see. Colorlessness of fire occurs when fuel is completely burned. When it emits only water vapor and carbon dioxide. And these substances are invisible even when heated.

Any combustion is accompanied by smoke, as a fine aerosol is formed. Its particles are so small that they do not have time to settle to the ground and are carried away by heated air masses. And the amount of secretions depends on oxygen. With a very high concentration, the fire burns almost smokelessly. And if it barely smolders, spreading clouds of smog, then this indicates its shortage.

Extinguishing fireSource pixabay.com

The color of the emissions is directly related to the water content in the fuel. If you put wet firewood or freshly cut grass into the kindling, thick and white smoke will come out of the chimney. But when it turns black, this indicates a large amount of soot in the fuel. A striking example is the dense black smog caused by a burning car tire.

Choice of material: wood, vinyl or steel

In fact, soffits in their design and production method are not much different from siding. As well as in terms of strength, because soffits also need to have mechanical strength to impacts and strong winds.

Soffits made of plastic or vinyl are relatively fireproof, very light and do not rot, are easy to process and can take almost any shape. Thanks to this, soffits cover complex architectural elements.

Vinyl soffits go well with popular vinyl siding, are flexible, durable and lightweight. With a thickness of 0.4 cm, they weigh only 1.16 kg/m2.

Because The spotlights are always in the shade; there is no need to worry that they will fade in the sun. PVC is also good because it is not destroyed by mold or mildew, does not need painting and can withstand frost of -50°C and heat of +60°C. By the way, vinyl soffits today are often made not only to match the color of the roof or facade, but also to imitate natural wood.

Modern metal soffits are manufactured using special equipment by rolling. They are made from galvanized steel with a polymer coating such as pural, plastisol, polyester or polyvinylidene fluoride. In fact, their price directly depends on the coverage. They are durable, reliable and practical.

Polyester as a coating for steel soffits is good for color fastness and ductility, and plastisol is resistant to mechanical stress. Pural is more resistant to ultraviolet radiation and temperature changes, and is most suitable for use outdoors.

Typically, manufacturers offer to purchase a whole set of necessary roofing materials at once, so that in the end the entire roof has a complete look, where all the elements are in perfect harmony with each other in shape, color, and type of coating.

Flexible and lightweight aluminum soffits are made from thin (0.5 mm) aluminum strip. Such soffits are highly resistant to corrosion, do not emit an unpleasant odor under the steaming rays of the sun, and are absolutely environmentally friendly.

The decorative coating adheres well to such material, even if it has to endure significant temperature changes. Thanks to this, aluminum soffits are suitable for any climate.

Aluminum soffits are practically not subject to corrosion, are not flammable, and are little susceptible to thermal expansion, fading and mechanical damage. However, this is the most expensive type of spotlights.

In this regard, wooden soffits are much more profitable. True, from time to time they will have to be restored to their original form, treated with antiseptics and tinted.

There is also such an interesting type of spotlights as planken. Essentially, this is the same plastic, only made in a wooden style. Moreover, both beveled and straight planken look good. In this case, under-roof ventilation is provided by a ventilation gap.

But copper soffits are considered not only the most durable material, but also the most unpretentious, aesthetically pleasing and naturally protected from environmental influences. Copper products form a natural anti-corrosion coating, thanks to which the service life of such soffits can reach 150 years!

For example, the Soffitto filing system is popular. These are copper soffits, the color of which changes over two to three years from golden to dark brown, and then to matte black. And finally, the last stage of oxidation is a greenish patina.

Fiber cement siding is also becoming popular, which is quite durable and attractive with the beautiful texture of cedar wood. Such a binder is made from a cement-sand base and fibers - synthetic or natural.

The service life of such material reaches 50 years; there is no linear expansion due to temperature changes. In addition, fiber-reinforced concrete siding, unlike ordinary wood, does not rot, is not attractive to insects and is not afraid of moisture. And such a binder is processed and attached in the same way as a wooden one.

If the filing is solid, then special slots 0.5 cm thick are made in the panels. In this case, you need to install a mosquito or metal mesh on the inside

It is important that all components are made of aluminum. This includes external and internal corners, J-profiles and connecting strips

Also suitable for filing overhangs are profiled sheets with a thickness of 0.45 mm or more made of galvanized steel or polymer-coated steel. They differ from other analogues in good strength and rigidity and a large selection of colors.

If you decide to make overhangs from such a material, then cut the corrugated sheet into strips of the same size and carefully paint over the sections so that corrosion does not spread, but the paint is not noticeable on the main surface of the sheet.

Why do you need chimney sealing?

The chimney is designed to remove hot combustion products from the combustion chamber of a heating unit - boiler, stove, fireplace. When any fuel is burned, it produces a lot of carbon dioxide (CO2), a small amount of carbon monoxide (CO), sulfur oxide (SO2), a small amount of oxides of some other elements, water, and unburnt fuel particles (soot). All of them are harmful to humans.

The temperature of the exhaust gases from solid fuel boilers can reach 600 °C and above, from gas boilers - 200 °C, when cleaning the smoke hog by igniting soot it reaches 1000 °C. A small stream of hot gas from a chimney is a common cause of fire. Even 200 °C for a long time is enough for the wallpaper to begin to smolder.

Therefore, the tightness of the chimney is a prerequisite for its operation. Modern heat-resistant sealants are used to seal the joints of individual elements of prefabricated chimneys. In addition, they are used for emergency sealing of leaks that occur during the heating season, when it is not possible to turn off the heating device and disassemble and replace part of the chimney.

Heat-resistant sealants are even used to seal holes and cracks in traditional brick chimneys. Traditionally, clay was used for this, but it is unreliable as a sealant. In addition, heat-resistant sealants are used to waterproof the exit of chimneys to the roof - this protects the rafters and under-roof structures from getting wet and rotting.

Requirements for the installation of chimneys for solid fuel boilers

- Maximum vertical design. Ideally, it should look straight up, then the aerodynamic force for removing combustion products will be most effective.

- The cross-sectional area of the channel must be larger than that of the pipe. It is also possible that they can be equal, but this is a last resort.

- The height of the pipe is not less than the required figure in the heating equipment passport. When arranging the sleeve, the level and angle of the roof, as well as the distance to the ridge, are taken into account.

- It is necessary to make an acceleration section that will stimulate traction. To do this, install a tee, immediately behind which a 1 m long passage is created perpendicular to the roof, and only after that other sections are created.

- The presence of a deflector is mandatory (if there is wind support).