Life is full of examples when something grandiose, monumental holds or works thanks to small details that non-specialists are unlikely to know about. For example, in construction, when pouring screed, a technological gap is needed. Which of the home craftsmen knew about this before they climbed onto the World Wide Web in search of appropriate instructions. That's right - units.

And why should they know - they are not professional builders. Although the “pros” often screw up: either they will forget about the problem, or they will deliberately ignore it in order to speed up the work. And those who knew previously used wooden slats or pieces of reinforcement (then removed), pieces of linoleum or bubble polyethylene from packaging to maintain the distance between the main wall and the screed. Manufacturers of building materials knew firsthand about the constantly emerging difficulties. The problem was solved simply: they began to produce a special damper tape for floor screed.

The editors of the StroyGuru portal decided to help all those who carry out repair and construction work at home with their own hands: tell what damper tape is, why it is needed, what varieties can be found on sale, how to choose the right one and attach it to the wall. Let's talk about manufacturers and prices.

What is it and why is it needed

Hardened cement-sand mortar has one unpleasant property - it expands under the influence of temperature and humidity. The screed also has it. It “breathes” both in height and width. In this case, the linear dimensions in length/width vary within 0.5 mm per 1 m2, but not more than 1.0 cm in total.

But even an expansion of 2-3 mm is enough for the screed to either collapse itself or damage the wall. A layer of material that can dampen (extinguish) the breathing of cement stone saves from the destructive consequences.

The builders forgot about the damper tape.

Definition

The word damper came into the Russian language from Germany. There “Dämpfer” - muffler, shock absorber, from the verb “dämpfen” - to muffle. Therefore, in a general sense, a damper device is understood as anything capable of preventing vibrations that occur in machines, devices, systems or structures during their operation.

Taken in a narrow sense, a damper tape (sometimes called edge or compensation tape) is a specially made strip of elastic material that can compensate for the linear expansion of concrete and other building materials under the influence of moisture and temperature.

If this definition is translated into a simple language understandable to a non-specialist, then the tape should be understood as a voluminous, plastic material that can compress when the screed expands and recover when its size decreases, while constantly maintaining some gap between the wall and the expanding cement stone.

Functions

The main task of the damper tape is to ensure free expansion of the screed. Those. A plastic strip of material several millimeters thick, fixed along the perimeter of the walls, creates a technological compensation gap that allows maintaining the integrity of the surface layer of the poured base for the finishing floor covering.

In addition to the main function, there are a number of auxiliary tasks that are no less important for apartment owners:

- creation in certain areas of a restrictive barrier for the solution, a kind of formwork;

- organization of additional hydro- and thermal protection at the joints between the floor and walls;

- strengthening sound insulation in the most vulnerable areas of the house that transmit structural noise;

- absorption of microvibration of walls due to mechanisms operating in the building, such as forced ventilation or an elevator - are not transmitted to the floor, but through it to a person;

- In some cases, leveling the walls and the base of the floor, at the joints between them, under the screed.

It is a mistake to think that the compensation layer is needed solely for the screed. The increased popularity of plasterboard walls and partitions has shown that gypsum plasterboard also expands and is destroyed without a special strip under the guide profile. This strip is called profile damper tape.

What is it for?

Since there is no mention of damper tape in SNiP, we can only talk about what this polyethylene strip is needed for as a recommendation. Therefore, the use of a compensator is desirable:

- when pouring cement-sand screed, wet and semi-dry;

- when filling expanded clay to level the floor (dry screed);

- when heating floor coverings made of tiles, porcelain stoneware, laminate, linoleum using water and cable “warm floor” systems;

- creating blind areas outside the building.

In large rooms, the compensating gap along the walls is not enough. It is placed in the middle of the screed at certain intervals using a T-shaped strip of polyethylene foam. You also need a damper tape for the self-leveling floor. Don't forget about the tape for the drywall profile.

Installation of heated floors using damper tape

So, we come to the most exciting question - how to install a heated floor in your home using damper tape? The answer is simple - just like the usual one, but at one of the installation stages it is necessary to lay the material along the wall. This will be discussed in detail below in the instructions.

For now, it is important to find out what needs to be done before installing the tape

Making a heated floor using damper tape

Preparatory work before installation

The preparatory stage before installing a heated floor using damper tape includes the following steps.

- Wall treatment. They must be plastered and puttied in advance, if this work has not yet been carried out. The fact is that during installation of the damper tape it is glued directly to the wall. Then it will be inconvenient to carry out this work.

- Installation of door slopes, installation of windows. It is also necessary to carry out this part of the work before laying the damper tape so that construction debris does not interfere with working with the screed.

- Preparing the subfloor. All damage to it must be repaired; if necessary, the surface must be pre-grinded.

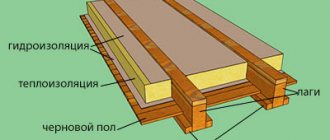

- Laying waterproofing. This type of work is also carried out before installing the damper tape.

Preparing to install heated floors

The main stages of installing a heated floor using damper tape

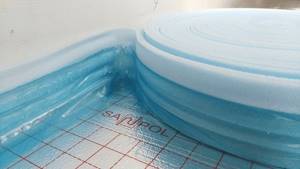

Step 1. After all the preparatory work, the first step is to lay the compensation tape. It is mounted along all the walls of the room being renovated. If the tape has a sticky layer, it immediately sticks to the walls. The “skirt,” if there is one, is laid and straightened on the floor along the wall. The tape is mounted so that in the end the level of the concrete screed is slightly below the upper border of the tape. At the end of the work, its remains are cut off or simply covered with a plinth.

Laying damper tape

Laying process

Step 2. Next, thermal insulation boards are laid. They should be located close to the wall and damper tape and connected tightly to each other.

Laying thermal insulation boards

Step 3. Heat distribution plates are laid. They have notches that allow you to separate them with your hands if necessary. The plates are easily fixed on thermal insulation boards. Laying step – 2 cm.

Installation of heat distribution plates

Installation process

Another photo of the process

Step 4. Plastic pipes for the coolant (16 mm in diameter) are laid in the grooves of the plates. Laying starts from the supply manifold and is carried out according to the scheme - first along the outer walls of the room with a laying step of 150 mm, then in a snake with a step of 200 mm.

Laying plastic pipes

Snake laying

Step 5. A waterproofing film is laid on top of the laid pipe system.

Next, waterproofing is installed

Step 6. Sheets of gypsum fiber are placed on top. After this, the finishing floor covering is laid.

Installation of gypsum fiber sheets

Also, a concrete screed can be poured directly on top of the heating system - without laying gypsum fiber. Usually this is a cement-sand mortar with the addition of a plasticizer. The latter is necessary to ensure that the mixture is plastic but dense. Thanks to the plasticizer, the floor surface will be smoother.

Do not also forget about installing a temperature sensor. It will record the floor heating temperature and transmit its readings to the thermostat. Installation is carried out before pouring the screed.

Installation of a warm water floor

What is it made from?

Ideally, the damper edge tape should have the following characteristics:

- have a low thermal conductivity coefficient;

- have good plasticity, allowing volume to be restored after compression, which, however, is not important. After all, after the screed has set, the damper can be removed;

- do not be afraid of moisture, do not absorb it, so as not to create a favorable environment for the growth of mold and mildew;

- be light and easy to use.

All these qualities are fully manifested in tapes made of foamed polyethylene, which can be chemically cross-linked (PPE or HPPE) and non-cross-linked (NPE). Both materials have similar technical and operational indicators, which affects prices. They are almost equal.

On sale you can find tape made from densely woven polyester fibers, as well as from foamed synthetic rubber. The tape is sold in rolls of 10, 15, 20, 30, 50 and 100 m in length. It can be in the range of 3-10 mm in thickness, 8-15 cm in width. The widest, 150 mm, is a damper tape for warm floor.

Types of compensation tape and their features

Today, there are different types of compensation polymer layers on sale. This section will look at what they are and what they are used for.

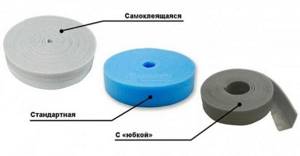

| Illustration | Brief description of the material and its application |

| Standard version of compensation tape. It may vary in width and thickness. This layer is simply laid upright against the wall along the entire perimeter of the future screed. The material has the most affordable price of all types of tapes, but it is also the most inconvenient for installation, since the manufacturer does not provide for fastening to a vertical surface. If desired, the tape can be fixed with double-sided tape or polyurethane glue. Sometimes it is even pressed against the wall with piles of mortar or dry backfill. | |

| A self-adhesive type of damper tape - equipped with an adhesive strip, temporarily covered with a protective film, and which is removed immediately before laying the material against the wall. An easy-to-install option, it is well fixed to the wall, so during the pouring process the screed does not move and does not “lubricate” the edge of the slab. True, such a tape will stick well only to a flat and clean wall - otherwise there is no need to overpay, you can be content with the usual one. | |

| A ribbon equipped with a “skirt” (basque). This type of material is divided along its entire length into two parts - the main one, made of foamed polyethylene, and the “skirt”, consisting of ordinary dense polyethylene. The dense part of the tape is installed along the wall, and the “skirt” is laid on the floor. This way the joints between the wall and the floor are waterproofed. An excellent solution for preparing for pouring screed in the bathroom. A tape equipped with a peplum may have an adhesive layer or be left without it. | |

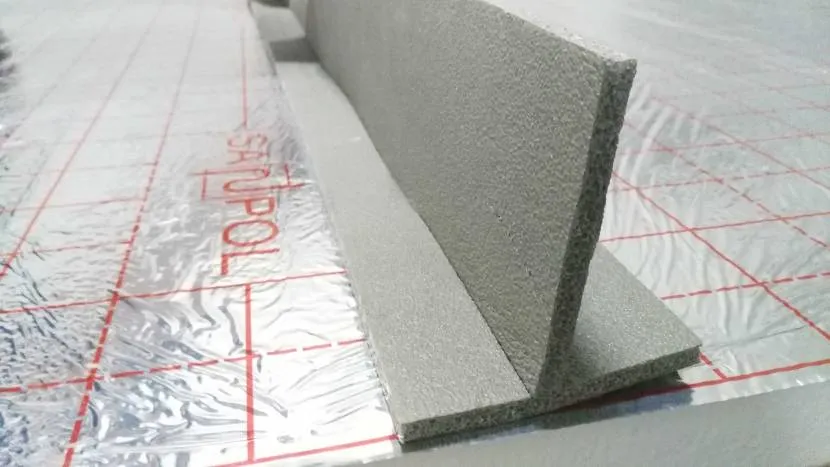

| The T-shaped version of the damper tape is used in cases where the screed has a large area, and the deformation gaps along the walls alone are not enough to compensate for the expansion of concrete. The installed T-shaped tape, after pouring and hardening of the screed, as is probably understandable, turns into a ready-made expansion joint. | |

| For ease of working with tape, some manufacturers make samples that have several cuts - tear lines along their entire length. When working with such a tape, it will not be a problem to remove the excess protruding upward after the screed is ready. However, cutting off the excess with a sharp knife doesn’t take long either. So the author of the article, for example, has doubts whether it is worth overpaying for such a bonus. |

There are probably no standardized forms of tape release - each manufacturer is free to use their own standards. We can only clarify that the following sizes are most often found:

- the thickness of the material usually varies from 3 to 10 mm;

- width - 80÷150 mm;

- tapes are sold in whole coils (rolls), 10, 15, 20, 30, 50 and 100 m long

The tape, which has a width of 150 mm, is usually used for prefabricated structures, for example, if a “warm floor” system or dry screed is installed. The material, 100 mm wide, is used for one- or two-layer screeds, including when leveling floors with self-leveling compounds.

Is it possible to do without it?

Some experts argue that expansion tape is only needed for floating screeds. If the CPR is poured directly onto a rigid base, for example, in a garage on a concrete floor slab, then you can do without a damper tape. It is not needed for self-leveling floors with a thin layer of self-leveling mixture.

Let's try to figure out whether a damping strip is needed in the listed cases. Let's start with the screed. Let's not theorize, but refer to accumulated experience. There is no need to go far - look at what is happening (or was happening) with the screed in houses built in the 80s of the last century: CPR was poured directly onto the floor slabs without a damper tape (it began to be widely used in the late 90s). After a few years, the layer of mortar crumbled, in most cases in the heating area. Fortunately, there is linoleum on top, which is not critical for the floor covering.

The argument about thin self-leveling floors is also unclear. For thick people it is necessary, for thin people it is not. Where is the logic? After all, linear expansion in length/width does not depend on the thickness of the concrete. It is always equal to 0.1 mm per 1 m of length when the temperature increases by 1oC. Let us especially emphasize - at +1oС.

Where you really don't need a damper tape:

- frame houses. The walls there are not concrete or brick, and the screeds do not provide resistance to linear expansion;

- The thermal insulation is made with rolled materials extending onto the walls to the thickness of the CPS filling - they act as a shock absorber.

Conclusion: damper tape is always needed for hard walls. The owner of a house or apartment can refuse the compensation gap only at his own peril and risk.

As for the damper tape for the profile under plasterboard, in the bathroom when installing a false wall (box), it is required. When installing interior walls, it is advisable to lay. But nothing bad will happen if the owners refuse to use the compensator strip.

Installation of deformation tape

Advice: if you want to save money, you can get by with a product that does not have an adhesive side. In terms of functionality, it will not be any different, and ordinary liquid nails or a construction stapler are quite suitable for fixation.

Fixation possible using a construction stapler

This procedure is quite simple, but just in case a small instruction may come in handy:

- We make marks at a distance of two centimeters above the level of the future floor screed of an apartment or house.

- We thoroughly clean the areas of fixation so that the adhesive layer adheres well.

- Removing the protective layer from the adhesive side, we lay it along the entire perimeter of the walls.

Tip: If there are columns or other decorative elements in the room, be sure to trim them with edge tape as well. Otherwise, subsequent expansion of the concrete screed will come into destructive contact with them.

- Fill the floor. After hardening, remove all unnecessary elements.

It can be used not only in the installation of poured floors, but also when using a conventional cement-sand mixture.

Is it possible to replace it with something?

To save money, the damper tape can be replaced. Suitable for this:

- wooden slats;

- strip of plywood;

- trimmings of linoleum and polymer materials;

- Styrofoam;

- wooden strip wrapped in plastic film - allows you to remove the strip. Without film, wood is difficult to remove. In most cases, it remains and takes on the pressure of the screed.

There is a lot of criticism of these materials from experts. But it is baseless. After all, the damper can simply be removed and the gap closed with a plinth.

Description and functions

Damper tape belongs to the group of construction auxiliary materials for arranging a floating floor.

What is a damper tape based on quality characteristics. It is made of foamed polyethylene, designed in the form of a tape. It has a protective surface that takes on the load. To understand why a damper tape is needed, it is necessary to disassemble the process of floor screed. Concrete may begin to expand with temperature changes. This is based on its physical properties. After the cement-sand mixture dries, heat is released. It influences the expansion of the screed. The expanded screed begins to put pressure on the walls. As a result, cracking and sometimes swelling of the coating occurs due to the rigidity of the wall material.

To prevent cracks from appearing, builders began laying gaskets between the walls and floor. Bars, linoleum blanks and other means were used as gaskets. But they all have their drawbacks. After the appearance of damper tape on the market, construction specialists began to actively use it as a compensator for the compressive force of concrete on walls.

Thanks to the presence of foamed polyethylene, the material performs the following basic functions:

- prevention of deformation changes and destruction of the cement-sand mixture;

- neutralization of temperature changes;

- absorption of vibration actions;

- compaction and filling of voids and joints;

- creating additional heat insulation;

- preventing water from entering.

Such functions are due to the properties of polyethylene. After all, this component is soft, plastic, resistant to water, aggressive environments, and changes in temperature conditions. Damper tape for heated floors is an indispensable material.

Advantages and disadvantages

The damper tape has a number of significant advantages:

- durability - the service life is comparable to the service life of the screed;

- elasticity - volume and geometric dimensions are restored when the load is removed;

- good thermal insulation properties - thermal conductivity coefficient no more than 0.035 W/(m*K);

- ability to cut off structural noise;

- environmental safety - does not emit harmful substances when heated, is not an allergen;

- the material does not rot or decompose;

- low moisture absorption - picks up no more than 2% water per day;

- simple fastening;

- affordable price.

Among the disadvantages is flammability.

Purpose of damper tape. types and sizes of material for protecting floor screeds

The last stage of the rough floor covering is the installation of the screed. This constructive component levels the surface and eliminates existing imperfections.

Some external factors can significantly reduce concrete strength, for example, high levels of moisture or strong temperature changes. Under their influence, the cement base expands, which subsequently turns out to be the basis of its cracks in a chaotic manner, and defects may form on the lower edge of the walls.

To eliminate bad consequences, experts advise using damper tape, sold in any construction store. We will answer questions about whether it is necessary and how the material can be replaced.

The base of the product is polyethylene foam. The tape is very soft to the touch and has excellent flexibility. It is used to compensate for thermal expansion of concrete.

The edge tape is placed between the surface of the room wall and the screed being poured. Under pressure it contracts, and then returns to its first state. This minimizes the distance between the walls and the concrete layer, and further reduces the damage that occurs when loads appear.

If you need to dismantle the edge tape, it is very easy to remove it from the groove.

What is the material used for? The main purpose is to compensate for temperature deformations of the screed. Side tasks are thermal insulation and sound insulation of the wall groove. Plus, the buffer tape is capable of performing other functions, namely:

- Eliminate spreading of the solution over the entire coating area.

- Reduce the influence of the concrete screed on the wall surface.

- Act as a separator when working on large areas.

- Fill expansion joints.

- Stop the spread of bacteria and mold.

The material’s decent performance qualities explain its popularity when compared with alternative wall joint filler options.

Edge tape is considered an environmentally friendly material, so it can be used in arranging both non-residential and residential premises. The list of its advantages includes the following factors:

- Ensuring good insulation properties.

- Resistance to temperature changes and ultraviolet radiation.

- Moisture-resistant (not susceptible to mold or bacteria).

- Formation of a strong and completely sealed connection.

- Long service life (more than 10 years).

- Easy to install and dismantle.

The only drawback of the product is its high cost, which, however, is fully compensated by the benefits received.

Manufacturers recommend more than ten types of damper tapes needed for installing floor screeds. They differ from each other in external design and performance. They are divided like this:

- Typical. Straight tapes without adhesive layer. For fastening to the wall surface, in most cases, double-sided tape or a specialized composition is used. Preparatory preparation of the surfaces involved is required - cleaning of small debris after construction work.

- Self-adhesive. On the back of the products there is an adhesive strip, which is protected on top by a specialized backing that is gradually removed during the installation process. Professionals note the economical consumption of this tape.

- With a "skirt". The product has a characteristic feature - a “skirt” made of thin oilcloth material, which is spread across the floor during the installation process. The key purpose of this addition is to ensure complete sealing of the seam.

Standard sizes

There are several standard sizes on the basis of which the compensation tape is made. The ideal option is products with a width of about 15 cm and a thickness in the range from 4 to 10 mm, sold in rolls of 50 meters.

It is recommended to choose the width of the tape taking into account the thickness of the upcoming concrete layer. In the process of rough pouring concrete, a 10 cm wide strip is sufficient, and for a thicker screed it is best to use 15 cm wide strips.

In order to create a wall joint of the required size, at the preparatory step it is necessary to provide for the area of cement pouring and the expected temperature differences characteristic of the room.

| Options | ||

| Width, mm | Thickness, mm | Length, m |

| 100 | 10 | 25 |

| 150 | 10 | 11 |

| 100 | 10 | 11 |

| 100 | 10 | 25 |

| 150 | 10 | 50 |

| 80 | 8 | 20 |

| 100 | 8 | 25 |

How to attach the tape

During installation, additional fixation of the damper tape is required, especially when using standard products without an adhesive backing. Other fastening options may include:

- Scotch tape for painting. Short-term fixation during the pouring of concrete screed.

- Construction stapler. Suitable for working in rooms with walls made of foam concrete blocks, aerated concrete blocks, or wood.

- Liquid Nails. The best option for walls with uneven surfaces.

- Screws and dowels. Suitable for rooms with brick walls.

The last method of fixation must be used in exceptional cases, since iron hardware tears the tape, causing it to cease to be elastic and ductile.

Installation specifics

The implementation of the technology for installing compensation tape is considered the key to obtaining a high-quality and durable screed. There are three key stages:

- Preparation. Leveling the wall surface and clearing debris caused by construction work.

- Sticking. Laying the tape is carried out constantly at a height of 1.5-2 cm from the floor, starting from one of the corners of the room along the perimeter. Much attention is paid to fixation at the corners of the room.

- Ending. Trimming the tape after returning to the place where installation began.

The areas where the tape pieces “meet” must be overlapped. This will improve the tightness of the seam.

The price of the product seems high for some consumers, so they try to find an alternative option and try to change the “shock absorber”:

- Expanded polystyrene.

- Wooden bars wrapped in polymer ethylene.

- Isolon.

When using these materials, in most cases certain inconveniences arise. First of all, they need to be cut into strips of equal thickness and width. Secondly, during installation a considerable number of joints are left due to insufficient length. Also, there is no layer of glue.

The performance of alternative products for mitigating screed deformation is inferior when compared with damper tape. There is no real replacement for it.

We invite you to read: How to fill the floor in a bathhouse with a slope under the drain with your own hands?

Biofilters

Damper tape for screed is one of the most important elements from the group of auxiliary building materials. It is widely used in the construction of “floating floors” and effectively helps prevent cracking or premature failure of the concrete base.

A damper in the form of a tape is a kind of vibration damper; its absence causes expansion of the screed during temperature and other external changes, which can be the main cause of damage to building elements.

The damper in appearance resembles a strip, for the manufacture of which modern polystyrene foam or polyurethane foam materials are used, supplemented with an adhesive composition. Thanks to the physical properties of the raw material, the finished tape acquires a dense foam structure that can easily cope with long-term floating dynamic loads.

A special screed tape can also be called a buffer, edge, or compensation tape. And its main name comes from the German word Dämpfer, which translates as “silencer”.

High-quality material is neutral and completely chemically independent of the characteristics of the working environment, and does not emit foreign odors when interacting with other materials or when temperature changes. An equally important quality is the presence of zero hygroscopicity, which is ensured by the complete absence of pores for the accumulation of moisture and the formation of mold colonies.

Upon completion of the repair, the material will be completely hidden if the installation was carried out using technology

Due to decent flexibility in the molecular bonds of polyurethane foam materials, it has sound-absorbing qualities and effectively dampens even significant transmitted vibrations.

Manufactured in accordance with special technology and using foamed polyethylene raw materials, the material is designed for repeated compression and expansion processes.

This allows the concrete screed to “breathe” and greatly increases the durability of the base.

All modern and high-quality expansion tapes have a huge number of very important properties, which are determined by the basic technical characteristics of such auxiliary building materials. The most significant advantages of the application are presented:

- low thermal conductivity;

- good sound absorption;

- increased level of water resistance;

- resistance to sudden and frequent temperature changes;

- durability if installation rules are followed;

- complete environmental safety throughout the entire period of operation.

Thanks to the advantages listed above, polyethylene edge tapes are widely used in sealing existing gaps, and are also actively used as a separator between floors and wall structures.

Available in several versions: standard type, with a “skirt” and self-adhesive.

Edge tape differs not only in properties, but also in price

With the right choice of material, it is possible not only to compensate for the expansion of the screed and reduce heat loss through wall structures, but also to minimize noise and vibration, significantly improving the sound insulation in the room.

Standard

Straight type buffer tape that does not have an adhesive layer. Fixing such auxiliary material to the walls is usually carried out using double-sided tape or a special adhesive.

Standard damper tape is cheaper than other varieties

A feature of the use of standard compensation tape is the need to carry out preliminary and thorough preparation of all surfaces involved in the work. Even the smallest construction debris and dust can be removed.

With a skirt

A ribbon “with a skirt” or “with an apron” has a characteristic feature - the presence of a kind of “skirt” made using thin but quite durable oilcloth material. During installation, such a part is carefully spread across the floor, thereby ensuring complete sealing of all seams.

Classification of damper tapes

Damper tape can be classified according to two criteria:

- method of fastening;

- according to release form.

Mounting method. According to the method of fastening to the wall, there is a simple (sometimes called standard) tape and self-adhesive. Simple tapes can be fastened with all available means: hot-melt adhesive, double-sided tape, staples, self-tapping screws, piles of cement mortar. The “self-adhesive” has a strip of glue in the middle, covered with a film.

According to the form. There are 4 types of tape based on shape:

- regular;

- with a “skirt” (basque);

- L-shaped or with a notch in the middle;

- T-shaped.

Regular strip. Conventional tape is a single strip of polyethylene foam. It can be standard or self-adhesive, different in width and height. Widely used in private construction: attached vertically to walls, pipes, columns, partitions.

Ribbon with peplum. The damper consists of two parts: a regular tape and a glued bottom, a “skirt,” made of polyethylene film 3-10 cm wide. The purpose of the basque is additional waterproofing of the joints between the base of the floor and the wall and preventing the solution from flowing under the bottom of the tape.

It is used when pouring screed in the bathroom and bathhouse (prevents water leakage near the walls) and installing cable “warm floors”. From the purpose it is already clear that the dense part is attached to the wall, and the plastic film is laid on the floor. It can be with or without an adhesive strip.

L-shaped. On a regular tape, only wider, manufacturers make a cut, which allows the strip to be bent. The wider part of the strip should be attached to the wall, the shorter part should be laid on the base of the floor, similar to a strip with a peplum. Prevents the CPR from getting under the lower edge of the damper.

T-shaped. The use of T-shaped expansion joints in private construction is limited. This is an inter-circuit damper tape that divides a large screed into parts when it is necessary to relieve stress in the concrete in the middle of the floor. Laying is carried out with a pouring area of more than 40 m2.

Installation features

The developer may have a question about how to attach the damper tape and when to do it. Installation is carried out before pouring the screed, but after installing the waterproofing. As a rule, film and any other waterproofing on the sides is lifted and placed on the walls, in which case the buffer tape is installed on top of it.

The installation method depends on the type of product. If it has an adhesive layer, everything is simple: place the roll with the sticky side to the wall and, gradually unrolling it and removing the protective layer, glue the strip to the base, slightly pulling it so as not to falsify. If there is a film release (“skirt”), it is spread on the floor, folded at the corners into a triangle.

Installation of L-shaped tapeSource o-builder.ru

Having finished gluing one roll, the second is mounted overlapping, starting the beginning of the second strip 5 cm from the end of the first.

If there is no adhesive strip, you first need to determine the front and back sides. The reverse side is usually smoother and shiny, and it is pressed against the wall.

Rigid fastening is not necessary - the strip can simply be pressed with the solution during its installation. But this is very inconvenient: you have to constantly make sure that it does not fall or bend under the screed, otherwise the whole point of why the damper tape is needed is lost.

Therefore, choose one of the most convenient fixation methods:

- shoot with a stapler, the staples of which easily fit into the wooden base;

- drill the dowel with nails;

- glued with double-sided tape, liquid nails or other adhesive.

Recommendations for selection

Damper tape is an ideal object for counterfeiting. A student can print (download and then print on a color printer) the insert. Cutting the tape itself from the roll backing is just as easy. Roll it up and seal it in cellophane - no problem. Therefore, when shopping for goods, you need to study some nuances.

- While at home, you need to decide on the width and thickness of the tape, as well as its appearance.

- The tape must be in undamaged packaging, box (packed by European manufacturers) or film. This will protect you from many troubles.

- If the packaging is damaged, the following steps should be taken:

- ask to see a certificate of conformity;

- check the density of the bay, especially a large one - they could rewind ten meters;

- make sure the strip is intact, and if there is a skirt, then that too. If there is damage, even at a discount, it is better to refuse the purchase.

- The self-adhesive tape should not have partial peeling of the protective strip - the glue has lost its properties.

- The thickness should be the same along the entire length, which is clearly visible on both sides of the bay.

- The cutting line must be perfect. Irregularities indicate a fake.

- Dirt on the surface is not allowed.

- Preference should be given to trusted manufacturers.

How to choose compensation tape?

Construction stores offer a large number of products from different manufacturers. The same type of tapes from different brands differ more in their appearance and price than in their characteristics. And in order to choose a high-quality material that will be able to perform all the functions mentioned above, you need to pay attention to some nuances:

If the product is sold in a package, you are less likely to purchase tape that is deformed or damaged during transportation

- Before purchasing a compensation tape, you need to decide on its width. In this case, the total thickness of the entire multi-layer floor structure being created must be taken into account. The tape should rise above the surface of the screed by 10÷15 mm.

- The tape is sold in rolls, and it is better if it is enclosed in a sealed factory packaging. You should pay attention to the integrity of the roll and the absence of deformations.

- If the tape is damaged, then even if it is discounted, you should not buy it, since this means that the normal conditions of its storage and transportation were grossly violated.

- There should be no contamination on the surface of the material.

Manufacturers often include in the attached product label not only the characteristics of the material, but also recommendations for installing the tape.

- It is necessary to pay attention to the density of the roll winding - so as not to buy a coil from which tens of meters have already been unwound.

- If you purchase a self-adhesive version of the tape, and even the slightest delamination is noticed in the roll, then it is possible that the glue is no longer suitable for use.

- It is worth giving preference to products manufactured by well-known companies that have been producing building materials for a long time, for example, Energoflex, Knauf and others.

And further. Nowadays, counterfeiting a paper label is a piece of cake. That is, when purchasing tape from hand or on the market, you can easily run into a fake, a cheap cut of strips from a roll backing. Therefore, it is better to buy all building materials, and compensation tape is no exception, in specialized stores where you can “find the ends” of the origin of the product.

Popular options and prices

The list (not rating) of the most popular brands of damper tape includes:

- Kermi is a German company. Produces tape for “warm floors” 160 mm wide and 8 mm thick. It is wound into coils 25 m long. The price per roll starts from 500 rubles;

- Oventrop is another representative of Germany. It supplies the building materials market with L-shaped tape coated with glue (“self-adhesive”), 12-15 cm wide and 10 mm thick. It is wound into rolls of 25 and 50 m. You can buy the cheapest one for 20 rubles/m .;

- "Upolon" - to introduce Swedish industry. Produces universal, self-adhesive tape 10 mm thick and 150 mm wide. Sold in coils 50 m long at a price of 7,100 rubles. per roll;

- "Energofloor" is a brand of damper tape with a skirt. Supplied in length - 11 m, width - 10-15 cm, thickness - 10 mm at a price of 860 rubles. per roll;

- "Tilit Super" is a Russian manufacturer of peplum tape at a price of 1 m from 35 rubles. and more.

- "Teploflex";

- "Knauf" FE;

- "Valtec" etc.

Technical advantages

In addition to solving the problem of compensating for screed expansion, damping tape has a number of useful technological advantages.

- Serves as an effective sound insulator, absorbs floor vibrations without transmitting them to walls and other structures.

- Does not form a cold bridge, which is important when zoning a heating system and to minimize parasitic heat leaks.

- Absolutely safe for health, does not serve as a breeding ground for bacteria and mold, does not rot or form toxic compounds, and is chemically neutral.

- It is not afraid of temperature fluctuations and has a long service life.

Damper tape is especially valuable for modern renovations in apartments of reinforced concrete monolithic buildings. When installing a warm floor, you should not ask the question why such a compensatory polymer layer is needed. It will not only preserve the integrity of the coating as it expands, but will also reliably protect the room from heat leaks into the walls, especially external ones.

Another property that accurately answers the question of why a damper tape is needed in a heated floor screed is water resistance and a manufacturing format with a special skirt. Such a product will not only perform the tasks of thermal insulation and compensate for the expansion of the screed. The tape with a skirt will prevent capillary movement of moisture (for example, from colder walls into the screed), and will also protect structures from water in the event of emergency leaks of the heating system.

How to mount it correctly

The work of laying a damper layer between the wall and the screed is not difficult. It is performed in several stages.

1. The surface of the wall and the base of the floor are cleaned of dust and dirt - otherwise the glue will lose adhesion to the wall material. This step is especially important if you need to secure the tape outside the building, along the base. After this, degreasing is carried out. 2. The compensation strip is attached to the wall. Here the correct order of operations is as follows:

- laying starts from the corner. Conducted from left to right. The roll is laid on the floor with an adhesive strip to the wall and unwound. In this case, you need to go into the adjacent wall by about 50 mm so that at the end you get an overlap. You can start from a corner without entering the adjacent wall, but then you must also complete it by entering the already laid damper. Naturally, the splicing must be done overlapping;

- the roll needs to be unwound as you pass the perimeter - the tape will lie flat, without sagging or twisting. The protective film from the adhesive strip is also removed slowly - you can contaminate the adhesive layer with an awkward movement;

The protective tape is removed as the perimeter is passed.

- the tape is laid continuously without tension;

- in the corners the “skirt” is not cut, as some experts advise, but is laid in a triangle. This solves the problem of acute and obtuse angles;

- as you pass the perimeter, you need to roll the tape to the wall with a roller, and level the plastic film of the “skirt” so that there are no folds under which the solution can get;

- To attach regular tape, you can use double-sided tape, hot glue, liquid nails, masking tape (the damper is glued to the wall with its top edge) or piles of mortar. It is undesirable to use self-tapping screws and staples - they will interfere with the thickness of the tape. If they are still used, then the fasteners must be installed above the screed, at the level of the floor covering;

- all pipes, columns and partitions in the room are also covered with a compensation strip.

3. The tape is cut, but only after the tie has set. If the height is insignificant, the operation can be ignored - everything will be covered by the baseboard. By the way, some manufacturers make cuts at the top. In this case, it is enough to pull the protruding part and the excess will come off without a knife.

In conclusion, laying damper tape around the perimeter of the walls avoids the destruction of the screed. The work is simple. You can do it yourself. Experience shows that it is more convenient to work together: one rolls out and glues the tape, the second compresses it with a roller and straightens the plastic film of the skirt.

Installation features

Before arranging the screed, you should decide on the choice of damper tape:

- tape width: thickness of rough fill thickness of finishing layer thickness of floor covering additional technological 10÷15 mm;

- length: perimeter of the room perimeter of columns and partitions (if any) small margin;

- thickness: the greater the height of the screed, the thicker the damper belt strip should be;

- if the room area is large, you need to purchase a T-shaped tape.

Installation of the compensation tape is quite simple. To do this you will need glue or double-sided construction tape (if there is no adhesive layer) and a construction knife. After the waterproofing layer is applied to the base, we attach the damper strip, starting from the entrance to the room.

Advice! It is better to secure a piece of T-shaped strip in the doorway itself (as an expansion joint and a limiting edge to prevent the solution from spreading).

We fix the tape to the walls along the entire perimeter of the room. If the length of the roll is not enough, then we attach the extension end-to-end (we seal the seam with construction tape).

After finishing the floor arrangement, carefully remove the edge of the strip protruding above the surface of the floor covering with a knife (or tear it off if there are longitudinal technological cuts). The damper seam itself will not be noticeable, since it is usually covered with a plinth. If we use ceramic tiles as the finishing floor covering, then remove the excess edge strip before laying it.

Important! When installing heated floors, the screed is divided into sectors by T-shaped expansion joints in accordance with the manufacturer's instructions

Preparation. Leveling the surface of the walls and clearing construction debris.

Pasting. The tape is laid continuously at a height of 1.5–2 cm from the floor, starting from one of the corners of the room along the perimeter

Particular attention is paid to fixation at the corners of the room. Completion

Trimming the tape after returning to the place where installation began.

Completion. Trimming the tape after returning to the place where installation began.

Installation of compensation materials necessarily requires additional fixation, especially when using products that do not have an adhesive base. As an alternative method of fastening, you can use:

- masking tape - as a temporary fixation during the process of pouring a concrete-based screed;

- with a construction stapler - when performing installation indoors with walls based on foam and aerated concrete, as well as wood;

- liquid nails - the best way to fix on walls that have a very uneven surface.

Technology for laying compensation tape when making concrete screed indoors:

Preparation of working surfaces with the most thorough cleaning of construction debris, dust and dirt.

Installation begins before pouring the concrete screed

Laying the product from the corner area of the room with gradual unwinding of the required amount of material from the roll. When using self-adhesive tape, the protective top layer of the backing is removed during installation.

Standard tape is fixed with adhesives or other types of fasteners.

Since the tape is supplied in rolls, installation is very convenient, gradually unwinding the required amount of material

Laying is carried out continuously, and the joints of tapes from different rolls must overlap.

The compensation tape should be higher than the level of the finishing screed; the excess centimeters can then be trimmed off

Particular attention should be paid to corner areas in the room, where the compensation material should be fixed as carefully as possible. For better adhesion of the tape to the wall, it is advisable to degrease and dry the surface of the latter.

For better adhesion of the tape to the wall, it is advisable to degrease and dry the surface of the latter.

Completion of installation is carried out at the starting point, where the compensation tape should be cut using a stationery knife with a slight overlap.

The edge tape must be laid along all perimeters and elements of the room, including columns, thresholds and protrusions

The finished version must be neat and carefully fixed, since it is compliance with the basic rules for attaching the compensation tape that has a direct impact on the final quality of the concrete screed.

After completing the work, you can walk along the tape with a roller to seal the connection of the material with the wall

What can be replaced

Before manufacturers began offering specialized polyethylene edgebanding, builders used a variety of materials: pieces of linoleum, roofing felt, polystyrene foam, and thin strips of wood. All of these alternatives have disadvantages. Wood rots and disintegrates over time, polystyrene foam crumbles, and linoleum and roofing felt are too rigid and cannot effectively compensate for the movements of the concrete screed.

To save money, instead of ready-made tape, foamed polyethylene is purchased in large rolls. The material is cut into strips of the required thickness. Sometimes penoizol and penofol are used for this purpose. But all these materials do not have the same performance characteristics as damper strips.

Penofols and substrates are also made using polyethylene foam, but such material will need to be cut into strips, measuring the required width and joining correctly. Polystyrene foam is unable to return to its original shape after compression, and cracks will naturally form. Any wood previously used as damping materials is very short-lived, swells when exposed to moisture and is susceptible to rotting.

In addition, fixing any replacement with adhesives or fasteners also involves additional costs. Thus, there is no complete replacement for the damper tape, especially if it is necessary to install a “warm floor” system. Therefore, when pouring a concrete screed, it is not advisable to waste time on using other materials, and it is very important to correctly select a high-quality edge strip.

The cost of a finished edge strip is quite affordable for the average consumer, but if it is not possible to use high-quality and ready-made expansion tape, it is sometimes possible to replace it in wall joints with a thick floor underlay, penofol or polystyrene foam, and even traditional wooden slats.

However, it is important to remember that such replacement options are, according to experienced specialists, extremely unreliable and short-lived, negatively affecting the outcome of the work on concrete screed in any type of room.

Sometimes the damper edge tape is replaced with other building materials (if there is insufficient budget). The easiest way is to use regular thick polyethylene, cut into strips. It will have to be applied in several layers, but the functionality is similar to damper tape. It is possible to use isolon, penoizol, penofol, folgoizol, ceiling tiles made of polyurethane foam or any floor substrate, but they are significantly inferior in thermal insulation. Such materials are the same foam material, which has a larger width, in contrast to the edge tape.

Installation

Before installing the damper, you need to clean the floor from dirt, and its surface is covered with plastic film to ensure waterproofing. It won't hurt to degrease the lower part of the wall surface. Installation of the damper tape inside must begin from the corner of the room. To do this, you first need to remove the paper layer from a piece of self-adhesive damper unwound from a roll.

Having glued or attached a part of this damper to the wall approximately two centimeters above the expected level of the screed, move further and repeat the same actions. You can also attach the damper with glue or self-tapping screws. Since this polyethylene material must be laid continuously, an overlap must be made when starting a new roll.

Let's look at how to attach the damper tape to the wall. If the purchased damper is not self-adhesive, you can use self-tapping screws, dowels with a screwdriver, liquid nails, a furniture stapler with staples, or masking tape to strengthen it.

Essence

Deformation tape is also called damper, edge, buffer or damping tape. It is a thin layer of foamed polyethylene or styrene, cut into strips. The width of the material ranges from 5 cm to 20 cm, thickness – from 5 millimeters. On the back side of the damper there may be an adhesive layer that helps to securely attach it to wall surfaces; it can be striped or banded, that is, applied in stripes, or solid.

The name "damper" comes from the German word Dämpfer or "silencer". The main purpose of such a damper is to compensate for thermal expansion, which can act on concrete floors and floors of the house. Properly installed damper tape between the floor and walls prevents the floating slab of the house from coming into contact with the adjacent walls.

The action of the material in question is associated with the presence of many air bubbles, which are easily compressed under periodic load. It is exerted by an alternately contracting and expanding floor screed (according to generally accepted rules, an expansion of 0.5 mm per linear meter is allowed). When the pressure decreases, the tape returns to its previous shape.

Let's take a closer look at the concept of damper tape and what it is used for. So, damper material is needed to:

How the floor cracks Source mtdata.ru

- act as a buffer, reducing the possibility of formation and increase in the number of cracks that appear when poured concrete hardens;

- provide insulation in screeds on concrete foundations, reduce heat loss;

- form expansion folds;

- ensure that there is a gap required when laying heated floors;

- ensure a flattened floor surface;

- act as a separating element when pouring concrete into large parts of the floor.

It turns out that the floor screed tape additionally protects the structure from factors such as sudden temperature changes, changes in the soil and other circumstances due to which concrete can crack and deform. This is especially true for the installation of dry, semi-dry screeds and underfloor heating systems. The edge damper is also used outside buildings when constructing a blind area of a house, a special waterproof structure around a building, and for arranging foundations.

Such a buffer should also be used to construct a blind area Source saucyintruder.org

See also: Catalog of companies that specialize in finishing materials and related work

Benefits of use

Having considered what a damper tape is and what it is used for, we can highlight the positive aspects of using this special material:

- safety (the polyethylene material from which the damper tape is made is not dangerous for humans and animals because it does not emit harmful substances; mold will never form on its top layer and microorganisms and fungi will not be able to multiply);

- elasticity (the elasticity of the damper material is a constant quality that does not change over time: the linear deformation rate is zero);

- sealing (the ability of the tape to seal seams);

- low cost (compared to other building materials used for the same purposes);

- constancy (thanks to closed cavities with air, the buffer material does not allow moisture to pass through, therefore it is constant in size);

- ease of installation;

- noise insulation, vibration damping, chemical, temperature resistance;

- durable (damper tape is not of interest to rodents, it does not deteriorate over time, does not rot, and is not exposed to ultraviolet rays).

Buffer material helps to insulate the floor Source stroyfora.ru

This is interesting! Previously, rolled pieces of polyethylene and wood were used, although the latter option was dangerous due to the high likelihood of mold and fungi, and the first was inconvenient and ineffective.

Additional uses

Edge tape, as it is also called, is used not only as a compensator when arranging the floor. In addition to its main function, it can play the role of a barrier when using a spreading solution. If the screed area is large, division into sections is required. Therefore, the use of such a separating material will be useful.

We invite you to read: What is an expansion joint in a blind area

Please note: when installing a thin layer screed or self-leveling floor, the damper tape will be a useless element. After all, self-leveling floors or leveling compounds refer to contact leveling of the surface.

https://www.youtube.com/watch?v=InFLQbL8MB8

Deformation polyethylene tape is also used for outdoor work. Namely, in the process of constructing a blind area. It helps preserve concrete during temperature changes. To do this, it is laid at the junction of the blind area and the wall.

Selection rules

Since the service life of the material largely depends on the conditions of use, manufacturers often try to diversify the range with different options. Although when choosing, many are guided by the price and area of the room. But it is worth paying attention to the quality of the materials offered. This is due to the disposability of the tapes. It is laid once and until the next major overhaul.

When choosing, you need to consider the following rules:

- the material should be stored in a dry, ventilated area;

- the tape must be rolled into a roll;

- there should be no damage or stains;

- When choosing self-adhesive, you need to check the density of the roll (delaminations and cracks are excluded).

When installing a heated floor in a room, you should calculate the area and height of the screed. Based on these parameters, purchase the material.

Types of damper

The damper tape for the screed may not have a layer of glue at all or be self-adhesive. The latter may stick to surfaces after removing the protective paper strip. The third type of this material is an edge damper with a skirt (basque), a protruding element made of dense oilcloth material. This “skirt” can be from 3 to 10 centimeters in width.

The most common tape has the shape of a long strip, which is rolled into rolls when sold. It is convenient to attach such a buffer element directly to the walls, using special glue or ordinary wide double-sided tape. Also, for the corner areas of the room, you can purchase an appropriately angled (L-shaped) buffer tape. In this case, the short edge covers the wall, and the long edge should touch the floor.

This is what the demarcation damper looks like when installed Source sanpol.ua

If there is an uneven concrete surface in the room, it is recommended to use a tear-off damper. For convenient tearing of the desired piece from the polyethylene tape, notches are applied to its surface, the distance between which is 2-3 millimeters.

To divide the floor of a room into smaller parts, a T-shaped tape was developed, which is placed in the right place when renovating a room. This special damper is used to divide the screed into several rectangles. Also, a similar type of damper is used if the length of the room is more than eight meters.

Tape selection

In order to correctly select a damper tape for a self-leveling floor for a specific room, you need to take into account all its parameters. The width of the buffer edge damper is calculated as follows: the height of the future floor screed is determined and another two centimeters are added to it. The thickness of the damper depends on the total area of the room: the more concrete is poured, the thicker the damper should be selected.