The popularity of this type of hybrid heating devices, which combine a solid fuel heater with an electric heater, is due to the desire not to depend on the supply of electricity. The user receives an independent heating scheme for the premises. This feature is especially relevant given the current increase in tariffs for electricity and gas supply.

This type of equipment allows you to use a wood-burning stove, maintain constant heating of rooms with automatic mode, without controlling the process of burning wood.

Application of combi boilers

Heat generators operating on various energy sources did not appear yesterday. Since the times of the USSR, “dual-fuel” gas-wood boilers have been known; in them, to switch to wood, the burner device had to be removed. In modern heating units, solid fuel is combined not only with gas, but also with electricity, which is more important for users. A homeowner who decides to buy a heating boiler using wood and electricity solves several issues in one fell swoop:

- It uses two energy carriers for heating, alternative to natural gas.

- Eliminates cooling of the premises of a private house when the contents of the firebox are completely burned and a new portion of coal or firewood is not loaded.

- Increases the convenience of using water heating, since you no longer need to get up in the middle of the night and run to the boiler room.

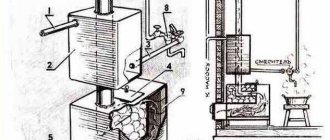

Construction of an electric wood-burning boiler "Kupper" from

New generation combined heat generators are designed in such a way that electric heating is switched on automatically when the water in the boiler tank begins to cool. Switching back to wood burning without the intervention of the owner of the house is impossible.

The principle of operation of an electric wood-burning boiler

The design of this type of heater is similar to that of a traditional solid fuel boiler, consisting of the following main elements:

- combustion chamber (firebox), where logs and coal are loaded;

- from the outside it is washed by a coolant enclosed inside a water jacket;

- a fire-tube or water-tube heat exchanger, where combustion products give off most of the heat to water before being released out through the chimney;

- the grate is located at the bottom of the firebox, and under it there is an ash chamber;

- the firebox and ash pan at the front are equipped with doors;

- To change the combustion intensity in the heat generator, a mechanical draft regulator or a fan - air blower is used (if manual control of the air damper is not provided).

Scheme of the Kuper-Carbo mine-type electric-coal heat generator

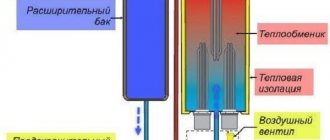

Domestic combined heating boilers are distinguished by the design of their water jacket, which provides space for installing a block of tubular electric heaters - heating elements. The heating part of the element is immersed in the coolant, and the contacts are brought out and connected by cable to the control panel.

The operating algorithm of a solid fuel heater equipped with electric heaters looks like this:

- The boiler is fired and heated as usual. While the wood is burning, the temperature of the coolant is maintained by a mechanical thermostat or a fan together with a sensor, and the heating elements are inactive.

- After the contents of the firebox burn out, the water in the system begins to cool, which is recorded by the temperature sensor. When the coolant has cooled to a certain point, the sensor signal will turn on the heating element (one or more). From this moment on, the boiler switches to electricity.

- After loading the next portion of solid fuel, the coolant is heated from the side of the combustion chamber, and the electrical part is automatically turned off until the next time it cools down.

The heater control unit can maintain a certain water temperature based on the readings of the water or air sensor

The transition from one mode to another allows for continuous heating of water, which is what the inhabitants of a private house require for comfort.

Pros and cons of universal heat generators

By installing a combination boiler for heating a private house with wood and electricity, you receive the following bonuses:

- Thanks to the built-in heating elements, water heating will continue to function after the main firebox goes out. This will keep the house warm, and during your absence will prevent pipes and heating radiators from defrosting.

- Comfort. Supporting the heating of the system with electricity will save you from night trips to the boiler room to lay logs.

- If electricity metering is carried out according to a multi-tariff scheme, then in addition to convenience you will receive savings from the operation of heating elements at night.

Electric heaters of a combined boiler are designed only to maintain the temperature of the water in the system; they cannot fully replace the combustion of solid fuel. The reason is the insufficient power of the heating element unit installed by manufacturers on TT boilers.

Example: all “Kupper” units of the famous Russian brand “Teplodar” with a power of 9...20 kW have the same electric heaters with a heat output of 6 kW.

This is what a 6 kW heating element block looks like, used in Russian-made Teplodar, Prometheus and ZOTA wood-burning heaters

This feature of combined heat generators can easily be considered a disadvantage. The exception is low-power heaters (the same “Cooper” 9 kW with 6 kW heating elements), purchased for small-sized dwellings (up to 100 m²). In this case, the heat transfer from electricity is comparable to burning wood, so in moderately cold weather (down to about -5 °C outside), the heaters are able to completely heat a modest-sized house.

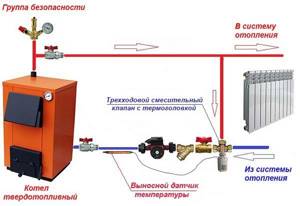

Another important point. Like a conventional solid fuel heater, a wood-electric combination boiler should be connected to the water heating through a three-way valve, as shown in the diagram below. A small circulation circuit serves to protect the firebox from the harmful effects of condensate during kindling.

To prevent condensation from appearing on the walls of the combustion chamber due to temperature changes, the TT boiler must be connected according to the standard circuit with a three-way valve

If the power of the heating elements is enough to heat the coolant to a temperature of +55 °C and above, then condensation will never form in the combustion chamber of the combined boiler during lighting, and the unit with a three-way mixing valve becomes seemingly irrelevant. In reality, a small circulation circuit is still needed, at least in case of a power outage or failure of one of the heating elements.

Heating a private house with wood and electricity from one boiler also has other negative aspects:

- The heater block takes away the useful volume of the firebox to the detriment of combustion duration per load.

- The operation of the unit depends on the stability of the power supply.

- The prices of combined products are higher than classic solid fuel boilers.

- The efficiency of electric heaters when operating is reduced by 2-5% due to the air flow passing through the cooled firebox. The reason is the constant draft in the chimney, forcing air from the premises to escape through the fuel duct into the chimney pipe and cool the water jacket of the heater.

In order to fully replace natural gas with electricity and firewood, it is better to take a closer look at another option for heating the building - install 2 separate heat sources, properly tie them and connect them to the heating system.

Connecting boilers using wood and electricity

Without a doubt, purchasing, installing and wiring two separate units will cost you more than one combined heat generator. But by implementing this option, you get full heating with two energy carriers, operating effectively in automatic mode.

Reference. In non-gasified private houses in the Russian Federation, the combined operation of a solid fuel and electric boiler is used quite often, since this is the most convenient way to heat a home with wood. The combination of gas and wood is no less common, and the third place is occupied by the so-called multi-fuel boilers, which we will discuss in a separate article.

In our pair of heat sources, the wood (coal) boiler is the main one, and the electric one is the auxiliary unit. As the latter, you can use any of the three types of electric boilers offered on the market:

- traditional heating element with built-in circulation pump and control unit;

- electrode with remote control panel;

- induction with separate remote control.

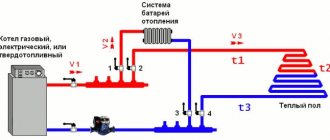

We will not analyze the advantages and disadvantages of each type of electric boilers; this is the topic of another article. Here we will show in diagrams how to connect boilers using wood and electricity, so that the second one supports the first one automatically. Let's start with the joint piping of a wood-burning and heating element heating unit:

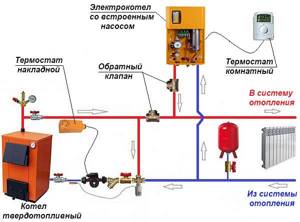

Connection diagram for 2 boilers - with electricity and wood. Thermostats ensure automatic starting of the electric boiler after the wood boiler is stopped and vice versa.

Reference. The presented circuit can be used for joint connection with a gas wall-mounted boiler, which is installed in place of the heating element.

The system operation algorithm looks like this:

- The TT boiler is inactive and its circulation pump is switched off. Heating devices receive heat from an electric boiler, which is guided by a room thermostat, where you have set the desired temperature. To prevent the coolant from moving in a circle through a parallel ring, the circuit uses 2 check valves.

- You have melted a solid fuel unit. For some time it will begin to gain temperature, and the water will circulate in a small circle, directed by a three-way valve with a thermal head. The pump will turn on at the command of the overhead thermostat installed on the supply pipeline.

- When the coolant in the small ring heats up to 55 °C, the temperature sensor of the thermal head located on the return line will operate. The three-way valve will open slightly and heat will flow into the heating system.

- The electric boiler will turn off the heating based on the signal from the room thermostat and go into standby mode.

- After the solid fuel burns out, the water in the system, followed by the air in the rooms, will begin to cool. The overhead thermostat of the TT boiler will “see” that the coolant has cooled down and will stop the pump.

- When the temperature in the house drops to the value you set, the room thermostat will turn on the electric boiler again.

Important! Since the internal circulation pump of a wall-mounted heat generator cannot be turned off, a more powerful unit must be selected for a solid fuel heat source. As a rule, a pump with a pressure of 0.6 Bar is sufficient (in an electric boiler it is usually set at 0.5 Bar). Point two: install all overhead sensors and thermostats on metal pipes; they will lie on metal-plastic or polypropylene.

Our expert Vladimir Sukhorukov will tell you in detail about how to properly connect an electric and solid fuel boiler in his video:

Watch this video on YouTube

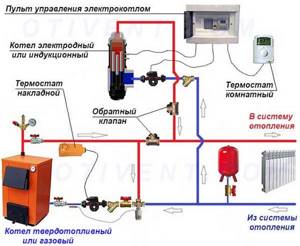

Induction and electrode heat generators are not equipped with their own filter and circulation pump, so the latter will have to be purchased and installed separately. This is all the difference in the connection diagram for heaters of this type, only the pump unit needs to be connected to the network through the control cabinet so that the room thermostat turns it off together with the electric boiler, as shown in the diagram:

In this scheme, the circulation pump of the electric boiler will be turned off along with it thanks to a separate control cabinet

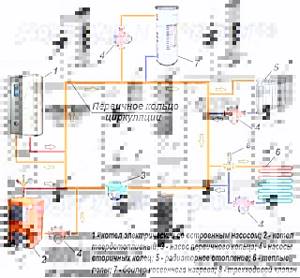

If the heating system of a private house consists of several circuits (radiators on different floors, heated floors and an indirect heating boiler), then to work together, the wood-burning and electric boiler are connected using the method of primary and secondary rings. The operating principle of this type of harness is described here.

Connecting an electric and solid fuel boiler to the heating system using the primary and secondary ring method

How to choose an electric boiler?

Before buying and installing an electric boiler, you need to understand what characteristics you should pay special attention to.

According to the installation method, all heating equipment that belongs to this category is divided into two types:

- floor-standing models - usually used in systems with a large volume of coolant;

- wall-mounted devices - take up less space, well suited for use in private homes.

The connection can be:

- single-phase - 220 V, as a rule, this is a sign of a device for domestic use;

- three-phase - 380 V, most often this is typical for powerful models intended for industrial use.

An electric heating boiler connected to a 220 V network is the best option for a residential building.

When choosing, you need to take into account the equipment. It is advisable that the device that interests you already has all the basic elements. That is, you need an electric boiler with a pump, a safety valve, a filter responsible for cleaning the coolant, and an expansion tank. Purchasing a basic device and retrofitting it with individual units can be more expensive than purchasing a complete set.

The power of a device for a heating system is usually calculated according to a simple principle: 1 kW per 10 square meters. And it is advisable to have a small power reserve to compensate for a possible voltage drop in the network.

What else is important to know about hybrid boilers?

Before buying hybrid boilers for heating a country house, you must take into account that such installations will require a professional connection to the electrical network. Equipment can be installed only after receiving all permits, and when a separate line designed for 380 Volts is connected to the residential property.

To ensure the necessary safety when operating hybrid equipment, it is necessary not only to connect the installation to the devices, but also to ground it. In this case, you cannot experiment. The only correct option is when the grounding is connected to a special circuit dug deep into the soil of the earth.

Combination boiler power

In general, combination boilers were once developed in order to increase the time between fuel additions.

That is, if you put firewood in a regular wood-burning boiler, then you will have to do the next load in 3-4 hours.

In the case of a coal heat generator, this time increases to 6-8 hours, and sometimes, depending on the design of the boiler, up to 12 hours.

It seems to be good. But what if there is no good coal in your area or its supply is irregular?

All that remains is to use firewood or briquettes. And in this case, as already written above, you will have to go to the boiler every 3-4 hours.

Of course, there are options for long-burning solid fuel boilers, which are designed so that the fuel load burns from 12 to 24 hours. However, the cost of such thermal units starts from 70,000 rubles.

There is a much cheaper alternative - using a combi boiler to heat your private home. Which option is better to choose in this case is up to you to decide.

In terms of cost, a wood-electricity combination boiler is practically no different from a simple wood-burning boiler.

At the same time, when you calculate the power of a heating unit for your home, you can safely add up the thermal power of wood and the power of electricity. After all, you can heat the coolant with a heating element right in the process of burning wood.

Installation of an electric wood-burning boiler

The design of heating boilers using wood and electricity is very simple. It consists of just a few elements:

1. Combustion chamber

It is located in the lower part of the boiler and has dimensions that allow you to lay firewood up to 600 mm long. The fuel is placed on a grate, under which an ash box is installed.

2. Heat exchanger with heating elements installed in it

The heat exchanger connected to the heating system is located above the firebox so that the hot gases generated during the combustion of wood blow over its surface.

3. A simple control unit

This component monitors the temperature of the coolant and, if necessary, supplies voltage to the electric heaters.

4. Housing and flue pipe

Heating element for boiler

The above list refers to the simplest version of an electric wood-burning boiler, but many of the modern models have various improvements. For example, the boiler can be equipped with an automatically controlled air damper, through which the control system doses the volume of air entering the combustion chamber and thus regulates the boiler power.

Double-circuit combined heating boilers are also more functional in comparison with the basic design. Such models have a second heat exchanger, which is connected to the hot water supply (DHW) circuit. This improvement eliminates the need for the home owner to purchase a separate heater for preparing hot water.

Rating of the TOP 10 best combined boilers for heating

| Place | Model | Price |

| Models of small and medium thermal power up to 30 kW | ||

| #1 | Teplodar Kupper OVK 18 18 kW | |

| #2 | Teplodar Kupper PRO 28 28 kW | |

| #3 | ACV Delta Pro S 25 26 kW | |

| #4 | Protherm Bizon 30 NL 27.1 kW | |

| #5 | Buderus Logano G125 WS-25 25 kW | |

| High power models from 30 kW | ||

| #1 | Teplodar Kupper PRO 42 42 kW | |

| #2 | Sime 1R6 FREEST 64.8 kW | |

| #3 | Ferroli Atlas Evo 47 | |

| #4 | Sime 1R7 FREEST 74 kW | |

| #5 | Lamborghini Calor EL DB DN EVO 32 |

What are the benefits of combined installations?

The solution is truly non-standard, and makes it possible to kill several birds with one stone:

- find an alternative to natural gas for heating;

- play it safe for the future by having as many as two additional energy carriers in reserve;

- At the same time, ensure comfortable operation of the heater, eliminating the need to tinker with firewood in the furnace room at night.

Organizing heating with electric wood boilers is also important in new buildings, for the same reasons. At the same time, it is possible to remember old-fashioned methods and install a gravity heating system in order to maximize independence from external influences. Although the convection system is not the best solution in terms of efficiency, it is affordable for installation. And in the event of a power outage, you can always safely switch to firewood.

About heating private houses

Installing a modern double-circuit gas boiler in a three-room apartment and connecting it to an autonomous heating system will entail a significant reduction in utility bills.

In country houses, automated heating equipment can simplify the process of heating a building, eliminating the need to control the degree of combustion of wood/coal and maintain a flame in the furnace firebox.

Natural gas is considered the cheapest energy source , but not all areas, especially dacha cooperatives, are gasified. And the only alternative to solid fuel in such settlements is electricity, which is why electric heating boilers are widespread there.

But unfortunately, in our conditions, the power supply to objects of the third category, which include country houses and residential settlements, cannot be called stable. According to current legislation, the electricity supply organization has the right to turn off the electricity supply to these facilities for three days without warning.

In any case, in winter, even a three-day shutdown can be fraught with danger for a country house or residential building - possible freezing and destruction of water-carrying communications, moisture condensation on internal surfaces and building structures, which leads to rapid growth of mold fungi and damage to decorative finishes.

What to do in this situation? The best solution would be to install a combined boiler in the heating system that operates on both solid fuel and electricity.

Heating boilers in the Tavago store

The heating system is one of the most important components of a comfortable life. It is difficult to imagine life without basic amenities, such as hot water and warmth in the house. And in the Russian climate, living without heating is not at all possible.

For the system to operate, a whole range of equipment is required: a pipeline system for circulating coolant, radiators for transferring heat to the room. But the key element is the heating boiler.

In our online store you can select and buy a heating boiler of the desired configuration. The range is represented by both models for home use and industrial devices for heating systems in residential complexes, offices, and retail facilities.

Calculation of required boiler power

The easiest way to calculate the required power of heating boilers is to follow the construction SNiPs, which state that for heating 1 sq.m. area of housing it is necessary to spend 0.1 kW of thermal energy. However, this dependence is very approximate, and in reality, a 10-kilowatt boiler for a room of 100 square meters may be either insufficient or in excess.

When correctly calculating the power of any heating boiler, many secondary factors are taken into account, such as heat loss through the roof and walls, and the climatic features of the region. It is recommended to entrust this task to specialists, or use one of the available online calculators.

Combined heating boilers (wood-electricity) in Moscow

If you would not like to monitor the filling of the combustion chamber all day long and require a powerful heating device, we recommend buying a combined boiler for heating (wood-electricity) on this website in Moscow. We provide a 6 month warranty on products.

Electric wood heating boilers include both built-in heating elements (heaters), which are powered from the mains, and a classic combustion chamber for solid fuel. The units will heat the home more efficiently to the required temperature, and if there are no logs, they will continue to work, preventing freezing. The prices of solid fuel modifications with electric heaters are higher than those of wood-burning ones, which is justified by their practicality and increased efficiency. Some variations have built-in hobs with two to four burners.

We deliver to: Moscow.

Operating principle of hybrid equipment

How does an electric wood boiler work? How does he work? The operating principle of the installation is based on the use of several combustion chambers and electric heating elements. A separate heat exchanger is connected to each firebox. It is this design feature that allows you to use the type of fuel that is at hand.

If electric heating elements are turned on, they heat not the coolant, but the water that is in the boiler. There are many advantages to this heating option. At any time you can use the most accessible type of fuel, for which you just need to change the burner. Doing it yourself is not that difficult. A detailed description of the switching circuit is in the instructions.

Practice shows that in most cases, owners of hybrid installations use electricity to heat a country house. But if it is turned off, the house will not cool down. The hybrid stove can be heated with wood, coal, and even waste from wood processing.

Any electric wood-burning boiler is capable of operating autonomously for several days, without requiring human presence. If you choose the electric heating option, you do not need to monitor the installation at all. Its operating time will be limited only when the power supply to the network stops.

Note! When installing the equipment described, experts recommend starting an electric wood-burning boiler by warming up the firebox, and only then transferring the unit to network operation. This will help you significantly save on electricity and warm up all rooms in the house in a matter of minutes.

There is a huge range of described equipment on sale. In order to choose the right model, you need to consider several important factors.

Energy-saving electric heating boilers - main advantages

Electric boilers are used for heating houses, apartments, and commercial buildings. This is a practical heating equipment that does not require the installation of a chimney and does not need a gas line. The systems are connected to the electrical network and function as long as there is electricity.

Types of devices

Electric heating boilers are of three types:

- induction;

- electrode;

- with heating elements.

The most popular models are equipped with heating elements - special tubular heating elements. The simplest heating elements can be seen in old portable water heaters. An electric heating boiler of this type should be used with caution where there is hard water - limescale will form on the heating element. It is recommended to use a system with automation.

The electric electrode boiler is small in size, safe, and economical. The system uses electrodes that heat water by passing current through a medium. It is not possible to regulate the power of the device. Antifreeze and antifreeze are not used in such a boiler. As in models with heating elements, you need to monitor the formation of scale.

Induction units do not use current for heating, but electromagnetic induction. In such boilers, care must be taken to ensure that there is no coolant leakage. The problem with limescale remains relevant.

Advantages of electric boilers

The electric heating boiler became popular not by chance. It has several advantages:

- compact dimensions;

- relative autonomy;

- high efficiency (about 98%);

- no noise during operation;

- no chimney required;

- It’s easy to select automation for the equipment.

Electric boilers for private homes are no less in demand than for apartments. In private homes they are used as the main or additional source of heating. Floor-standing ones are usually used as the main sources of energy.

Electric boilers have few disadvantages. One of the main ones is the high cost of electric energy compared to gas. But this is a safer way to obtain energy. Also, in modern boilers it has not been possible to completely solve the problem of limescale, which spoils the equipment. The only way to reliably protect heating elements is to prepare the water in advance. Some devices have a risk of coolant leakage.

Buying an electric boiler for heating is not difficult - a large selection of equipment is available online. It is possible to choose a device of the required power for an apartment or private house.

Pros and cons of combined heating

Such heating systems serve well in remote villages where it is not possible to use gas or liquid fuel. Our country is rich in forests, so firewood in some areas can serve as very inexpensive fuel for a stove. Such boilers are excellent for maintaining comfortable working conditions in sawmills and woodworking industries. Combination boilers are also installed on mobile boiler houses intended to work on various expeditions or to play the role of a reserve boiler house in case of an emergency. They can easily be connected to any electrical network, and if necessary, they are heated with coal or wood.

What are combi heating boilers?

For your information! A combined heating boiler is a device designed for heating a room that can operate on solid (wood) or diesel fuel, electricity or gas.

The equipment is universal in use, has a high efficiency and is considered very environmentally friendly .

The device is equipped with everything necessary so that it can be easily connected to a home heating system or to a “warm floor” structure - all additional accessories are usually included in the delivery package.

Types of boilers

One of the main parameters by which combined heat generators are classified is the types of fuel used.

This is usually reflected in the marking, which consists of several letters meaning:

- T - solid fuel (wood, coal, pellets, peat, etc.);

- G - gas;

- E - electricity;

- F - liquid fuels (fuel oil, kerosene, used engine oil, diesel fuel, etc.).

For example. the combination of the letters “TG” in the name of the heat generator means that it can operate on solid fuel and gas, and the design will use a design with two combustion chambers. If necessary, you can buy a multi-fuel unit, the name of which contains four letters “TGEZH”. Such heat generators are the most versatile devices, however, the complexity of the design and high price do not have the best effect on their prevalence among consumers.

The most optimal solutions for private homes remain devices using two types of fuel.

Gas/electric combination

Electric gas equipment is usually used in gasified areas where interruptions in the supply of pipeline gas occur. Considering that the cost of electricity is approximately three times higher than the cost of gas, in combined units of this type gas is used as the main source of heat, and electricity as a backup. Compared to solid fuel heaters, gas-electric heaters are more compact and are often mounted on the walls of residential premises, significantly saving space.

Wood/gas combination

Wood-gas heat generators are represented quite widely on the heating equipment market. They are popular in gasified areas with harsh climates, where the use of two types of fuel during an extended period of cold weather can reduce overall heating costs.

Prices for combined boilers ZOTA

combi boilers ZOTA

There are two types of solid fuel-gas installations:

- Units that use gas as the main fuel and wood as an alternative fuel. To switch from one type of fuel to another, a small upgrade is required.

- Universal heat generators in which the gas turns on automatically when the wood burns out.

This type of equipment usually has two combustion chambers with a common chimney. Grate bars are installed in one chamber, and a gas burner is installed in the other.

Wood/electricity combination

In those regions where the cost of firewood is low and there are no gas mains, combined wood-electricity installations remain the most preferred and in demand. Two sources of thermal energy not only minimize heating costs, but also increase the overall stability of the system. The heating circuit is inertial. Constantly maintaining the required coolant temperature by electric heaters reduces the consumption of firewood for heating it when igniting, which makes it possible to use less wood.

Multi-fuel installations

The prevalence of multi-fuel installations in private homes is hampered by two main factors: high price and difficulty of maintenance. The use of fuel with different physical properties in one unit requires the installation of a larger number of burners, pumps, nozzles and other elements. This leads to more complex control automation and a decrease in overall reliability.

For private households, a maximum of three fuel combinations are usually used, including wood, gas and electricity. Combinations such as pellets/liquid fuel/gas are very rare.

How to choose a heating boiler?

Employees recommend choosing heating equipment according to the following parameters:

- Heated area. The boiler power must cover the heat loss of the building.

- Type of fuel. The availability and cost of fuel differs in different regions of Russia.

- Additional functions. The catalog includes models with a hob that can be used for cooking and heating food.

To make your selection easier, you can use the filter at the top of the page.

How to choose a combi boiler

The choice of heating boilers for wood and electricity is limited, since they are all very similar floor-mounted designs with a steel heat exchanger. When choosing, you should pay attention only to:

- Number of circuits . Single-circuit models are used only for heating. Double-circuit systems also heat water in the DHW circuit, the sanitary water of which does not mix with technical water in the heating circuit. Double-circuit models are 10-30% more expensive, but this is still the cheapest way to organize hot water supply.

- Burnt fuel . Typically, such boilers are designed to burn not only wood, but also coal, peat, pellets - this information is always indicated in the product description or operating instructions. However, there are exclusively dual-fuel models (wood-burning with built-in electric heaters) that are not designed to burn coal.

- Operating pressure . Due to the steel heat exchanger, many models are characterized by a maximum permissible operating pressure of only 1 bar. This means that they can only be used in an open heating system with natural circulation, since in closed systems the operating pressure is usually within 1.5-2 bar.

- Efficiency . Despite the fact that this is an efficiency indicator, in this case it can be paid attention only as a last resort, since it very much depends on the quality of the fuel. The 75% declared by the manufacturer can turn into 60 or even 50% when using too damp wood or ash-based, non-calorific coal. However, an excellent indicator is 80% or more, indicating a successful and efficient boiler design.

Minimum required power

For a standard uninsulated or weakly insulated house in the climatic zone of the Moscow region, with 2 bricks and a ceiling height of 2.7 m, the minimum required power is calculated using a simple formula: 1 kW for every 10 m2 of area. We also recommend setting aside a power reserve of 20-30%.

For example, for the average house described above with an area of 120 m2, the minimum required heating capacity of heating equipment is 120/10 * 1.2 (20% reserve) = 14.4 kW, that is, 15 kW.

If the boiler is double-circuit, it is advisable to add another 10-15% reserve so that heating the water does not affect the heating. If the house is located in the south or north of the country, is well insulated, has high ceilings or a large glass area, correction factors are taken into account, changing the result by 5-30% up or down.

Using long-burning TT boilers

Not every homeowner has the technical ability to connect powerful electrical equipment, which includes combined and purely electric boilers. The reason is the limitation of the allocated power limit for a private house. The size of the limit depends on the capacity of local power supply networks, which the owner of a country cottage cannot increase.

In the absence of natural gas on the site or with the high cost of connecting to the main line, there is only one real solution - buy a long-burning wood and coal boiler or make it yourself. The operating time from 1 load for a conventional TT boiler is 3-6 hours, which forces the owner to work near it as a stoker. A comfortable interval between fuel additions is at least 8 hours, and not every heater provides that much.

The latest pyrolysis boiler with an increased firebox volume ATMOS D30

The trouble is that any seedy manufacturer calls their products long-burning boilers in order to sell them to an ignorant user. You can recognize the correct unit among other heat generators by the following features:

- with the same power, a boiler with a large power reserve is equipped with a firebox of increased volume (from 100 l) and differs in size;

- the passport indicates a burning duration of 8 hours (on wood);

- For convenience, the unit is equipped with an additional loading door.

Detailed information about heat generators of this type and recommendations for their selection are published in a separate topic.

Advantages of heating equipment "Teplodar"

- Fuel versatility. Most solid fuel boilers "Kupper" operate on wood, coal, and fuel briquettes of various compositions. Many series can be equipped with pellet and gas burners.

- Work in open and closed heating systems. Heating equipment of the production operates in circuits with natural and forced circulation. Based on solid fuel boilers, it is possible to create a heating system with a high degree of automation and autonomy.

- High efficiency. The design of the water jacket and tube heat exchanger for each model is designed taking into account the types of fuel used, as well as its combustion modes. Heating boilers absorb the maximum possible amount of heat.

- The warranty period is 3 years. The warranty on all solid fuel boilers is 3 years.

To buy a heating boiler in the online store, add the selected model to the “Cart” and complete the purchase. You can receive additional information on the configuration, installation and operation of equipment, and check the cost of delivery by phone.

Installation Requirements

Combination boilers in accordance with SNiP 41-01-2003 must meet the requirements. At the same time, they have their own characteristics during installation and operation, which distinguish them from similar units operating on a single fuel.

These requirements and recommendations must be known and followed in order for the boiler to operate safely.

Premises requirements

Wood and electric boilers for home heating are produced only in a floor-standing version and are installed in a boiler room with ventilation, and in accordance with other SNiP requirements:

- The walls in the room are made of non-combustible material.

- Equipment in the boiler room is installed no closer than 300 mm from the walls.

Example of boiler installation Source pingru.ru

- The boiler room must be a dry and moisture-proof room.

- Since the boiler is heavy, the platform under it is reinforced with a concrete screed.

Also, the room must meet fire safety standards: there are no flammable objects or flammable liquids near the boiler; A sheet of iron is installed in front of the firebox to prevent fire from falling coal or sparks from the firebox.

Chimney

When installing an electric wood-burning boiler, an indispensable condition is the presence of a chimney like a unit with solid fuel. For uninterrupted operation of the installation, good draft is needed, for which the pipe must rise above the ridge of the roof of the house and have an internal diameter no less than the boiler pipe.

The chimney pipe must be free of mechanical damage and have a hermetically sealed joint. During operation of the heating elements, it is recommended to make a view to preserve heat in the chimney. It is also advisable to insulate the pipe to prevent condensation from forming in sub-zero weather.

A high-quality chimney is the key to uninterrupted operation of a heating boiler Source kakpostroit.su

Features of choosing a model

Modern manufacturers offering to evaluate the features of electric wood-burning boilers produce series for domestic and industrial service. Among them there are compact floor-standing units and mini-boiler rooms. Each unit has its own equipment and its own scope of application.

Therefore, when choosing a specific model, it is worth considering:

- Installation power.

- Number of circuits.

- Dimensions of the unit and its weight.

When choosing a boiler power, experts recommend relying on the type of fuel that will be used as the main one. In a suitable installation this figure should exceed the heat demand.

The number of coils that will allow you to heat water using the combustion chamber is also important to consider. In some electric wood-burning boilers, hot water is heated mainly using heating elements. And this is not always convenient. After all, the electricity can be turned off at any time, and then property owners will be left without hot water.

When purchasing an electric wood-burning boiler with several combustion chambers made of cast iron, you need to be prepared for the fact that such equipment will weigh too much. The total weight can sometimes reach several centners, so you will have to prepare a powerful foundation for the equipment. And these are additional costs, and considerable ones.

When buying a hybrid model, it is useful to ask what material the grates are made of. Experts recommend choosing units with cast iron or steel grates coated with ceramic enamel.