Construction of heating element electric boilers, principle of operation

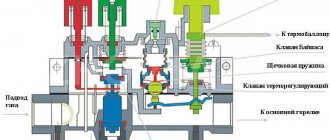

An electric boiler equipped with heating elements is a device that has heat exchangers. The design includes elements:

- Depending on the model, the content of heaters can be from one to several.

- Automatic block. The function of the block is to regulate and heat the coolant.

- A circulation pump can be installed.

- Air valve.

- Built-in expansion tank.

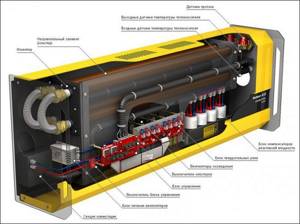

Internal part of the equipment

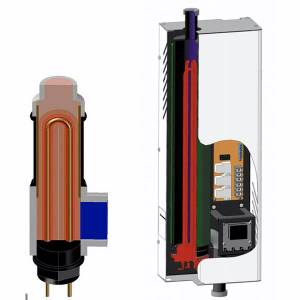

The heating element (heating element) is a bent tube. The inner part of the heater contains a rod and an incandescent coil.

The spiral and tube are metal, the space between them must be insulated. Quartz sand is poured inside the tube, between the spiral and the wall of the tube. Provides good insulation and thermal conductivity. The ends of the tubes are reliably sealed, preventing accidental entry of water into the rod.

Distilled water is often used as a coolant. Prevents scale formation on heaters.

Tap water can be used, but the formation of deposits is inevitable. Reduces the efficiency of the device. Damage may occur.

When choosing a boiler for heating your dacha, consider the device. The design of the device should be simple, so that if there is a malfunction, you can get to any element and replace it.

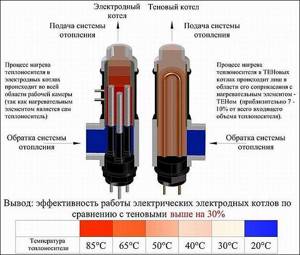

Which boiler is better - heating element or electrode?

When choosing between boilers based on different operating principles, you should pay attention to the following characteristics:

It should be noted that the efficiency when using heating elements often reaches 95-98%. That is, the electricity used to heat the air in the room is used with almost no loss.

Durability is expressed in the fact that over time a layer of scale forms on the heating elements and the walls of the tank, which can lead to damage to the device. As a preventive measure, you need to clean it regularly.

Heating of water also occurs in different ways. Heating elements heat water intermittently, so the required value is reached in 10-15 minutes. Electrode ones cope with this task faster, about one minute.

At the same time, heating elements consume twice as much electricity as electrode ones. Thus, when choosing which boiler is better, you should note the advantages of each. Electrode ones last a long time, are small in size, more economical, and have increased fire safety.

Heating element boiler Vulcan-turbo

The answer to the question of how much a heating element boiler costs is clear - much cheaper than the rest. They work with various coolants, but scale forms in them, which leads to increased electricity consumption and, ultimately, to breakdown.

If the question is how to choose a heating element boiler, then price and efficiency are decisive. Since electricity is quite expensive, it is quite possible to purchase an electrode heater as an emergency heater, if funds allow.

As a permanent heater, it is more profitable to buy a heating element, which will cost much less, and repairing and replacing it will not hit the budget as much as buying a new electrode. In addition, you can do it yourself, which will not entail significant financial costs.

Coolant circulation

The boiler is simple in design; various types of circulation can be used - with natural movement of the coolant, a circulation pump.

Circulation pump

Some heater models have circulation pumps installed. They help disperse coolant through the heating system. The circulation pump used in the heating system reduces the load on boiler equipment, and the energy consumption of the equipment is reduced several times.

The versatility of boiler heating elements

You can use different types of coolant:

- Tap water, but the device is more vulnerable to scale formation. Plain, untreated water carries debris that causes breakdowns.

- Distilled water. Scale formation is excluded, the liquid does not contain heavy metal salts and does not contribute to the formation of deposits. No debris from entering. Coolant promotes longer operation.

- Antifreeze. Suitable for cottages, private houses. It is used in premises where the owners do not live permanently. In the absence of owners, in order to prevent freezing, the systems are filled with antifreeze.

Distilled water, antifreeze

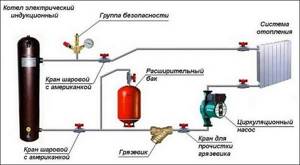

Installation

Installing a heating element heating boiler with your own hands is not difficult; for this you do not need to have a special permit, as, for example, in the case of gas equipment.

You can install electric heating element boilers both in a separate room and in the kitchen. They do not make noise, so you will not experience any discomfort.

Heating electric boiler Kospel Ekco

Such a heating system involves the installation of the following elements:

- Directly the heating boiler itself, which heats the coolant. In addition, it can be equipped with an electronic control unit, interlocks and other devices that ensure reliable and safe operation.

- A system of piping and radiators that runs through all rooms. Its design includes: supply and return pipes, along the first the coolant moves in the direction from the boiler to the radiators, along the other it returns back and begins to warm up again.

- A circulation pump is a device that ensures constant circulation of the coolant and uses a minimum amount of energy for heating. The operation of the pump ensures that the coolant does not have time to cool in the radiators and much less energy is consumed for its secondary heating. Due to this, greater efficiency of the entire system is achieved, and the house will always be warm.

- An expansion tank is a device that compensates for the thermal expansion of water and prevents excess pressure from appearing in the system.

Do-it-yourself installation can be carried out only with strict adherence to the rules and only if you have skills in working with electricity.

In addition to the above parts, auxiliary parts such as a safety valve and shut-off valves are installed, which allow the removal of accumulated air from the pipeline and prevent the formation of plugs. All parts are assembled into a complete system, the boiler is connected to the electrical and pipeline network of the house.

Advantages, disadvantages of heating elements of boilers

Advantages:

- Compactness. The device can be placed without worrying about the installation location.

- Availability.

- Ease of installation. Installation takes several hours.

- Devices can be adjusted. A suitable temperature can be set.

Flaws:

- The equipment is subject to frequent breakdowns. The heating element is a heating element (thermal electric heater). The main part is the tube. It may break if exposed to heat.

Design

- The electrical appliance is not resistant to scale formation. If hard water is used as a coolant, the device becomes coated. The heat transmission capacity decreases, the temperature readings set on the sensor will differ from the real ones.

The equipment does not have many disadvantages; they are mainly related to the peculiarities of its operation. If you monitor the condition and use only soft, settled water, errors can be leveled out.

Otherwise, it’s a decent option for heating your home. You can heat small rooms and large rooms.

Reviews of economical household electric boilers: advantages and disadvantages

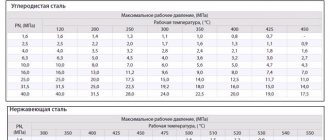

| Advantages | Flaws |

| Compact sizes. Models with a steel square case are much smaller than gas models. Electrode boilers can be slightly larger than the main heating system in the house. | High energy consumption and, as a result, the most expensive heating costs. Therefore, even the most energy-saving boilers can hardly be called economical. According to practice and reviews from owners, heating even a small house with an area of 80 m2 with electricity costs 9-12 thousand rubles. per month. To use cheap night rates, you need an appropriate meter. |

| High efficiency and heating rate of coolant | Models with a power of more than 5-6 kW require a three-phase power supply (380 V). |

| Easy to install and operate. You can install an electric boiler without any special skills; moreover, it does not require a chimney, ventilation system, or boiler room. Operation and maintenance require minimal attention. | When used as the main heating equipment, it is completely dependent on power supply. For stable operation in domestic conditions, a stabilizer and a UPS or generator are desirable |

| Electric boilers are absolutely environmentally friendly because, unlike other types, they do not emit any substances during operation | Powerful models create a significant load on the electrical network of the house. Therefore, they require high-quality and serviceable wiring. |

| Absolutely silent operation | |

| Availability of both single-circuit and double-circuit models (providing heating and hot water supply). Many models can be used in underfloor heating systems. | |

| Extremely low cost of most models |

Types of heating elements of heaters

By design, heating elements are divided into two categories:

- Single-ended.

- Double-ended.

Single-end heaters resemble electric boilers in appearance. The heating elements are distributed on one side.

Single-end, double-end

In addition to conventional tubular heating elements, there are more expensive devices that are distinguished by more durable materials. Devices work longer. Types of electric heating elements:

- Made from an alloy of cupronickel and nichrome.

- Ceramic.

- Made from composite material.

The most durable is a ceramic heater.

Manufacturers

- Galan boilers are popular. Equipment made in Russia. Components are used that are supplied from abroad. The devices are automatically controlled and accessible.

- "Nevsky". Used in closed heating systems. The necessary temperature parameters are automatically set, the device provides comfortable conditions. When the set temperature is reached, the device turns off until it cools down slightly. The boiler has a reliable assembly and components.

- Imported manufacturer Dakon (Czech Republic). There are about 30 models of units with heaters from Dakon. Models with additional equipment are possible - circulation pump, expansion tank.

- Kospel boiler (Poland). Used in single-circuit heating systems.

Comparison of induction and heating element boilers with the same power

For comparison, two models of the same power will be taken - 25 kW.

- The price of induction is 85 thousand. The price of heating element is 46 thousand. Prices are indicated for the period of 2021.

In order for the induction device to be put into operation, it is equipped with the following elements:

Induction heater

- Pump.

- Flow sensor.

- Spirotop, pressure gauge, safety valve.

- Electrical panel.

- Temperature sensor.

- Shut-off ball valves.

- The weight of the complete structure is 80 kg.

Compared to a heating element boiler:

Equipment

- Weighs 40 kg less.

- The electronics are located inside. The advantage eliminates the need for an additional electrical panel.

- Automatic power selection and temperature maintenance are possible. An induction device is not capable of this. The setting is done manually. Affects the maximum power consumption of the heating element boiler.

A flaw when switching boiler equipment will cause the light to blink.

- Contactors built into induction devices are powerful; when switching, loud pops will be heard.

When compared with a heating element device, it has a small contactor, the operation of which will not cause irritation and is almost inaudible.

- The unit is equipped with thermal protection. Makes sure that the system does not overheat or cool.

- You can see a sensor that detects low water pressure. Essential for leak detection. For induction devices, heating of the heater core is observed, which will lead to complete breakdown of the device.

Types of electric boilers for home heating

There are several types of electric boilers based on the principle of electricity use and operation. Traditional and familiar to everyone - heating elements. More innovative and energy-saving are induction (vortex) and ionic (electrode), they are more expensive, but the cost is paid off by extreme efficiency and efficiency, which weakly or does not decrease at all over time.

The efficiency of all electric boilers is the same - 94–99%, but some types are more efficient due to the design and method of operation. And also over time, due to scale, this characteristic decreases by 10–20% for heating element boilers, but this is not typical for induction and ionic products.

Types of electric boilers:

- with heating elements;

- ionic (heating by electrodes);

- induction (vortex).

Heating elements new electric boilers

Heating boilers with heating elements can only be classified as economical only conditionally: different models may have more efficient heating elements, programming capabilities, and power settings.

Inside the device there is a tubular electric heater - a copper or stainless steel tube (there may be sand or oil inside) with a filament (nichrome). The principle of operation is the same as that of a conventional boiler or air heater: the spiral inside the shell heats up and transfers heat through the tube in which it is enclosed to the water entering the chamber (flask) with the heating element.

When choosing electric heating for a home with a special emphasis on economy, units with heating elements should not be seriously considered. You can choose a high-quality device with more or less energy consumption, but it will still be more power-hungry than induction and ion boilers. On the other hand, the cost reduction can be compared to some extent, since a boiler with a heating element is cheap to maintain.

Advantages and disadvantages of heating elements electric boilers

Advantages of heating heaters with heating elements:

- cheap and convenient repair (the body is easily disassembled, parts are replaceable);

- advanced functionality: power adjustment, programmability, ability to connect a thermostat;

- usually produced in a monoblock compact case (there are convenient wall-mounted sizes) ready for operation, including a safety group, expansion tank, and pump. There is no need to separately purchase and install these elements; you only need to connect the device to the input and output of the heating system.

Minuses:

- the most uneconomical type of electric boilers, especially if two heating elements are used;

- Scale and plaque forms on the heating element, which requires periodic cleaning and replacement. A hard crust reduces efficiency by 10–20%. This statement is controversial, since the water of the heating system is not prone to intense scale formation, but it should not be ignored.

Induction boilers

Types of induction boilers for home heating (sometimes perceived as brand names):

- VIN - “vortex induction heaters”, more innovative with a ferromagnetic body. Smaller in size and 1.5–2 times more expensive than SAV, but more efficient;

- SAV - the principle is the same, but they are positioned as less advanced.

The second heating with vortex boilers is “inverter”. The product includes a current converter from direct to alternating current - an “inverter” (like welding machines).

Immediately after their appearance on the market, induction heaters for heating were positioned as the most advanced and efficient, but application experience showed more shortcomings than expected.

Operating principle of vortex SAV and VIN electric boilers

How does an induction SAV boiler work:

- A high-frequency alternating current (from 50 Hz) is supplied to a metal coil (inductor) - a rod (its role can be played by the coolant pipe itself) with turns of wire. A magnetic field is generated.

- The polarity and vector of the magnetic field change with high frequency.

- An object located close to the described phenomenon is penetrated by constantly changing fluxes of magnetic induction. Foucault eddy currents arise, turning electricity into heat, which heats the water.

The principle of heat transfer in induction boilers is non-contact - the object is heated by electromagnetic fields, and instantly. There is no need for physical contact with the inductor, which increases efficiency.

The electromagnetic principle is used in industry to melt metals. Even a small homemade induction device with a coil with a dozen turns and a few cm² in size is capable of heating metal to red in a few seconds, which illustrates the power and efficiency of a vortex boiler for heating.

Advantages of induction boilers for heating

Advantages of SAV boilers:

- heating is powerful, almost instantaneous;

- microvibrations repel dirt, so there is no scale or deposits on parts in contact with water, no cleaning required;

- economical, the highest efficiency among electric boilers.

Induction boilers are the best for preparing water as it flows through the apparatus, as they provide extremely fast heating. At the same time, heat loss is zero, which distinguishes VIN from heating elements units. Despite the disadvantages, if we consider purely the efficiency of using electricity, induction boilers are the most economical type of electric heaters.

Disadvantages of vortex boilers for heating, feasibility of use

Many sources list many advantages of VINs and SAVs, but in reality the picture is somewhat different; many shortcomings have been discovered:

- most standard sizes have significant dimensions;

- more expensive than heating elements and electrode units;

- heating is extremely powerful, so if the auto-shutdown system breaks down, there is an increased risk of explosion;

- the electromagnetic field is harmful, electrochemical processes provoke corrosion;

- complex repair. It would seem that the device is extremely simple - a coil and a housing - but usually the cylinder of SAV boilers is securely sealed, and it is extremely difficult to disassemble it. It contains electronic circuits of the control unit, which complicates repairs. The coil may burn out, and the cost of a new one is higher than, for example, a new heating element;

- if the SAV is not in a compact case, and the majority are, then a large control unit, a separate expansion tank, a pump, and a safety group will be required;

- in most cases, they are not equipped with a soft start - when turned on and even when simply switching modes, there is a sharp increase in the load on the network, which is fraught with voltage drops (flashing lights and similar effects).

Still, despite the listed disadvantages, a vortex energy-saving electric heating boiler should be considered as a heater for heating a house due to its high level of efficiency (30% more efficient than heating elements). Some of the listed disadvantages are relative, for example, there are small and compact sizes similar to those of products with heating elements. This is the only type of heater whose efficiency does not decrease over time.

Ion (electrode) boilers

Ionic (electrode) energy-saving heating boilers must be distinguished from induction units, despite the fact that they also use the properties of alternating current. The organization of energy use itself is different. The body of the device contains a sealed chamber with a coolant and electrodes located in it with a certain gap.

With a constant current, the cathode attracts water ions with a positive charge, and the anode attracts negative ones, but if you change the characteristic to a variable one (starting from 50 Hz), then a constant movement of these particles will occur. The medium has resistance, so the kinetic energy of moving ions (cations and anions) is transformed into thermal energy, and the electrolyte is heated.

In the ion boiler, a special electrolyte solution is heated, circulating in the pipes of the heating system; in certain cases it can be water. In fact, such a boiler is a simple heat exchanger.

Advantages of ion (electrode) boilers for heating systems

Advantages and features of ion boilers for heating:

- extremely compact: low-power models are only slightly larger than the diameter of the pipes. This is a small cylinder cut into the wiring. They do not require any space around them, so they can be installed literally anywhere;

- the cheapest - 4–9 thousand rubles. (A new heating element costs about 15-30 thousand), but if you have to buy an expansion tank, thermostat, safety valves, pump, then it’s another 10-12 thousand;

- scale does not form - this is prevented by electromagnetic processes;

- service life before the first breakdown is 12–15 years. According to this characteristic, electrode heaters are comparable to induction devices;

- maintainability. The design is simple and can be disassembled without much difficulty. Parts are replaceable and cheap;

- the safest: if induction or heating element boilers, if the automatic shutdown (protection against overheating and dry operation) fails, continue to heat up until an explosion or fire, then ionic boilers will simply stop working on their own without any intervention if the coolant leaks;

- no electromagnetic field.

Disadvantages of electrode heaters

Installation of the electrode device itself is simple, but it is somewhat complicated by the need to install a pump, safety group, and expander. There are also products with the last two elements on the body or in the form of a ready-to-use monoblock, but this arrangement is less common. In this aspect, heating element boilers have an advantage, since they are often produced in standard sizes with everything necessary in one housing.

Minuses:

- There are devices with a heat exchanger and an expansion tank on the body, but in most cases an additional purchase of these elements is required, as well as a pump and safety group;

- scale and plaque do not form, but electrical processes increase corrosion of the metal of the heating system circuit. In this aspect there is a similarity with SAV boilers;

- Pipe water can act as an electrolyte, but usually special solutions from the manufacturers of such boilers are always used. The mixture must be undistilled and unfiltered. Special substances are the most effective. Propylene glycol and ethylene glycol are used. You cannot use antifreeze, oil, or distilled water;

- requires replacement of the coolant every 3–4 years.

Electrode boilers consume 20–30% less electricity than heating element units, but they are slightly less energy efficient than induction models. That is, in the economy rating, if we take into account the convenience, low cost of the product and service, they are in the middle.

Which one is better for home?

Electric boilers can have a built-in or remote control panel.

- Built-in panel includes thermostat, power switch. Located on the body. The price of the equipment is acceptable for buyers with average incomes.

For example, an Elektromash EVPM-3 device with a power of 3 kW, which heats a living space of 35 m2, costs about 3,000 rubles.

Has limited functionality. Based on the possibility of changing the temperature of the coolant and starting the heating element heater.

Elektromash EVPM-3 from the inside

- Devices with a remote control panel have great capabilities. The downside is that the device and control panel must be purchased separately. You will need to purchase an installation block. It happens that the equipment is fully equipped, but more often, additional elements have to be purchased.

For example, a ZOTA 12 Econom device that heats 120 m2 costs around 10 thousand rubles; for additional equipment in the form of a unit and a control panel, you will have to pay an additional 5 thousand rubles.

How to choose an economical electric boiler

Having decided on the type of electric boiler, it is worth considering all models based on other criteria that affect efficiency.

Single-phase or three-phase power type

Low-power models up to 5-6 kW inclusive can operate from a single-phase network (220-230 V). For higher power models, a single-phase network will simply not be enough. This means that the coolant will take longer to heat up to operating temperature, the heating elements will be active for a much longer time, and the economical operating mode of the automation will be disrupted.

Conversely, for low-power electric heating boilers, a single-phase network is quite sufficient; there is no need to specially re-equip the wiring to provide three-phase power.

It is also worth remembering that the installation of models with a power of over 10 kW requires approval from the Energy Supervision Services.

Automation functionality

Simpler, less expensive models must have at least a three-stage power switch. Accordingly, more expensive models should have power smoothly modulated by a temperature sensor. Some models have factory-installed economical modes and the ability to program boiler operation by day and hour, which allows you to focus on maximum heating of the coolant at night at reduced electricity rates.

By the way, when using night tariffs, a buffer tank will be especially effective, which will allow you to use the heat accumulated during the night during the day, without turning on the boiler at all during peak and half-peak tariff periods.

The most economical and comfortable operating mode is using a room thermostat. Even the simplest models of room thermostats have many fine settings, and the boiler automation is guided not by the temperature of the coolant, but by the air temperature in the room, which is more correct.

Instructions for selecting and connecting an external thermostat to an electric boiler

Calculation of the minimum required power

To use an energy-saving electric boiler as an auxiliary heat source in houses up to 120-150 m2, models with a power of 3-6 kW are sufficient. For constant use of an electric boiler, the minimum required power must be calculated based on the heat loss of the house.

To put it simply, for an average house with 2 bricks and a ceiling height of up to 2.7 m in the climatic zone of the Moscow region, heat loss is 1 kW per hour. It is also advisable to provide a power reserve of 10-15%, and for electric boilers with heating elements - 20-30% due to scale formation and reduced efficiency.

Total, for example, for a private house with an area of 80 m2, the minimum required electric boiler power is: 8 kW + 20% = 9.6 or 10 kW.

How to calculate the required boiler power Individual calculation, formula and correction factors