In fact, a boiler room in a wooden house is not much different from its arrangement in rooms made of brick, aerated concrete and other materials. This communication attracts increased attention only because a building made of wood is supposedly more vulnerable to fire, since the wood itself burns, but the same brick does not. However, both in a wooden house and in a stone one, it doesn’t matter, there is something to burn. Therefore, the arrangement of a boiler room must be approached with due attention in any home.

There are, however, some nuances when arranging a boiler room in a wooden house. They, and other equally important points, are described to the maximum in the material under consideration.

Premises requirements

The first task is choosing the installation location. The basic standards are set out in SNiP 02/31/2001. Installation in residential areas, bathrooms or toilets is prohibited. Installation in the basement room is possible, but not in the basement. It also cannot be installed in the attic. For powerful equipment over 36 kW, you need to equip a separate boiler room.

It is necessary to take into account the basic requirements - a gas boiler in a wooden house with a power of up to 60 kW can be installed in a room with the following parameters:

- Minimum volume – 15 m?. For every kilowatt of energy above the norm, you need to add 1 m?.

- Ceiling heights are from 2.5 m and above.

- Availability of forced and natural ventilation.

- Artificial lighting should be complemented by natural lighting.

The installation site is isolated from the living quarters by a door; if the installation is carried out in a separate boiler room, there must be an exit directly to the street.

Installation of a wall-mounted gas boiler in a wooden house in a separate boiler room is carried out according to the following rules:

- standard requirements for the volume and height of ceilings – 15 m? and 2.5 m;

- interior wall decoration with fire-resistant material with a fire resistance limit of 0.75 hours;

- normal room lighting - artificial and natural;

- the presence of ventilation systems.

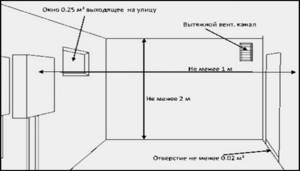

In addition to the door to the street, there may be an additional doorway into the house. It is important to ensure tightness - combustion products should not enter the building. Ventilation parameters depend on the type of combustion chamber - closed or atmospheric. For the second, the air exchange value should not be less than 3 boiler room volumes per hour. Additionally, combustion air consumption is taken into account. This parameter is indicated in the boiler passport. The distance from the heating equipment to the ventilation hole is at least 2 meters. The glazing area depends on the volume of the boiler room. At 1 m? 0.03 m required? light opening. Important - this is an indicator of the net influx of light, without taking into account the width of frames and imposts.

Houses with a boiler room from SK "Stroyudacha"

Stroitelnaya offers everyone the construction of a cozy house made of timber for permanent or seasonal stay on a country site. We build residential buildings according to standard designs (see them in the catalog on the website) or individual customer designs. Below are popular projects of houses made of timber with a boiler room, the construction of which you can order today.

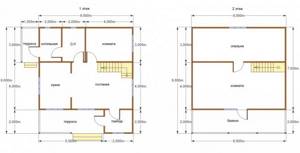

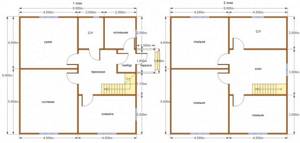

Project D-63. Timber house 8x9 with terrace

This building is suitable for permanent residence of a family of 3-4 people, and for seasonal residence. Useful footage – 144 sq. m. The nuance of the layout is two entrance doors. A terrace with an elegant fence in front of the first door is designed for a pleasant stay in the warm season; in front of the second door there is a miniature terrace of 4.5 square meters. m.

The first floor is occupied by premises: a vestibule, a kitchen-living room (combined) of 32 sq. m. m; Next is a free room of 12 square meters. m for a children's room, playroom or bedroom, a bathroom of 6 sq. m and a boiler room 2x3 meters. There are two bedrooms in the attic: the first is 24 sq. m. m, the second – 32 sq. m, which opens onto the balcony. The successful layout allows you to stay comfortably.

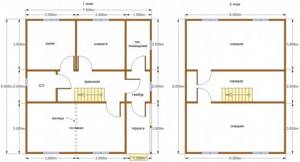

Project D-43. House made of 7.5x8 timber with an attic

Residential building with a useful area of 108 sq. m. m is suitable for permanent and seasonal stay. It will become both a cozy home with comfortable conditions and a decoration for the countryside for many years. The layout of the first floor includes premises: vestibule (hallway), kitchen, living room, bathroom, free room for organizing a bedroom or nursery, and a boiler room 1.5x3 meters. In the attic there is a sleeping and relaxation area - two bedrooms, each measuring 17 square meters. m. With the project you will forget about the inconvenience and discomfort.

Project D-61. Timber house 9x9 on 2 floors

A house with two full floors is suitable for those who like a comfortable country holiday in the summer and stay in a country area all year round. Useful area – 160 sq. m. First of all, the owner gets into the vestibule, and from there into the rest of the premises of the residential building. Opposite the vestibule there is a boiler room 2.5x2.5 meters. On the first tier there are premises: separate living room and kitchen, bathroom, large hallway and a spare room, which can be converted into a children's room or an additional bedroom. On the second floor there are three bedrooms and an additional bathroom. Here the owners relax and sleep. The roof is covered with ondulin or roofing material at the customer's choice.

Permits

Unlike installing a solid fuel boiler in a wooden house, gas equipment requires a permit. To do this, you need to contact the local organization responsible for gas supply - Oblgaz or Gorgaz. Connection to the gas main should only be carried out by certified specialists, but installation of boiler equipment can be done independently.

Stages of obtaining a permit:

- Obtaining technical conditions. It indicates the requirements for connecting to the gas main. It is necessary to provide a house plan with its characteristics.

- Drawing up a gasification project. This work is performed by specialized licensed organizations.

- Based on the project, permission is issued to install a parapet boiler in a wooden house. The same applies to wall-mounted or floor-standing models.

- After installation, representatives of the gas service must check the building and the main line for compliance with the technical conditions and the agreed project. They also connect the equipment to the pipeline.

To optimize time and financial costs, it is recommended to use the services of Gorgaz subsidiaries. Their representatives know the nuances of design and the latest changes in requirements for premises and equipment.

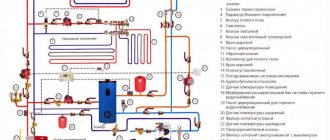

Installation diagrams

After preparing the premises and obtaining permits, you can begin installing the boiler. The equipment installation site is finished with fireproof materials. For wall-mounted models, the use of reliable fasteners is mandatory.

How to hang a gas boiler on a wooden wall, and what standards must be followed? To do this, you need to familiarize yourself with the general rules:

- Drawing up a diagram. The location of the pipes for connecting to the pipeline and the location of the gas main are taken into account. Before installing a gas boiler in a wooden house, the diagram indicates the location of auxiliary equipment - indirect heating tanks for domestic hot water, a circulation pump, an expansion tank and a protection group.

- The minimum permissible distance to the surface of the wall on which the equipment is installed is 4.5 cm. To the side ceilings this value is at least 20 cm. The distance to the floor is from 30 cm, to the ceiling 45 cm.

- The hole in the interfloor ceiling or wall for the chimney is protected by a special fire-resistant sleeve. Its function is to prevent direct contact of wood with the heated surface of the chimney.

- Use of plastic pipes in heating. To protect the surface of the main from overheating, it is recommended to install a steel pipe up to 0.5 m long at the hot water outlet from the boiler.

In practice, the same installation of a wood-burning boiler in a wooden house will be easier. But in the future, heating and maintenance costs will be higher than for gas heating.

Types and prices

The advantage of such boilers is a large selection of models with different mountings: floor-mounted and wall-mounted. When choosing a boiler, real connection conditions are taken into account.

Boiler equipment from European factories, Russia, CIS countries and China is quite widely represented on the construction market. It is clear that the quality of equipment from the EU is higher than that of boilers from China, but the price is also much higher.

Popular parapet boilers:

- TERMOMAX-C are non-volatile compact boilers for individual heat supply of single-storey and multi-storey buildings, equipped with a flue gas exhaust system through a coaxial channel, horizontally built into the external wall.

Structurally, they are carried out in both single and double-circuit versions with markings E and EB and thermal power from 7 to 16 kW. For heating systems with high hydraulic resistance, a circulation pump is provided. Control, protection and start-up are carried out through the gas valve EuroSit 630. The burner is started using piezo ignition. TermoMax C 16EB has an efficiency of 90% and is capable of heating rooms measuring 120 m2, the cost of the unit is 20,100 rubles. - Another Russian model of a parapet boiler is Lemax Patriot 20 with a closed firebox. The steel heat exchanger is treated with an inhibitory compound and covered with an enamel coating to resist corrosion processes. Mounting type: wall-mounted. The range of thermal loads of Lemax boilers is from 6 to 20 kW. Gas burner equipment from the Italian concern “SIT” with an injection flare burner “POLIDORO”. There are special holes on the front panel to create a convection effect and increase heat transfer in the room. Features include: removable cladding elements, igniter, coaxial smoke removal system, non-volatile installation option. The cost of the unit is 25,820 rubles.

- The double-circuit boiler “Slim 2.300 Fi” is produced by the Baxi brand with a heat load from 14.9 to 29.7 kW, capable of heating objects measuring 140 -160 m2. The boiler is made of high-quality materials, with a price from 120.0 to 140.0 thousand rubles.

- EcoCompact VSC D INT 306/4-5 190L, boiler of the German brand Vaillant - a highly efficient unit, can heat 160-180 m2, price 240.0 thousand rubles.

- The Danko parapet boiler, with a power from 7 to 18 kW, is equipped with a cast iron boiler with a wall thickness of 3 mm and a closed combustion chamber. The universal design allows for two-way connection of utility networks; the control unit is located on the operating panel of the boiler. The units are equipped with Honeywell gas automatics, piezoelectric ignition and a micro-torch burner, heating area up to 160 m2, price – 21 thousand rubles.

- Eurotherm KT TSY (P2) for individual heat supply in systems with natural and forced circulation of the heating circuit, with water heating temperature up to 90 C, thermal power 10 kW, gas consumption 1.13 m3/hour, efficiency 92%, weight 59 kg, warranty period 24 month, heating area 100 m2, price – 24 thousand. rub. Steel boilers are equipped with a copper recovery system with a bypass channel. A specially designed copper coil is placed in a water cavity to produce hot water. Design features: heat recovery system with a receiving tank, housing, control and protection unit, air duct, flue, wind protection cover. The design allows you to install the unit at floor level near the wall. The DHW circuit connecting pipelines are made on one side. The air intake duct passes through the outer wall with a thickness of 200 - 500 mm. Mounting on walls in a wooden house is not allowed without fire protection measures.

Wall backing material

The main requirement in finishing walls, floors and ceilings is fire protection. For this purpose, a special substrate is used for a gas boiler in a wooden house. It should not support the combustion process and protect the walls from temperature effects.

Recommended backing material:

- Basalt wool. A layer with a thickness of 50 mm or more is installed on a rigid base (metal sheet). The density of wool is maximum.

- Basalt fireproof sheets. In the event of an open flame, they will protect the wooden surface of the walls from thermal effects.

Preparing for installation

Before installing a parapet gas boiler, you must prepare all the tools and mounting materials.

To make a hole in the wall for the chimney outlet, you should prepare a hammer drill with a diamond bit corresponding to the diameter of the coaxial pipe. You need to prepare keys and screwdrivers corresponding to the fasteners, rulers, level, marker, knife.

Personal protective equipment will also be useful during installation: mask, goggles, gloves.

Coordination and design

The boiler can be installed in private houses made of wood, brick and other materials. The owner of the building must take into account that installation work must be carried out in accordance with regulatory documents. They regulate the conditions for installing systems. Installation of a gas boiler in a house is carried out taking into account the following documents:

| SNiP 42-01-2002 | It talks about the features of connecting country houses to gas. Here are the requirements that exist in the field of gasification of buildings |

| SNiP 41-01-2003 | The document is devoted to heating, ventilation and air conditioning |

| SNiP 2.04.01-85 | Here are the requirements for internal plumbing |

| SNiP 21-01-97 | An important document on fire safety requirements for buildings and structures |

After studying the documents, the home owner will become familiar with the specifics of installation work when creating an autonomous heating system running on gas. He must take into account that the first step before installation will be to obtain technical specifications (TS). Based on them, work is carried out to connect equipment to the main line.

In order to obtain specifications, you must visit the gas service. The owner of the house must write a statement indicating the volume of gas that he plans to use for heating. In the central zone, heating a private house requires 7-12 cubic meters of fuel per day.

The organization's specialists will review the application. If it can be satisfied, the citizen will receive technical conditions. They may not be issued, but in this case representatives of the gas service must explain the refusal. 30 days are allotted for consideration of the application, but the response is often received earlier. Installation of gas equipment cannot be done without technical conditions. If they are not there, installation of the equipment will be considered illegal.

When the specifications are received, they move on to design work. The project can be created by specialists; they must have all the necessary licenses. You cannot make a plan on your own. The document includes an equipment installation diagram. It should reflect how to install the boiler, how the pipes will go from the central highway to the land plot. They show the course of the pipe from the land plot into the building, how it will pass through the boiler room and in each subsequent room.

When the project is ready, it is sent for approval; 90 days are allotted for this procedure. The package of documents must include the following:

- Documents for a gas appliance. This is a technical data sheet of the product and instructions compiled by the equipment manufacturer.

- Certificates.

- A document confirming that the unit complies with safety requirements.

Even if a refusal is received, the citizen who submitted the papers for approval will receive an explanation. He will be given a list of recommendations, following which he will receive permission to connect the house to the gas main.

Why do you need a boiler room?

A boiler room is needed to provide hot water to the residents of the house. The heating process can be carried out in various ways, which are selected depending on the availability of a heat source, or the greatest economic benefit from using the type of heating.

In an apartment building

In apartment buildings, the heat source is hot water (or steam) from the central heating system (CH). A boiler in an apartment building has the same purpose as in any other place, but from a design point of view it is somewhat different from other types, being an ordinary heat exchanger. The principle of its operation is simple: hot water from the central heating system (coolant) is passed through a container, inside of which there is a pipe system that does not communicate with the internal volume of this container. Cold liquid flows through them, which is heated by the coolant and sent to the domestic hot water system. That is, the coolant is used not only for heating rooms, it also provides the availability of hot water.

In a private house

In a private house that does not have a connection to the central heating system, the boiler performs the function of heating the liquid using heat from the boiler . Fuel can be electricity, gas, firewood, coal, briquettes, etc.

In this case, the term “boiler” is used according to tradition, but not entirely correctly. The exact name of such a device is a boiler, and the room for it, accordingly, is a boiler room. If there is a connection to the central heating system, then you can install a heat exchanger, but this possibility is still rare in rural areas.

Requirements for private houses

The home owner should be aware that there are requirements for installing a gas boiler that must be met. They are as follows:

- All materials that are planned to be used for connection must be of high quality.

- Gas pipeline connections are made outdoors.

- It is prohibited to route the gas pipeline through platbands, window and door frames and other elements of the exterior decoration of the building.

- There should be no distortions when installing pipes. It is prohibited to make risers in living rooms and bathrooms; they are placed on staircases or in the kitchen.

- The thrust nut must not be placed on the wall side.

In order to supply gas to a private home, you need to purchase a boiler; when choosing it, you need to take into account the area of the heated premises. To determine the required power, the formula is usually used:

Power = Area * Specific power of boilers / 10 Specific power of a boiler per 10 sq.m. determined from the table:

| 0.7-0.9 kW | for southern regions |

| 1.0-1.2 kW | for the middle zone |

| 1.2-1.5 kW | for Moscow region |

| 1.5-2.0 kW | for northern regions |

Thus, for a house with an area of 250 sq.m. in the Moscow region the required capacity will be: 250 km. * 1.2 / 10 = 30 kW.

General requirements for gas equipment

When installing the boiler, it is necessary to comply with installation standards. They are indicated in the instructions that the manufacturer encloses with the manufactured equipment. In this case, if the equipment stops working, the company will perform warranty repairs. Before starting installation, it is determined whether it is necessary to allocate a room for a boiler room or whether it is sufficient to prepare a furnace room. The information is indicated in the unit's passport.

Separate rooms for the boiler room

A fire-resistant base 20 cm thick is made for the installed equipment. This can be a concrete or brick platform. Powerful boilers are installed in a separate room; it must be non-residential. The installations use the entire heating season; a prerequisite for their placement is a sufficient volume of the room.

Preparatory stage

Even at the project development stage, it is important to provide for the conditions of the regulations under which the facility will be built. The main recommendations of these documents include:

- planning artificial heating in the room. The heat generated by the unit is not enough to maintain the required temperature;

- purchasing equipment in advance will help to take into account the manufacturer’s instructions for the construction of technological openings and the installation location of the unit;

- The planned extension of a boiler room to a wooden house is prohibited in places with window and door openings. You can only use completely blank surfaces or seal all holes where the boiler room adjoins the wall of the house;

- The dimensions of the building for gas equipment are given above, and for options with other types of fuel these parameters are height - 2.5 m, area - 4 sq. m. m, volume – 15 cubic meters. m;

- It is recommended not to adhere to the minimum values, but to maintain the dimensions established for gas boilers.

The hood must pump at least 3 times the volume of air per hour in comparison with the sum of the volumes of air mass consumed during combustion and the room itself.

Gas boiler installation diagram

Connecting equipment should be approached responsibly. It is necessary to study the SNiP documents and take into account the layout of the premises. You should take into account the power of the boiler and how far from the walls it should be placed. A diagram for connecting gas equipment will be issued along with the permit, only after which the owner of a private house can begin installation work. Specialists will make a connection to the central pipeline line, the pipe from it will go to the house.

Is it possible to install a gas boiler in a wooden house?

Room requirements for installing a gas boiler in a wooden house include the following:

- The boiler room is located on the ground floor or in one of the rooms. In a wooden house, it is prohibited to install a gas boiler in the basement, except in a specially equipped, separate room.

- The premises must meet the requirements described in the PPB and sanitary standards.

- It is prohibited to place heating equipment in living rooms. Installation in the kitchen-living room is not allowed; installation in the bathroom and toilet is conditionally prohibited.

- It is mandatory to have personal protective equipment and fire extinguishing equipment, as well as smoke detectors and fire alarms.

Furniture for boiler room

In the boiler room you often have to store some things that are necessary for servicing the boiler. It is important to install fire-resistant furniture indoors. The best option is metal racks. They are durable, reliable, look beautiful and do not ignite when exposed to open fire.

Knowing how to properly equip a boiler room, you will be able to make it safe to use and protect your home. If the owner of a cottage or summer house doubts that he can ensure the fire safety of a room with heating equipment himself, he should seek help from specialists.

Requirements for a gas boiler room in a wooden house

The basic rules for installing a wall-mounted gas boiler in a wooden house cover three important areas:

- Standards stipulating the minimum requirements for a boiler room.

- Rules for connecting smoke removal and ventilation systems.

- Existing fire safety regulations.

Acceptable standards for the arrangement of a gas boiler room inside a wooden building stipulate the types and types of interior decoration, the security system, the presence of a fire alarm and fire extinguishing equipment.

To install a boiler in a wooden house, strict compliance with existing requirements is necessary. A gas boiler room is a place of increased fire danger, which will need to be taken into account during the arrangement.

Boiler room room standards

The requirements for installing a floor-standing gas heating boiler in a wooden house take into account the operating features and the increased fire hazard associated with the structural material of the building. In this regard, the standards indicate the need to comply with the following requirements:

- The volume of the boiler room is calculated based on the overall performance of the heating equipment. Gas boiler up to 30 kW, installed in an isolated room of at least 9 m³. Provided that the ceiling height is at least 2.5 m.

- It is allowed to locate a gas boiler in any technical room of a wooden house. Sanitary standards prohibit the installation of heating equipment in living rooms, as well as kitchens and living rooms. Some restrictions affect the location of the boiler in the house. PPB standards prohibit the installation of a boiler room in the basement, but allow, with several reservations, the installation of a gas boiler in the basement.

- The boiler room is fenced off from the living rooms by a wall. To increase fire resistance, the walls are coated with special impregnations. In the boiler room, a door leaf with a minimum width of 80 cm is installed, not adjacent to the frame at the bottom, for a constant flow of fresh air.

- It is necessary to have natural lighting, as well as windows for ventilation.

Organization of ventilation and smoke removal

In a wooden house, special attention is paid to the installation of supply and exhaust ventilation and the correct connection of the smoke exhaust system. Minimum requirements applicable to the boiler room:

- Exhaust device - the diameter of the ventilation duct, calculated based on the boiler productivity - 8 cm² for each kilowatt of power.

- The installation of the smoke exhaust pipe is carried out in compliance with fire distances and gaps. The height of the chimney is calculated depending on the distance from the roof canopy. The pipe head must not be covered with decorative elements. To increase traction characteristics, it is recommended to install a deflector.

It is not allowed for the horizontal section of the chimney to have a total length of more than 3 meters. It is allowed to install no more than 2 rotary couplings on the entire smoke exhaust system.

Some requirements for chimneys and supply ventilation are specified in fire safety rules.

Fire standards for a gas boiler in a wooden house

Fire regulations cover: placement of the boiler, arrangement of the boiler room and installation of the smoke exhaust system:

- Placement of the boiler - optimal use for the needs of a boiler room, a separate building made of non-combustible materials: ceramic or silicate bricks, foam blocks, aerated concrete, etc. It is allowed to install a boiler room in the house, provided that the conditions of the safety regulations are met.

- The floor and walls of the boiler room are lined with non-combustible materials. If this is not possible, fire safety requirements stipulate the need for partial protection of surfaces at the location of the boiler and the chimney. The walls and floor are protected with non-flammable basalt insulation. Additional protection is provided by special fire-fighting compounds. Preliminary preparation of walls, ceilings, and floors will be required by treating them with mastics or impregnations with a high degree of fire resistance.

- When the chimney passes through the floor slabs and roof, a special fire-resistant cutting is used.

How to hang a gas heating boiler in a wooden house

The technical conditions for installing a gas boiler in a frame or log house differ significantly.

In the first case, we are talking about a hollow material, therefore, special fastening bars are used for fixation. If the boiler equipment is heavy, it is recommended to install a gas boiler in a frame house on through studs that are fixed outside the building.

Mounting a boiler in a frame house significantly increases the load on the wall. There are restrictions on the weight of the equipment. If you plan to install a model with a built-in buffer tank, preference should be given to floor-mounted boilers.

Methods for attaching a boiler to a wooden wall of a log or timber house are characterized by ease of fixation. For installation, special wood bolts are used to ensure reliable fastening.

When installing attachments, you will need to comply with safety regulations and maintain minimum distances to door and window openings.

What underlay to use on a wooden wall

If the boiler room is lined with wood, fire protection is provided. The backing on a wooden wall under a gas boiler can be done in several ways:

- A layer of basalt insulation is hung on the wall, after which it is sheathed with steel sheets.

- Special basalt fireproof sheets are used. The advantage of this solution is the minimum thickness of the protective layer, while simultaneously ensuring maximum fire protection.

Installation of a mounted boiler in a wooden house without first making a protective layer is prohibited!

Heating with forced circulation

The installation diagram of a solid fuel boiler for a heating system with forced supply of coolant provides for the installation of a bypass and a three-way valve to create a primary circulation circuit.

Installation of a solid fuel boiler in a forced circulation heating system

This principle of connecting solid fuel boilers eliminates the formation of condensation in the combustion chamber of a steel boiler or the destruction of a cast-iron unit when cooled coolant enters the water jacket of a hot heat generator. A three-way valve set to a given temperature and a bypass allow you to mix heated coolant into the return until the heating system reaches its optimal operating mode.

Article on the topic: Rules for installing double-circuit equipment

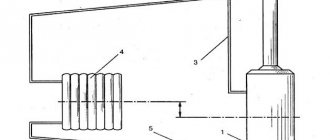

The installation diagram of a solid fuel boiler may include a tank for preparing water for hot water supply - an indirect heating boiler. Its heating element is a coil through which the coolant heated by the boiler passes.

Schematic representation of the installation of a solid fuel boiler with an indirect heating boiler

In the above diagram, the boiler and heating branches are installed in parallel, directly after the primary circulation circuit. This connection allows you to prepare water for domestic hot water using the maximum heated coolant. A straight-through thermostatic valve, which is mounted at the outlet of the boiler, does not allow the coolant to pass freely through the coil. It passes water that has cooled to the set temperature, which releases heat for the hot water supply.

The complexity of piping the boiler unit is also affected by the presence of a second heat generator (gas or electric boiler), the number and types of heating circuits (radiator heating, heated floors).

There are different schemes for connecting two different fuel boilers to service one heating system. The best option is to use a heat accumulator (buffer tank), to which a solid fuel unit and an electric boiler are connected, each with its own circulation pump. The electric heat generator is turned on by a signal from the controller with an air temperature sensor when the temperature in the room begins to drop after the fuel in the main unit has burned out and the coolant in the system has cooled.