- 1 Types of stoves 1.1 Advantages of brick structures

- 1.2 Advantages of metal structures

- 6.1 Construction of a brick kiln

Comfortable living in a country house is impossible without good heating. Heating of a country cottage in the absence of the possibility of connecting to central heating is carried out using a stove.

How to build a brick oven in a wooden house? Or maybe it’s better to choose a metal option? Which one to install and which stove is better for a wooden house? This article provides recommendations for building and installing a stove in a wooden house with your own hands. When performing installation, you should remember fire safety rules and strictly follow the established standards.

Types of stoves

There are several classifications of heating structures for country houses.

There are mainly two types of stoves designed for heating wooden buildings:

- made of brick;

- made of metal.

Each of these materials has its own characteristics that affect the quality of heating.

Stove in a wooden house, photo

The classic option is a brick stove .

Many years ago, such ovens were designed using bricks made from fired clay. We made clay bricks ourselves. The structures made of clay bricks were large in size, provided cooking surfaces and an oven, and had sleeping places in the upper part. Such stoves are often mentioned in Russian folk tales. Interesting! In Rus', a stove was first built, and only then the walls of the home were designed around it.

The stoves were bulky and required a solid foundation. When designing a brick stove, it is important to perform the masonry correctly: it has its own characteristics, and at least basic theoretical knowledge is required for this matter.

Advantages of brick structures

Brick is the main material for designing stoves. There are bricks that are empty inside and full (filled). For the installation of heating structures, exclusively filled bricks (solid), mainly ceramic, are used.

When choosing bricks for the stove, pay attention to the following points:

- bricks must have the same color and shape;

- Cracks and other noticeable defects are unacceptable.

Advice. To ensure a reliable heating structure, do not use bricks with burns or chips - this way you will avoid additional costs for remodeling and repairing the stove due to defective material that is prone to rapid destruction.

The advantages of brick structures include:

- the ability of the material to retain heat and transfer it to the surrounding space;

- a small stove can heat a two-story wooden house;

- high fire resistance;

- low cost of the stove when doing the masonry yourself.

Brick stoves take a long time to cool down, and the structures themselves heat up for a long time even after the fire has died out . The brick is not susceptible to splitting, and the likelihood of a house fire is minimized.

If you use homemade bricks, you will get significant savings on the purchase of material.

The disadvantage of brick heating structures is that they need a stable base , i.e., a reliable foundation will be required. A brick oven without a foundation can cause the structure to tilt or sink into the ground.

For brick structures, monolithic foundations are made or reinforced concrete slabs buried in the ground are used. A third of the costs are for foundation design. The masonry of the brick structure is very specific.

Brick stoves should be placed in spacious rooms or in a separate room, as they require a lot of space.

Stove-fireplace in a wooden house, photo

Advantages of metal structures

The material for designing metal furnaces is cast iron or high-strength steel.

Among the advantages of metal structures it is worth highlighting:

- compact dimensions - a cast iron or metal stove will not take up much space;

- presentable appearance;

- variety of shapes (metal is easy to process and can take different shapes);

- material strength, increasing the service life of the furnace to 50 years;

- automatic control (the fire can be extinguished or, conversely, the heat can be turned up);

- reasonable prices;

- fast and uniform heating of rooms of various sizes;

- fire safety.

Metal stoves have an aesthetic appearance and a long service life, but they also have disadvantages.

Metal structures heat up in a short time, and, unfortunately, they cool down just as quickly . Metal stoves are not able to heat large rooms. Such designs are more suitable for small kitchens.

Stoves made of metal should not be placed near flammable objects . For safety reasons, surfaces are coated with fire retardants.

Find out which house is better - made of timber or frame: in detail about the advantages and disadvantages, features of buildings for individual construction. How much does it cost to build a brick house? You will find a calculator for calculating construction costs in this article.

Bavaria (Ekokamin, Russia)

The Russian company Bavaria calls itself a leader in the production of furnace equipment.

They have been working since 2000. Specialization: fireboxes, conventional and tiled stoves. The plant offers 3 product lines, the most popular of which is Bavaria. These are steel furnaces lined with fireclay bricks. They can be standard or corner, with or without a hob, lined with ceramic tiles or tiles. The range of this line includes products costing from 16 to 75 thousand rubles. Main characteristics of Bavaria stoves from Ecofireplace

| Characteristic | Bavaria | Bayern Corner | Bavaria Prismatic (wall-corner) |

| power, kWt | 6-13 | 6-13 | 7-15 |

| Volume of heated room, m³ | 90-195 | 90-195 | 105-225 |

| Maximum log length, mm | 300 | 300 | 400 |

| Chimney diameter, mm | 150 | 120 | 150 |

| Size, mm | 476x579x835 | 515x650x860 | 527x638x1000 |

| Weight, kg | 107 | 70 | 107 |

| price, rub. | 21 000 | 18 000 | 27 000 |

Impressions from use. Compact dimensions, laconic design that is suitable for any country house, interesting cladding solution, you can choose tiles to suit your taste. Warms up a cooled house of 50 square meters to +7°C at -15°C outside in 2 hours. The maximum burning time on one tab is 6 hours. The possibility of connecting a chimney behind or on top of the stove is conveniently implemented. However, you should not count on efficient use of the stove, because it heats up very slowly.

Watch a video review of the corner modification of Ecofireplace Bavaria with stove:

Fuel for metal structures

The following is used as fuel for metal furnaces:

- electricity (in the furnaces an element responsible for heating and a generator are installed);

- natural gas (heating level is controlled by a thermostat system and burner);

- wood (wood stoves are easy to maintain and repair, and wood stoves quickly heat rooms);

- diesel fuel (advantage – safety).

Selection of oven

When choosing a stove, you should pay attention to the following points:

- find out the speed at which heating occurs;

- find out the minimum and maximum heating limits of the entire structure;

- estimate the size of the stove and the furnace separately;

- find out what metal the furnace is made of and the components of the alloy;

- check how comfortable and safe the equipment is to use.

Important! It’s up to you to decide which stove to put in a wooden house: if the priority is maximum heat, then a brick one; if the complexity of the work scares you, then a metal one.

What else is important?

The main fuel for fireplace stoves is wood.

Logs can be of different sizes, and this must be taken into account. The larger their size, the easier and faster it is to prepare firewood and put it in the firebox. The manufacturer usually indicates the maximum allowable log length, and it is better if in your stove this value is not less than 300 mm. If you go to the store, be sure to take a tape measure with you. With it, you can not only estimate the size of the loaded firewood, but also estimate the volume of the firebox, which manufacturers often do not indicate in the specifications. Summary table with furnace models

| Model, country of manufacture | Heated volume, m³ | Features of the line | Price range, rub. |

| 1. Termofor/TMF Fire-battery (Russia) | 100, 150 and 200 |

| 13000-21000 |

| 2. Zhara (Russia) | 100 and 200 |

| 12000-17000 |

| 3. META Ardenfire Marseille (France/Russia) | 150, 200 and 250 |

| 41000-64000 |

| 4. Eco-fireplace Bavaria (Russia) | 90-195 and 105-225 |

| 18000-27000 |

| 5. Thorma Andorra (Slovakia) | 98-200 |

| 69000-77000 |

| 6. Kratki Koza K (Poland) | 135, 190 and 250 |

| 32000-61000 |

| 7. Supra Tomera (France) | 150-320 and 300 |

| 77000 |

| 8. La Nordica Ghisa (Italy) | 172, 200 and 258 |

| 84000-127000 |

Safety

Equipment used for heating a wooden structure must be safe to use.

To comply with fire safety standards, fireplace stoves are equipped with heat-resistant glass; open stoves are unacceptable.

Do not ignore safety rules when installing heating structures.

Installation nuances

How to place a stove in a wooden house?

It is necessary to determine the location of the furnace when designing the structure. This is explained by the fact that in a wooden house you will have to construct and install a chimney with a pipe for removing combustion products. Advice. Choose a place next to the internal main walls.

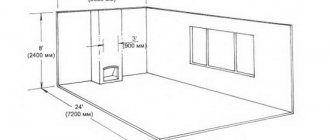

You can also place it next to the main wall in the corner to leave maximum free space. Having decided on the type of stove to install in a wooden house, study the installation rules:

- decide on the location of the heating equipment;

- make fire-resistant insulation in the area where the chimney comes into contact with the wall;

- design the foundation. The best options are a concrete base or a sheet of steel. Take care of the thermal insulation layer;

- treat wooden surfaces with fire retardants;

- choose heat-resistant materials.

Installation

Construction of a brick kiln

Installing a brick heating structure is not an easy task. First of all, you should decide on the location of the stove. The most suitable room for a brick stove is the kitchen: you will have the opportunity to cook food without running to another room.

It is recommended to lay a foundation for a brick stove when designing a structure or during the process of pouring the foundation. An average brick oven weighs about 300 kg, so be sure to design a monolithic concrete support so that the structure does not push through the wooden floor .

If the house has already been built, dismantle the floors in the place where the stove will be installed, dig a recess of about 25 cm, arrange a cushion of sand and gravel and fill the reinforced base.

The video below shows the features of preparing the base for installing a stove in a wooden house:

A reliable foundation is a guarantee of confidence in the safe operation of heating equipment and its durability.

Important! The foundation area should be 10-15 cm wider than the lower part of the structure.

Insulate the wall. The foundation for the stove is laid in accordance with the dimensions of the structure.

How to properly install a chimney in a wooden house? Design it as far as possible from the matrices located between the floors. In most cases, the smoke exhaust system is designed next to the outer wall. A chimney located next to the outer wall will protect the home from drafts.

After finishing the masonry, plaster the stove or tile it.

Which material is better? Choose one that is resistant to fire and do not forget that it will become very hot when heated. Advice. It is worth finishing the stove with fire-resistant plaster or fire-resistant tiles: these materials do not interfere with the transfer of heat.

Installing a brick structure to heat a wooden house is a labor-intensive task. Installing a metal stove will take less time.

The video below discusses in detail the process of laying a budget version of a brick kiln:

Installation of a metal heating structure

Beginners in installation are recommended to give preference to metal heating structures . It is possible to assemble a metal stove in a few hours. Fully equipped models with smoke removal systems are available for sale. You can also make a metal structure for heating a country house with your own hands: it’s not that difficult.

Which stove is easier to install? Metal is easier to do than brick, but it also has its own subtleties: take them into account before you begin installation work.

How to install a stove in a wooden house? The first rule of installation is: the stove should not stand close to the wall .

The optimal distance from the heating structure to the wooden wall is 25 cm. It is recommended that the wall be tiled, especially for surfaces located in the immediate vicinity of the stove. Advice. Place the stove near the wall on the opposite side of the door - this will ensure sufficient air flow from the street to maintain the fire.

Metal structures are placed on a base made of a sheet of steel or a small elevation is used. Having completed the design of the podium on the floor, the racks are fastened under the floor as additional protection from the load. This is an important point when installing cast iron structures.

Manufacturers offer hanging models of metal stoves that do not require supports and will protect your floors.

The stove needs a chimney. It is possible to route the pipe to the street in any way - either through the ceiling or through the wall.

The diameter of the smoke exhaust pipe must correspond to the size of the pipe: this will provide powerful draft. Insulate the chimney to avoid heat loss .

Recommendation: Before installing a new metal stove, perform the first firing in the open air, this will allow the paint covering the internal and external parts to set, and the characteristic odor will also go away.

For large country houses, it is recommended to install several metal stoves to ensure a comfortable temperature in the home.

How wood stoves work

One of the features of heating devices is a secondary combustion chamber, which is characterized by slow combustion of fuel. Simply put, the logs in the firebox do not burn, but smolder. This effect is achieved by adjusting the amount of air entering the fuel chamber.

The combustion chamber is divided into two compartments. When wood is smoldering, unburnt combustible gas enters the second compartment of the chamber, where additional air is supplied from the injection pipes, after which the gas burns out completely, and the wood remains to smolder further.

Unburned gas from the main combustion chamber enters the additional combustion chamber, where, after mixing with an additional portion of air, it ignites, releasing additional thermal energy

Among the advantages of the system, it is worth noting: an increase in the operating life of the devices, greater efficiency - the stove operates for 8-9 hours on one load of firewood.

There are a few more disadvantages: the system only works on dry wood, the combustion mode will have to be constantly adjusted, which is somewhat inconvenient. It is also necessary to constantly monitor the cleanliness of the chimney and periodically clean it.

Chimney

The first most important part of the heating structure is the firebox, and the second is the chimney. How to properly install a chimney in a wooden house? The system responsible for removing smoke must be designed very carefully. The operation of the stove is affected by the correct insulation of the chimney .

A mandatory requirement for chimneys in wooden houses is lining. Due to this, the level of surface cracking is reduced and the likelihood of a fire is reduced.

In most cases, chimneys are designed from galvanized steel pipes. Chimneys made from this material should be insulated with fire-resistant materials. Special attention should be paid to those areas where the pipe comes into contact with the roof and other wooden surfaces.

Do you dream of a fireplace in your country house or apartment? Find out how to make a fireplace with your own hands: details about the types, components, materials and cost of the fireplace when installing it yourself. Read about how to choose a storage water heater; here the types and criteria for choosing equipment are described.

Photos of beautiful container houses can be seen in the article at: https://kvartira-rf.com/residential-real-estate/house/dom-iz-kontejnerov.html

The optimal solution for wooden houses is sandwich chimneys . The surfaces of sandwich chimneys are well insulated, which prevents them from overheating. There is only one drawback - a relatively short service life, ranging from 10 to 15 years. After this time, the insulation may peel off, and the chimney will have to be repaired.

Chimneys made of ceramic materials are leaders in quality . There is almost no condensation on them, the integrity of the structure creates a powerful draft, and a constant one. The service life of ceramic chimneys is several decades. There is only one drawback - significant weight.

Combustion chamber design and volume

The most common option for a combustion chamber is a cube, which is equipped with an outlet channel through which carbon monoxide is removed.

At the same time, the process of burning wood occurs quite quickly. For this reason, it is best to consider the option of long-burning stoves for heating your home. When using a stove, the combustion process occurs in the form of smoldering, which is accompanied by the formation of wood gas. Entering the cutter, it then reaches the area of action of the air nozzle. The interaction of oxygen with gas leads to combustion of the latter.

Stoves for heating a house of this design have the following advantages:

- High efficiency rate, which reaches 85%. In this regard, conventional models cannot compare with them.

- Less fuel. When the furnace is fully loaded with fuel, the smoldering process may take several hours.

- Ease of use. Compared to traditional stoves, when using such models, you have to load new portions of firewood much less often.

An important parameter is the volume of the combustion chamber, which determines the amount of firewood needed to maintain the temperature, as well as its length. Most often they do not exceed 40 cm in length . However, the value of this parameter may differ for different models, so before purchasing it would not hurt to clarify this issue with the seller.

Stoves for various interiors

In wooden houses, Russian stoves, cast iron structures and fireplace stoves are installed.

Russian stoves have a special flavor.

Fireplace stoves are an ideal design solution for country houses and country houses , especially with chalet-style interiors. This type of stove serves both a practical (heating) and decorative purpose (decorates the interior).

With the help of cast iron construction it is easy to create an atmosphere of comfort. Among the variety of models, you are guaranteed to choose a stove for any interior.

Having acquired basic knowledge, you can begin installing a stove in a wooden house and connecting heating equipment. A responsible approach to business will allow you to cope with the task yourself.

Koza K (Kratki, Poland)

The products of the Polish manufacturer Kratki have been known in Europe since 1998.

A couple of years later they began to actively promote it in the CIS. Today the equipment of this TM is available in 56 countries of the world. The range includes fireplaces, free-standing stoves, bio-fireplaces and accessories for all of the above. One of the popular lines is Koza K, cast iron equipment in the Victorian style. The manufacturer offers several varieties of each model: with decorated doors, made of steel or cast iron, with or without a turbine, water circuit, thermostat. The inside of the firebox is completely lined with fire-resistant ceramics. There is a “clean glass” system against soot and a pipe for supplying air from outside - a convenient feature if it is important not to dry out the air in a heated room. Main characteristics of Koza K stoves from Kratki

| Characteristic | Koza K6 | Koza K7 | Koza K9 |

| power, kWt | 9 | 5 | 13 |

| Volume of heated room, m³ | 190 | 135 | 250 |

| Maximum log length, mm | 350 | ||

| Chimney diameter, mm | 130 or 150 | ||

| Size, mm | 578x630x490 | 536x557x413 | 766x660x546 |

| Weight, kg | 115 | 75 | 160 |

| price, rub. | 56 400 | 32 000 | 61 000 |

Impressions from use. An important advantage of the line is its appearance. Large firebox for 9-10 logs, large glass that keeps it clean. The products are made of cast iron, so you need to be ready to return to operating mode within an hour. This is compensated by the inertia of the system; on one tab it is possible to maintain a comfortable temperature in the room for 5-6 hours. If the case itself is massive and there is no doubt about its strength, then the quality of the fittings is average. The latches are made of thin steel; over time, the door handle ceases to sit securely in its place. There is a possibility that after a couple of years the fittings will have to be changed, but it all depends on the nature of use.

View a review of the k9 model, the oldest of the ones presented above: