Characteristics of apartment insulation under wallpaper

To begin with, we suggest that you familiarize yourself with the features of heat-insulating plaster in relation to its composition:

- material based on sawdust - this filler is cheap, so this plaster is the most economical, plaster has low resistance to moisture, so it is only relevant in rooms with low humidity levels, this option is not suitable for insulating walls in the bathroom, veranda or on the balcony;

- materials based on polystyrene foam are an excellent option, which is characterized by high thermal insulation and sound insulation characteristics, however, the insulation is unstable before ignition and has low fire safety, so its installation is not relevant in places where the heating temperature of the walls is too high; in addition, during the combustion of polystyrene foam, emissions are released substances that are highly toxic;

- materials in the form of perlite or vermiculite are another type of mineral-based insulation; among the positive qualities of such a material, we note its high fire safety, resistance to chemical and biological substances, and environmental safety; however, the material tends to quickly absorb moisture, therefore, it needs additional vapor barrier ;

- Another option for insulation is a material in the form of foam glass; among the advantages of the material, we note its moisture resistance, environmental safety, and good thermal insulation properties.

Please note that the use of plaster solutions for thermal insulation of a room requires their further finishing using putty. Because after plastering, roughness remains on the walls.

Plaster compositions are sold packaged in bags, weighing from 10 kg. Each of the compositions has an individual consumption rate.

Recommendations for selection and installation

When choosing polymer insulation, you should know that according to the manufacturing method they are divided into:

- Non-crosslinked gas foam.

- Cross-linked: chemically and physically.

The simplest is uncrosslinked polyethylene. Its manufacturing technology is the simplest. The strength and thermal insulation properties of this material are 1/4 less and worse than the others.

Both chemically and physically cross-linked polyethylene are similar in their properties, therefore, when buying insulation, you need to focus on:

- Color of the material (uniform, white or light gray).

- How tightly the paper is attached to the base.

- Presence of odor (normally there should be no odor).

- Elasticity (the surface quickly recovers after finger pressure).

- Structure.

- Edge decoration.

- Durability and certificate availability.

When choosing a substrate, it is worth considering that the main differences between them are thickness and density. Cork material is more dense, so it does not require thorough leveling of the walls before installation. Polyfom allows you not to thoroughly putty the walls. And non-woven fabric, which is a very durable material, will protect the wallpaper from tearing and the walls from cracking.

Some tips for laying the material:

- The joints must be treated with wide masking tape to stabilize the canvas and prevent the formation of hills on the seams.

- The seam of the wallpaper must not coincide with the seam of the insulation.

- If there is a suspicion of the presence of a fungus, the necessary antiseptic measures are urgently taken.

These tips will help maintain the integrity of the wallpaper and prevent the seams from coming apart. It is better to use a primer that contains antiseptic substances. This is necessary to prevent the proliferation of various microorganisms. The finished surface must be dry and smooth.

Insulation for walls under wallpaper - possible options

To insulate internal surfaces intended for wallpapering, various materials with enhanced thermal insulation properties are used. Special substrates not only maintain a comfortable room temperature, but also perform a number of additional functions:

- hide defects and minor irregularities in processed, insulated surfaces;

- reliably soundproof the living space, making it difficult for extraneous noise to penetrate;

- prevent moisture condensation, which causes dampness and promotes the formation of mold.

Heat-protective materials, which are the basis of the finishing, can be conditionally classified as follows:

- roll thermal insulation;

- special substrate “Polifom”;

- cork lining.

When deciding on the use of a specific heat insulator, the following factors must be taken into account:

- the costs of its acquisition;

- thermal protection characteristics;

- Possibility of self-sticking.

Let's consider the performance characteristics and properties of the most common types of heat insulators used for finishing.

Roll insulation for wallpaper

Thermal insulation materials offered in rolls are a protective coating with a backing made of thin polystyrene foam, which is easily glued. The following is used as the supporting base of polystyrene foam thermal protection:

- thin foil. The foil base effectively maintains the temperature in the room by reflecting heat;

- paper. It has increased adhesion and can be located on both sides of the polystyrene foam layer;

- cardboard. The material is securely glued to the surface using standard adhesives.

The gluing of polystyrene foam insulation is carried out using the following compounds:

- glue designed for fixing heavy wallpaper;

- plaster mixture based on fine-grained gypsum;

- special types of construction adhesive mixtures.

Special glue for heavy wallpaper

Wallpaper is glued to a polystyrene foam base using a special polymer-based cement adhesive.

The features of this type of substrate are:

- thermal insulation efficiency;

- reliability of fastening;

- resistance to high humidity;

- excellent noise protection;

- vibration absorption;

- preventing mold formation.

Rolled thermal insulation is easy to use and can be easily glued to the base on your own.

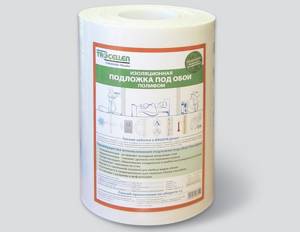

Thermal insulation for wallpaper brand "Polifom"

Thermal insulation based on polyethylene foam, known as “Polifom”, is close in structure to heavy types of wallpaper. Consists of the following layers:

- a heat-insulating substrate made of polyethylene foam having a porous structure saturated with air bubbles;

- paper protection located on both sides of the heat insulator and facilitating gluing of the insulation.

With a high-quality sticker, polyethylene foam (“Polifom”), which has a thickness of 5 mm, reliably hides irregularities and small protrusions on the surface.

Wallpaper backing

Advantages of "Polyphom":

- high coefficient of adhesion to various types of bases;

- ease of self-gluing to walls;

- no need to use special adhesives;

- thermal conductivity coefficient of no more than 0.04 W/mK;

- The dimensions of the material in a roll that are convenient for performing work are 0.5x14 meters.

“Polifom” is glued to a previously prepared surface. Three days later, after the glue has completely dried, you can begin wallpapering.

Cork insulation for wallpaper

If it is not possible to ensure the flatness of the walls, it is advisable to give preference to a substrate made of balsa wood. It has a set of advantages:

- impeccable environmental friendliness;

- excellent thermal insulation;

- increased sound absorption;

- attractive appearance.

The original texture of the insulation allows it to be used as a decorative cladding when finishing premises.

Disadvantages of cork substrate:

- susceptibility to moisture, which is easily eliminated by impregnation with moisture-repellent mixtures, including wax-based ones;

- the need to use special adhesive mixtures. To facilitate fixation, the side of the material in contact with the wall is impregnated with a special compound;

- the presence of deep imprints on the front surface due to mechanical impact or careless gluing of the cork base.

Polypom insulation

The minimum area of a roll with a cork base allows you to thermally insulate 5 square meters of wall.

Functions

The substrate consists of several layers. In the middle, as a rule, there is foamed polyethylene, enclosed between layers of paper.

Many multi-apartment “anthills”, both old and new, do not have good sound insulation. Residents hear other people's conversations, and not only in raised voices, but also music and harsh sounds from their neighbors. All this is unnerving and does not allow you to live in peace. Sound insulation is ensured by using a wallpaper backing. This material also allows you to overcome the problem of indoor humidity.

It is an excellent lining for any wallpaper. Using it, the outer decorative layer is easier to glue and it will look better on the walls.

As a result, the finish will last longer and the problem of new repairs, as well as the material costs associated with it, will be postponed. Once upon a time, old newspapers were used as a backing. It was easier to glue wallpaper on them. Technology has come very far since then. Taking into account all the possibilities of modern substrates, their use cannot be considered a whim.

What materials cannot be used

Relatively recently, a popular method of thermal insulation was covering walls with foam plastic (expanded polystyrene).

Due to its low cost, the material is often used to this day for facades, ceilings and other surfaces. However, it has huge disadvantages and is not suitable for wallpaper upholstery:

- Wallpaper glued to polystyrene foam is easily subjected to mechanical stress and comes off. This occurs due to the fact that the material does not have the required rigidity;

- To achieve the desired level of insulation, you will need a layer of foam plastic at least five centimeters thick. Such a design will not stand out aesthetically;

- during the subsequent renovation of the room, you will have to remove not only the wallpaper, but also the insulation itself. It will not be possible to remove the finishing material without damage;

- One of the important reasons why foam cannot be used is flammability. According to the rules, during installation it must be insulated with another non-flammable layer.

Advantages

Repair non-woven fabric is an excellent leveling base for wallpaper. At the same time, it can not only be covered with wallpaper, but also painted. The number of repaints can be up to seven times.

Due to the ability to mask minor surface defects, the stage of preliminary thorough preparation of the base can be skipped, which will speed up the repair process.

Non-woven backing can be a good contribution to an existing system of thermal and sound insulation of a room. Good density and integrity of the material ensure heat retention and noise reduction.

However, for the purpose of greater noise and heat insulation, it is better to give preference to substrates made of foamed polyethylene or cork samples.

The material is quite resistant to moisture. Along with this, it is vapor permeable, which, with periodic humidity, will help to avoid the formation of mold due to natural air exchange that occurs unhindered.

Painting non-woven fabric is extremely durable. It does not stretch when gluing and during use. Thanks to its strength, it occupies a leading position and displaces cheaper fiberglass mesh.

We recommend: Perforated underlay for heated floors

It is glued similarly to wallpaper, using glue for non-woven fabrics. Do not forget that it is necessary to coat the surface with glue, and not the non-woven material under the wallpaper. Before you begin finishing with wallpaper, it is advisable to wait several days until the lining is completely dry.

Environmental friendliness is the next advantage. Natural raw materials and unique production technologies guarantee the safety of the substrate.

It is impossible not to note the durability - construction non-woven fabric can be used for at least 25 years. This speaks not only of strength, but also of stability, as well as the resistance of the material to both temperature and mechanical influences.

How to choose insulation: tips

In order for the thermal insulation material to meet the stated requirements, it is necessary to choose the right type, taking into account the condition of the walls and the type of wallpaper. Recommendations:

- Roll-type insulation has additional functions: it levels the surface, has sound-proofing and vapor barrier properties, and wallpaper can be glued to it several times;

- when purchasing, read reviews about the manufacturer and the technical qualities of the product;

- consult with the seller before choosing, check the characteristics of the material;

- Cork insulation costs on average from 900 to 6 thousand rubles, while roll insulation costs around 900-1000 rubles per piece. Prices vary depending on the company.

Varieties of heat-insulating materials based on natural cork

Natural cork raw materials can act as a heat insulator. But at an extremely high cost, it is more advisable to use special materials based on it, which include expansite (black agglomerate) and impregnated plates (white agglomerate). Cork bark is best used as a decorative finish for floors and walls. Its thin layer will not provide complete thermal insulation, but its original appearance can decorate any interior.

Both of these materials are produced on the basis of cork raw materials crushed into granules. The technology for producing black agglomerate involves heating to 300°C, which triggers the process of sublimation of suberin and, as a result, produces a homogeneous mass. By increasing the volume of internal cavities, the initial volume can increase up to 30%, which has a positive effect on the thermal conductivity and cost of the material.

The international format for this material is 1000 by 500 mm slabs. But depending on the brand, its thickness can vary from 10 to 300 mm. Thin sheets up to 50 mm are rolled into rolls, while thicker ones are supplied in the form of ready-to-use slabs. Due to swelling, the density of the expansite decreases to 120 ± 10 kg/m3, but the thermal conductivity remains at the same level - 0.04 W/m*K. This type of thermal insulation can be used at temperatures ranging from −200 to +150 °C, which allows it to be used even for insulating unheated floors and walls.

The technology for producing white agglomerate is much simpler: cork granules are pressed with the addition of natural adhesives. The standard format is slabs 900 by 600 and 1000 by 500 mm. If the sheet thickness does not exceed 50 mm, impregnated plates are also rolled into rolls. Density ranges from 110 to 260 kg/m3, average thermal conductivity is 0.05 W/m*K.

Cost of insulation

The price range of these products may vary depending on the chosen manufacturer, as well as the material itself. Below is the average cost per item:

- Roll insulation for wallpaper, price varies from 800 to 1000 rubles. total area 5 sq.m.

- Cork insulation. Depending on the thickness, the cost of the product varies from 800 to 6000 rubles.

- Polyph. 1100 rub., per package. Total area 7 sq.m.

The most widespread among all the presented materials was the polyphome. It is easier to glue it to the wall, and if you follow all the manufacturer’s recommendations, it perfectly insulates the walls of the room.

Specifications

The characteristics of insulation depend not only on the properties of the material, but also on the form of its manufacture. Therefore, if we talk about this material as a whole, we can outline its average characteristics:

- the density of the material is 110-130 kg/cm3;

- specific gravity 200 kg/m3;

- thermal conductivity 0.04 ± 0.1 W/m*K;

- vapor permeability 0.2 mg/m*hour*Pa

- fire resistance class M3.

It is important to know that manufacturers of cork insulation claim that it is not subject to aging . Therefore, it will serve as long as the building itself lasts.

Selection of adhesive composition

Different types of insulation require different adhesives. Expanded polystyrene insulation and polyfoam can be fixed to the wall using adhesives designed for heavy wallpaper.

The most durable adhesives are those based on carboxymethylcellulose (CMC) and methylcellulose with the addition of PVA. Among domestic brands, KMC Super Extra and Moment Classic stand out. Foreign wallpaper adhesives are widely represented on the Russian market.

Special mention goes to Kleo, Semin (France), Pufas and Metylan (Germany).

Cork insulation cannot be glued with regular wallpaper glue. Special adhesives are used for it. Adhesives received positive reviews: Pufas K12, Lacrusil, Multifix, Wakol.

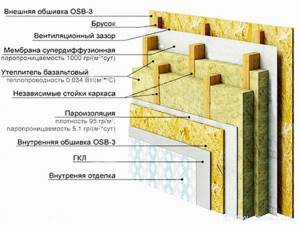

Mineral wool, its properties and features

One of the most common materials for internal insulation of building walls is mineral wool. It is an inorganic insulation with a fibrous structure, which is made from rocks, glass and slag.

This material is produced in the form of plates and rolls . For wall insulation purposes, it is preferable to use the first option.

The main advantages of high-quality mineral wool are:

- environmental friendliness;

- high thermal insulation performance;

- good air exchange;

- fire resistance and water resistance;

- long service life.

NOTE!

For internal wall insulation, purchase mineral wool from reliable manufacturers . Keep in mind that dubious and cheap options have more disadvantages than advantages - they are characterized by an increased level of dust, when wet they lose their thermal insulation qualities, and when heated they can emit vapors of dangerous pheno-formaldehyde resins.

Working with mineral wool indoors is carried out in several stages:

- Installation of a durable metal frame.

- Laying mineral slabs (panels) between the frame posts.

- Installation of plasterboard sheets to mask the insulation.

Mineral wool

Effect after insulation

People planning to renovate their apartment doubt that insulation under wallpaper really “works.” First of all, the question is about its thermal insulation abilities. To prove the performance of roll materials, the following examples can be given:

- Polyfom has a thermal conductivity coefficient of 0.03 W/mK, which can be equated to brickwork more than 10 cm thick or a wooden covering 5 cm thick.

- Foil insulation 5-6 mm thick provides thermal insulation similar to a half-brick brick wall.

- Numerous experiments show that cork insulation 8-10 mm thick raises the temperature inside an unheated room by 3-4 degrees.

These examples perfectly show that the insulation under the wallpaper copes with its task. In addition, it must be taken into account that the cork creates a thermos effect. It helps keep the house cool in hot weather. To obtain complete comfort in the house, you should ensure a combination of wallpaper insulation with external wall insulation.

The need to insulate the internal surface

If the design of a country house allows thermal insulation work to be carried out outside and inside, it is better to implement both methods. Alas, some circumstances force residents of private buildings to neglect external insulation. These include:

- location immediately behind the wall of another building or other object, the distance to which does not allow placing a layer of heat insulation;

- passage of energy cables and similar equipment along or inside walls that cannot be removed;

- the presence of an expansion joint between buildings behind the wall;

- authorities ban on modifying the façade (for example, a cultural heritage site);

- acute reluctance of residents to change the appearance of the building.

If at least one of the above conditions occurs, you can limit yourself to insulating the walls inside.

Does it save you from mold?

The answer to this question can be confidently given in the affirmative. Resistance to mold and fungal attack is inherent in the very nature of these materials. Cork tends to absorb moisture, but even this circumstance does not lead to these negative phenomena. Polymer insulation is good waterproofing; they do not accumulate moisture, which prevents the formation of a favorable environment for mold.

Roll insulation is rightly considered a practical and effective substrate for wallpaper. They smooth out small surface defects, provide hydro-, steam-, and thermal insulation of the room, and protect walls from mold and fungi. The costs are offset by comfort in the home and an increase in the service life of the finishing coating. If the insulation is installed correctly, it will perform its functions for a long time and reliably.

Tips and tricks from the experts

If the room borders on another building, the only solution for insulation is internal thermal insulation. This will slightly reduce the internal area, but will make the interior more comfortable. In order to avoid mistakes at different stages, it is necessary to calculate in advance the optimal amount of materials, draw up an action plan and strictly adhere to it.

A vapor barrier with one-way conductivity must be secured between the finishing layer and the insulator. When designing internal insulation, it is necessary to take into account the process of dew point transfer through fences. Therefore, the vapor permeability of the insulator should decrease from building to street.

How to glue insulation to walls with your own hands

When thinking about how to insulate a wall inside an apartment under wallpaper, you need to know that the technological sequence of operations for thermal insulation of walls under the finishing coating is similar to the process of gluing wallpaper and includes the following steps:

- Processing the base for gluing thermal protection.

- Preparing insulation and glue for further work.

- Sticker of heat-protective material for future finishing.

Let us dwell in detail on the specifics of each stage of work. At the preparatory stage, perform the following activities:

- Clean the surface of any existing wallpaper.

- Remove loose pieces of plaster and remaining trim.

- Remove protruding nails, protruding reinforcement and fasteners.

- Use a chisel to knock out concrete and cement sagging.

- Clean the surface from dust and dirt.

- Seal the cracks and cavities with cement mortar.

- Coat the prepared surface with a deep penetrating primer.

- Reapply primer to improve adhesion.

PVA glue

Experts sometimes use PVA glue for priming and antiseptic treatment, which, like primer, is applied with a paint brush or wide roller. After the soil has completely dried, further measures can be carried out. The drying time is regulated by the manufacturer of the primer composition and is indicated on its packaging.

Follow the following algorithm to prepare the substrate and adhesive mixture:

- Calculate the required number and sizes of substrate fragments.

- Use a tape measure to measure the dimensions of the future thermal protection sheets.

- Cut the insulation into pieces of the required sizes.

- Carefully study the manufacturer's instructions for preparing the adhesive composition.

- Dilute with water and vigorously mix the glue ingredients.

Please note that the amount of roll substrate required to complete the work must be calculated as follows:

- Determine the total area of the walls to be thermally insulated.

- Divide the resulting value by the area of one roll of backing.

- Multiply the estimated number of rolls by a safety factor of 1.05–1.1.

- Round up the resulting value.

The final stage of work is the installation of insulation, which must be carried out under the following conditions:

- ambient temperature and the surface being treated is more than plus 10 °C;

- maximum moisture concentration in the room up to 70%;

- complete absence of drafts.

Wallpapering

Further procedure:

- Mark the vertical and mark the base.

- Apply the adhesive evenly to the wall surface.

- Lubricate the back of the insulating sheet with glue.

- Let the material soak for 5 minutes.

- Attach the insulation to the base, following the markings.

- Remove air bubbles by smoothing the surface of the glued sheets.

To smooth out and remove air bubbles you can use:

- wide spatula;

- regular roller.

When performing work, pay attention to the following nuances:

- uniform lubrication of the surface with glue;

- no gaps when installing panels;

- sticker of the backing from the ceiling to the floor;

- rolling with a roller from the center to the outer parts;

- the need to glue the joint areas using masking tape.

Ventilation of the room can be carried out no earlier than 24–72 hours after completion of thermal insulation measures, depending on the properties of the heat-insulating material.

Features of cladding the internal surface of the house

The impossibility of external thermal insulation of walls is in itself a disadvantage of the structure. To it you can add the following disadvantages of the lining inside:

- reducing the usable area of the room (in the case of insulation of the floor and ceiling, also the volume);

- although the temperature becomes higher, heat does not accumulate in the walls - they remain cold;

- the previous fact contributes to the formation of condensation, causing dampness, mold, corrosion, and the appearance of microorganisms.

Fortunately, there are also advantages, and the main one is the normalization of the indoor microclimate.

Distinctive features of the internal thermal insulation of the walls of a private house, regardless of the material of the latter, are:

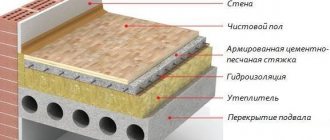

- The presence of two additional layers - hydro- and vapor barrier. The first reduces the likelihood of moisture getting on the insulation from the outside, the second - from the inside (from the side of the rooms).

- Rapid change in room temperature when opening vents, windows, doors.

- When using some insulation materials, “cold bridges” may appear - sections of the walls where condensation with cold air is concentrated.

- If possible, it is worth using environmentally friendly material for interior cladding.

- You can save money on wall insulation, which cannot be said about exterior work.

- Carrying out work inside the house in comfortable conditions all year round - the process will not be affected by natural factors.

- The presence of assistants is not necessary - all stages can be easily completed independently.

Important requirements are imposed on the structure at the preparatory stage of interior cladding. The key one is maximum dryness of the walls.

Installation of cork underlayment: what do you need to know?

Insulation based on cork material is attached to the walls, following the diagram:

Clean the surface of old finishes, remove dust, dirt, putty cracks, chips and uneven surfaces.

- Prime the cleaned surface.

- Cut strips of insulation in accordance with the parameters of the walls.

- Prepare glue according to instructions.

- Use a roller or brush to lubricate the insulation strips and the surface of the walls.

- Glue the backing end-to-end, sealing the seams with glue.

- Trim off excess backing with scissors.

The glued substrate is left to dry for several days, after which wallpaper is glued on top using the same technology.

Another alternative option for insulation on walls under wallpaper is an expanded polystyrene backing with characteristics similar to expanded polystyrene material. Sold in rolls, glued using the same principle using wallpaper glue with the addition of gypsum-based plaster. To simplify the process and improve the result, insulation is combined with fiberglass mesh.

Substrate and insulation

Interestingly, a material that can be used as a heat insulator is suitable not only for its main function.

Let's determine its directions of use:

- Insulation of walls in the apartment. Moreover, we are talking about the fact that the walls are insulated from the inside under the wallpaper.

- Incredibly high sound insulation rates; the material can be used specifically as a sound insulator.

- It prevents moisture from appearing on the wall, which prevents the spread of fungus.

- Helps level walls or even ceilings if plastering work could not do this adequately.

In addition, the backing is quickly and easily glued and its installation does not require any special or professional knowledge; even if you have never glued anything to the surface, the work will not confuse you.

Separately, it must be said that the price of thermal insulation will always be acceptable, and this is also a kind of plus for this type of finishing.

The material is simple, inexpensive and easy to work with.

Advantages

Modern roll insulation for walls under wallpaper has a number of undeniable advantages.

Let's denote the main ones:

- Easy to apply to a solid surface with heavy wallpaper adhesive. At the same time, it has high resistance to condensation formation.

- It retains heat perfectly in rooms adjacent to unheated spaces, for example, a staircase.

- As already mentioned, it shows excellent sound insulation, but also noise absorption. That is, you will not be heard or noises behind the walls.

Let's take, for example, the modern roll substrate "Polifom".

It comes in the following options:

- The length of the material per roll is 14 meters.

- Width – 0.5 meters.

- Thickness 5 mm.

The material is made only from environmentally friendly components, which exclude the presence of freon or butane. In addition, the material does not have any foreign odor, so it is ideal for interior finishing work.

Environmentally friendly and convenient "Polifom"

Working moments

In addition to the technical characteristics and capabilities, wall insulation for wallpaper has its own operating points, about which it is also necessary to say a few words:

- To paste the material, there is no need to hire workers; everything can be done easily and quickly yourself. The same rule works here as when wallpapering - everything is joint to joint.

- If, with a simple pasting of walls, it is necessary to plaster, seal cracks and unevenness, then with a rolled heat insulator you can safely skip these steps, the material easily hides all surface defects and acts as a primer, topcoat and plaster at the same time.

- Plus, the underlayment is always extremely useful in the fight against dark spots on the walls that show through the finish, and is simple mold, which is impossible to deal with once it appears.

Installation of the substrate is very simple and quick

Preparation

Installing insulation does not seem difficult and you can carry out the entire process easily with your own hands.

Let's go through the main steps that precede the final gluing:

- The old decoration is removed from the walls. Old wallpaper, paints and varnishes. If the plaster is not durable, then the finishing layer is also removed.

- Obvious defects on the surface are filled with dry mixture or cement mortar. As mentioned above, insulating walls under wallpaper hides many flaws, but if the cracks are deep enough, they still need to be repaired.

As for the adhesive composition, you need to choose an adhesive that is suitable for sticking heavy wallpaper.

An example of a ready-made glue that is ideal for gluing a heat insulator

Is it possible to glue wallpaper over foam plastic?

The most popular insulation material was and remains polystyrene foam - ordinary polystyrene foam. Due to its minimal cost and good thermal insulation characteristics, this material is used everywhere - for insulating walls, facades, ceilings, floors, etc.

Of course, the rationality of using this insulation is difficult to dispute, but it is worth understanding that polystyrene foam is not the best choice for direct wallpapering.

Firstly, the surface of the foam does not have sufficient rigidity, as a result of which, even with minimal external influence (someone leaned against the wall, or the wall was caught by some object), the wallpaper will break through.

Secondly, since polystyrene foam, like Izover Optimal insulation, is a slab material, and for effective insulation from the inside of the walls you will need at least a 5-centimeter layer of insulation, the joints of the foam plastic after pasting will be very noticeable under the wallpaper.

Thirdly, when the time comes to redecorate the room, and you need to change the wallpaper, you will have to change the insulation along with it, since you will not be able to tear the wallpaper off the surface of the foam without damaging the latter.

Related article: Why walls in a private house become damp

And the last factor that prevents you from gluing wallpaper onto polystyrene foam is the issue of fire safety, since according to SNiPs, polystyrene foam must be insulated with a layer of non-flammable material.

If you want to insulate the walls from the inside of the house with polystyrene foam, then for subsequent wallpapering you can either cover the thermal insulation with plasterboard, or cover the insulation with a reinforcing plaster composition using fiberglass plaster mesh. But for such a thing, sometimes it’s easier to buy polyurethane-based insulation in Kirov.

Plastering foam plastic using reinforcing mesh

Preferred materials for internal insulation

The range of insulation materials presented in construction stores is large. The following are high-quality materials that are better suited than others for interior cladding of houses.

Expanded polystyrene

The material is relatively cheap and has good thermal insulation characteristics. Suitable for all types of houses, except brick. The thermal conductivity coefficient is not the highest - there are analogues with better performance. Other advantages of using polystyrene foam are:

- durability (30-50 years depending on the region where the house is located);

- lightness of the material (supplied in slabs that weigh a couple of hundred grams);

- ease of installation.

- prone to fire;

- the material can be broken or crumbled if handled incorrectly;

- poor vapor permeability;

- attractive to rodents;

- Synthetic materials are used in production.

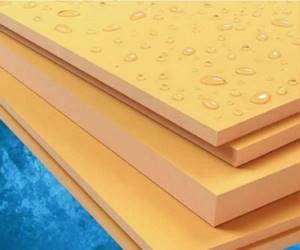

Penoplex

A good alternative to the above-mentioned insulation, which is extruded polystyrene foam. It is denser than polystyrene foam and can be used to insulate any surface of the house, but is expensive. It is better for them to sheathe small areas from the inside of buildings - attic floors, caissons, basements.

- low thermal conductivity coefficient;

- minimal tendency to fire;

- does not absorb water well;

- high strength.

- high cost;

- poor vapor permeability.

Mineral wool

A modern material that is gaining popularity within the Russian market. Supplied in slabs or rolls of various densities and thicknesses (from 2 to 10 cm). In terms of environmental friendliness, it is better than the two previously described insulation materials, suitable for any home, and has a low thermal conductivity coefficient (approximately equal to polystyrene foam).

- low flammability;

- resistance to rodents and insects;

- excellent vapor and air permeability;

- additionally acts as a good sound insulator.

- absorbs moisture (if more than 2% of the surface of the slab is wet, you can safely replace the insulation);

- A vapor barrier is definitely needed (when covering the EPS from the inside, it is permissible to neglect the rule);

- the material shrinks, requiring replacement after 10-15 years;

- For installation, you will need to make a sheathing, which will steal a large internal volume of the house.

Ecowool

The most preferred material from an environmental safety point of view. It consists of elastic granules that do not allow the insulation to shrink, which distinguishes it from mineral wool.

- does not ignite;

- durable (up to 50 years);

- environmental cleanliness;

- sound insulation is akin to mineral wool;

- low thermal conductivity.

If you make a rating of insulation materials according to the preference for cladding the walls of a house from the inside, it will look like this:

- Ecowool (recommended first).

- Mineral wool.

- Foam plastic (extruded polystyrene foam).

- Penoplex.

Supporters of diversity and unusual solutions can look at the options listed below for insulation from the inside:

Eco-friendly, safe; at the same time they can be used as insulation and decorative finishing. Unfortunately, due to the thin layer, they are ineffective and are only suitable for the southern regions.

They have a thickness of 3 to 10 mm (more than cork), can cover wall defects, almost do not reduce the area of the premises, and are applied like regular wallpaper, only with special glue. They do not smell, are safe, protect well from noise, are moisture resistant - they protect walls from mold. The only negative is flammability.

An innovative material consisting of two layers - fiberboard with a thickness of 10 to 25 mm and pressed flax. It is mechanically strong, environmentally friendly, but its thermal conductivity is worse than that of recommended insulation materials.

The material is obtained by drying wood chips, then mixed with a binder and pressed. The protective layer better protects against rodents, insects, as well as mold or mildew. But it is not suitable for insulating the inside of most private houses, since it begins to deteriorate at a humidity of more than 35%.

To achieve normalization of the microclimate in the house by insulating the walls, it is better to tip the scales in favor of proven materials - mineral wool, ecowool, polystyrene foam. You should not think that the impossibility of external thermal insulation will reduce the heat in the premises, because a competent choice of material and adherence to installation technology will certainly lead to the desired result.

Where is the foil insulation method used?

Foil insulation reflects infrared rays, which are essentially thermal rays. But there is no need to use the material everywhere. In some places it will not work properly.

It is mainly installed near thermal energy sources:

- heating devices - batteries, air heaters. The insulation is mounted on the wall with foil in the room;

- boiler, fireplace stove.

It is also used when installing “warm floors”. The reflective layer will direct the heat in the desired direction.

Small spaces where every centimeter plays a role. Here, thin insulation would be appropriate on the walls and ceiling.

In the attic. Here the insulation is installed on the roof. Apply 2 layers to combat heat and cold.

In baths and saunas. The heating of the room is not constant; foil material is suitable for such purposes.

Garages, hangars, outbuildings - an installed radiator or potbelly stove.

They also insulate heating pipes, air ducts, wells and wells.

Warm plaster

Insulating plaster, characterized by excellent thermal insulation properties and ease of use, is increasingly in demand. It is made from perlite and foam glass . The second option is more preferable for interior work.

It is based on unsorted foam glass granules, due to which this plaster has a number of positive features:

- excellent heat and steam conductivity;

- environmental friendliness;

- durability and strength;

- fire resistance;

- sanitizing properties.

Plaster

Izolon

Izolon is an elastic insulating material made from polyethylene with a cellular structure . It is available in the form of plates or rolls and may additionally have an aluminum foil coating.

Its main advantages include:

- durability;

- environmental safety;

- excellent shock and sound protection.

Izolon

Expanded polystyrene

Expanded polystyrene is a gas-filled material produced in the form of granular slabs.

It is often used for internal wall insulation, although, according to professionals, it is more preferable for external decoration.

The advantages of this material include durability, environmental friendliness, light weight, moisture resistance and high thermal insulation properties.

However, it is not without its drawbacks - in particular, such as the lack of fire resistance and the need to use additional fasteners (adhesives or dowels).

Types of foil penofol

There are 3 types of penofol with foil on sale. Each is marked with Latin letters, which indicate the packaging.

Folgoizolon for external and internal work

Produced in different thicknesses. Suitable for complex insulation of buildings inside. Glass wool is used together with this insulation. They also produce foil insulation with perforation. It is installed in log houses to allow the wood to “breathe.” TYPE B – foil is located on both sides. This is maximum protection against heat loss. Penofol type “B” is used for thermal insulation of the attic, supporting structure, basement, and floor. As well as insulation of the pipeline and heating system.

TYPE C - on one side there is foil, on the other there is a thin layer of glue protected by film. Self-adhesive penofol is easy to install without spending a lot of time. For installation, cut into pieces of the required length and glue to the prepared surface.

TYPE R – a complete comparison to type “A”, but with a pattern on the foil. Used as decor for indoor walls. And also with multi-layer insulation, creating an air gap.