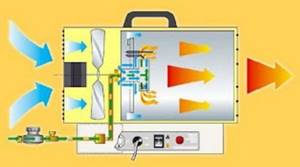

The principle of operation of a heat gun, regardless of price, complexity of the device or any classification, is quite simple and, in fact, the same for both diesel or gas and electric guns.

A powerful fan drives cold air through heating elements or a combustion chamber, in which the air is heated and the same fan contributes to the even distribution of hot air throughout the room or open space.

The most common types of heat guns in use at the moment are electric, gas and diesel. Diesel engines, in turn, are divided into direct and indirect heating units.

In the first case (direct heating), the combustion products together with the incoming air are the coolant. Such guns are used either in open areas or in rooms with a good supply and exhaust ventilation system. Indirect heating devices are designed in such a way that combustion products do not enter the room, but are discharged outside it. Both diesel and gas guns require an electrical connection to power the fan, ignition system or security system.

Based on the principle of fuel injection, ejector and electromechanical guns are distinguished. The ejector principle is implemented as follows: the air flow created by the pump creates a vacuum and sucks fuel from the tank. Next, the air-fuel mixture is supplied through the nozzle into the combustion chamber. Electromechanical injection is carried out by installing a fuel pump and an air blower.

Operating principle of a gas heat gun

Using an electric motor, a fan is started, sucking cold air inside the gun. Fuel in the form of gas enters the burner through the reducer. Ignition occurs through a piezoelectric element (the safety of the unit is ensured by an automatic system with a temperature sensor that stops the gas supply if the flame goes out). The heated air flows passing through the gun are pushed out by a fan.

Some features of gas heat guns

- Possibility of quick connection and replacement of a gas cylinder

- Stable operation even in severe frost (in the worst case, you need to shake the cylinder)

- The efficiency of the device is close to 100%

It is important to remember that when the unit is operating, oxygen in the room is burned, so when heating the room there should be no people in the room, and after the unit has finished operating, ventilation is necessary.

Butter gun

Some garage craftsmen make devices using waste oil with their own hands, but why reinvent the wheel when there are factory installations that are approved for use in any premises. They work on any hydraulic or motor waste product that can be purchased inexpensively.

A waste oil heat gun made by a garage craftsman will be much cheaper, but what about safety? Who will answer if something happens to an oil-based installation? In the factory version, all combustion products are discharged through a pipe to the outside, but in a homemade unit, the oil often burns in a dirty cup from a blowtorch aimed at it. The factory version has an efficiency of 100% and oil combustion does not disturb the ecology of the premises, which cannot be said about handicraft production.

Gas supply diagram in a gas heat gun

|

After connecting the gas cylinder, the gas enters the gas inlet pipe (1), then into the flame extinguishing chamber (2), the solenoid valve (3), into the gas supply regulator valve (4), into the gas injector (5), then ignition (ignition) occurs from the spark plug.

The thermocouple (7) heats up and facilitates the passage of gas into the flame retardant chamber (2). The thermostat (8) starts the electrical circuit and allows gas to pass through the solenoid valve.

General information

It is difficult to find a simpler and more convenient to use device for heating various rooms than a heat gun. This device is a structure consisting of a powerful heating element and a fan, which are located in one housing. A heat gun can quickly heat the air and distribute it just as quickly. It will take a few minutes to heat a small room, and it won’t take much time to heat a large room.

The design of this device is quite simple, so a DIY heat gun almost never fails . You can choose different fuels to operate the device:

- natural gas;

- electricity;

- petrol;

- kerosene;

- diesel fuel.

The heating efficiency of the gun will depend on its power. For home use, a device with a power of 5-12 kW is sufficient. For large premises, equipment with a capacity of 250-350 kW will be required.

To operate the gun you will need fuel

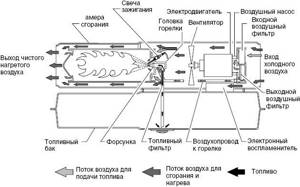

Operating principle of a diesel heat gun (direct flow)

From the fuel tank of a diesel direct-flow gun, fuel (usually diesel fuel or kerosene) enters a special settling filter. Next, using a pump or compressor, the fuel enters the injector.

A fan located at the rear of the gun delivers cool air into the combustion chamber, while at the same time distributing fuel from the nozzle there. Ignition occurs via a spark plug and an electrical element. Hot air masses, together with combustion products, rush into the heated space.

Some features of diesel heat guns

- Economical fuel consumption (10-15 hours of continuous operation)

- Low energy costs (0.3-1 kW)

- In the case of direct heating, combustion products enter the heated space, so ventilation of the room is necessary

Some important tips for assembly and operation

The rules for the safe operation of a homemade gun are practically no different from the operation of other electrical appliances: you must avoid tipping the device and getting moisture inside it, do not touch the heated body and do not leave the unit working unattended.

One of the important features is that before turning it off, you must first stop the operation of the heating element, let the fan run idle for a few minutes, and only then pull the plug from the power supply.

Homemade heat guns without thermostats are not intended for long-term operation - they can cause a short circuit in the network or ignite from a hot spiral, in addition, electrical appliances dry out the air very much, so it is recommended to ventilate the room more often

Tips for assembling homemade products:

- The body for any type of electric gun is best made of metal with a wall thickness of at least 1 mm or asbestos cement. Although you can buy a thermoplastic container of suitable size, it can emit unpleasant odors when heated, and will require strict control over the temperature of the coil.

- The annoying noise from the operation of the impeller can be reduced if relatively quiet car fans are used for the design.

- To prevent the hot surface of the housing from causing a fire, it can be installed on a frame made of reinforcement, an asbestos-cement stand, or a heat-absorbing coating can be applied.

- The power supply to the fan and heating element is always carried out separately.

- Monitor the quality of the insulation of all wires protruding beyond the gun body.

Grounding the metal body of the device will help prevent accidental electric shock.

And the last piece of advice - if your knowledge of electrics is at the level of an amateur beginner, then before connecting your homemade device to the network, consult with a specialist who will evaluate the performance and safety of your creation with a professional eye.

The following article will introduce you to the criteria for choosing a factory-made electric fan heater. If you doubt your own abilities or you don’t have time to assemble a homemade product, read the material we recommend.

Operating principle of an electric heat gun

The cold air taken by the fan enters the gun and is heated there with the help of special heating elements (heating elements), and after that it is again thrown into the room.

Some features of electric heat guns

- The speed of passage of air masses through the heating system is high, so the heating efficiency directly depends on the power of the heating elements

- The speed of the air flow affects the uniformity of heating. The higher the speed, the more evenly the heat is distributed (while the heating itself occurs more slowly, since the air does not have time to heat up much)

- Electric heat guns are not intended for heating open areas. For these purposes, diesel or gas engines are used.

- During operation of the electric gun, no foreign odors are emitted (in the very first days of operation, a specific smell from the heating elements is possible, which soon disappears)

What power should the gun be?

How to choose the right heat gun for your home based on power? Power affects the size of the room the device can heat and for how long. There are average power calculations for the heated area. Typically, for rooms with a ceiling height of 2.5 m, the following ratio of power and area is taken: 100 W of thermal power is required per 1 m2. For example, if you need to heat a garage of 15 m2, you need to choose a heat gun with a power of at least 1.5 kW.

If you need to warm up a box with high ceilings, then it is better to calculate the power based on the volume/power ratio: 2.5 m3 = 100 W. For example, you need to heat a box with an area of 30 m2 with a ceiling height of 4 m. Then you will need a device with a capacity of: 4 * 30 * 100 / 2.5 = 4.8 kW. So, you can take the Resanta TEPK-5000K with a power of 5 kW. You should not take power “for future use”, because the higher it is, the more expensive the device.

Which heat gun to choose for suspended ceilings? In order for the film to lay clearly on the ceiling without sagging or stretching, it is necessary to warm it evenly to 60° C. A device of 3 - 5 kW is suitable for a living room, bathroom or bedroom. For unheated new buildings, it is better to take a gun up to 10 kW.

Device and purpose

A heat gun is a metal cylinder, inside of which there is a heating element and a powerful fan. When turned on, the heating element heats up, and the heat from it spreads throughout the room with the help of a fan.

The gun body has a cylindrical shape, but there are also rectangular options

The overall design of the device is simple, but the internal elements are presented in various versions. For example, the heating element may be of the following types:

- a spiral made of refractory metals, for example, nichrome. Such parts heat up quickly, but reduce the amount of oxygen in the room;

- A heating element made of sealed tubes containing sand inside. Devices with such an element are low in cost;

- a ceramic part that consists of plates with a large number of small cells that serve to allow air to pass through. This heating component is the safest of all options.

The additional components are a thermostat and a thermostat. The first element serves to protect the device from overheating during prolonged operation, and the second activates the operation of the unit if the room temperature drops below a predetermined norm.

The cylindrical body includes important parts that are securely fixed inside

All heating and distribution components are contained in a metal housing, which is often cylindrical in shape. On the outside there are adjustment buttons, sensors, a stand, a protective grille and a wire for connecting to the mains. This makes operation convenient, and the guns serve for heating and drying rooms after renovation, as an additional source of heat.

Criterias of choice

A set of parts turns into a functional device designed for quickly heating rooms of different sizes. When choosing, it is worth considering that the larger the space, the more powerful the electric heat gun should be. And also the choice is based on the following criteria:

- For long-term operation, purchase professional-type heaters that can withstand intensive use. If short-term heating of the room is necessary, then simpler devices are suitable;

- the housing and protective grille must be made of metal. If plastic was used for this purpose, then such a gun may be a fire hazard;

- a 50 kW or other voltage gun must be equipped with a heating level regulator and switches that control air flow;

- the power must correspond to the heated area. To calculate, you need to take into account the formula: for every 10 m2 of area, 1 kW of power is required;

- The optimal operating time of the device is indicated on the packaging. For example, the wording 24/2 means that the gun can work around the clock, but needs a break of 2 hours.

Sensors in the form of light bulbs notify about the process that is activated at the current moment of operation of the device

The size of the electric heat gun should be considered if it will be installed in a small space. Small models have low power, and therefore they are often chosen for short-term heating of a space of 10–25 m2

It is important to remember that flammable materials and flammable liquids should not be located near the device.