Operating principle of a convector type heater

As you know, the densities of hot and cold air differ. Heavier air, which has a low temperature, accumulates near the floor, and light, warm air rises to the ceiling. The body of any convector has two slots - at the top and bottom, respectively. They are needed to allow air of different temperatures to pass through.

Convector heaters operate very quietly and do not take up much space

The design of such a heater is simple. Small width metal case with a heating element inside. It works from the mains. The thermostat regulates the heating temperature, the thermostat handle is on the external panel. Convector heaters are distinguished by types of heating elements.

Thermostats

The installation of a thermostat is primarily due to the task of saving energy. The secondary goal is to prevent the object from overheating.

When choosing a thermostat and relay, pay attention to the load current - use the safety factor 1,6

for self-regulating cables, and

1.35

for resistive and zonal.

If the calculated current exceeds the thermostat relay rating (usually 16A), then it is necessary to assemble an electric heating control panel. It's not that difficult. We will definitely tell you how to do this if you intend to buy a heating cable from us.

Thermostats

- Electronic temperature regulator RT-300 2704 rub.

- Thermostat for heating pipes ETI-1551 6060 RUR

- Universal thermostat OJ electronics ETN4 1999 RUB 9,200

- Pipe temperature sensor OJ electronics ETF-622 2500 RUR

- TCON-CSD/20 Electronic thermostat for DIN rail RUB 27,114.2

- Electronic temperature controller RTM-2000 RUR 10,175

- Thermostat exTHERM-AT, type 60/00588595 RUR 31,788

HEATING CARBON TAPE review + measurements

Hello to all lovers of new, interesting things and also making things with your own hands. Today I will do a short review of the HEATING CARBON TAPE and, of course, we will test it in work.

First, as expected, a little lyrics and history - well, just a little bit)).

The first time I heard something about it and tried it in my work was more than two years ago. The material was new to me then, little known, there was little information on it. I’m probably one of those people who is not afraid, condemns, resists something new, but vice versa ,studies, tries, implements.

I collected several types to try, began to try, used them in my projects, where I needed to warm up)) - I liked the work. And now everything is in order - let's go.

CARBON HEATING TAPE - a heating element of a new generation, of course not yet as well known as our good old NICHROMYCH).

It comes in different widths. The manufacturer and supplier that came to me with a width of 15 mm and more - about 6-7 types - has room to roam creatively.

The photo shows the sizes I worked with or tried.

How does it work? Yes, everything is simple - we apply voltage to it like a regular coil - it heats up - of course, all the parameters need to be calculated.

Here's technical information about it.

I have so far managed to work with it at low voltage, from 5-20 volts. (In the video there is a temperature measurement from a power bank).

How to connect it to the wire? It’s as if I’m not exactly an electrician, so I used my own simple methods.

I tied the wire to the tape itself and threw heat shrink on top, or did the same thing, just crimped it with a metal tube and the same heat shrink on top (see video).

I liked the tape in my work because it is elastic - you can lay it out as needed. Products with it are flexible and pliable than with wire, let's say in comparison.

It heats over its entire width - hence the large heating area - this is its feature - nichrome, of course, cannot do that.

Another advantage is that you can simply sew it on, either by hand or by machine; I tried both options and the tape can easily withstand it.

It can also withstand getting wet - the manufacturer claims that products with it can be washed - so far I haven’t gotten around to this, but there have been repeated wetting and drying - I see that the characteristics of the tape have not yet changed.

What can I say on my own, friends, about the cons.

So far I haven’t noticed anything so serious; there are specifics to working with it. During installation, it is important not to delaminate it along the weave - you can be a fool, believe me). Another point - you need to jam the edges so that it doesn’t crumble in this place - that’s all

Another point is that you need to jam the edges so that it doesn’t crumble in this place, that’s all.

I definitely won’t say that it is better than nichrome, these are just different heaters, that’s why it’s not worth bombing here, you need to understand this.

For my use guys, I see many advantages and prospects in it, so I will try and implement it further.

Well, good old NICHROMYCH, he’s like an old friend - he’s always there, he’ll always help out)).

I think I’ll finish this short review. Watch the video, there will be added to my chatter a picture with measurements and other things. You can also look there where to buy the tape and all the juicy details about it.

That's all for now. Handy Samodelkin.

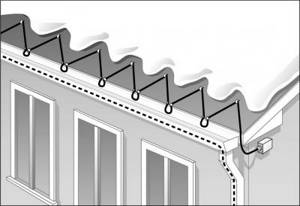

Heating of roof and gutter

In order to protect the roof of the house and drainage from the adhesion of icicles, prevent the fall of snow and ice layers, organize normal regular drainage of melt water, and eliminate clogging and deformation of the drainage system, a heating system is mounted on the roof and gutters, drainpipes tape system.

As a rule, the entire structure has high strength, meets fire safety requirements and is characterized by increased resistance to temperature fluctuations, precipitation, and sunlight.

The heating tape is suitable for all types of roofing and has automatic control. The pipe heating kit is easy to install, so it can be removed for the summer season.

The type of heating tape is selected according to the degree of possible icing of the roof. Self-regulating systems are able to operate without control, since they themselves determine their power under the influence of precipitation and temperature fluctuations. Many homeowners prefer the use of thermostats.

The thermostat will help you adjust the temperature

Modern roof and gutter heating systems greatly simplify the maintenance of the house and surrounding area and completely eliminate the occurrence of icing. Thanks to built-in sensors and thermostats, the design can operate in standby mode and turn on as needed, thereby ensuring minimal energy consumption.

Main characteristics of the material

temperature adhesive tape has high strength and heat resistance, but these are not its only advantages.

Among the main characteristics of the material are:

- ability to withstand high temperatures for a long time;

- wear resistance;

- elasticity;

- high adhesive properties;

- no toxic emissions when heated;

- moisture resistance;

- resistance to aggressive substances;

- ease of use.

In addition, one of the main advantages of this material is its affordability and wide range.

Characteristics

To systematize and simplify the selection of the desired device from the many types of tape heaters, the following characteristics are used:

- symbol;

- connection type

- heater type;

- resistance (Ohm);

- active part length (m);

- width x thickness or diameter (mm);

- length of low-temperature wires (m);

- minimum bending radius (mm);

- weight (kg);

- rated voltage (V);

- heat power (W/m);

- power consumption (W);

- surface temperature (oC).

These characteristics are used in the calculations of heating systems necessary to ensure the process or operating temperature of pipelines, equipment and premises.

Connection diagram

The film type of infrared heaters is one of the most popular. And not the least role in this was played by the fact that such models can be easily installed at home with your own hands. The most widespread installation of PLEN on the ceiling or under the floor covering. However, if desired, you can place the panels on the walls, but the efficiency of the heater will decrease due to the limited coverage area of the device. It is most often used as an additional source of heat, but not the main one.

The main technological stages are as follows:

Creating protection from any thermal insulation material. This is necessary in order to direct the infrared radiation in the desired direction. Installation of the film to the base. It can be either thermal insulation or a special sheathing

It is important that the front side of the PLEN “looks” into the room. Fastening is done using self-tapping screws or a construction stapler. Work on connecting the PLEN to a source of electricity

This stage will require some experience in carrying out such work. Installing a decorative layer.

Before installation, several important points should be observed, on which the final quality of the work will depend:

check the integrity of the heating element before installation using a special tester; optimize the electrical wiring diagram by directing the contact terminals towards the panel; pay attention to the installation zones on the sheets, and under no circumstances violate these boundaries, otherwise this will lead to breakdown of the PLEN.

The film can be installed on the ceiling either directly on the insulation (it hides about 15 cm from the ceiling height) or on the sheathing (it takes up more height). The progress of work is as follows:

The ceiling is measured and divided into equal sections. Thermal insulation is cut into sheets of the required size and mounted to the ceiling using a stapler. The seams are taped. Excess thermal insulation material is cut off using a utility knife.

Installation of PLEN. To do this, you will need a soldering iron, the heater itself, wires, a thermostat, a screwdriver and a plastic box. The film is attached in increments of 25-30 cm using a stapler. The wires are routed to one side. Next, the wires are carefully placed in a plastic box, which is located in a convenient place. The box is fixed using a screwdriver.

Soldering wires. To do this, you need to expose the wires. This must be done as carefully as possible without damaging the wires. The wires are divided into 2 parts of 2.5 cm each. After 2 wires we connect (twist) each other to ensure good contact between them. Cut off the excess wires and remove the insulation using a soldering iron and a piece of plastic. Similarly, we connect all the remaining wires to each other.

Connection. In order for the PLEN to work, two main wires need to be brought to the panel and connected. Connection diagrams for IR heaters require the use of a contactor

It is important to take into account that with a total power of 5 kW and below, a single-phase input is made, and for values above 5 kW, a three-phase input is made. After this, a thermostat is installed, usually at a height of 1.4 -1.5 meters.

To install PLEN as “warm floors”, you must perform the following steps:

Prepare the surface for work. The floor must be level, clean and dust-free.

Thermal insulation flooring. The material is fixed with a stapler, the joints are glued with aluminum tape

It is important to cut the material to the required size, since the fewer joints the coating has, the better.

PLEN is mounted with indentations from the places where furniture and other interior items are placed. The wires are routed towards the baseboards and pulled to the power cable.

Installation of a thermostat

You can use remote models or place the equipment directly on the floor surface.

The connection is made in the same way as when connecting ceiling infrared heaters.

Heat-resistant chimney tape

High-temperature tapes have a wide range of applications, including in smoke exhaust systems, chimneys and furnaces. High adhesive properties, strength and density allow the material to provide good insulation of various materials to heated surfaces.

Using heat-resistant tape you can:

- glue decorative elements to the heating surface;

- carry out decoration, masonry, cladding or repair of the stove;

- protect the room from harmful fumes and smoke;

- seal cracks in fireplaces and chimneys;

- ensure reliable fire safety;

- ensure high-quality joint density.

To ensure fire safety and reliable sealing of joints of stoves, chimneys, fireplaces, fireboxes and air ducts, not every heat-resistant tape is suitable. For this purpose, there is a special type of heat-resistant silica tape, which has maximum thermal insulation and can withstand temperature changes of up to 1100 degrees.

Device and characteristics

Film IR heaters (PLEN) are devices that allow you to heat a residential or industrial space. Their design includes:

- a heating element;

- film;

- foil.

Heat transfer occurs due to the release of infrared waves. Their safety and benefits for the human body have been proven by more than a dozen scientific studies.

The main difference between PLEN and more conventional heating devices is that during operation it is not the air in the room that is heated, but the surrounding objects, which subsequently give off heat. This allows you to achieve more comfortable and gradual heating of the air in the room without drying it out, which is very important in winter.

The advantages of infrared film heaters include the following.

- Flexible temperature control due to the fact that you can supplement the IR device with a thermostat.

- Uniform heating of the room. This is achieved thanks to the special operating principle of the device.

- Low power consumption. This difference is especially noticeable in comparison with the consumption of classic electric heaters.

- Fast and straightforward installation. Installation is carried out quickly and does not require special equipment, however, this matter has its own subtleties that cannot be neglected.

- The shelf life of PLEN is 50 years.

- Wide temperature range. This heater can be used at temperatures from -40 degrees. In addition, the IR heater is not afraid of temperature changes.

- PLEN does not dry out the air in the room, does not reduce the amount of oxygen, and is also safe for humans and the environment.

- Fast heating of the room. For example, in order to heat a room with an initial temperature of +10 degrees to a comfortable +20, it will take no more than 50 minutes of operation of the device.

In addition to its advantages, PLEN also has disadvantages.

- In order to achieve normal and stable heating of the room, a large number of IR devices will be required.

- It is irrational to install PLEN in poorly insulated rooms. Before installing this type of heater, you will first need to take care of eliminating possible heat leaks from the house.

- If the heating film installation technology is violated, it can become very hot, thereby producing an uncomfortable temperature in the room.

- If you install additional thermostats and protective screens to the PLEN, this will lead to a significant increase in the cost of the project.

Recommendations for sealing a chimney with tape

For a chimney made of stainless steel or plastic, aluminum and polymer tape is suitable. The method of using the tape is very simple. It is enough to heat the edges of the material and wrap it around the joints. As the tape cools, it shrinks, providing a tight adhesion and sealing. However, even with the easiest types of work there is a risk of errors.

To ensure high-quality and durable sealing of chimney pipes, we recommend using the following recommendations:

- sealing pipes and other chimney elements at temperatures below 5+ degrees is not recommended;

- work is carried out exclusively in protective gloves and clothing with sleeves;

- the adhesive composition of the tape requires about a day to compact and completely harden;

- After completing the sealing work, it is necessary to light the fireplace to check the quality of the work done.

Installation of film-type IR heaters

Installation of flexible film heaters, regardless of the installation location, does not require the contractor to have high-level professional skills, but must be carried out in compliance with the following rules:

- the installation site of the PLEN must be level and dry;

- cutting rolls, if provided for by the model, should be performed only according to the markings specified by the manufacturer;

- testing the functionality by plugging in a rolled-up heater is prohibited;

- the length of one strip film fragment should not exceed 8 m;

- adjacent strips of the heating system are located at a distance of at least 5 mm;

- bending the PLEN at an angle of more than 90 degrees is not allowed;

- installation of the film to the base is carried out with staples using a construction stapler or special fasteners (the use of ordinary nails and self-tapping screws is not effective);

- It is prohibited to carry out installation work at sub-zero air temperatures - after warming up the room, the film strips will increase in size and form folds.

Sequence of installation of film IR heaters

To protect against overheating, the base for placing the PLEN must be equipped with a foil reflective screen that acts as a heat and water insulator, for example, penofol, isolon.

The protective coating is mounted on the base with an overlap of adjacent edges of 3-5 cm; to speed up the process, it is advisable to use special fasteners for fastening, which are available in a wide range on sale.

From above, the joints of the screen strips are glued longitudinally with special foil tape.

The elements of the film heater are mounted on top of the laid screen - after preliminary layout and in accordance with the installation instructions supplied with the device. Installation is carried out taking into account the rule - for 1 square meter of flexible film there should be 8-10 fastening elements.

When the heating circuit is ready to be installed, it is connected to the thermostat, which should be located at a height of 1-1.5 m from the floor, and the system’s functionality is checked.

In addition, to correctly monitor the temperature in the room, the thermostat must be located away from other heating devices, have a thermal insulation pad underneath, and be protected from direct sunlight and drafts.

If the results of testing the IR device are positive, finishing materials are laid - floor covering or suspended ceiling, which are installed with a gap of 10-15 mm between the cladding and the film.

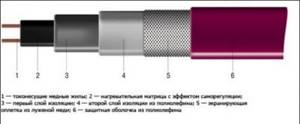

Types of strip heaters

Depending on what device the heating wire is used in the tape, ENGL, identical to cables, are divided into resistive and self-regulating.

Resistive tape heaters consist of several (from 2 to

To connect to a power source, the device has terminals located, depending on the design of the device, at one or two ends of the tape.

The length of resistive ENGLs cannot be changed during installation, that is, cutting the tape to fit to the dimensions of the heated equipment is excluded.

Self-regulating tape heaters are improved cables of identical purpose and design, having a flat cross-section due to larger area matrices.

The matrix plates, located between parallel copper wires, are made of a material whose resistance, when current passes through it from the phase wire to the neutral wire, changes depending on the ambient temperature. Consequently, the degree of heating of the matrix and the amount of heat transfer also depend on this temperature, that is, when the air temperature rises, the matrix cools down and produces less heat. The parallel connection of conductors in the cable allows, during the installation of such heaters, to cut the tape into pieces of the required size without compromising functionality.

Types of high temperature tapes

Heat-resistant high-temperature tapes are divided into separate types depending on the base material, adhesive and method of application.

Each type has its own characteristics and performance properties, which determine the efficiency and service life of the belt.

Varieties based on base materials

High temperature tapes come in three main types depending on the base materials. Let's take a closer look at them.

Aluminum tape

Aluminum-based tape is considered one of the most common. The main layer is made of aluminum foil, which gives the product the following features:

- high temperature resistance;

- low density;

- high strength;

- thermal insulation and electrical conductivity;

- manufacturability of use;

- resistance to chemicals and corrosion.

Aluminum tapes are quite in demand for installation work, repair of pipelines, air conditioning and ventilation systems, as well as hydro and thermal insulation work. The tape is also used to seal joints of equipment and protect it from corrosion.

Aluminum foil tape

Heat-resistant tapes based on aluminum foil are considered a fairly durable insulating material. They are made of aluminum foil and are used as an independent thermal insulation material.

Among the features of the material:

- ability to withstand high temperatures (from 150 to 350 degrees);

- high resistance to moisture;

- corrosion protection;

- reliable sealing of joints;

- excellent adhesive ability in high humidity conditions.

Due to its moisture resistance, this material is ideal for baths, saunas, bathrooms and other rooms with high humidity levels. Most often, tape is used to seal seams and fasten insulating materials.

Kapton

Kapton high-temperature tape is made on the basis of Kapton, a high-strength dielectric polymer that perfectly conducts heat and electricity. The material stably withstands temperature changes from 60 to 300 degrees Celsius.

Among the features of the product:

- high dielectric capacity;

- reliable fixation thanks to silicone adhesive;

- preservation of original properties when heated to 300 degrees;

- high thermal and corrosion resistance;

- high wear resistance.

High-temperature tape based on Kapton is widely used in the repair of equipment and various equipment, for insulating electrical cables, circuit boards, heating elements, as well as in the production of military and aviation equipment.

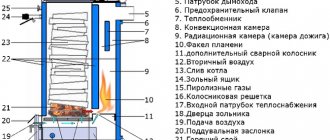

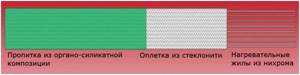

Tape heater ENGLU-400

The heater contains eight strands of nichrome wire, the outer insulation contains three layers, the fiberglass of the first and second layers is impregnated in an organosilicate solution. It is produced in certain sizes, is not cut, the end is hermetically sealed with a cap.

Main technical characteristics:

- maximum operating temperature – 400 °C;

- power supply – 220, 24, 12 V, depending on the model;

- the length of low-temperature leads for connecting to the network is 70 cm.

Technical characteristics of some models of ENGLU-400 tape

| Tape brand | Supply voltage, V | Length | Power consumption, V | Operating temperature, °C |

| ENGLU-400 | 220 | 3 | 0,9 | 400 |

| Width - 21 mm, thickness - 1.9 mm, bending Rmin - 10 mm | 220 | 3,7 | 0,7 | 260 |

| 220 | 4,1 | 1,2 | 400 | |

| 220 | 5 | 1 | 260 | |

| 220 | 6 | 1,8 | 400 | |

| 220 | 7,4 | 1,5 | 260 | |

| 220 | 8,3 | 2,5 | 400 | |

| 220 | 10 | 0,5; 1; 2 | 70-260 | |

| 24 | 1 | 0,23 | 260 | |

| 24 | 1 | 0,12 | 200 | |

| 24 | 1,5 | 0,34 | 260 | |

| 24 | 1,5 | 0,15 | 170 | |

| 24 | 1,5 | 0,085 | 120 | |

| 24 | 2 | 0,46 | 260 | |

| 24 | 2 | 0,25 | 200 | |

| 24 | 2 | 0,11 | 100 | |

| 12 | 1 | 0,23 | 260 | |

| 12 | 1,5 | 0,15 | 170 | |

| 12 | 2 | 0,11 | 100 |

This tape is recommended for use on industrial production lines, for heating asphalt, bitumen, in order to maintain tin and other low-melting metal alloys in a liquid state. They are successfully used for heating molds in injection molding machines. To set the desired temperature in electrical circuits with ENGLU tape, various types of thermostats are used.

Appearance of the thermostat

Industrial Applications

Cable electric heating systems were originally created for the petrochemical industry, and only then, as decades passed, they began to penetrate the mass market. Now industrial grade cables formally differ from general construction ones by having certificates for use in hazardous areas.

The range of tape heaters and their components is extremely wide, and correct configuration for a specific task requires data collection (filling out) and professional competence to select the optimal solution in each specific case.

Cm.: ""

Frost protection

To protect industrial product pipelines from freezing, low-temperature electrical cables are used: Maximum operating temperature 65°C. Maximum temperature without load 85°C.

Heating tapes 65°/85°

- Self-regulating electric heating tape 27VR2-F RUB 817

- Self-regulating electric heating tape 25NTR2-VT price on request

- 5BTV2-CT (487509-000) Self-regulating heating cable Self-regulating strip heater 3255.13 RUR

- Self-regulating heating cable HeatTrace 40FSR2-CT RUB 985.01

- Self-regulating parallel heating cable BARTEC PSB 33 (07-5801-2336, polyolefin) price on request

Maintaining process temperatures

Maximum operating temperature 120°C. The maximum temperature without load is 120°C - operation does not include steaming mode.

Heating tapes 120°/120°

- Self-regulating heating cable Nelson QLT210-J RUB 2688.5

Maximum operating temperature 120°C. Maximum no-load temperature 190°C - operation with steaming mode.

Heating tapes 120°/190°

- Self-regulating electric heating tape 60VC2-F RUB 2,221

- Self-regulating electric heating tape 45VTS2-BP price on request

- Self-regulating heating cable Nelson HLT215-J RUB 3,291.47

Warming up the product

Maximum operating temperature 190°C-240°C. Maximum temperature without load 240°C - operation with steaming mode.

Heating tapes 190°/240°

- Self-regulating electric heating tape 80ВТХ2-ВР price on request

Long distance pipelines

In this case, such cable characteristics as conductor cross-section and maximum circuit length come to the fore. From one connection point, using self-regulating pipe heating cables, you can heat mains up to 600 m or more in length. For uninterrupted transportation of liquids and gases through ultra-long oil and gas pipelines, LongLine systems and technologies based on .

Heating of pipelines

- Self-regulating heating cable Nelson LLT-2-J RUB 1868.23

- Constant power electric heating cable LLS 3x3.00 price on request

Drainpipes

Despite the consonant name of the task, so-called ice-breakers are used to prevent the formation of ice in drainpipes. roofing cables. They have a UV-resistant shell, improved mechanical protection, and an extended power window when passing through 0°.

See: “Heating of gutters”

Cables for heating drain pipes and storm drains

- self-regulating heating cable Raychem ICESTOP GM-2X RUR 1,618.46

- Self-regulating heating cable for roof heating Nelson SLT-2-JT RUR 917.43

- Self-regulating heating cable Freezstop-25K 477 RUR

Flexible carbon heating tape LUNG

Flexible carbon heating tape (LUNG) is intended for heating pipelines, technological equipment with flat surfaces and complex geometric shapes, as well as for installation in electric heating products as a heating element.

- Heating of pipelines for pumping bitumen.

- Heating of fuel oil pipelines and regulation of fuel oil temperature in front of boiler burners in boiler houses and thermal power plants. “Soft” heating and maintaining the temperature of various chemical materials in product pipelines. The LUNG tape is wound onto pipelines with a given calculated winding pitch; it is recommended to lay a non-flammable thermal insulation coating on top of it.

- Heating of surfaces, for example, construction formwork, drying chambers. LUNG tape is glued to flat surfaces using heat-resistant silicone glue.

- Creation of flexible heating panels of various sizes by gluing LUNG tapes onto metal sheets. Such mobile heating sections can be used to heat containers, including railway tanks.

- Embedding in rigid casings to produce convective room heaters operating in a mild temperature regime without burning out oxygen in the air.

- Use in heaters and air ducts to heat air flow with minimal aerodynamic resistance and inertia-free heating.

Operating conditions for LUNG tape

- All surfaces on which the LUNG tape is mounted must be cleaned of burrs and sharp edges to avoid mechanical damage to the tape.

- Do not place flammable materials or products near the belt.

- During operation, it is not allowed to use tapes without a thermostat if heating to a temperature exceeding 250ºC is possible.

- It is allowed to cover one side of the LUNG tape with non-flammable heat-insulating material.

- LUNG tape can be bent with a radius of at least 5 mm.

- To obtain the best results in terms of electrical and fire safety, it is recommended to use an RCD as a protective element.

Flexible materials: Flexible pipe: flexible water pipes, plastic water pipes

LUNG tape design

The LUNG tape contains a heating element made of fibrous carbon material, an electrically insulating cover made of fiberglass backed with a layer of silicone material. The low-temperature leads connected to the heating element are made of copper wire in heat-resistant insulation and are used to connect the supply voltage to the tape. The heating element and end seals are sealed for protection from the external environment.

LUNG tape is produced according to TU 3443-001-10829030-07. The LUNG tape is protected by a patent of the Russian Federation.

It is possible to produce LUNG shorter than 5 meters. In this case, connecting to the power supply can be done in two ways. The first method is to connect LUNs in series with each other to a length of at least 5 meters. The second method is to connect each LUNG shorter than 5 meters to the power supply via LATR, with a voltage supplied to the LUNG, giving a current consumption of no more than 3-3.5A.

- Large heating surface.

- Elasticity and flexibility.

- Small thickness and weight.

- Low thermal inertia.

- Wide range of power densities (up to 250 W/m strip length).

- Supply voltage from 0 to 220V (by agreement with the customer, the technical parameters of LUNG heating tapes for individual use are agreed upon).

- Ease of design and installation on equipment.

- Possibility of installing the tape at temperatures down to –60ºС.

Description and composition

High-temperature tape is one of the few insulating materials that can withstand temperatures up to 400 degrees Celsius, while the base material does not burn or melt, and the adhesive does not lose its adhesive properties. This is possible due to the composition of the tape. As a rule, high-strength temperature-resistant polymers or other materials are used as the basis for such tapes:

- aluminum/copper/brass foil;

- Kapton;

- Teflon;

- fiberglass;

- electrical insulating paper.

It is thanks to the properties of the base materials that the tape acquires thermal insulation and electrical insulation properties. High-quality silicone adhesive or synthetic rubber-based adhesive is most often used as an adhesive layer.

What determines the choice of device

Pipe length

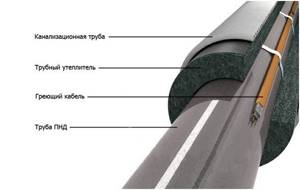

Tape heating system

When purchasing an electric pipe heater in the form of a tape, you need to clearly know the length of the pipes that need additional heating. In addition, it is necessary to clarify what the level of soil freezing is in the region of residence and the specific place where it is planned to lay pipes (the temperature conditions of operation of the entire pipeline will depend on these factors).

Heating mode

You also need to decide on the mode in which the heater will operate. If pipes need to be protected from freezing, you need to choose a tape with a constant operating mode, but if you just need to maintain a certain temperature in them, then systems with periodic operation are suitable.

Specialists will help you make the correct calculations (they will determine the required power and conductor length), and additional advice can be obtained directly from sales representatives, who will not only recommend a specific model, but also give advice on installation.

Device type

The choice of device will undoubtedly be influenced by its type. The most accessible and inexpensive is a resistive tape heater, which is a multi-core wire (from 2 to 8 cores), which is securely fixed on a special fiberglass base. This type is equipped with low temperature leads for connection to the power supply. They are located at one or both ends of the tape. This heating for pipes has a certain drawback - its length cannot be changed, since it is a clearly fixed value. During installation, the bending radius should not be less than 20 mm.

Additionally, the system has a thermostat for heating the pipes, which limits the degree of heating of the cable.

Self-regulating tapes, which consume a small amount of electricity, are more economical. They are a pair of wires that can change their resistance depending on the temperature. The wires are secured in an outer armor sheath, which protects them from bends and breaks. The connection is made through control devices.

The system does not require additional installation of temperature sensors and other control devices. The tape itself reacts to the ambient temperature and regulates its operation.

Such systems are easy to model. The required element can be cut off, and the length of the entire system can be adjusted without causing any harm to it. The price of such a device will, of course, be higher, but the ease of installation compensates for this.

The structure of the tape

The only thing you should pay special attention to is that if the heating tape is installed using a spiral method, it is necessary to avoid overlapping ends, since the system can overheat and cause it to malfunction. Manufacturers have recently introduced infrared film to the market using a composite material incorporating copper conductors.

Today this is the most effective method of heating pipes

Manufacturers have recently brought infrared film to market by creating it using a composite material with incorporated copper conductors. Today this is the most effective method of heating pipes.

Whatever type of tape is preferred, it should be remembered that the effective operation of the system will depend not only on the uninterrupted functioning of the tape, but also on how well the line is insulated from moisture and insulated. Otherwise, it is not the pipeline that will have to be heated, but the soil.

Market Review

Belt systems have several varieties, which differ in their technical features and manufacturing technology. Among them are:

Stranded heaters

This material is a glass fiber tape on which several rows of wire are attached (from 2 to

Since the connections are made using high-tech factory methods, the tape pieces have a fixed length. Their bending radius should not be less than 20 mm. Additionally, the system is equipped with a thermostat that limits the degree of heating of the cable for heating the pipes.

Tape installation diagram - linear and spiral

Self-adjusting tape

A self-regulating tape for heating pipes consists of two parallel copper conductors, between which there is a material that changes its resistance depending on the temperature. All this is enclosed in an outer armor shell.

The advantage of a self-regulating cable for heating pipes is that there is no need for additional temperature sensors and control devices - the tape itself reacts to changes in ambient temperature.

Also among its advantages is the simplicity of the device, which allows it to be sold in reels, or even by the meter. It connects to the network through conventional control devices.

Important information! When installing heating tape using the spiral method, you should avoid overlapping the edges of the material - this leads to overheating.

Infrared tape (film)

The newest and most promising of this class of materials. This heating tape for pipes is in the form of a conductive polymer film based on a carbon composition with the inclusion of copper wire. The principle of its operation is based on the transmission of infrared radiation directly to the heated surface.

Requires installation of temperature sensors (on the surface of the film) and thermostats (at power supply points). The outside is covered with a special layer of thermal insulation. Available in rolls of various lengths.

Household strip heaters

In the conditions of frosty winters, communications (water supply, sewerage) of private houses, country houses, and rural housing have always needed protection. For this purpose, pipelines and units located in basements, basements and attics were insulated with heat-insulating materials, and pipes buried in the ground were laid below the freezing mark. With the advent of strip heaters, the solution to this problem has become much simpler - pipes, shut-off valves and units began to be protected from defrosting by installing cable or strip electric heating.

In this case, the method of placing the tape or cable allows you to vary the degree of heating and material consumption. If the goal is to protect the water supply from defrosting, then the tape can be run linearly along the pipe. If you plan to get water at room temperature at the outlet, then you can insulate the pipe by placing a heating strip in a snake shape, or equip the water supply system over the linear arrangement of the strip with a layer of heat-insulating material.

More accurate results can be achieved by using a thermostat in combination with a strip heater.

The sewer system of private buildings also needs protection from frost, but there is no need for excessive heating of the main line. Therefore, sewer pipes are equipped with strip heaters located linearly on the system, and a layer of thermal insulation with a protective casing is mounted on top of the sewer.

The use of tape and cable heaters for the installation of icing systems on the roofs of private houses in order to prevent the dangerous formation of ice in gutters and icicles is gaining popularity.

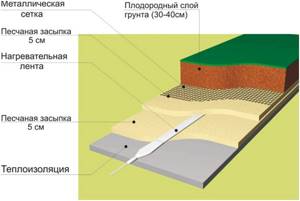

Tape heaters are also used in greenhouses, since creating the necessary temperature and air humidity in them is not enough to grow heat-loving crops - the soil must be heated. In this case, the heating system is arranged on a specially prepared base - a heat-insulating layer, on top of which sand backfill is made and leveled horizontally. A layer of sand is repeated on top of the laid heating tape, then the base is covered with reinforcing steel mesh and a layer of fertile soil. In this case, laying resistive tape is also impractical - self-regulating tape is required.

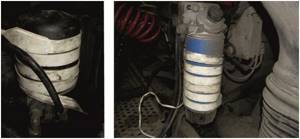

Band heaters have also found their application in automotive technology, since the operation of vehicles in winter is significantly difficult due to the thickening of motor oil and diesel fuel.

The operating instructions for a car strip heater also say whether self-installation of this device on a car is allowed, or whether this must be done in a specialized car service center.

Taking into account the fulfillment of these requirements, the tape heater can be heated:

- salon;

- crankcase;

- for a diesel engine: fuel filter;

- fuel line;

- fuel tank outside at the pump location;

- canister with diesel fuel;

- dehumidification settling tanks;

- battery.

The use of tape heaters in industry is no less widespread; they are used for heating tanks with non-flammable liquids, process and main pipelines, pipeline and pumping equipment, shut-off valves, etc. The list of technical equipment that requires technological or preheating during operation is very long.

Installation of industrial devices is carried out by specialized organizations based on design data calculated taking into account all available factors.

How is power calculated?

To select the most optimal power and length of the strip heater, you will need to take into account the following parameters:

- Pipeline diameter.

- The depth of its laying.

- The temperature difference between the walls of the line and the environment.

- The length of the area requiring heating.

- Type and thickness of the thermal insulation layer.

- The type of band heater used and the features of its operation.

By strengthening the thermal insulation layer, natural protection of communications from heat loss is created: this allows you to save on the length and power of the heating tape.

These pipe heaters can operate in two modes:

- Continuous. With its help, the coolant inside the pipe is maintained at a given temperature tone. This is mainly true for hot water supply.

- Periodically. In this case, the heater turns on only if the temperature in the line drops below a predetermined level.

Despite the comparative novelty of the very idea of active heating of pipelines, the use of cables is considered yesterday. In this regard, heating tape for pipes is recognized as a more promising solution with a very good future.

Areas of application

Thermal protective finishing tape has a fairly wide range of applications. Often, such material is used when carrying out finishing and insulation work, namely:

- electrical wiring insulation;

- protection of individual equipment elements from heat/fire;

- thermal insulation of cryogenic equipment;

- gluing parts of thermal insulation of utilities;

- temporary protection of surfaces, finishing materials and structures characterized by high operating temperatures.

The area and method of application of this type of tape largely depends on their type. In order to choose the most suitable finishing material, it is important to familiarize yourself with its types and properties of each of them.

What is heating tape for pipes

Heating tape for pipes is a type of device that is designated as “active heating of heating communications, water supply and sewerage systems.” Pipes transporting hot water are usually not in danger of defrosting: in this case, the main problem is significant heat loss, which takes a noticeable toll on your pocket. To avoid additional waste, active resistance to cooling of the coolant is used.

As for transport communications of cold water and sewage waste, pipe heating tape brings even more noticeable results. It consists in achieving a significant reduction in the depth of laying communications, which, with the level of soil freezing in the middle latitudes of our country at 1.4 - 1.5 m, leads to very noticeable monetary savings. This is achieved by reducing the complexity of excavation work, providing a reliable guarantee of pipeline safety even in severe frosts.

Read with this

- How to choose self-adhesive insulation for windows and stick it correctly

- Insulating windows for the winter with masking tape and other materials

- Using tape to insulate windows

- Waterproofing pipes: review of popular moisture-proof materials

- Methods of laying pipelines

- Which heater to choose for an apartment or house - pros, cons and selection criteria

- Do-it-yourself installation of metal-plastic pipes: types of connections and tools

- Self-assembly of a vapor-drip heater

- How to choose a changing table for a newborn

- Making a fireplace out of boxes for the New Year with your own hands