Combating freezing of external pipelines in a private house during the cold season is an urgent task when introducing water into the house from water supply sources and discharging wastewater. One of the effective options for combating pipe freezing is to connect a heating cable to utilities, in particular, water supply or sewer lines.

The construction market offers a wide range of electrical cable products for heating from both domestic and foreign manufacturers. Modern developments, thanks to feedback, make it possible to regulate the heating temperature of the wire by changing the current consumed. When choosing products, it is important to know the technology for correct installation of electrical cables on various types of pipelines and the required heat transfer power, which is associated not only with electrical parameters, but also with the length of the conductor.

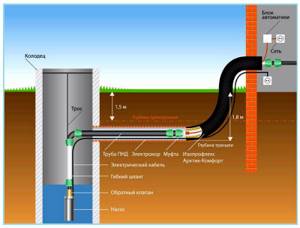

Rice. 1 Complete set of heating cable for water supply

What is and why do you need a heating cable?

The operating principle of any heating cable is quite simple and is no different from all electric heating devices. The technology is based on the resistance of materials to the passage of electric current - the higher it is, the more heat is generated on the heating element. The heating cable is connected to a 220 V alternating voltage network and generates heat when alternating electric current passes through it.

Almost all devices have manual or automatic adjustment, which allows you to change the heating temperature of their core (matrix). In everyday life, electric cable heating systems are widely known called heated floors, in which a zigzag wire in the form of a mat on a mesh is laid under a screed or tile.

A similar device with higher protection against moisture has a heating cable for external pipelines, most often used for the following domestic purposes:

Heating of water supply

When drawing water from a well or well, HDPE (low-density polyethylene) pipes are most often used, which flow from the source into the house through the foundation, and are buried underground at a distance from the surface below the freezing depth of the soil.

In accordance with building regulations, the distance from the ground surface to the point where the water supply pipe is located should be 0.5 m greater than the freezing depth, in some cases the calculated value reaches 2.5 meters. In real conditions, when using a standard caisson well 2 m high, from which a casing pipe extends half a meter, the average depth of the water pipe is 1.5 m, which is not always enough to protect it from freezing.

At the same time, the use of thermal insulation of the pipeline with building materials along the entire length may be ineffective, because the insulation does not heat the working environment, but only increases the time it freezes.

In this case, using an electric cable to heat water inside or on the surface of the pipes is guaranteed to protect the line from freezing, while it is possible to reduce the depth of the water supply underground and make the water supply unfreeze.

Rice. 2 Use of heating cable on roofs and gutters

Heating the wellhead and pipe entry into the house

When a well is located in a caisson pit, the problem of freezing of the external pipeline in the head zone, as well as the equipment and surface pumping station when using it, is relevant. If you use an electrical cable immersed at a shallow depth in a pressure pipe or in one of the sections of water supply located on the surface, the problem of freezing of pipes in a coffered chamber can be easily solved.

Not every house has a strip foundation located below ground level. For example, modern country houses made of blocks or SIP panels are placed on stilts above ground level. Therefore, open entry points of water pipes into the house require insulation, which is provided by using building materials or electrical cables.

Warming up the sewer pipe

If a water pipe can be lowered deep underground to combat freezing, the sewer pipes leaving the house should technologically be located a little closer to the surface. This is due to the fact that for normal sewerage operation it is necessary to maintain a slope depending on the diameter of the pipes. With standard dimensions of 110 mm, the pipeline level should be reduced by 20 mm per linear meter.

It is clear that if the sewer septic tank is located at a great distance, for example 50 m from the house, then the slope will be 1 meter. It should also be taken into account that the sewer pipes must enter the upper point of the septic tank, and if the entry point is located at a great depth, it will be very difficult to assemble a technically workable structure. Therefore, it is important to ensure thermal insulation of sewer pipes, and even better, heating them at the highest point at the exit from the house.

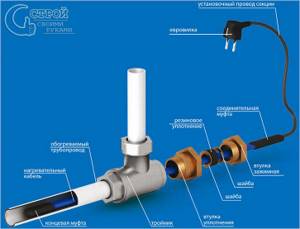

Rice. 3 Heating by connecting a cable to a water outlet

Heating with cable for storm water system

During the cold season, sudden temperature changes cause snow to melt on roofs with periodic freezing of water - as a result, drainpipes become clogged with ice, and icicles form along the perimeter of the drains. Heating cable can be used to combat freezing by laying it on surfaces or inside drainpipes, or by running it down storm drains.

It should be noted that in addition to placement in pipelines, special modifications of cables are produced designed to melt ice and snow on roofs.

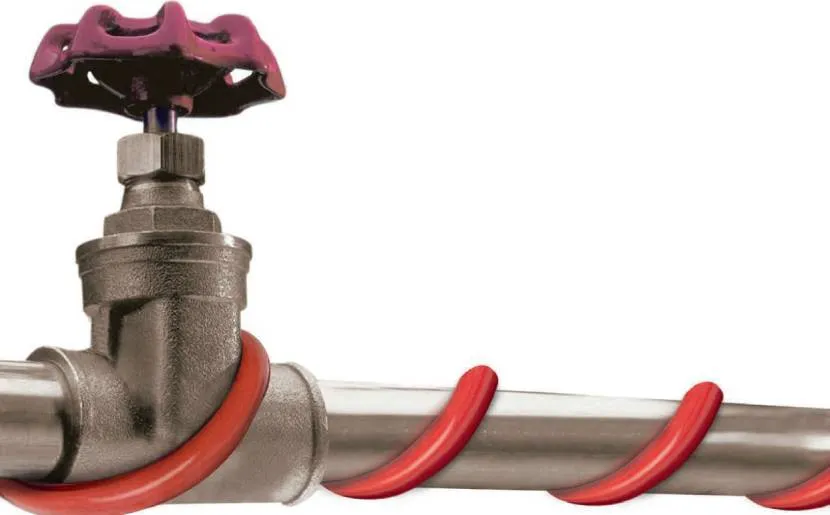

Heating of surface pipelines and fittings

When constructing coffered pits, a pipe with a shut-off valve is often installed outside to use water for household purposes in the garden; usually, in warm weather, a hose is connected to it for watering the garden. Sometimes they drill an Abyssinian well and use not a surface pumping station to collect water, but a hand pump through which they pump water using physical effort.

In all these cases, using surface water intake equipment at subzero temperatures, you can heat it with an electric cable connected to an alternating current network, which is mounted on the external surface.

Rice. 4. How to lay the cable for heating gas tanks

Cable heating of gas tanks

With an autonomous gas supply, many owners install gas cylinders outside the house, which must be kept warm for normal operation. In winter, it is convenient to heat them with a two-core electric cable used for working in pipeline systems - unlike a single-core loop for heated floors, it is much easier to install. It is known that many mobile gas tanks on trailers are equipped with a similar gas tank heating system from the manufacturer.

Ground cable heating

The technology can be used by gardeners when growing plants in greenhouses, greenhouses and underground basements in cases where external frosts can damage the crop. In this case, the heating cable protects the root system of plants from damage and warms the air in the area where it is located.

Thermal systems

When heating individual houses with liquid or gaseous fuel, you can use a warm electric cable as an additional heat source to warm up the coolant. It can be placed in a pipeline heating system and turned on at night at reduced electricity consumption rates - this will help save money and reduce the gap between cycles of filling gas tanks with gas or supplies of liquid fuel.

Similarly, you can increase the water temperature in hot water supply systems. On the construction market, modifications of heating electric cables are available for sale in environments with hot coolant.

Rice. 5 Cable heating of external shut-off valves

System advantages

A heating cable for water supply inside a pipe has many advantages for communications. If there is such a heater inside the networks, the system will be durable and reliable. In this case, water supply lines can be installed above the soil freezing level.

When choosing a quality product, the owner of a private home can count on a long service life of the system. Condensation will not form on the pipes. Therefore, their surface will not be subject to rapid destruction. The service life of a self-regulating wire reaches 40 years. At the same time, it consumes a minimal amount of electricity. It starts working only when the ambient temperature drops. If it is above +15 °C, the wire itself stops functioning. Therefore, you can forget about interruptions in the water supply system.

How does a heating cable heating system work?

Heating of pipelines with a heating cable, which is connected to a 220 V AC electrical network, is carried out using two main methods:

1. The cable is placed outside the pipe. This method is used to insulate an already laid highway or sewer pipes, while the wire fits tightly to the outer surface of the pipe. On the construction market, pipes with a ready-made channel for placing a heating cable are sold - this allows to reduce heat losses; also, to save energy, additional insulation of underground pipelines is used with a shell made of foam plastic (penoplex) or polyurethane.

The electric cable is laid along the pipeline; to increase the heating temperature along the entire length or in critical nodes, spiral winding is used.

Rice. 6 Heating diagram for well water supply

2. Heating inside the pipes. The main disadvantage of external insulation with electric cables is low efficiency - most of the heat goes into the environment and additional insulation has to be installed, which leads to higher costs of work.

Therefore, in water lines it is better to lay the heating cable inside the pipes - this applies to water mains. In the sewer system, the presence of foreign objects inside can cause a blockage.

It is not profitable to lay wires located inside pipes along the entire length - the cable is quite expensive and will increase hydraulic losses, reducing the useful cross-section of the pipeline. Therefore, it is more rational to install it in the area of the well head in front of the water supply system and pressure pipe that supplies water to the house. In this case, warm water will prevent freezing in the well, automatic devices and surface pumping station, and heated water will also flow into the water supply system leading to the house.

The main difficulty when installing an electrical cable internally in a pipeline is choosing an installation method and a sealed fitting for connecting it to the pipe when immersing the wire.

Scheme

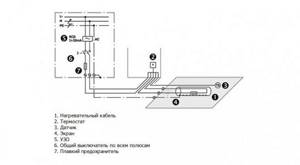

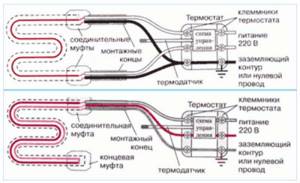

To power the cable heating system from the switchboard, a separate wire is laid, protected by its own circuit breaker and RCD. It is connected to the temperature control unit of the system. On the other hand, a heating cable is connected to it. The thermostat is equipped with a temperature sensor.

Heating cable connection diagram

All contacts of the thermostatic unit usually have symbols. Otherwise, their purpose is specified in the instructions.

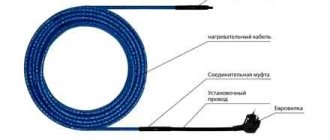

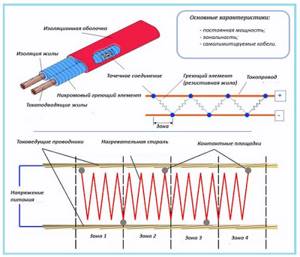

Heating cable device

All types of electrical cables have a device, the main components of which are:

- Lead wires and plug. The heating element is connected to a power cable that comes from the house, therefore, to supply electricity to it, the working core is connected to the electrical cable using special methods that ensure reliable sealing of the joint.

- A heating element. In a device with a resistive principle of operation, heating is produced due to the high resistance of the core passing inside; in self-regulating modifications, the temperature rises near the plastic matrix located between two current-carrying conductors.

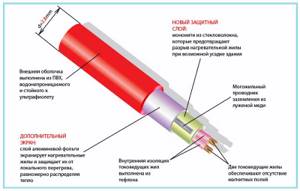

- Insulation. Protecting exposed electrical wires from the aquatic environment in which the electrical cable is located is the main task in its manufacture, therefore all devices have at least two layers of internal insulation. Also, in its manufacture, to reduce heat losses, they strive to use synthetic materials with the best thermal conductivity. It should be noted that there are two main options for insulation: for placement inside and outside the water supply; in the first case, food-grade outer plastic is used.

Rice. 8 Zone-resistive cable for roofs - design

- Shield and ground wire. Braided shielding is used in all high-quality cable products; it not only performs protective functions against interference, but also additionally increases the safety of cable use by solving the problems of a grounding wire. The fact is that when connecting, the shielding braid is grounded or connected to the neutral wire, and if the cable is damaged, the current-carrying conductors are likely to come into contact with the screen and the machine will turn off the power supply.

- Thermal sensor. If heating cables did not have feedback that allows them to regulate the current passing through them and, accordingly, the heating temperature depending on the state of the environment in which they are immersed, their operation would become ineffective and lead to increased energy consumption. In addition, the physical parameters of the heated water-containing medium would go beyond acceptable standards - all this would lead to the impossibility of using the cable for its intended purpose. Therefore, all heating cables are equipped with sensors that allow the current to be automatically changed depending on the temperature of the environment at their location; in self-regulating modifications, the temperature change is associated with the conductivity of the interconductor matrix.

Rice. 9 Resistive two-core heaters for pipes - device

Resistive heating cable

Resistive cables are manufactured in single-core and two-core versions; the first type must be connected at two points and is widely used in modifications for heated floors, where the wire forms a winding zigzag heating circuit and returns back to the starting point.

This option is too inconvenient to be placed on pipelines, so pipe heating systems use a two-core design, that is, the heating circuit passes and returns inside the wire.

The heating core of a resistive cable must have high resistance to electric current, so it is made of a chromium-nickel alloy that has the necessary characteristics. The connection of the supply wires with the braid and the heating core is carried out in a closed sealed coupling; the powered conductors are connected to an automatic control unit, from which a two-wire temperature sensor extends.

Distinctive features of resistor heaters:

- Slightly lower cost compared to its main competitors - self-regulating electrical cables.

- A resistive cable is supplied with the thermostat; the system is designed to work only with this product, which has a calculated resistance to electric current - the wire cannot be cut, lengthened or shortened.

- During installation, it is necessary to have a temperature sensor, which should be located in the area where the cable is located - this complicates its external installation and makes it impossible to use inside pipelines due to the interfering head of the temperature sensor.

- If the wire is damaged or broken at any point, it must be completely replaced. The exception is specially designed resistive heating cables for deicing roofs and gutters. In their design, current-carrying conductors are connected by a heating coil running inside at many points, so the heater can be lengthened or shortened at the user’s request.

- The minimum power of most resistive devices is 10 W per linear meter (you can find modifications with a power of 8 W); the maximum value can reach 60 W in zone-resistive modifications to combat roof icing.

Fig. 10 Self-regulating heating cable - operating principle

Self-regulating heating cable

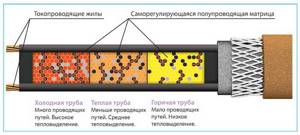

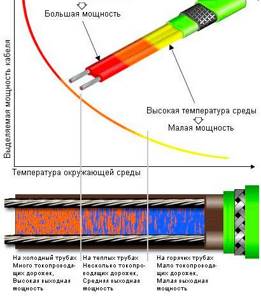

Currently, self-regulating heating cables have practically replaced resistive competitors in the field of pipe heating due to their simple design and ease of connection. Structurally, the cable is made in the form of two conductive cores, between which a temperature-dependent matrix containing finely dispersed graphite powder is placed.

In a cold state, an electric current passes through micrographite contacts from one wire to another, heating the surface of the matrix, and accordingly the wire warms up the environment. As the outside temperature increases, the heating of the matrix increases even more, its material increases in volume as a result of thermal expansion - this leads to an increase in the distance between the conductive graphite grains. The resistance of the electrical circuit increases, the current and heating power drop, the cable cools - thus self-regulation of temperature occurs.

Self-regulating heating cable has the following features:

- Versatility. Self-regulating cables can be used to heat pipelines inside and outside, roofs and storm drains, in heating system pipes and on various tanks.

- Economical. Unlike a resistive cable, a self-regulating cable heats up most at the point with the lowest temperature, while current consumption is minimal in warm areas.

- Ease of installation. The cable consists of two parallel sections of wire with a heating matrix between them; when installing self-regulating heaters, they can be shortened or extended by a significant distance.

Rice. 11 Self-regulating cable device

Types of heating wire with characteristics

Heating cable for water supply.

Heating wires convert electrical energy into heat due to high internal resistance. These are flexible products that can be laid on surfaces of any configuration. The wire has at least 2 layers of reliable insulation that protects from harmful external influences. The design may include a foil screen or copper braid that prevents short circuits and neutralizes the magnetic field.

There are 2 types of heating wires produced - resistive and self-regulating. The action of the former is based on the ability of metals to heat up when electricity passes through them. In self-regulating designs, heat is generated by a special matrix, and the conductors remain cold.

The main characteristic of all heating cables is the electrical power they consume per 1 linear meter. m. To place a heating product inside the pipeline, 10 W/m is enough. Outdoor installation requires an increase in power density of 20 W/m and more.

When choosing a heating wire, other characteristics are taken into account, including:

- Maximum permissible line length including branches. The parameters are directly influenced by the thickness, resistivity of the conductor, and the number of cores. If the permissible length is exceeded, the entire heating system may fail.

- Limit operating temperature - characterizes the ability of the product to maintain it for a long time. 3 lines are produced, each of which is designed for operation in appropriate conditions.

- Maximum permissible temperature when switched off.

Heating cables are available in round and flat sections. The latter are more suitable for outdoor placement. Sold complete with a wire for connecting to the working part. To save energy consumption, a temperature sensor with automatic control is used. Self-regulating options are used with a compact thermostat, which is installed on the supply wiring.

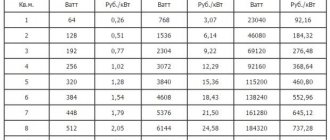

Heating cable power for water supply

It is quite difficult for a user even with an engineering education to determine exactly how much power is required for the effective operation of a resistive or self-regulating heating cable - the calculation formulas are too cumbersome and the calculation takes a long time. The task is only possible for qualified specialists, and its solution in everyday life is carried out by manufacturers and distributors of heating electrical cable products.

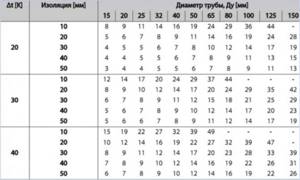

It has been experimentally established that for heating pipelines, an electric cable with a power of 10 W per linear meter is sufficient when using a 50 mm shell made of foam plastic or penoplex insulation and a pipe diameter of no more than 50 mm; the ambient temperature should not fall below -30º C.

For household water pipes made of HDPE with a standard diameter of one or one and a half inches, the optimal thickness of the insulation shell is 30 mm; when using sewerage, you will need a higher power cable of about 20 W per meter or spiral winding, with an insulation thickness of 50 mm.

For external heating, the power of the heating cable is linearly related to the ambient temperature and the state of the heated elements; for pipelines, its average value is about 20 W per linear meter; on roofs and in drainpipes, powerful resistive electric cables of up to 60 W per linear meter are used.

Rice. 12 Connection diagram for heating cable of single-core and double-core design

With or without thermostat?

If you want to pay a pittance for heating the water supply, it is better to install a thermostat. Even if you are planning to install a self-regulating heating cable. Basically, the characteristics are as follows: switches on at +3°C, switches off at +13°C.

If your water is supplied from a well, it will never have a temperature of +13°C. It turns out that the heating will work all the time, even in spring and summer. In the summer, of course, the cable can be turned off, but in the spring and autumn this cannot be done due to the possibility of sudden frost. With wells it is somewhat simpler, but not much - in summer the water there can have a temperature slightly above the shutdown threshold. But this is in the summer, and during the hottest period. And in general, why do you need to heat, say, the water that goes into the drain tank? And you will still heat the one that goes to the kitchen or shower with boilers or instantaneous water heaters.

In any case, it turns out that a thermostat is needed. On it you set the shutdown temperature to around +5°C. The costs of heating the pipeline fall significantly. At the same time, the service life of heating cables increases significantly - they have a certain service life of working hours. The less they work, the longer they will serve you.

Heating cable for water supply - connection diagram to the thermostat

When installing a water heating system with a thermostat, you will also need to install a temperature sensor. There is a difficulty here. It must be placed on the pipe so that it is not affected by the temperature from the heaters. That is, it does not need to be thermally insulated from the pipe, but it is necessary from the cables.

It is advisable to install the thermostat itself indoors. It is connected to the house electrical panel through a circuit breaker and, preferably, an RCD. The power consumption of the heating cable is small, so the rating of the machine can be about 6A, the rating of the RCD, choose the nearest larger one, otherwise the leakage is preferably 30 mA.

Connect the heating cable for the water supply to the corresponding connectors on the thermostat housing. If there are several branches, they are paralleled. A temperature sensor is connected to adjacent contacts. Each thermostat has markings that make it clear what needs to be connected and where. If there is no marking, it is better to buy another one: the performance of this copy is very doubtful.

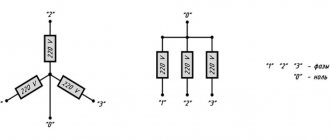

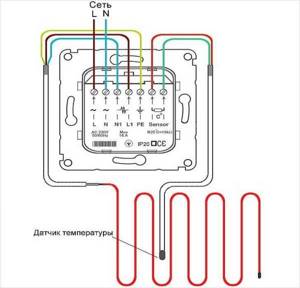

Diagram and connection to the heating cable network

Any heating cable is connected to a temperature control unit, on which the contacts for connecting the temperature sensor, heater and external electrical network are marked; if there are no markings on the case, you can always use the connection instructions.

The procedure for connecting a cable to a box is not particularly difficult; the task is made easier by knowing the color markings: the blue and brown wires are connected to the electrical network, the yellow-green wire is connected to the neutral or ground bus.

Attractive idea and practical disadvantages

A sink with a bedside table combines the functionality of two devices. There is space saving, which is relevant for a small bathroom. Additionally you receive:

- Space on the countertop for accessories.

- Accessible, splash-proof storage for detergents and equipment.

- The aesthetic effect of hiding the drain pipe and supply wiring.

An original hand-made cabinet for a ceramic sink in a home bathroom will bring ideas to life and, if desired, save the family wallet.

The rosy impressions will be spoiled by:

- Difficulty in inspecting the siphon and hoses.

- Possibility of moisture getting inside the cabinet.

- Loss of appearance, breakage, reduced service life due to non-moisture resistant components.

To make a do-it-yourself bedside table for a standard sink in your bathroom, you will need:

- Ability to present an idea on paper or draw it in a 3D program on a computer.

- Carpentry skills, accuracy.

- Various accessories, hand and electric tools.

Branded bath furniture is designed taking into account the operating conditions. When starting creative work, evaluate the feasibility by comparing costs and characteristics.

Basic methods and types of laying

When deciding how to properly lay a cable in a pipeline, they take into account its purpose, location, presence of additional insulation, and heater power. When laying, linear and spiral installation is used, and the cable is placed inside or on external sections of the water supply system. The main condition for installation is the prohibition of the use of metal materials and polymer adhesive tapes for fastening the cable, and its intersection with contacting surfaces is also unacceptable.

Rice. 13 Linear installation and connection of the heating cable

Linear installation on underground pipelines

When deciding how to connect a heating cable for a water supply system, they often choose linear installation, which refers to the main types of connecting the heater to the pipeline, in which the wire is placed on the surface and secured with adhesive tape.

A significant disadvantage of the method is that plastic pipes have low thermal conductivity and simply placing the cable on their shell does not always provide the necessary heating.

Higher heat transfer can be achieved by using special pipes with a channel recessed inside - the electrical cable located in it releases much more thermal energy. During installation, adhesive tape made of aluminum foil is used; the process of installing the heater on an underground pipeline consists of the following operations:

- For linear installation, the cable is placed on the bottom side of the pipeline; for this, a strip of aluminum foil is glued along the entire length - this is necessary to increase heat transfer to polymer pipes, which have low thermal conductivity.

- Wrap the cable with transverse sections of tape in increments of 300 mm, trying to achieve good tension and a tight fit without gaps.

- An aluminum tape is glued on top along the entire length of the cable, ensuring its tight contact with the surface of the pipeline; if there is a temperature sensor, its wire and measuring element are connected separately with transverse ties.

- Then the cable along its entire length is additionally secured with nylon ties (fastening is done in the absence of tight-fitting outer insulation) - this will prevent it from peeling if the aluminum tape loses its adhesive properties due to high temperature or aging during operation.

- Upon completion of the work, put a heat insulator on the pipeline and fix it with glue or ties. If two or more conductors are used, they are fastened in a similar way from below at some distance from each other.

Laying methods

When heating any pipeline, a self-regulating cable for heating pipes can be placed either inside or outside. Moreover, none of the options is difficult to install. And for external use there are even two methods.

Linear

The simplest and most convenient method is in which the cable is pulled along the pipeline, tightly adjacent to it. You just need to protect the wire from possible mechanical damage. To do this, it is placed at the bottom of the pipe, and aluminum tape is used to securely fasten it.

Spiral laid heating cable Source gizbar.com

Spiral

With this method, the wire is wound around the pipe in a spiral. And the density of turns can increase the heating effect. Moreover, it is possible to carry out winding either completely close to the communication or with a slight sag. And to secure the conductor, the same aluminum tape is used.

Interior

If there is no access to the external sides of the communications, then a self-regulating cable for heating the pipes is placed inside the system. To do this, a special tee is cut into the highway in the right place. And wires are laid through it. Upon completion of the operation, the connection is carefully sealed.

Connecting the heating cable to the network and controlling the temperature

On the market you can most often find modifications of cable heaters complete with thermostats, while the length of the cable, which is connected to the heating elements through special sealed couplings, does not exceed 3 - 5 meters.

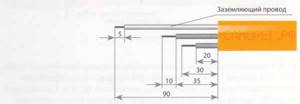

When heating pipelines, the thermostat is installed in a convenient place, protected from harmful environmental factors, as far away as possible (a residential building), and there is a need for a hermetically sealed connection between a short cable and a long wire coming from the house. To do this, use a household hair dryer, special couplings and clamps, installation work is carried out as follows:

- The conductors of the connected cables are cut at different distances (with a ladder) and removed from insulation to a length of 10 mm.

- Heat-shrinkable sleeves are placed on each conductor, and a common large-diameter sleeve is placed on top of the cable.

- Insert the ends of the wires into the sleeves and clamp them on one side with pliers; after inserting the other ends, the sleeve is crimped on the other side.

- Internal couplings of small diameter are pulled onto the wires and heated with a hairdryer; after compression, an outer coupling is placed at the junction and also heated with a hairdryer.

- In self-regulating cables, it is necessary to seal the two end wires; to do this, they are cut with a ladder, a special heat-shrinkable sleeve with a closed end is put on top and heated with a hairdryer.

To control the heating temperature, a thermostatic regulator is used, which is placed in a convenient place near the electrical panel; to increase safety, automatic RCD circuit breakers are installed in its circuit, which open the circuit when a short circuit occurs in the line.

Rice. 19 Thermostats to which the heating cable is connected

Thermostats and sensors for heating cables

Thermostats allow you to reduce energy costs several times when using cable heaters; with their help, you can set the temperature limits for switching on and off depending on the application.

Manufactured thermostats, depending on their purpose, are divided into several groups:

- for heated floors,

- de-icing on roofs,

- for heating water supply and sewerage,

- maintaining heat in hot water pipelines.

The main difference between all types of thermostats is the temperature thresholds for operation; when used in wells, the switch-on temperature is set within +2 - +3 degrees, the switch-off temperature is +10 C; to save energy, the threshold values can be lowered. Thermal sensors with response thresholds from -15 to +5 C are installed in external systems to combat roof icing.

Thermostats are made in the form of manual or touch devices; when using several wired heating systems, multi-channel devices are installed, the temperature threshold of which varies within a wide range.

Industrially produced thermal sensors with two wires and a tube at the end differ in their operating principle; the most popular are resistive and semiconductor types. The operating principle of the former is based on a change in the electrical resistance of the resistor depending on temperature; in semiconductor devices, when the temperature conditions change, the characteristics of the pn junction change.

In both cases, the electric current passing through the resistor or semiconductor changes its value with temperature, and the electrical signal from the sensor controls the operation of the electronic circuit that supplies power to the heating cable.

It should be noted that modern semiconductor devices operate in a wide linear temperature range from -55 to +150 C, have a high measurement accuracy of about 2% and a response to temperature changes of 0.125 C.

Rice. 20 Connecting a heating cable and subsequent methods of thermal insulation of the pipe

Thermal insulation of heating cables

When laying outside, thermal insulation must be used - it prevents heat from escaping from the cable into the environment, thereby increasing the heating efficiency. When immersed in the ground, hard types of waterproof insulating shells made of polystyrene foam, penoplex or polyurethane foam are used.

When laying pipelines externally, there is no earth pressure on their insulation; you can install a heated sewer entrance to a house using soft materials - polyethylene foam, all types of mineral wool, glass wool. It should also be taken into account that the thickness of the protective shell of the insulation for external installation should be greater than the underground version.

Coupling installation

What materials will you need?

- self-regulating shielded cable

- plug with wire and grounding pin

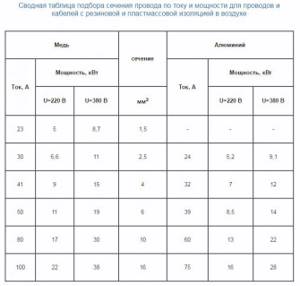

The wire must be three-core, copper. The cross-section is selected depending on the current load (cable power).

Mistake #1

Moreover, according to the instructions, it cannot be less than 1.5mm2.

Even if you have a very short section of low-power cable.

- wire stripper

- crimper for crimping sleeves

- coupling set

It is important to note that heat shrink tubing comes with and without adhesive.

Mistake #2

Do not use thin-walled tubing without adhesive.

They will simply insulate the connection, but will not create the required tightness. It is also desirable that the tube be of mid-wall thickness.

Thin walls are very easily damaged by external influences.

- construction hair dryer

- stationery knife

What to look for when choosing a heating cable

When choosing a heating cable for pipes, the following factors are taken into account:

- Operating principle. The disadvantage of resistive cables is their uniform heating temperature along the entire length. In order to save energy, it is better to use a self-regulating cable on underground pipes. In addition, its design, in the absence of a remote sensor, is convenient for placement inside pipelines, and the minimum power of the device is 10 W. per linear meter is sufficient for its linear placement underground in a heat-insulating shell.

- Power. For external heating, devices with high power are used; the best performance is achieved by linear cable modifications with a spiral winding of the heating wire inside.

- Insulation. When installed internally in water pipes, devices with insulation made of food-grade plastic should be used; it is better to choose modifications with a copper screen - the presence of the element reduces interference and protects the user from electric shock if damaged. Also, a braid of tinned copper wires promotes more intense heat removal from heating cores or matrices.

- Manufacturer. The market offers a wide range of models of heating cables from various manufacturers; among foreign suppliers, the products of Raychem, Nelson, Lavita, Ensto, Devi are well known; a wide range of cable heating products from a domestic manufacturer - a company from the Moscow region - is sold on the construction market. Special systems and technologies SST .

Rice. 21 Table of dependence of heater power on pipe diameter and insulation thickness

The use of a heating cable for sewerage and water supply is the most effective method of combating icing, because any thermal insulation does not heat the pipeline, but only increases the time it freezes. Self-regulating cables, which have recently appeared on the construction market, are slightly more expensive and more efficient compared to resistive devices; they are the best option when lowering into water supply.

Briefly about the main thing

First of all, it is important to choose the right cable for heating pipelines.

There are self-regulating and resistive types of cable that are used for plumbing. When choosing a cable, pay attention to the number of cores, type of cross-section, heat resistance, length, presence of braid and other characteristics.

For plumbing, a two-core or zone wire is usually used.

Of the methods for installing the wire, it is better to give preference to the external one. The cable should be secured inside the pipe only if it is not possible to install it from the outside. In general, internal and external installation technologies are practically the same, but the second method minimizes the risk of blockages and also increases the service life of the wiring.

Read later

We will send the material by email

Location inside the pipe

Layout inside the pipe

This method of placing a heating cable is quite effective. The conductor is in direct contact with the liquid and in case of freezing there will be no need to first heat the pipe, which will subsequently melt the ice. Knowing the components of the cable, you can proceed to practical actions:

- Decide where your thermostat will be mounted. It’s better to start with it, this will simplify further measurements. To install it, a special box with a Din-rail is used. Supply power to it. If you are laying several meters of a heating element, then a cable with a cross-section of 0.5 mm2 will be sufficient for the wiring. If you plan to lay large volumes, then make calculations based on the fact that for every 2 kW it will be necessary to increase the cross-section of the supply cable by 1 mm2.

- Cut the required length of cable.

- Carefully cut through the top layer of insulation. Do not overdo it to avoid snagging the grounding braid. To determine which part of it needs to be removed, measure the distance you need to connect the conductive wires to the thermostat.

- Assemble the braid into one core, put an insulating cambric on it or wrap it with electrical tape, and secure the copper tip.

- Remove the inner layer of insulation.

- Separate the conductors, insulate each and attach connecting lugs.

- Now you need to insulate the end that will be placed in the pipe. Make a straight cut. And remove approximately 10mm of insulation.

- Cut off the shielding core.

- To prevent the cable from shorting, make one conductor 5 mm shorter than the other.

- Place the heat shrink tubing, but make sure it does not overlap the outer layer of insulation. Warm it up with a hairdryer.

- Install the plastic or rubber tip that comes with the kit.

- Place a piece of heat-shrinkable tubing that is larger in diameter on top of the tip and heat it with a hairdryer.

- Now pass the cable through the tee and place it inside the pipe; use a set of fittings to fix it.

- Connect the cable to the thermostat and enjoy the results.

The first 6 steps will be repeated for any type of installation.

Example 2: Underfloor heating

Calculation of cable heating

General floor heating scheme

In addition to protecting pipes from frost, heating cables are also used to install floor heating systems. Unlike film heated floors, the cable is convenient primarily because its laying density can be adjusted.

The efficiency of floor heating with a cable laid in a screed is ensured by its correct layout. In this case, it is necessary to focus on the power consumption of the room:

| Room | Required specific power for heating, W/m2 |

| Open area | 180 and above |

| Balcony/loggia | 140 |

| Bedroom | 120 |

| Children's | 120 |

| Living room | 100 |

| Kitchen | 100 |

| Hallway | 100 |

| Bathroom | 130 |

When calculating a warm floor, please note that heating cables are laid only in areas free of furniture. Conductors located under a heavy headset may suffer from either pressure or overheating due to poor heat dissipation. Well, heating the bottom of the cabinet or kitchen cabinets at your own expense is also not a good idea.

Example of power of different models of heating wires

We carry out the calculations as follows:

The optimal step value is from 6 to 15 cm. In this case, the heating is both intense and fairly uniform (we do not feel the difference between the temperature of different areas of the floor).

If the cable is laid too infrequently, the temperature difference will be significant - this is noticeable in the photograph taken by the TV

If according to calculations the step is more than 15 cm, then you can go in two ways:

Thick screed allows for more even heat distribution

READ How to connect an electronic speedometer to a classic

When using mats, everything is quite simple: we simply select products with suitable power density. Considering that the market mainly offers 120–160 W/m2 models, there should be no problem.

Cable heated floor installation technology

If you have calculated everything, then all we have to do is figure out how to properly install the floor itself.

| Illustration | Cable heating installation technology | ||

| Preparing mounting holes. We make a hole in the wall to install the distribution box and thermostat. We cut a groove in the floor for installing a temperature sensor. | Connecting wires. We install a socket box into the hole, through which we insert the wire from the panel. It is from this that the cable heated floor will be powered. | ||

| Primer of floors. The floor on which the heating cable will be laid is cleared of debris and treated with a penetrating primer. If the coating has significant unevenness, leveling with a screed may be required. | Laying thermal insulation. If the heated floor is not laid under glue or screed, but under another floor covering, then it is advisable to lay an additional thermal insulation layer. Rolls of foil material are laid end-to-end and sealed with tape. | Layout of heating mats. When using mats with a cable attached to a polymer mesh, lay the products on the floor. When making a turn, carefully cut the mesh, trying not to damage the cable. | Attaching mounting plates. When using cables not secured to mats, install steel mounting plates on the floor. We fix them to the base with anchors with plastic sleeves. |

| Laying cable from a coil. We lay the cable with the pitch that we determined during the calculations. To fix it, we press the cable with the protrusions of the mounting plates. | |||

| Laying the temperature sensor. We insert the temperature sensor into a corrugated pipe, close it with a plug and place it in a groove in the floor. We seal the groove with mortar. We connect the wire from the sensor to the thermostat. | Connecting the thermostat. We connect the wires from the temperature sensor, heating cable and power cable to the thermostat terminal block. When connecting, we focus on the terminal block markings - it is important not to confuse the zero and phase from each wire. | ||

| System check. We install the thermostat in the socket and apply voltage. We check the functionality of the entire system: the cable should heat up evenly and quickly enough. We carry out the check in one or two minutes to prevent overheating. | Laying the adhesive mixture. Apply about 5-10 cm of tile adhesive mixture on top of the cable mats. We level the mixture with a spatula and a notched grater, forming furrows without touching the conductors. We lay the glue without gaps, which can lead to poor heating of the floor covering due to the low thermal conductivity of the air. | Floor covering. Lay the tiles on the adhesive mixture. We try to ensure that the entire surface of the cladding is in contact with the glue - this way the heat transfer will be more efficient. |

Connection diagrams for different types of heaters to the thermostat

Tips and tricks

Be careful when laying. This will make it possible to avoid some problems.

Do not twist the wires together. A short circuit will occur.

The black polymer surrounding the current-carrying conductors must be insulated. It conducts current, so it is considered a conductor and must be treated as such.

The electrical connections of the entire system must be well insulated to prevent sparking and also to prevent fire.

Any electrical connection for the heating cable must be properly protected from moisture.

Do not use it if its heating temperature reaches the maximum value. This leads to a decrease in its service life.

If the cord is damaged, it must be replaced with a new one. Even stopping the operation of any element will make the entire system inactive.

For explosive environments, it is necessary to install only a specialized cable with special components. Similar conditions include some industries:

- Chemical.

- Petrochemical.

- Coal.

Special cables are installed for them, approved for use in this area.

If inappropriate equipment is installed, an explosion or severe fire may occur.

Similar articles:

Why is it necessary to use cable heaters?

Many extended structures located outside are susceptible to ice formation, followed by an emergency:

- roof eaves . Ice and icicles spoil the roofing, and if they fall, they are dangerous for people below;

- drainage system . Icing causes deformation or breakage of gutters, and moisture drainage is also impaired;

- porch, walking paths . Become slippery, which leads to injury to people;

- water supply, sewerage, other pipelines, tanks. An ice plug clogs the line, and if there is severe icing, the structure collapses (water expands when it freezes).

There are several types of heaters.

Unregulated

It is often also called resistive, but this is incorrect: all heating cables are resistive. Unregulated is the simplest type. The cores are made of a high-resistance alloy, such as nichrome. Accordingly, its heat generation power is always constant. The advantage is low cost.

- if the heat dissipation is disrupted (cores overlap or a section of the heater is covered with something) or if the temperature rises, the cable burns out;

- it cannot be shortened: this will lead to a decrease in resistance and, accordingly, an increase in current strength in excess of the calculated one;

- A thermostat or human intervention is required to turn it on and off.

Unregulated are divided into two types:

- 1-wire . They have serious shortcomings. Firstly, they are a source of electromagnetic fields and therefore are not suitable for “warm floors”, paths, porches and other objects with which people come into contact. Secondly, they are connected from both ends, because the additional heater circuit is connected from one end, and the magnetic fields generated by the cores are mutually destroyed due to the multidirectionality of the currents.

Unregulated zonal

Consists of 2 conductive cores with many heating wires between them. Unlike the previous one, it can be cut: since the wires are parallel-connected conductors, as their number decreases, the resistance increases.

Self-regulating

It also includes two conductive cores, but the resistive element between them is a semiconductor matrix. Its peculiarity is a much more pronounced dependence of resistance on temperature than that of metals. The higher the matrix temperature, the greater the resistance.

Advantages:

- overheating is not possible. Heated areas stop passing current, that is, they actually turn off;

- efficiency. When heated, the cable reduces heat production or turns off completely, even if there was no command from the thermostat to do so. Moreover, each section works with the heat transfer that is required in a given place;

- ability to cut the heater.

The disadvantage is the high cost.

Do-it-yourself instructions for sealing

The instructions use the KTU kit

Equipment and tools:

- Air heat gun (hair dryer);

1. Installation of connecting and end couplings of the heating (heating) cable.

1.1. Installation of the coupling

1.1.1. Cut and remove the sheath from the heating cable (see Fig. 1).

1.1.2. Unravel the shielding braid and twist it into a “bundle”. Cut with a knife and remove the insulation from the heating cores, leaving 30 mm (see Fig. 2).

Figure 21.1.3. Cut with a knife and remove the semiconducting matrix. Shorten one core by 15 mm. Place heat-shrinkable tubes T2 3.0/1.5 onto the stripped cores and heat-shrink them using an air heat gun with hot air (see Fig. 3). Shrinkage temperature 200°C.

1.1.4. Strip the installation wire PVA 3×1.5 according to Fig. 4.

1.1.5. Place heat-shrinkable tubes T-2 6.0/3.0 30 mm long onto the core (length 45 mm) of the heating tape insulated with a heat-shrinkable tube and the insulated core (length 45 mm) of the installation wire. Place a heat-shrinkable tube CFM 19/6 100 mm long onto the heating tape, and a heat-shrinkable tube CFM 19/6 140 mm long onto the installation wire.

1.1.6. Insert the strands of the installation wire and heating tape into the copper tubes M 4×0.75×10 (see Fig. 5). Crimp using a hand crimper (see Fig. 6).

1.1.7. Push heat-shrinkable tubes T2 6.0/3.0, 30 mm long, over the connection points of the cores and heat-shrink them using an air heat gun with hot air (see Fig. 7). Shrinkage temperature 200°C.

1.1.8. Slide a 100 mm long heat-shrinkable tube CFM 19/6 over the resulting connection (lead the grounding wire and shielding braid outside the heat-shrinkable tube, as shown in Fig. 8). Heat shrink it using an air heat gun with hot air. Shrinkage temperature 250°C. Connect the grounding wire to the shielding braid using a copper tube M 5 × 0.5 × 5 and crimp it with a hand crimper.

1.1.9. Slide a 140 mm long heat-shrinkable tube CFM 19/6 onto the resulting connection and heat-shrink it using an air heat gun with hot air. Shrinkage temperature 250°C. The final view of the coupling is shown in Fig. 9.

1.2. Installation of the heating cable end sleeve. 1.2.1. Cut and remove the sheath from the end of the heating cable (see Fig. 10).

1 2.2. Trim the shielding braid, leaving no more than 5 mm (see Fig. 11).

1.2.3. Cut the end of the tape with a step and put on a heat-shrinkable tube CFM 10/3 30 mm long (see Fig. 12).

1.2.4. Heat shrink the CFM 10/3 heat-shrinkable tube using an air heat gun with hot air and immediately crimp the free end of the tube with pliers (see Fig. 13). Shrinkage temperature 250°C.

1.2.5. Place the 80 mm long heat-shrinkable tube CFM 19/6 over the outer sheath of the cable (see Fig. 14). Heat shrink it using an air heat gun with hot air and immediately crimp the free end of the tube with pliers (see Fig. 15).