Gas is supplied to the end consumer in apartments and houses through a distribution network. Transportation is carried out through pipes for which certain GOST standards are established. The same standards establish the service life of gas pipes in residential buildings for their various types.

After the expiration of the operating period specified by the manufacturer, the gas pipeline must be completely replaced. This should be monitored by specialized control services, however, it would also be useful for consumers to know how long the pipes should be used, how to determine the degree of their wear and the need for replacement.

What does service life mean?

Service life is the calendar duration of the period of use of mains and gas pipeline branches connected to them from the beginning of commissioning of the system or after its repair until transition to the limit state. It is determined by the manufacturer of gas pipes, as indicated in the certificate.

There is no universal service life limit as such. In each specific case, it is determined individually, since one gas pipeline is operated in favorable conditions, while the other is deformed and destroyed much faster due to the influence of external factors.

Types of pipeline

Several types of metal products are used in heating and water supply systems:

- black steel pipes - steel of different grades is used in production, but it is not corrosion resistant. Such rolled metal products require additional protection - painting, for example;

- galvanized steel pipes - products are coated with a layer of zinc. The latter forms a galvanic couple with iron and is destroyed by an electrochemical reaction, protecting the steel from corrosion. Obviously, the service life according to SNiP and GOST for such a model is much longer;

- stainless steel – alloys with the addition of nickel and chromium. Depending on the size of the alloying additive, steel can be resistant to corrosion under normal conditions, is characterized by increased resistance, which allows use in sea water, for example, and also does not oxidize under the influence of not only moisture, but also high temperature. The product does not need protection, however, its cost is noticeably higher;

- copper - rare, but used in domestic conditions. They are distinguished not only by their resistance to corrosion, but also by their disinfecting properties.

Each option from the list can be used for water supply, gas pipelines, heating, and not only water, but also steam. However, their service life will vary.

Regulatory framework: what does the Law say?

According to Order No. 558 dated November 21, 2013, which regulates safety rules when handling liquefied gas.

Technical inspection of an underground gas pipeline is carried out after the expiration of the estimated service life, which is for:

- steel pipes – 40 years;

- polyethylene pipes – 50 years.

Pipelines assembled from polymer pipes last longer due to higher resistance to mechanical and chemical influences, as well as the absence of prerequisites for the appearance and spread of mold.

In this case, during such diagnostics the following parameters should be checked:

- gas pipeline tightness;

- protective coating (for steel pipes);

- the condition of the material from which the gas pipeline is made;

- quality of welding at joints.

Early inspections are carried out only in case of accidents or receipt of reliable information about the deformation of gas pipelines underground.

Surveys are still carried out in accordance with the instructions from RD 204 of the RSFSR 3.3-87, approved back in 1987. The provisions contained in the Decree of the Government of the Russian Federation of October 29, 2010 N 870, contain rather vague wording regarding this issue.

Thus, paragraph 76 states that the operational life is determined at the time of design, taking into account the conditions for ensuring the safety of objects, the forecast regarding changes in their parameters, as well as the guarantees for pipe products provided by the manufacturer.

In addition, this act states that the gas pipeline can be operated even after the expiration of its service life, if diagnostics did not reveal any serious malfunctions in the operation of the system or defects in the pipes. Based on the results of such diagnostics, the service life limits should be re-established.

As for external gas pipelines and equipment, as a rule, their service life is shorter. In any case, you should always pay attention to their working “experience”, which is indicated by the manufacturer.

For example, the manufacturer “Gazovik” for GRPSh-6, 10 and 10MS defines the following terms:

- average (before write-off) – 15 years;

- warranty period – 5 years.

But “First Gas Company” in the passports for most of its gas distribution plants indicates a 20-year period, which, by the way, is the average for gas turbine installations.

ASSESSMENT OF THE TECHNICAL CONDITION OF EXTERNAL (OVERGROUND) AND INTERNAL GAS PIPELINES

4.1. Density assessment of overhead and internal gas pipelines

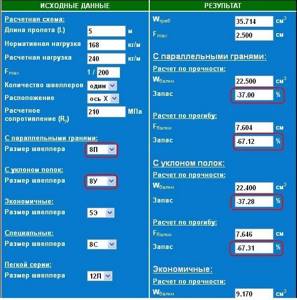

4.1.1. The density of gas pipelines is assessed based on statistical information about the technical condition of the gas pipeline from the start of operation in accordance with Table. 1.

If the length of the inspected section of the gas pipeline is less than 1 km, the score (in points) is determined by reducing the number of leak cases to a length equal to 1 km.

For example, the length of the inspected section of the gas pipeline is 400 m, one leak was detected on it, therefore, the number of leaks normalized to a length of 1 km would be 2.5. This value in the table. 1 corresponds to a score of 1 point.

Table 1

| Cases of gas leaks associated with damage from rupture of a gas pipeline or welded joints that have occurred since the beginning of operation on each kilometer of the gas pipeline inspected | Rating, points |

| More than 2 | 1 |

| 2 | 2 |

| 1 | 3 |

| 5 |

4.2. Pipe metal condition assessment

When measuring the thickness of the walls of a gas pipeline, pulse resonant thickness gauges should be used, which allow determining the thickness with one-sided access. For this purpose, thickness gauges “Kvarts-6”, “Kvarts-14”, “UIT-T10” can be recommended.

If unsatisfactory results of wall thickness measurements are obtained from at least one measurement, the scope of control is increased at least twice and is established by the technical manager of the power facility. If three or more unsatisfactory results of wall thickness measurements are obtained on the section of the gas pipeline being tested, the entire section of the gas pipeline must be replaced.

The condition of the pipe metal is assessed on the basis of data obtained from direct measurement of the pipe wall thickness in accordance with Table. 2.

table 2

| Thinning of the gas pipeline wall from the passport (design) value, % | Rating, points |

| More than 20 (at least three dimensions) | 1 |

| More than 20 (less than three dimensions) | 2 |

| Less than 20 (all measurements) | 3 |

| Less than 10 (all measurements) | 5 |

Gas pipelines that receive a score of one point based on the condition of the pipe metal, regardless of the total points received according to other criteria, are subject to replacement.

4.3. Assessment of the condition of welded joints

Checking the quality of welded joints must be carried out in accordance with the requirements of the “Standard instructions for monitoring and extending the service life of the metal of the main elements of boilers, turbines and pipelines of thermal power plants: RD 34.17.421-92” (M.: SPO ORGRES, 1992).

Inspection of welded joints of gas pipelines by the physical method should be carried out selectively from the number of joints that did not undergo ultrasonic testing upon acceptance into operation in the amount of 10%, but not less than one joint welded by each welder on the gas pipeline being tested. The control results should be documented in a protocol in accordance with the requirements of SNiP 3.05.02-88. If the results of testing welded joints using physical methods are unsatisfactory, it is necessary to check twice the number of joints welded by the welder whose welded joint was found unsatisfactory based on the inspection results. If, upon re-inspection by physical methods, at least one of the inspected joints turns out to be of unsatisfactory quality, all joints made by the welder on the gas pipeline must be inspected.

The quality assessment of welded joints is carried out according to table. 3.

Table 3

| Quality of joints | Number of joints from the total number checked, % | Rating, points |

| Defective | More than 50 | 1 |

| Less than 50 | 2 | |

| Less than 20 | 3 | |

| Less than 10 | 4 | |

| Valid | 100 | 5 |

If, as a result of the inspection, it is determined that 50% or more of the inspected joints are defective, then a score of one point is given, and the gas pipeline, regardless of the total points received according to other criteria, must be replaced.

4.4. General assessment of the technical condition of overhead and internal gas pipelines

A general assessment of the technical condition of the gas pipeline is carried out using a point system by summing up the scores for each indicator determined in accordance with Table. 1-3.

Gas pipelines that receive an overall score of 6 points or less are subject to replacement.

Gas pipelines that receive a total score of 7 to 10 points are subject to major repairs in ascending order of points.

Gas pipelines that receive an overall score of over 10 points are considered suitable for further operation, and their technical condition is satisfactory.

Application

Mandatory

| I CONFIRM:______________________ (job title) ______________________ (Full name.) "____"__________ 199_ (date of) |

What factors influence the condition of gas pipelines?

As the experience of leading Russian expert organizations shows, underground steel gas pipelines retain their physical and mechanical properties even after forty years of service. Welded joints are also kept within regulated limits so their service life is extended.

But this does not happen for all pipes and still not always, so you need to figure out what determines the condition of pipes with identical characteristics over time.

The actual state of the pipeline and the time it takes for it to reach the limiting state depends on:

- the correctness of engineering decisions made at the time of design;

- integrity of construction and installation work;

- quality of materials used in construction;

- level of soil corrosion activity;

- effectiveness of electrochemical protection;

- monitoring;

- regularity and quality of repairs, etc.

CRITERIA FOR ASSESSING THE TECHNICAL CONDITION OF OVERGROUND AND INTERNAL GAS PIPELINES

2.1. The main criteria that determine the technical condition of gas pipelines when determining the need for their repair or replacement are: the density of gas pipelines, the condition of the pipe metal and the quality of welded joints.

2.2. When determining the state of density of gas pipelines, gas leaks associated with damage to the metal of the pipe and with the opening and rupture of welds detected during operation (according to operation data) must be taken into account.

In this case, gas leaks caused by mechanical damage to the gas pipeline during construction or repair work, which are episodic in nature and not associated with the general deterioration of the technical condition of the gas pipeline, as well as gas leaks that occurred during operation through leaks in fittings and in flange connections or from - for damage to fittings not related to the general deterioration of the technical condition of the gas pipeline.

2.3. When determining the condition of the pipe metal, it is necessary to measure the thickness of the walls of a straight section of a gas pipeline with a diameter of 150 mm or more, and measure the thickness of the stretched part of one bend on each gas pipeline Dy 50 mm or more.

The thickness of the walls of the straight section should be measured every 50 m of the internal gas pipeline, but not less than one on the gas pipelines of each boiler or hydraulic fracturing unit, and every 200 m of the above-ground external gas pipeline, but not less than one. Wall thinning should not exceed the values regulated by OST 108.030.40-79, OST 108-030.129-79 and TU 14-3-460-75.

The results of measurements of the wall thickness of gas pipelines must be reflected in reports that should be stored along with the gas pipeline passports.

The act must be accompanied by a diagram of the gas pipeline indicating the places where the thickness of the walls of the gas pipeline is measured.

2.4. The quality of welded joints is determined in accordance with the requirements of SNiP 3.05.02-88, GOST 16037-80, RD 34.17.302-97 “Steam and hot water boilers. Steam and hot water pipelines, vessels. Welded joints. Quality control. Ultrasonic testing. Basic provisions" (OP 501 CD-75). - M.: NPP “Norma”, 1997.

Quality control of welded joints on existing gas pipelines is carried out in cases where:

during operation of this gas pipeline, cases of opening or rupture of welded joints were observed;

When checking for tightness, it was determined that the leakage point was a poor-quality welded joint.

If during operation of a given gas pipeline no ruptures in the joints were observed and no leaks were detected through them, then the joints are considered suitable and are not checked.

2.5. The technical condition of gas pipelines for each criterion must be assessed using a point system in accordance with Section. 4 of these Recommendations.

What are the signs that determine the need for replacement?

The conditional standard service life was indicated above. They are “detached” from reality and are exemplary. In some cases, a gas pipeline may fail earlier, or it may last much longer than the average service life of gas pipes in industrial and residential buildings and industrial facilities.

In practice, the service life of a gas pipeline made of steel pipes is on average 30 years.

It is also worth noting that it is not possible to determine the condition of steel structures “by eye” by external signs. Utility service employees must carry out appropriate examinations and measurements.

Signs by which it can be determined that a gas pipeline needs pipe replacement are:

- thinning of the walls is higher than normal;

- change in the nature of connections at welding sites;

- gas leak according to meter readings.

Their results are reflected in protocols, which the consumer has the right to review. In addition, he may require an oral explanation of the material presented.

Repair work

Gas leakage is a factor that requires urgent repair of pipes and taps

Planned pipeline repair work is carried out after the expiration of the warranty period established by their manufacturers. However, preventive inspection is carried out every 5-10 years, depending on the operating conditions of the system. Special instruments are used and various types of examinations are carried out. Based on the results of the audit, a protocol and work plan are drawn up.

The following signs indicate the need for repairs:

- thinning of the walls;

- violation of welding seams;

- leak detection;

- the appearance of rust;

- peeling or fading of paint.

The repair procedure involves complete or partial replacement of pipes. Rejected areas are cut out and new fragments are installed in their place.

This process is carried out in the following sequence:

- Shutting off the gas supply to the riser.

- The pipeline is pumped with air.

- Damaged areas are cut out.

- New pipes are being welded.

- The system is checked for leaks.

- Steel parts are painted yellow, and in apartments they are painted according to the taste of the residents.

The final stage is drawing up a certificate of completion of work.

What to do if the service life of the gas pipeline has expired?

If their service life expires, they must be repaired, which includes complete or partial replacement of elements.

If an inspection has already been carried out by competent persons and they have concluded that a replacement is necessary, the consumer no longer needs to do anything. Repair work must be carried out by employees of GorGaz or other similar services servicing the facility.

To completely replace the gas pipeline, a mobile team is sent to the site, which removes the failed sections of the main passage to the common pipe complex, and then looks at the situation.

Partial replacement of pipes in a multi-story building is carried out by cutting off old sections and placing new ones using welding.

Such events are carried out strictly in accordance with safety rules:

- Gas access to the pipes is blocked.

- From the site that will be replaced, gas must be completely removed in accordance with safe handling standards for hazardous facilities.

- The old section is cut off.

- Using welding, a new element is mounted in its place.

- The integrity and tightness of the area is being checked.

- Starting a gas flow through the pipe after they have been purged.

You cannot repair gas equipment yourself. This is a complex and dangerous process that can only be carried out by gas industry employees with the necessary equipment.

Moreover, the fact that such work was carried out, as well as the date of its implementation, must be entered into the technical passport, which notes all actions carried out with the system. This is necessary so that the service life of the new gas pipeline can subsequently be determined.

If the consumer has suspicions that the pipes have become unusable, he can make a request to the relevant utility services and wait for their employees to arrive, but in no case should they check their version without their presence.

Maintenance

Regular maintenance of gas pipelines makes it possible to identify and eliminate emergency situations and extend their service life.

Maintenance of gas pipelines includes the following activities:

- External inspection for detection of external damage, corrosion, peeling of the protective coating.

- Monitoring the performance of shut-off and control valves.

- Checking the tightness of the system by pressure testing.

- Restoring the integrity of joints.

- Removing rust, applying a new protective coating.

- Replacement of emergency fragments.

- Checking equipment for leaks and leaks.

Only qualified gas service employees can perform these manipulations.

What to do to extend the service life?

In fact, how long a gas pipeline will last depends, among other things, on the consumer.

To extend its service life, you must systematically follow simple rules:

- Rule #1. Timely inspection and inspection of pipes. To do this, you need to let the inspectors in and try to stay at home if the time of the inspection is announced in advance.

- Rule #2. Turning on equipment in the correct sequence. Carrying out pressure testing of the gas system in accordance with the instructions and safety rules. The consumer must know which valve is responsible for what. If you are not aware of this, it is better to consult the gas workers servicing your home.

- Rule #3. Urgent check if there is a suspected gas leak. You should call your gas service immediately. They are obliged to promptly leave for the specified address. Before their arrival, it is better to turn off the gas valve in the apartment.

You can check the leak yourself as follows: in areas of the pipes where the smell of gas is especially noticeable, coat the suspicious area with soap foam. If bubbles begin to swell in the area, there is most likely a leak.

However, this is not a 100% leak detection method, much less a professional one. But for domestic use in the absence of professional equipment, it is quite suitable and, as practice shows, quite effective.

Maintenance

Gas pipeline maintenance is carried out by licensed companies

Regular maintenance of gas pipelines makes it possible to identify and eliminate emergency situations and extend their service life.

Maintenance of gas pipelines includes the following activities:

- External inspection for detection of external damage, corrosion, peeling of the protective coating.

- Monitoring the performance of shut-off and control valves.

- Checking the tightness of the system by pressure testing.

- Restoring the integrity of joints.

- Removing rust, applying a new protective coating.

- Replacement of emergency fragments.

- Checking equipment for leaks and leaks.

Only qualified gas service employees can perform these manipulations.

Conclusions and useful video on the topic

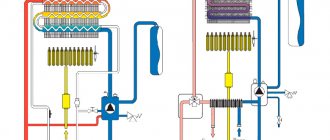

For calculations, the strength determined at a temperature of 20 ° C for a service life of 50 years according to ISO 9080 is taken:

Compliance with the deadlines specified by building regulations and guaranteed by the manufacturer is necessary to ensure the safe operation and operation of the system. Checking the technical condition of the gas supply, which is classified as explosive communications, is a necessary measure. It will eliminate risks and a lot of problems.

Please write comments in the block below, post photos and ask questions about the topic of the article. Tell us about your experience in inspecting gas pipes and identifying their critical technical condition. Share useful information that may be useful to site visitors.

When developing gas supply projects, it is necessary to include data on the service life of gas distribution system facilities in the explanatory note: Service life of gas distribution system, polyethylene and steel above-ground and underground gas pipelines.

Calculation of pipe wear

When planning inspections and repairs of pipeline systems, gas service specialists do not limit themselves only to external inspections and laboratory tests. Such events are productive, but it is simply unrealistic to cover all the houses in a big city.

To develop a repair schedule, specialists use formulas developed on a scientific basis and observational practice.

To carry out the calculations, the following initial data are taken:

- design voltage;

- strength factor;

- Wall thickness;

- minimum long-term strength of the material.

The indicators imply the technical properties of the material at an air temperature of 20 degrees.

Service life of GRPS

The service life of gas-propelled gas pumps is established by the manufacturer of gas-using equipment.

For example, Gazovik sets the following deadlines for GRPSh-6, 10 and 10MS:

Average service life before write-off – 15 years

The warranty period is 5 years.

“First Gas Safety Rules in the Gas Industry”: ( Canceled . ->

Replaced by PB 12-368-00 Safety rules in the gas industry. Canceled . ->

Replaced by PB 12-609-03 Safety rules for facilities using liquefied petroleum gases. Canceled . ->

Replaced by “ Federal norms and rules in the field of industrial safety “Safety rules for facilities using liquefied hydrocarbon gases ”)

3.3.28. Extraordinary technical inspections (diagnostics of the technical condition) of gas pipelines should be carried out after the expiration of the design service life, accepted for steel gas pipelines of 40 years and for polyethylene 50 years. Diagnostics in order to determine the need for replacement or residual life with the development of measures to ensure the safe operation of the gas pipeline for the entire period of life cycle extension, should include checking: the tightness of the gas pipelines; condition of the protective coating (for steel gas pipelines); condition (wear) of the material of the pipes from which it is built; quality of welded joints. The inspection must be carried out in accordance with RD 204 of the RSFSR 3.3-87 “Technical condition of underground gas pipelines. General requirements. Assessment methods”, approved by the Ministry of Housing and Utilities of the RSFSR in 1987.

In the document “ Federal norms and rules in the field of industrial safety “Safety rules for facilities using liquefied petroleum gases ”

The only relevant item:

56. Diagnostics should be carried out after the expiration of the service life established by the manufacturers, but not more than: 20 years for technical devices; 30 years for gas pipelines.

The Document “ Resolution of the Government of the Russian Federation of October 29, 2010 N 870 ” states:

76. The duration of operation of gas pipelines, technical and technological devices is established during design based on the condition of ensuring the safety of technically regulated objects in the event of predicted changes in their characteristics and the guarantees of the manufacturer of technical and technological devices. To establish the possibility of operating gas pipelines, buildings and structures and technological devices of gas distribution and gas consumption networks after the deadlines specified in the design documentation, their technical diagnostics must be carried out. The deadlines for further operation of objects of technical regulation of this technical regulation should be established based on the results of technical diagnostics.

The document “ RD 12-608-03 – Regulations for conducting industrial safety examinations at gas supply facilities”, clause 4.2 (Cancelled) tells us:

. An examination of gas equipment in operation is carried out at the end of its service life established by the manufacturer ; in the absence of this information, diagnosis is made after 20 years .

Document “ PB 12-529-03 – Safety Rules for Gas Distribution and Gas Consumption Systems” clause 5.5.2 (Canceled. Replaced with “ Federal Norms and Rules in the Field of Industrial Safety “Safety Rules for Facilities Using Liquefied Petroleum Gases ”).

5.5.2. Diagnosis should be carried out after 40 years for steel above-ground in embankments, underground, as well as 50 years for polyethylene gas pipelines after their commissioning. Early diagnosis of gas pipelines is prescribed in cases of accidents caused by corrosion damage to steel gas pipelines, loss of strength (rupture) of welded joints, as well as in the case of construction of steel gas pipelines beyond the standard period in highly corrosive soils without electrochemical protection. The decision to carry out diagnostic work or reconstruction (replacement) of the gas pipeline is made by the owner of the gas distribution network.

Document “ PB 12-609-03 – Safety Rules for Facilities Using Liquefied Petroleum Gases” clause 5.3.7 (Canceled. Replaced with “ Federal Norms and Rules in the Field of Industrial Safety “Safety Rules for Facilities Using Liquefied Petroleum Gases ”):

5.3.7. Existing external gas pipelines must be subject to periodic inspections, instrumental technical inspection, technical condition diagnostics, as well as routine and major repairs. Underground gas pipelines with a service life are subject to diagnosis: steel - 40 years; polyethylene - 50 years. Gas equipment (technical devices) are subject to diagnostics after the service life established by the manufacturer, but not more than 20 years of operation.

Replacing outdated gas equipment is a necessary condition for safety!

Replacing outdated gas equipment is a necessary condition for safety!

The average service life of gas appliances in accordance with the manufacturer’s passports is 10 years. At the same time, morally and physically outdated gas equipment cannot ensure reliable, trouble-free operation and efficient use of natural gas.

If you operate worn-out, unrepairable gas equipment, you are putting yourself at risk.

Gas stove maintenance should be carried out at least once every three years. And after its service life has expired and its condition is satisfactory, maintenance is carried out at least once a year, which incurs additional costs for the subscriber during its operation.

Gazprom Gazoraspredelenie Arkhangelsk LLC strongly recommends that you replace a gas stove that has reached the standard service life established by the manufacturer before scheduled maintenance is due. Upon expiration of the standard service life of indoor gas equipment LLC

Gazprom Gazoraspredelenie Arkhangelsk has the right to suspend gas supply in accordance with clause 80 of the Rules for Gas Use regarding ensuring safety in the use and maintenance of in-house and in-apartment gas equipment when providing public gas supply services, approved by Decree of the Government of the Russian Federation dated May 14, 2013 No. 410.

Gazprom Gas Distribution Arkhangelsk LLC once again reminds you of the need to comply with the requirements of the rules for the safe use of gas in the home when operating gas appliances.

To avoid emergency situations, gas consumers are prohibited from:

• carry out unauthorized gasification of a household (apartment), rearrangement, replacement and repair of household gas-using equipment, gas cylinders and shut-off valves;

• make changes to the design of household gas-using equipment, change the design of smoke and ventilation systems, seal ventilation ducts, brick up or seal “pockets” and hatches intended for cleaning chimneys;

• turn off automatic safety and regulation, use gas if gas appliances, automation, fittings are faulty, especially when gas leaks are detected;

• use gas if the density of the masonry or plaster of chimneys is violated, and unauthorized installation of dampers in the chimneys of gas stoves;

• use gas without regular inspections and cleaning of smoke and ventilation ducts within the time limits specified by the Rules for Gas Use in terms of ensuring safety in the use and maintenance of in-house and in-apartment gas equipment when providing public gas supply services.

Dear gas consumers, we remind you that the current legislation obliges you to enter into an agreement on the maintenance and repair of in-house (in-apartment) gas equipment with a specialized organization, since timely maintenance is the key to your safety.

To conclude an agreement on the maintenance, repair of VKGO (VDGO) and carrying out work on its maintenance, you can contact one of the operational sites of Gazprom Gas Distribution Arkhangelsk LLC: Arkhangelsk, st. Severodvinskaya, 28, bldg. 1, tel..

Replacing outdated gas equipment is a necessary condition for safety!

Operational requirements for metal heating pipelines

It is necessary to take into account the most important characteristics of steel pipes. This:

- mass of products;

- sizes according to GOST and according to individual order (TU);

- outer and inner diameter (section of the coolant nominal diameter and wall thickness);

- metal properties.

All parameters for this product are reflected in the symbols. The length of the pipe is measured in meters, the diameter of the section and walls of the pipe is in millimeters, the mass is in kilograms, the pressure is in Pascals, the temperature is in Kelvin and Celsius. The parameters for pipe formation and welding type are indicated by a capital letter. The service life, measured in years, is quite arbitrary and depends on a number of factors mentioned earlier.

One of the advantages of metal pipes is their resistance to high pressure, which is present in any heating system.

Cink Steel

This material is much more resistant to corrosion, which significantly extends the standard time. The most significant destructive factor here is only the welded connection, if for some unknown reason the installation is carried out by welding. The photo shows water and gas steel pipes.

In fact, this installation method is prohibited: the zinc completely burns out during welding, and accordingly, the seams remain completely defenseless against rust.

Galvanized steel products overgrow much more slowly. Firstly, the smoothness of the wall is much higher, and secondly, there is much less “garbage” itself - particles of rust, scale, sand. But if the taps in the plumbing system are not fully opened and there is not a sufficiently dense flow of water, scale and sand can accumulate.

The service life of the product according to GOST is as follows:

- risers and connections in cold water supply systems are in use for 30 years;

- the service life of steel heating pipes in a house with a closed system is 20 years;

- an open heating system will last 30 years.

It is allowed to construct a gas pipeline from galvanized pipes. But there is still a nuance: unlike plumbing systems, the gas pipeline must be one-piece, which requires welding. And the connection destroys zinc at the junction. On the other hand, gas pipelines, like water pipelines, are coated with polymer paint, which prevents corrosion.

In fact, galvanized steel pipes for both water supply and heating last 50–70 years.

Heading

: Technical science

Publication date

: 24.02.2016 2016-02-24

Article viewed:

834 times