Buying a gas heating boiler is not a cheap pleasure. When making such a purchase, you don’t want the said equipment to break down after just a couple of seasons, right? And such a nuisance can really be avoided if you have knowledge about the factors affecting the service life of a gas boiler in a private home. As well as information about the possibility of preventing premature breakdowns.

It is these issues that our article is devoted to, in which we examined in detail the factors that directly affect the service life of gas equipment. We supplemented the presented material with visual photographic materials and useful thematic videos.

Maintainability of the heat exchanger

As noted above, the heat exchangers of modern gas boilers are made of: copper, stainless steel, cast iron. According to reviews, under the right operating conditions, the service life

a steel

heat exchanger in a gas boiler

is 15-20 years, and a cast iron one is up to 30 years. The life of a copper coil is limited to 5-10 years.

In single-circuit heating heat generators, one coil is installed, which transfers the thermal energy obtained from fuel combustion to the coolant. Depending on the design, two-circuit boilers can have two heat exchangers (primary and secondary) or one bithermic.

- In the first option, the primary coil is responsible for heating the coolant and is installed in the upper part of the boiler installation (above the burner). The secondary one is responsible for creating the hot water supply.

- Bithermic has a “tube-in-tube” design. The coolant for the heating system moves in the space between the outer and inner tubes; Water flows through the inner tube of the heat exchanger to provide hot water supply.

Any heat exchanger is susceptible to scale formation. This is especially true for devices through which hard tap water circulates. The separate coil can simply be washed or the damaged section replaced.

In a bimetric heat exchanger, scale forms much faster than its separate counterpart. Deposits that appear in the inner tube of such a device are almost impossible to eliminate. Heat transfer will gradually decrease, which means that in order to maintain the desired water temperature, it will be necessary to increase the volume of fuel burned. Constant operation of the boiler unit in this mode will significantly reduce its service life.

Intensity of work and nuances of operation

Before purchasing, the necessary calculations regarding the power of the boiler system must be carried out. As a rule, in a design organization, specialists “throw on” 15-20% of the power to reduce the load on the boiler at the time of peak loads. If you choose a boiler unit yourself, then often, in order to save money, you purchase a model whose power “butt-butt” corresponds to the calculated one. Constant operation at maximum load significantly reduces the service life of the gas boiler

, therefore, when purchasing a device, you should ensure a power reserve of at least 20%.

Corrosion can destroy a copper heat exchanger within a few years. To increase its service life, you need to get rid of the presence of air in the heating system, since oxygen is a powerful oxidizing agent. To do this, you should use air vents, regularly identify and bleed air from the radiators through Mayevsky taps. We recommend watching the video.

In it, a specialist talks about the relationship between the service life of the boiler system and corrosion in various types of heating systems.

The service life of the boiler unit is affected by the pressure in the heating and water circuits. The stability of this parameter in the heating system is ensured by proper selection of the volume of the expansion tank. Due to low water pressure, the volume may not be sufficient for continuous operation of the burner. Having reached the required temperature, the burner will periodically turn off, and when the temperature drops, it will turn on. When operating for a long time in this mode, the resource of the device is exhausted much faster, which affects the life of the entire boiler unit.

What you need to pay special attention to when choosing a gas boiler

With such a variety of different models, it is difficult to make a choice in favor of a specific one. But price should not be the main selection criterion. For effective operation, a modern boiler must meet a number of basic requirements: 1. No Frost system, which prevents freezing of the main components of the boiler, and in an improved form, the general heating system. 2. Improved or universal type of burner - conventional ones are not very economical. 3. Basic equipment should include: 3.1. A membrane-type expansion tank with a volume of at least 7% of the total volume of the heating network. 3.2. Circulation pump. 3.3. A set of sensors for monitoring the temperature of the coolant in the boiler, on the heating radiators, and preferably an air temperature control sensor. 4. Boilers from imported manufacturers must be adapted to the gas and electrical networks of Russia. 4.1. The presence of an automatic spotter on a piezocrystal or electric spark is mandatory. It is advisable to have a heating element with an incandescent element, which will make the operation of the boiler with low-calorie or unrefined fuel more economical and safe. 4.2. Products must be certified. 4.3. The range of operating pressure of gas and water is preferably the widest. 4.4. Built-in overvoltage protection system. Otherwise, you will have to buy and install an expensive filter. The possibility of connecting via a UPS with an output to an external battery is welcome.

Only after all the listed components are available and the requirements are met can the price of devices of comparable power be compared.

Each person chooses the best for himself. Each buyer puts their own meaning into the concept of “best”. Reliability? Safety? Price? Appearance? All this can be correlated with gas boilers. What are the best gas heating boilers? It all depends on what functions are your priority.

Many gas boilers have an automation system, pumps that run on electricity. Such boilers cannot function without a constant supply of electricity. If there are power outages, such devices will not be suitable.

It is worth considering such characteristics of boilers as the type of combustion chamber. Equipment with an open chamber burns the air in the room. Such boilers require an equipped chimney and a constant flow of air from outside. It should also be taken into account that their body overheats, so a boiler with an open combustion chamber should not be installed next to meters, wooden furniture and curtains. Boilers with a closed chamber have a coaxial pipe in their structure, which absorbs air from the street and exhausts it back. Such a boiler is an economical option, since gas and air are uniformly mixed in the coaxial pipe, so the boiler body with a closed combustion chamber does not overheat.

The modern market presents a choice of gas heating boilers to suit your taste, and which one is better for the buyer to decide. The choice of equipment depends on the needs that are most important to the consumer.

Results

So, we can draw the following conclusions:

- do not save when buying a boiler; more expensive models will provide your home with uninterrupted heating for several decades;

- choose floor-standing models with a cast iron heat exchanger;

- engage only professionals for installation and maintenance of the boiler;

- Follow all operating rules established by the manufacturer.

By fulfilling all these requirements, your boiler will operate smoothly, economically and safely for several decades!

Classification of devices

The basic criterion for choosing a boiler is its ability to heat the designated area. To ensure that the device does not operate at maximum loads, you need to choose a gas-efficient boiler with a small power reserve.

This indicator is conditional, but with its help it will be possible to select the necessary equipment.

It is worth choosing according to the accommodation option, because there are two large groups:

- floor boilers;

- wall-mounted boilers.

Floor-standing

The first option is in demand for heated premises with an area of more than 200 m2. These units are used not only for direct heating of housing, but also to create a special microclimate in the room. It should be noted that the efficiency of such a gas boiler will be lower than that of their wall-mounted counterparts. However, this is compensated by a significantly longer service life, which, with proper care, reaches several decades.

Such indicators are achieved through the use of optimal materials involved in the manufacture of the heat exchanger. As a result, due to low operating costs for large areas, floor-standing units are considered economical gas boilers for heating a private home.

Most of them use cast iron heat exchangers. Due to the physical and chemical characteristics, the cast iron grades used can withstand the effects of most negative internal factors. A good help is to use anti-corrosion materials that have effective additives that reduce the appearance of rust.

Wall mounted

A wall-mounted gas heating boiler has significantly less weight and smaller dimensions, so it easily fits on a vertical surface. Such a module must be connected to several systems simultaneously:

- gas supply for supplying fuel to the combustion chamber;

- power supply to start the automation and circulation of the water pump;

- heating system with an expansion tank and the required number of consumers.

All economical gas boilers have a process control unit concentrated in a single place. Here you can set the temperature, get data on the current pressure, or turn off the device completely.

Wall-mounted boilers are characterized by the use of two types of draft:

Most economical gas boilers have a forced system. To implement it, an electric fan and a discharge spiral cavity are used.

The main operational processes are regulated using automation. The positive factors of wall-mounted boilers are as follows:

- saving useful space in the room;

- minimum weight that does not load the wall;

- in some cases they can be converted to run on liquefied gas.

VIDEO: Which boiler to choose – wall-mounted or floor-standing

Unit service life

Most modern economical gas boilers last about 7-12 years. Their service life is affected by the quality of the working elements in direct contact with water, such as the heat exchanger and pump.

Gas boiler connection diagram

In the presence of high water hardness, salt deposits occur. To improve the quality of the coolant, polyphosphate filters are used. Due to the use of polymer salts in them, it is possible to reduce the hardness value to acceptable levels. This reduces the cost of heating the coolant and thus contributes to fuel savings.

The operating period is affected by the intensity of work of mechanical elements, for example, in a pump. In this regard, it will be necessary to regularly maintain it, changing oil seals, gaskets and rubbing elements.

The service life of a gas-efficient boiler is also affected by the quality of electricity. Weak or excessively strong voltage has an equally detrimental effect on the operation of such components:

- automation;

- gas valve;

- ignition module, etc.

The situation can be corrected by using voltage stabilizers. They are able to maintain parameters with an accuracy of 3-5%, which will protect the boiler from failures.

Compared to other models

The main advantage of gas boilers is their high efficiency - about 90%. The data sheets of some models indicate that their efficiency reaches 107-109%, but in reality this is only a successful marketing ploy. It is known from a school physics course that not a single device in the world can have an efficiency of 100% or more than this value - otherwise the unit turns into a perpetual motion machine!

Below we will talk about why manufacturers inflate the figures. However, a gas-fired boiler is significantly superior to equipment of another class in terms of efficiency. Only a pyrolysis unit can provide a worthy alternative to it.

The next advantage of a gas heating boiler is its long service life, which is explained by the simplicity of the design. The equipment does not have complex components; all its main parts can be easily replaced.

The main element of the boiler is the burner - its device determines the method of fuel combustion and also affects the efficiency of the unit.

Only solid fuel boilers have the same reliability as gas boilers.

Another advantage of gas-powered equipment is its high power. Unlike electric and solid fuel boilers, gas boilers have proven themselves to be excellent for heating large spaces. At the same time, temperature control in all rooms is carried out with high precision: solid fuel and diesel boilers do not have this function.

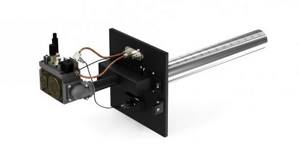

Burners for gas boilers

Gas boilers, regardless of their type, can be equipped with different burner options. The cost of the entire boiler ultimately depends on the quality of the burner and its features.

When choosing a boiler, you must pay attention to the type of burner and its quality. It’s better to overpay a little, but so that the burner for the boiler is reliable and durable

There are two main types of gas burners used in domestic boilers:

- Atmospheric. This category of burners is characterized by extreme simplicity of design, and, as a result, very low cost. In addition, it is worth noting the minimal noise level of such devices - during operation the atmospheric burner is almost inaudible. The main feature of atmospheric burners also deserves attention - if necessary, you can quickly change them with your own hands to switch the boiler to another fuel.

- Inflatable. Inflatable burners differ from previous ones primarily in power, which is determined by the fact that a certain volume of gas is supplied under pressure. Most often, such burners are used for heating large houses, various industrial buildings, etc.

Steam models

This category of boilers is designed to generate steam. Most plants that use steam in the process require high pressure. Therefore, the performance of such equipment consists of temperature and pressure indicators. For the most part, gas industrial steam boilers are units that, through fire tube structures, generate steam with a productivity of at least 0.25 t/h. Depending on the requirements of the enterprise, you can choose models with higher power. As a rule, the maximum reaches 55 t/h. Pressure indicators, in turn, can be up to 30 bar, and temperature conditions can be up to 300 ºС. Modern models are distinguished by their ability to operate on various types of liquid and gaseous fuels. When choosing, it would not be amiss to take into account additional equipment in the form of deaeration devices, dispensers and bubblers.

Electronic components and power supply

Today, all models of gas heating equipment present on the domestic market are equipped with automation, which can be non-volatile or require connection from a household AC network. One of the factors that leads to breakdowns and reduced service life of gas boilers is the unstable operation of electrical networks. A normal power surge can easily damage the elements of the control unit, controller, ignition system, gas valve, and other electronic and electrically controlled components.

Advice: If you want the lifespan of your boiler system not to be lower than that declared by the manufacturer, then choose models with a built-in voltage stabilizer or use an uninterruptible power supply in the device’s power supply circuit.

Standard service life of models from well-known manufacturers

The standard service life (declared by the manufacturer in the model documentation) is calculated from the date of commissioning, i.e. from the date of installation and first start-up, not the production of heating equipment. For most of their models (with regular maintenance), well-known manufacturers predict the following service life:

- AOGV – 10 years.

- Ariston - 8-10 years old.

- Baksi – 12-15 years old.

- Bosch – 12 years old.

- Vaillant – 10-15 years.

- Wissman – 15-20 years old.

- Lemax – 11-14 years old.

- Navien – 10 years old.

- Proterm – 10-12 years.

- Rinnai – 10-12 years old.

Types of floor-standing boilers

Floor-standing gas boilers are manufactured in all known design options. They can be divided into groups according to different characteristics.

By functionality:

- single-circuit. They are used only for heating the coolant. When connecting an external boiler, they are able to provide the room with hot water at the level of centralized water supply;

- double-circuit. They are capable of preparing hot water for household needs in parallel with heating the coolant.

By heat transfer method:

- convection Conventional heating of liquid in the flame of a gas burner;

- condensation A two-stage heating of the coolant is carried out - first in the condensation chamber from the heat of the exhaust smoke, and then in the usual way. The design has specific conditions for full operation - either a low-temperature circuit (warm floor) is needed, or the difference between external and internal temperatures should not exceed 20°;

- parapet. Units capable of operating in small spaces without a heating circuit. There are holes in the housing that provide circulation of hot air according to the convector principle.

According to heat exchanger material:

- steel. Stainless steel up to 3 mm thick is used;

- copper. As a rule, a coil is installed that has high durability and heat transfer;

- cast iron Used on powerful models that require stable and efficient operation of the unit.

By type of power supply:

- volatile. Boilers, the design of which uses devices that require connection to the network;

- non-volatile. Units capable of operating without being connected to a power supply.

Equipping the boiler room with high-quality automation

The operating instructions for hot water boilers are quite simple and understandable. The consumer is offered a variety of models of such equipment, so it is possible to choose exactly the one that will be most effective according to its parameters in each specific case of the heating system design.

The main reason for the popularity of boilers of this type is that their service life is longer than that of conventional simple boilers, moreover, the quality of the supplied hot water is much better.

Nowadays, water heating devices are produced that are able to operate on such types of fuel as:

• Electricity; • Liquefied and natural gas; • Firewood or coal; • A variety of liquid fuels.

In addition, there are high-quality universal boilers that are able to operate on different fuels; they are characterized by the ability to switch modes.

Factors that have the greatest impact on the life of a gas boiler

Heat exchanger material

The most common and inexpensive to manufacture is a steel heat exchanger. The wall thickness of steel heat exchangers does not exceed 3-5 mm, which, even when using purified coolant, leads to an emergency after 10-15 years of use. In addition, the likelihood of a steel heat exchanger burning out is much higher.

The cast iron heat exchanger is made with walls several times thicker; the metal itself is heat-resistant and corrosion-resistant. Potentially, the service life of cast iron heat exchangers can reach 50 years.

The most unpopular due to their even higher cost or technical impossibility of installation are copper heat exchangers. Despite its relative resistance to corrosion, copper, like steel, is characterized by the likelihood of burning out. Fortunately, multiple safety systems on expensive boiler models that use copper heat exchangers are almost guaranteed to prevent burnout. However, long service life of copper elements can only be achieved with regular maintenance.

Burner type

There are two types of burners:

- Atmospheric - used in boilers with an open combustion chamber with natural draft. Boilers with atmospheric burners accumulate significantly more soot and other combustion products, which not only requires more careful maintenance, but also slightly reduces service life.

- Inflatable (turbocharged) - used in boilers with a closed combustion chamber with natural draft through a coaxial (side) chimney or with forced draft provided by a fan or turbine. Combustion products are more efficiently released into the atmosphere and do not affect the operation of the boiler, and fans and turbines in most models have a long service life.

Automation

More expensive models of gas boilers are equipped with multifunctional automation, which will not only promptly warn about the condition of the boiler, but will ensure the most efficient operation of the boiler. By preventing emergency situations, automation with the functions of self-diagnosis, prevention of overheating and freezing, gas control, auto-ignition, and protection against blocking of the circulation pump significantly extends the life of the gas boiler.

However, for the correct operation of such automation, a voltage stabilizer and a UPS (uninterruptible power supply) are recommended.

Boiler cost and production technology

Prices for models from well-known European and Japanese manufacturers are, for the most part, quite justified, since they use more durable and reliable alloys, protection and insulation technologies, which affects not only efficiency, but also reliability and safety of operation.

terms of Use

The most common mistake is choosing an overly powerful gas boiler, when, due to the rapid heating of the coolant, it constantly turns on and off. This operating mode threatens not only higher gas consumption, but also a significant reduction in service life.

Also, the life of a gas boiler, or rather its heat exchanger (especially steel or copper), largely depends on the coolant. Using contaminated water promotes the formation of scale, oxidation and corrosion inside.

Heat exchanger of a gas boiler in section. The use of contaminated coolant and lack of regular cleaning led to serious consequences: serious overheating and almost complete clogging.

In conclusion, we can say that the manufacturer’s forecast regarding the service life of a gas boiler is very conditional. Even the most reliable models may not reach the predicted mark if not used properly and especially in the absence of regular (preferably annual) maintenance. This is why in practice there is such a huge difference in the service life of even identical models.

Number of circuits

All models of gas boiler systems present on the Russian market are classified by the number of circuits.

- Single-circuit ones are designed only for heating the coolant circulating in the heating system.

- Double-circuit ones are designed for heating and creating domestic hot water at home.

Single-circuit installations are simpler and therefore more repairable. Double-circuit, they have a lot of design features that significantly increase the cost of maintenance and repair in the event of failure of its elements.

Important! Despite the widespread belief that simplicity is the key to reliability, the number of circuits of a heating unit does not in any way affect its lifespan.

Do you want to know how to install a wall-mounted gas boiler with your own hands?

What factors should be considered

In addition to the class and price segment, other aspects also influence the lifespan of gas equipment.

Heat exchanger material

Why does a wall-mounted unit have a shorter lifespan than a floor-standing unit? Perhaps the type of placement matters? No, floor-standing units are simply equipped with cast iron or steel heat exchangers. Over the same period of operation, their wear rate is significantly lower than that of copper radiators that are installed in wall-mounted boilers.

Copper is thinner than steel, and during operation it is susceptible to oxidation and corrosion. The gaps in the heat exchanger can be soldered, but the unit will not last long. The average term of work is from 5 to 10 years maximum. Practice shows that copper radiators last no more than 7 years, after which they must be repaired or replaced. They are more sensitive to the quality of tap water.

The type of heat exchanger also matters. A regular coil can be descaled yourself, and the boiler will continue to operate. Bithermal radiators cannot be cleaned, and replacing a unit is almost equal to the cost of a new device.

Burner type

Gas appliances have two types of burners:

- Atmospheric - they take air from the room to maintain the flame. Combustion products are removed naturally using draft.

- Supercharged or forced (turbocharged chambers) - clean air is taken from the street through a coaxial chimney. The flame power can be adjusted, the smoke is removed by a fan.

What does the operating time have to do with it? Forced removal of combustion products is more efficient. The boiler works with greater efficiency, which increases efficiency and reduces the load on its units.

In devices with an atmospheric combustion chamber, a lot of soot accumulates in the holes and on the elements. As a result, the equipment spends more power to maintain operation and heating temperature, so the components fail faster.

Electronics and automation

Electronic models are equipped with control sensors, self-diagnosis and require a network connection. Network instability and power surges lead to damage to elements. We recommend installing a voltage stabilizer.

Features of operation

The service life of heating equipment initially depends on the correct choice. To do this, it is necessary to select a boiler taking into account the characteristics of the room in which it will operate and the planned peak loads. It is recommended to choose a boiler with a power reserve of 15–20%.

Choose a room for installing equipment in accordance with the regulations. It shouldn't be humid inside. Corrosion quickly destroys the heat exchanger, so install an air vent to bleed excess air.

Pressure also affects the lifespan of the unit. To ensure stable performance, include an expansion tank in the piping.

Recommendations for choosing heating equipment:

- Devices with steel and cast iron radiators have the longest service life.

- Devices with a forced-air burner are more efficient.

- With a voltage stabilizer, equipment will last longer.

How many years the boiler will operate does not depend on the manufacturer’s forecasts. Its maintainability is of great importance. Therefore, it is better to choose domestic brands to make it easier to find service centers and spare parts if necessary.

Today, gas boilers have become widespread to maintain a comfortable temperature in winter. On the market for such equipment, you can choose any model that is ideally suited to both the size of the consumer’s wallet and his personal preferences. These can be wall-mounted and floor-mounted units, single- and double-circuit, with forced and natural draft. However, the overwhelming majority of people buy floor-mounted household gas heating boilers.

How to extend service life

To ensure that the standard service life of household gas boilers, established by the manufacturer, is not significantly reduced due to the problems listed in the article, it is necessary to perform a number of operations.

Firstly, even before purchasing a unit, you should determine its optimal power. The reserve should be 10-15%. That is, if a heating capacity of 13 kW is sufficient for heating, then it is more advisable to buy a boiler whose specified parameter will be around 15 kW.

Secondly, before connecting the unit, it is advisable to check the electrical network and heating system. And, if shortcomings are identified in the form of pressure and voltage drops, then they should be eliminated. In addition, it is necessary to flush radiators and pipelines. And also take care of the presence of grounding.

Replacing an old product with a new one may not solve all heating problems. Therefore, before installation, you need to take care of a high-quality check of smoke removal systems, heating, and electrical networks, and eliminate any identified deficiencies

Thirdly, it is imperative to check the coolant. And, if the water is hard and contains impurities, then care must be taken to install filters in the system with a sufficient degree of purification, which can be coarse or fine. It is often necessary to use both types of equipment. Magnetic filters effectively remove metal particles.

Fourthly, you should not skimp on installing the boiler; it must be done by qualified specialists. From the moment of test start-up of the unit, a voltage stabilizer should be used to protect it.

It is also advisable to use:

- uninterruptible power supply - in the event of a power outage, this device will make it possible to eliminate system failure;

- dielectric inserts - they will eliminate the interaction of electric current with gas and the consequences of this.

Fifthly, it is advisable to use boilers regularly. That is, do not turn them off when leaving for work or even for a long absence.

The service life of the boiler will be extended by using it in the off-season. Why do you need to choose the most economical mode?

Sixthly, do not neglect boiler maintenance - this is the most important measure to extend their service life. According to the governing documents, it must be performed before the start of each heating season. But it is better if the owners carry out the necessary procedures 2 or even 3 times a year.

Seventh, you should promptly respond to any warning signals from the electronics during operation.

What factors should be considered

In addition to the class and price segment, other aspects also influence the lifespan of gas equipment.

Heat exchanger material

Why does a wall-mounted unit have a shorter lifespan than a floor-standing unit? Perhaps the type of placement matters? No, floor-standing units are simply equipped with cast iron or steel heat exchangers. Over the same period of operation, their wear rate is significantly lower than that of copper radiators that are installed in wall-mounted boilers.

Copper is thinner than steel, and during operation it is susceptible to oxidation and corrosion. The gaps in the heat exchanger can be soldered, but the unit will not last long. The average term of work is from 5 to 10 years maximum. Practice shows that copper radiators last no more than 7 years, after which they must be repaired or replaced. They are more sensitive to the quality of tap water.

The type of heat exchanger also matters. A regular coil can be descaled yourself, and the boiler will continue to operate. Bithermal radiators cannot be cleaned, and replacing a unit is almost equal to the cost of a new device.

Burner type

Gas appliances have two types of burners:

- Atmospheric - they take air from the room to maintain the flame. Combustion products are removed naturally using draft.

- Supercharged or forced (turbocharged chambers) - clean air is taken from the street through a coaxial chimney. The flame power can be adjusted, the smoke is removed by a fan.

What does the operating time have to do with it? Forced removal of combustion products is more efficient. The boiler works with greater efficiency, which increases efficiency and reduces the load on its units.

In devices with an atmospheric combustion chamber, a lot of soot accumulates in the holes and on the elements. As a result, the equipment spends more power to maintain operation and heating temperature, so the components fail faster.

Electronics and automation

Electronic models are equipped with control sensors, self-diagnosis and require a network connection. Network instability and power surges lead to damage to elements. We recommend installing a voltage stabilizer.

Features of operation

The service life of heating equipment initially depends on the correct choice. To do this, it is necessary to select a boiler taking into account the characteristics of the room in which it will operate and the planned peak loads. It is recommended to choose a boiler with a power reserve of 15–20%.

Choose a room for installing equipment in accordance with the regulations. It shouldn't be humid inside. Corrosion quickly destroys the heat exchanger, so install an air vent to bleed excess air.

Pressure also affects the lifespan of the unit. To ensure stable performance, include an expansion tank in the piping.

Recommendations for choosing heating equipment:

- Devices with steel and cast iron radiators have the longest service life.

- Devices with a forced-air burner are more efficient.

- With a voltage stabilizer, equipment will last longer.

How many years the boiler will operate does not depend on the manufacturer’s forecasts. Its maintainability is of great importance. Therefore, it is better to choose domestic brands to make it easier to find service centers and spare parts if necessary.

Any equipment has its own service life. Depending on the operating conditions, this period may vary to a greater or lesser extent, but there is always a calculated indicator that is used when choosing.

List of works

To understand what exactly should be cleaned, checked and adjusted in the boiler, and with what frequency, just look at the instructions and technical documentation, which must be included with the boiler when purchasing it. These documents contain a complete list of components and elements involved in the equipment, maintenance requirements and the frequency with which the condition should be checked, service performed and settings updated if necessary.

You absolutely cannot rely on this information to clean a gas boiler yourself. This information gives a clear idea of what to expect from the service company with which you are about to enter into a contract for servicing gas equipment.

The works are divided into three groups:

- Regular work carried out before and after the start of the heating season, preparing the boiler for summer inactivity.

- Major maintenance. Work carried out every few years and aimed at servicing elements with an initially intended long service life (flushing the heat exchanger, replacing seals and valves, maintenance of fans, etc.).

- Repair in case of breakdown. The procedure for actions and mandatory work in the event of an emergency situation, breakdown or consequences of external factors.

Seasonal service regulations

Before the start of the heating season, the boiler should be brought into proper working order and the operation of the sensors responsible for safety should be checked. Only after this the boiler is turned on for operation.

If the manufacturer allows routine maintenance to be carried out only once a year before start-up, then in addition to commissioning work, the main elements of the boiler are cleaned, with the exception of flushing the heat exchanger and a complete overhaul of the control units. If maintenance (maintenance) is carried out after the season, then cleaning is reserved for this stage.

Required list of works:

- General inspection, removal of dirt from internal and external surfaces.

- Cleaning filters (air, gas, coarse water filters).

- Cleaning and checking the burner.

- Cleaning the fire section of the combustion chamber.

- Checking the tightness of internal gas channels.

- Checking the ignition electrodes (piezoelectric element and burner).

- Test and diagnostics of the electronic control unit.

- Test and diagnostics of sensors and automation responsible for safety.

- Adjustment of boiler parameters, combustion settings. The process is accompanied by analysis of exhaust gases. Based on the composition and concentration, the master judges the accuracy of the boiler settings.

- Checking the condition of the shut-off valve.

- Checking the supply gas pipeline in the area from the main line to the gas equipment.

- Checking and adjusting the pressure in the expansion tank.

Major renovation

In addition to routine maintenance carried out every season, during a major overhaul of a gas boiler, elements with a limited warranty period are replaced, the internal surface of the heat exchanger, seals and valves are cleaned. The main task is to replace elements that are not subject to maintenance during routine maintenance, but still have a service life.

In case of breakdown

In an emergency situation when a breakdown occurs during operation, it is very important to respond to the problem as soon as possible and return the boiler to working condition. If breakdowns occur, they occur only during the heating season, for example, if the boiler operates for a long time at maximum power during the coldest period of the year.

At this time, it is extremely difficult to find a specialist for quick repairs, but with a service agreement, all you need to do is leave a request so that the repair team can arrive in a short time to fix the problem. Since the service center keeps records of boilers, a specialist arrives at the customer with a set of necessary tools and spare parts for a specific model of gas boiler.

Types of burners

Atmospheric burners take oxygen from the room

Burners of floor-standing boilers are divided into one-stage, two-stage and modulating. Single-stage systems assume that the device can produce only one power level; with a two-stage system, it is selected from two levels. Modulation regulates the available power. The efficiency of the equipment depends on the type of burners.

Inflatable burners are equipped with turbines for heating. They take air from the room and from the street. They do not require a separate room.

Atmospheric burners are one of the most reliable at an affordable price. Their disadvantage is considered to be air burning and low efficiency.