Ventilation, air conditioning and heating

Heating a house with gas is 2-3 times cheaper than any other method of heating a home.

However, this gap can be increased by 4 times superiority. To do this, you just need to choose energy-efficient gas burners for heating boilers. Since the efficiency (efficiency factor - the ratio of consumed and supplied energy) of the boiler, for the most part, depends on this unit. Types of gas burners

From a technical point of view, a burner is a regular mixer that ensures the formation of a gas-air mixture that is oxidized in the combustion chamber of the boiler. Moreover, the energy efficiency of the boiler depends on the degree of fuel combustion, which, in turn, is related to the percentage of gas and oxygen in the mixture supplied to the combustion chamber.

Gas burner for heating boiler

Therefore, the classification of burners is based on the method of supplying oxygen to the combustion chamber.

This sorting method allows us to distinguish the following types of gas burners:

- An atmospheric version of the “mixer” , which involves a natural flow of air.

- Inflatable option , which involves mechanical inflow, organized using pressure equipment (fan).

- A diffusion-kinetic design option that involves a dosed supply of air flow, mixed into the flow directly during combustion.

In addition, the energy efficiency of the boiler depends on the ability to regulate the intensity of fuel combustion in the working chamber of the heat-generating installation. And the wider the adjustment range, the higher the energy efficiency of the equipment . Moreover, this rule applies to both stationary boiler equipment and portable (cylinder) gas burners - KS 1005 and its analogues.

Therefore, the secondary classification of burners is based on the ability to control the flame in the combustion chamber of the boiler.

This sorting method distinguishes the following types of burners:

- Single-stage option , which eliminates the possibility of adjustment during the combustion process.

- Two-stage option, providing two modes of boiler operation.

- Modulating option , which provides the ability to adjust the combustion intensity in the range from 10 to 100 percent.

Of course, all the types of burners described above provide completely different energy efficiency. Therefore, each type of burner deserves a separate assessment.

Variety of burners by ignition type

The simplest method of ignition is considered to be with a wick - with a burning igniter. When the automation is triggered, the gas is ignited with a wick, after which the device begins to heat the liquid. There are two negative aspects to this - increased fuel consumption and an insufficient degree of safety, since the igniter may go out. Primary ignition is performed with matches or using a piezoelectric element.

The second method is electronic ignition in a gas appliance - it is provided by a high-voltage converter, the energy for which is supplied by electricity or batteries. Read also: “How a gas burner for a stove works - types, advantages of use.”

The first method is used in non-volatile devices - they do not have electronics, and the second option is when automatic gas burners are used for heating boilers. In this case, in addition to electronics, flame ionization control modules are installed on board.

Different types of fuel can be used to ignite the burner. The natural gas supplied from the main line is purer; it is supplied at optimal pressure, so the flame in the device does not smoke. Such boilers are connected to the network without making any modifications.

There are burners on sale that can operate on propane. This will require reconfiguring the system and installing the nozzle. When burned, the flame gives off a yellow glow, and there is an increased deposition of soot on the walls of the chimney. The jets normalize the propane pressure to a normal value; they are supplied as a kit or purchased.

Types of burners

Many people believe that a burner is simply a nozzle through which gas is supplied. But it is not so. It also mixes air into the fuel. It is important to consider that the product must have a special design that makes the mixture stable.

The device can be of several types, depending on the method of adding oxygen to the gas:

- atmospheric burner;

- ventilator;

- diffusion-kinetic.

Atmospheric

The operating principle of this component is simple: gas passes through an ejector, where its pressure is reduced. In this case, air gets inside due to different atmospheric parameters.

These devices have many advantages:

- simple design;

- compactness;

- quiet operation;

- reasonable cost;

- the possibility of converting a solid fuel boiler for this equipment - the burner is simply installed in the ash pan chamber.

Fan

In this type of device, air is supplied in the required quantity through a fan. Due to this supply of oxygen, they have many advantages:

- There are no restrictions on power - any amount of gas is provided with the required amount of air, which is needed for complete combustion without residues.

- The chamber in which the reaction takes place may be closed. Oxygen enters inside through a special air duct. This allows you to completely prevent combustion products from entering the house due to reverse draft. There is no need to install a separate air duct. For this, special coaxial chimneys are used, which in fact are a pipe located inside another. The smoke is discharged through the internal element, and oxygen enters the boiler, passing between the internal and external walls.

- Human participation during use is minimized, since the equipment has a “smart” configuration function.

This type of burner also has a number of disadvantages:

- Compared to atmospheric ones, they are noticeably louder.

- They have a high price.

- They only work in conjunction with electricity - they must have their own uninterruptible power supply. Otherwise, they may fail due to voltage drop.

Diffusion-kinetic

Basically, such equipment is found in large industrial heaters. The operating principle is based on both atmospheric and fan heating.

DIY gas burner

Since designing a fan type requires special equipment, let’s consider creating a gas burner for a solid fuel boiler with your own hands. It is best to choose a valve from an oxygen cylinder, standard VK-74. To do this you need:

- The outlet pipe is additionally equipped with a fitting, which can be connected to the reactor using a hose.

- A cap with a small hole for connection to the nozzle is installed on the inlet side of the pipe connected to the cylinder. The latter can be taken from a blowtorch or stove.

- A steel pipe with a length of 100 mm and a wall thickness of 2 mm is welded to the cap.

- It is imperative to ensure that there is a gap of 15 mm between the cap and the nozzle, through which oxygen will flow. That is why you must first attach three small pieces of wire to the first one (they can then be bent to the desired location), and only then the pipe.

- The burner itself is ready. After this, you need to make a base on which it will be located for installation in the combustion chamber.

Advantages and disadvantages

The use of gas heat generators in a bathhouse has many advantages:

- efficiency. You just need to open the valve and light the nozzle, and in an hour the steam room will be ready. There is no need to prepare and store firewood/coal, load the firebox, control the work process,

- high efficiency. The productivity of gas equipment is significantly higher compared to TT units,

- environmental friendliness. During operation, gas burners for sauna stoves provide a low level of emissions harmful to the environment,

- ease of maintenance and care. There is no need to remove ash, as is the case with solid fuel. All that is required is timely cleaning of the chimney,

- efficiency. This figure is almost 30% higher than that of TT boilers, and more than 100% higher than that of electric heat generators.

The main disadvantage of gas burners for sauna stoves is the need to obtain permits for installation.

Gas boiler fan burners

Fan or forced-air burners operate by supplying air from the street using a fan. Fan operation is adjustable. Burners with external air supply operate stably at any gas pressure; for such boilers there is no need to make vertical chimneys, a coaxial chimney is sufficient; the efficiency of such boilers is close to 95%. True, they work noisily and cost 2 times more than atmospheric burners.

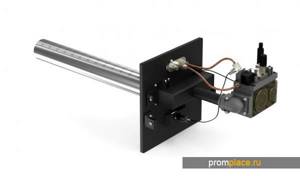

It is worth noting that fan burners are hung on the boiler. This makes it possible to change the burner and switch from gas to liquid fuel.

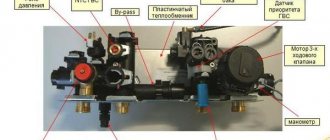

How do wall units work?

For small houses, wall-mounted gas boilers are quite suitable. Their operating principle is approximately the same, but smaller parts and additional elements are used in the form of a circulation pump and a membrane tank. They differ from conventional analogues in their compact size.

As with floor-standing structures, wall-mounted gas boilers can be single-circuit or double-circuit. They can be equipped with a closed or open combustion chamber. The devices are fixed to the wall using special brackets.

The operating principle of a wall-mounted gas boiler is based on the presence of a complex automation system, which is considered the most capricious unit in terms of maintenance. It often fails during operation of the device. It is problematic to repair it with your own hands, so you have to call a specialist, which leads to additional costs.

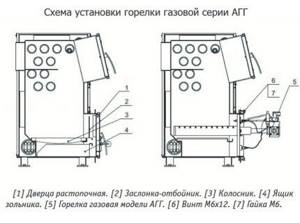

Installing a gas burner in a solid fuel boiler

After sound reflection and a real assessment of their capabilities, most home craftsmen still give preference to the modernization of solid fuel boilers that previously processed firewood or coal. A factory-made gas burner is simply placed in their firebox.

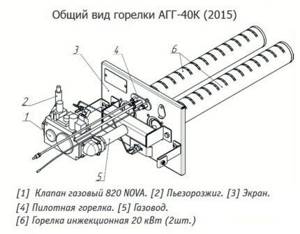

Let's consider the stages of installing a Teplodar AGG burner device:

- Dismantling the firebox door, the ashpan damper (or the ashpan itself, if it is made in the form of a drawer with a solid door), the bumper and the grate. In short, you need to remove all structural parts located within the firebox and ash pan.

- Fixing the burner device. A burner block is mounted in the firebox channel freed from the above elements. If the Teplodar stove is designed for changing fuel, then the burner module is fixed in the channel through standard ears with screws and nuts threaded into them.

- Connecting automation to the remote control. The devices included in the design of the burner block that ensure automatic operation of the boiler are connected to the control panel.

- Thermostat sensor mount. It is installed on the supply pipe, wrapped in insulation to protect against external mechanical and temperature influences, and on top with ties.

- Putting it into operation. It is carried out after checking the draft and burst ventilation of the room with a modernized boiler. Using a simple handle, you select the most suitable mode.

We remind you that in accordance with the requirements outlined in the “Safety Rules for Gas Distribution and Gas Consumption Systems”, all work on installing equipment, replacing burners, servicing equipment and connecting to the network supplying blue fuel must be carried out by gas workers.

In accordance with federal regulations and standards, it is necessary to conclude an agreement with representatives of gas services for the supply of gas and related services. It is clear that not all remote settlements will be able to be served by employees of gas organizations. However, it is advisable to adhere to the requirements in order to avoid catastrophic consequences.

Should you take risks or value and protect your health with the well-being of your loved ones? It's up to you to decide. It is wiser to refuse threatening measures, but knowing about the process of their implementation is very useful in order to monitor how efficiently and honestly the gas workers work.

Required Permissions and Installation Requirements

To install a burner in a sauna stove, permission from the gas supply authorities is required. In the case of atmospheric devices, operating conditions must meet the following requirements:

- the presence of a high-quality room ventilation system,

- adjustable traction,

- the volume of the premises being used is at least 12 m³,

- ensuring fire safety measures: reliable insulation of the chimney when laying the chimney through the floor slabs and roofing system, equipping the top with a spark arrester.

When purchasing a device, a set of documents is included in the form of certificates of conformity and permission from Rostechnadzor. If the installation rules are followed and the above documentation is available, there is a chance to obtain permission for operation from the gas supply organization.

When installing supercharged models, it is sufficient to comply with fire safety rules and the availability of accompanying documentation, since due to the features of the functionality, there are no requirements for the place of operation.

It is worth considering that all this is valid when using main gas. In the case of autonomous gasification, for storing liquefied gas cylinders, according to the regulations, a separate metal cabinet is used or a gas tank is equipped. The underground tank provides for volumes of 3 m³ and a location at least 5 m from the building. A pipeline of steel pipes is laid from the storage facility to the heat generator, ensuring reliable tightness of the channel.

Gas burners for boilers

A gas burner is a device in which gas is mixed with air, followed by combustion of the gas-air mixture in a heat exchanger - in a boiler.

A turbocharged (or pressurized) gas burner is an independent heating unit in which gas is mixed with air using a fan. It is installed in a heating boiler designed for this purpose - a universal boiler, on which diesel, oil, and combination burners can also be installed.

Gas burners can also be installed on solid fuel boilers, if this is provided for by their design. Most often these are pellet boilers. However, it must be borne in mind that in order to install a gas burner on a solid fuel boiler, it must be certified for this. Otherwise, gas workers simply will not give permission to connect gas to the boiler.

Gas burners are suitable for any universal heating boilers and can reach a power of 15 MW and above, they are easy to use, have low noise and emissions.

Modern gas burners for boilers are simple and highly reliable devices that do not require much effort to maintain and rarely break down. A properly selected and adjusted burner will last for years.

Classification of gas burners for boilers:

- Single-stage - operate with constant power.

- Two-stage - at the 1st stage they produce 60-80% of the power, at the 2nd - 100%.

- Three-stage - more often used in heat generators (at the 1st stage they produce approximately 40% of the power, at the 2nd - 70%, at the 3rd - 100%).

- Modulation - have smooth power adjustment from a minimum (about 30%) to 100%.

Modulation burners are the most economical in terms of fuel consumption.

How to properly install a gas burner on a boiler:

1. Burner

2. Hatch

3. Thermal insulation material

4. Flange

Flame size of gas burners

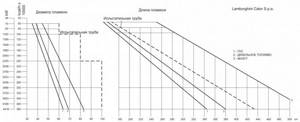

The flame sizes of the burners depending on the power are presented in the following graph:

Dimensions are approximate and depend on the following factors:

- Excess air.

- Combustion chamber shape.

- Location of pipes in the boiler (natural/forced circulation).

- Pressure (positive/negative) in the combustion chamber.

Don't forget to compare the size of the firebox and flame!

The graph shows the relationship between the sizes of the burner flame and the boiler furnace. The data is approximate and depends on many factors, such as firebox resistance, type of fuel, etc.

- Cash payment - upon receipt of goods. Prepayment in the office, if the product is a custom item;

- Cashless payment with VAT;

- Payment/prepayment by card.

- Delivery of the goods is carried out at the agreed time to the address you specified.

- Delivery in Moscow and the Moscow region is carried out by the company's delivery service. Delivery is possible in the evenings and on weekends by agreement with managers.

- Delivery cost in Moscow within the Moscow Ring Road: 400 rubles.

- Delivery of goods costing less than 20,000 rubles is carried out in agreement with the manager.

- Delivery cost outside the Moscow Ring Road: 400 rubles +30 rubles/km (tariff can be changed depending on the direction);

- Delivery throughout Russia is carried out by transport companies at the tariffs of transport companies, the cost of delivering cargo to the transport company: 400 rubles.

Design and principle of operation

The principle of operation of such a device is simple - gas, using an ejector, passes into the internal cavity at high speed, which allows air to be drawn into its volume, mixing it with gas.

Through distribution pipes, the finished gas-air mixture flows to the holes, at the exit of which it is ignited using a special ignition device. Most household heating boilers use a piezo igniter

Basic nodes:

- nozzle device;

- igniter or piezo ignition;

- primary sensor that monitors the presence of flame.

Features of setting up and cleaning the burner

In everyday life, users often encounter a problem when the burner of a gas boiler does not light up. This most often occurs due to poor purification of the incoming gas. It is often transported along with various debris, which clogs the burner and prevents gas from passing through the technological openings.

It is almost impossible to deal with this problem, because only utility services can install filters in the centralized gas supply system. You can try to do this in your apartment, but then you will have to constantly maintain the filters, which, in fact, creates a new problem that is absolutely identical to the previous one.

How to clean a gas boiler burner? This question is regularly asked by all users. In any case, boiler maintenance must be carried out annually to prepare it for the heating season. The cleaning procedure takes a lot of time, so it is better to do it on a weekend. The operation will require detailed disassembly of the heater, so you need to get the instructions and see how it is done correctly. There you will also find practical recommendations for cleaning.

Adjustment, adjustment and replacement of the burner of a gas boiler should properly be carried out by a representative of the trading company or service center. But users often do not want to spend several thousand rubles on calling a specialist and try to do everything themselves.

If you have the skills and tools, this is nothing to worry about. But improper handling can lead to damage not only to the burner itself, but also to the entire boiler. Then the savings will result in significant additional expenses. Therefore, you need to be aware of whether you can service the heater yourself, or whether it is better to dial a number to call a professional specialist.

About manufacturers and costs

On the modern market, the range of gas equipment is truly huge. Equipment from both domestic and foreign manufacturers is presented here. But, of course, European products are still more popular, in particular from:

- Great Britain;

- Germany;

- Italy.

Gas burner Weishaupt Monarch WM-G 20

Gas burners from these countries are compatible with many domestic boilers, in particular Lemax and Kolvi. As for the cost, it depends on a number of factors, including:

- brand;

- characteristics of a specific model;

- her type.

Prices vary widely - from 16 to 90 thousand rubles. It is for this reason that before purchasing, you should read the recommendations not only from manufacturers, but also from experienced specialists, and only then make a decision in favor of one option or another.

Coal-wood boiler "Topol"-M-14 with the possibility of installing a pellet or gas burner

| Technical features | Vertical and horizontal fuel loading. Type of fuel: firewood, coal, briquettes |

| Add. Options | It is possible to install (additional fee): a special heating element unit, draft regulator, pellet burner, non-volatile gas burner; |

| Equipment | Complete boiler (in a wooden container), chimney pipe, grate, ash box, poker, scoop |

| Weight without packaging, kg | 113 |

| Warranty from date of sale | 1 year |

| Heated area, m2 | Up to 105 |

| Rated thermal power, kW | 14 |

| Efficiency, % | 75 |

| Water chamber volume, l. | 46 |

| Water pressure in the heating system, kPa | 300 |

| Firebox depth, mm | 380 |

| Chimney diameter | 150 |

| Connection size | 40 |

| Overall dimensions, h*w*d, mm | 845x440x875 |

| By number of circuits | Single-circuit |

| Chimney type | Atmospheric |

| Selecting a fuel type | coal, wood, in combination with gas |

| Additional options | Heating element, draft regulator |

| Heat exchanger material | Steel |

The solid fuel heating boiler “Topol-M” is a modification of the “Topol” boiler. It is designed to work in autonomous heating systems with a working pressure of up to 3 atmospheres and can be used for heating residential and industrial premises with an area of up to 140 sq.m. The new line has been expanded by one model of lower power and consists of boilers of 14, 20, 30, 42, 60 and 80 kW. There are many differences from the previous model and they are quite significant. The first thing that catches your eye is the new design. The rest is less noticeable, but much more important. The boiler body has become thermally insulated and more gas-tight. The water jacket of the boiler under the decorative casing is now covered with basalt cardboard, which significantly reduced heat loss. The fire door opens in a horizontal rather than vertical plane and is locked with a lock. The ash pan door is equipped with a blower damper, which is adjusted manually using a screw or controlled by a mechanical draft regulator, which is installed as an option. Thus, the increased gas density of the boiler makes it possible to more accurately regulate the oxygen supply and extend the fuel combustion cycle on one load to 10-12 hours. The combustion chamber has undergone changes: an additional horizontally located heat exchanger in combination with a removable damper makes the gas duct three-pass. This increases the heat transfer area and improves heat transfer efficiency. The damper is made removable specifically for cleaning the heat exchanger. In addition, there is a cleaning hatch on the flue, which makes it easy to remove soot. A thermometer is installed on the top panel of the boiler to measure the temperature of the water supply. Topol-M uses coal and wood as fuel. As an alternative, electric heating is possible, which is provided by a built-in heating element with an external control panel (installed upon request and is an option). It is also possible to install a gas burner in place of the screw door. In addition, the presence of a screw door creates additional convenience for loading firewood into the firebox. The depth of the firebox ranges from 38 to 64 cm. A separate ash door allows you to remove ash at any time while the boiler is firing. For user convenience, new ergonomic handles are installed on all three doors. Due to the design features of the fuel combustion chamber, increased gas density and workmanship, the Topol M series of boilers has the highest efficiency among budget models of solid fuel and combined boilers.

Classification by type of fuel

The gas boiler will operate on natural (main) methane gas or liquefied gas from cylinders (propane-butane). At this time the difference in price is insignificant.

Since in conditions outside the city it is not always possible to connect to the main line, you will most likely need a propane or butane atmospheric burner for your heating boiler.

Structurally, these boilers are the same; the burners have their own small parts. Burners for real and liquid gas are distinguished by the design of their spray devices. Many units are equipped with spray devices for two types of fuel.

As a result, atmospheric burners for propane heating boilers can be easily reconfigured to work with main gas and vice versa.

Homemade units

Some craftsmen make gas burners for boilers with their own hands (for solid fuel boilers). Please be warned that this is not safe. And no one will allow you to connect such a structure to the gas main. Most often, such “crafts” are made on the basis of some gas units that have spent their time. Remember that a homemade gas burner for heating your home is far from the best option. It is best to purchase the simplest gas non-volatile boiler and convert it to bottled gas.

DIY options

Often, a homemade gas heating unit is made from an old empty cylinder, which is first filled with water to remove any remaining fuel. To assemble a metal heat generator with your own hands, use ready-made drawings.

Materials and tools:

- empty gas cylinder. You can buy a new cylinder or find a used one at a scrap metal collection point,

- used wheels from trucks and cars, they are selected depending on the expected power of gas-fuel heating equipment,

- metal pipes. For gas and air supply, a model with a cross section of 2 cm is used; for the construction of a chimney, a pipe with a diameter of 4 cm is suitable,

- atmospheric burner,

- Bulgarian,

- drill with appropriate attachments,

- welding machine.

Sequence of work:

- Using a grinder, cut a hole in the upper part of the cylinder to fit the dimensions of the wheel rim.

- The disk is inserted into the hole and welded using a welding machine.

- The air supply structure is made from a pipe d2 cm by drilling 9-11 holes with a diameter of 5 mm on the surface.

- A hole d50 mm is drilled in the lower part of the cylinder, a pipe is inserted so that on one side it protrudes 15-20 cm. The seams are sealed by welding.

- The gas pipe is welded in a similar way, the free end is equipped with an adapter for connection.

- A chimney is installed in the upper part of the structure.

At the end, the firebox door is made from a steel plate, a hole is cut out from the side of the homemade structure for it and installed on the hinges.

Hand-drawn diagram of a homemade gas burner for a sauna stove

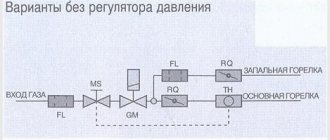

Variations with two stages

To arrange the operation of a two-stage burner, there are two modes or varying fire power. If using one stage the boiler operates at its maximum, then when switching to the second stage, productivity is reduced by 50-60%.

Variation of modes in boilers is carried out automatically based on a signal from special sensors. They control the temperature of the coolant. Also, modes can change when the gas pressure in the main network changes.

Switching the boiler to a less tormenting mode has certain advantages:

- There is a saving of gas or other fuel.

- All equipment develops an operational period, as the number of starts and stops decreases.

A device with two stages can have a smooth change of modes.