Czech gas water heater Mora: design, advantages and disadvantages

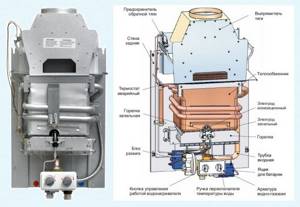

The Mora gas water heater is a flow-type device that allows you to provide hot water to an apartment, private house and cottage. The column consists of an igniter, a gas burner, a heat exchanger, and a gas-water valve block.

The principle of operation of the column is quite simple: when the tap is opened, the igniter ignites the burner, which heats the water in the heat exchanger.

Passing through the heat exchanger tubes, the water is heated and enters the heating and hot water supply system. When the tap is closed, the ignition goes out and the column turns off. Different Mora speakers can have different types of ignition: from a piezoelectric element and from rechargeable batteries (electric). The equipment runs on natural gas, but, if necessary, it can be switched to the mode of using liquefied fuel. Such multifunctionality of the speakers is extremely important for the implementation of continuous heating and hot water supply in country houses and cottages not connected to the gas main.

In addition, the advantages of Mohr's columns include:

- Multi-stage safety system: the dispensers are equipped with overheating protection, reverse draft valves, burner flame and dry start fuses;

- High efficiency (about 94%);

- High efficiency even at water pressure from 0.2 atm;

- Thick copper heat exchanger, which, over time, will not leak;

- Well-thought-out burner design and igniter protection system from contamination;

- Quiet operation.

Disadvantages of the equipment include user complaints about the lack of parts for Mora’s old equipment on the modern market, and the rather high cost of the speakers. Although, the price of the equipment does not exceed well-known analogues (such as, for example, Hayes). So, both Heis and Mora will cost the buyer 16 thousand rubles.

Geyser Mora Top: installation and operating instructions

The Mora Top line of wall-mounted Czech speakers consists of several models with different performance characteristics. In the floor-standing series, the Mora 100 NTR boiler is distinguished by its quality and efficiency. The most powerful wall-mounted model is considered to be Vega 16, capable of passing up to 15.2 liters of water per minute. The Vega 10 gas boiler is considered the most affordable of the Top line. All models are produced in a compact body and differ only in the type of ignition (models marked “E” have electric ignition).

When installing and putting the column into operation, you must follow these recommendations:

- Connection of equipment that has been in a cold environment for a long time should be carried out no earlier than after 120 minutes;

- When installing the boiler, it is necessary to leave at least 10 cm from its side walls to the nearest objects and adjacent walls;

- There should be a distance of 40 cm or more above the boiler;

- When installing a thermostat, you should use a device with a potential-free output contact: the thermostat should not supply voltage to the water heater;

- It is strictly prohibited to store explosive substances near the boiler.

The installation and operation instructions for the water heater do not recommend connecting the equipment with your own hands. It is better to install a strainer at the entrance to the system. It will allow you to extend the service life of the membrane and filter of the water receiving unit of the column, and heat exchanger tubes.

A little about the company

MORA-TOP began its 185-year history as a subsidiary of MORA MORAVIA AS. And only in 2003 it became independent. In the spring of next year, construction of the plant began in the Czech town of Unicov. The capacity occupied 5,000 square meters and was built in less than a year, so that in the spring of 2005 the world saw the first Mora instantaneous gas water heater produced at the new factory.

Today the company has a fully established technological chain for the production of equipment, including:

- Technology for processing copper and manufacturing heat exchangers, as well as stamping, degreasing stage, soldering and painting.

- Production of structural thermoelements.

- Assembly of finished products within the assembly line.

- Mandatory testing of devices.

Water part of the gas water heater: main faults

Often, problems with the operation of the column relate to problems in the gas-water unit system. In order to be able to troubleshoot problems yourself, if necessary, you need to know how the water part of the column works.

Thus, the gas-water block of the column consists of:

- Membrane and disc;

- Water temperature regulator;

- Water supply regulator when the mixer is open and closed;

- Venturi nozzle;

- A mesh filter at the entrance to the unit.

Malfunctions in the unit can occur both under the influence of external factors (for example, due to damage to the speaker housing, power cable) and due to wear and tear of the equipment. Most often, incorrect operation of water heating gas equipment is associated with low quality tap water, low water and gas pressure, and clogged ventilation pipes.

The most common internal failures of Mora geysers are:

- Clogged inlet water filter of the water intake unit;

- Deformation or clogging of the membrane of the gas-water unit;

- Blockages in the heat exchanger pipes.

In addition, often the reason for the incorrect operation of the electric speaker is the discharge of the power elements (batteries).

A little about the company

MORA-TOP began its 185-year history as a subsidiary of MORA MORAVIA AS. And only in 2003 it became independent. In the spring of next year, construction of the plant began in the Czech town of Unicov. The capacity occupied 5,000 square meters and was built in less than a year, so that in the spring of 2005 the world saw the first Mora instantaneous gas water heater produced at the new factory.

Today the company has a fully established technological chain for the production of equipment, including:

- Technology for processing copper and manufacturing heat exchangers, as well as stamping, degreasing stage, soldering and painting.

- Production of structural thermoelements.

- Assembly of finished products within the assembly line.

- Mandatory testing of devices.

What to do if the Mora column does not light up

If the Mora column stops igniting, it is necessary to check the equipment for depressurization (leaks) and external damage (both the housing and the power cable). In addition, you should make sure that there is ventilation draft and good cold water pressure. You can try changing the batteries in the electric speaker.

If the column does not light up even after this, then you need to:

- Clean the filter and membrane of the water intake unit from dirt. To do this, you need to hold the parts under high pressure of water.

- If there are breaks in the membrane or deformation of its edges, replace the element. At the same time, it is better to replace the old membrane with a silicone one: the service life of the second one is longer.

- Clean the ignition wick if the column ignites with pops and then immediately goes out.

- Replace the solenoid valve or servomotor if cleaning the wick does not help.

- Clean the ionization sensor electrode if there are ignition sparks, but the column does not light up.

All repair work must be carried out with the water and gas supply turned off. If the column does not turn on after all the manipulations, you need to contact a specialist.

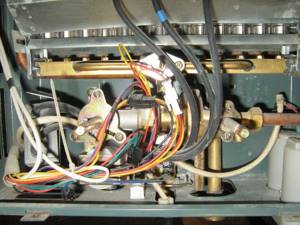

Full disassembly service

Do not be afraid to disassemble the water heating installation, the procedure is not that complicated. You will need the most common tools - screwdrivers, pliers, standard wrenches. What to do before starting work:

- Close the taps of the cold water, hot water and gas supply pipelines. Unplug the turbocharged dispenser from the outlet.

- Substituting the container, unscrew the union nuts (American) on the connection of the water pipes. Disconnect the connections from the unit without losing the rubber gaskets.

- For convenience, it is recommended to remove the gas heater from the wall. It is not easy to disassemble and clean a unit that is hung too high or installed in a narrow niche.

- To dismantle the water heater, disconnect the gas line and the chimney pipe. Remove the unit from the hooks.

Lay the hot water column on a horizontal surface and proceed to further work, the order of which is outlined in our instructions.

How to remove the heat exchanger and column burner

We will show the disassembly sequence using the example of a cheap Chinese Novatek water heater. We present step-by-step instructions with photos:

- Remove the control handles mounted on the front panel. Unscrew 2 screws (or 2 plastic clips) and remove the device casing.

- The next step is to remove the smoke collector. To do this, disconnect the wires from the draft sensor and unscrew the screws holding the diffuser box.

- Disconnect the heat exchanger tube from the water unit by disassembling the connection with the union nut. The second pipe must be freed from the lock washer, pressed with 2 screws.

- Disconnect the burner from the gas valve by unscrewing the 2 screws on the flange. Having moved the radiator upward, carefully remove the burner device (pull towards you) and move it to the side.

- Unscrew all screws connecting the heat exchanger to the rear panel of the water heating unit.

- Pull out the radiator completely and remove the burner, disconnecting the wires along with the ignition electrodes.

Note. While removing the heat exchanger, disconnect the wires from the temperature sensor.

Disassembly of geysers from other manufacturers may differ, but not fundamentally. The order of work remains unchanged. Let's list some important points:

- in a chimneyless turbo column, the fan will have to be removed;

- in units of the Italian brands Ariston (Ariston) and some others, the pipes are connected not with nuts, but with self-clamps;

- If the water heater is equipped with an igniter, then before removing the burner it is necessary to disconnect the gas tube connected to the wick.

Important! Be careful not to lose any rubber or other gaskets discovered during disassembly. Before assembling and installing the column, it is advisable to replace these seals with new ones.

Our expert plumber will demonstrate the above process in detail in his video:

Flushing procedure

This operation is very simple compared to disassembly - cleaning the gas water heater begins by immersing the heat exchanger in a container with washing liquid. The procedure is as follows:

- Take a bucket or deep basin, fill it with water and prepare a cleaning solution according to the recipe on the package. The concentration of citric acid is 50-70 grams per 1 liter of liquid.

- Immerse the heat exchanger in the container with the radiator down and the pipes up.

- Using a watering can, fill the coil with detergent. Rinse it periodically by adding new solution.

- Flush the heat exchanger until clean liquid comes out of the tubes without scale flakes. Then run tap water through the coil to remove any remaining product or impurities.

Advice. Using citric acid, heat the solution to a temperature of 50-60 °C. The reaction will be more intense and end faster.

The removed burner can be cleaned from the outside and purged or washed with a solution of citric acid (no more than 50 grams per liter of water). Finally, rinse the element with running water, blow with compressed air and dry thoroughly. Do not ignore other parts of the gas water heater - the mesh filter, smoke collector and combustion chamber, remove soot and other contaminants from them.

After washing and drying, put the heat exchanger back in place, connect the burner and follow the remaining steps to reassemble the water heater. It is important to achieve tight connections: when installing old gaskets, treat them with high-temperature sealant. Check the joints for tightness using water pressure (4-6 bar).

It wouldn’t hurt to blow out the inside of the burner with compressed air at a pressure of 4-6 bar

For reference. The duration of washing depends on the thickness of the scale layer inside the column heat exchanger and ranges from 2-3 hours (prevention) to 2 days.