Classification of furnace solutions

Firstly, we must immediately make a reservation that the construction of a furnace requires three types of masonry mortar. And that's the minimum. However, these solutions cannot be mixed like ordinary cement-sand ones.

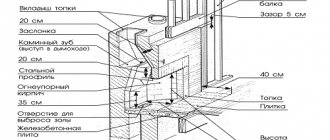

The thing is that the stove consists of three structural elements: the foundation, the stove itself with a firebox, and the chimney. Now imagine that the foundation must withstand quite serious mechanical loads. And most often in winter its temperature is 0°. In the firebox the temperature reaches up to +1000C, and the chimney located outside is constantly exposed to low temperatures. Now it is clear that ordinary cement mortar will not withstand such varied loads.

Secondly, today the building materials market offers ready-made mixtures. It would seem very convenient. Add water according to instructions and apply. But let's look at the economic side of the issue.

Ready-made oven mixtures Source applesakhalin.ru

Laying one hundred bricks will require three buckets of mortar. And 100 standard brick blocks are not enough for half the cooking surface of a regular summer kitchen. Not to mention the foundation and chimney. That is, you will have to purchase a fairly large number of bags of dry mixture for ovens from the store. And the prices for this material are considerable. So think about how to prepare a solution for laying a clay stove without buying ready-made mixtures. It will cost many times less.

Understanding the terms

In the kiln business, three terms are used in relation to masonry mortars:

- Heat-resistant solution. This material can easily withstand heating to fairly high temperatures. And when cooled, it does not crack, does not deform, does not change its structure, and maintains a high design load-bearing capacity.

- Heat resistant. Such a solution can easily withstand dynamic loads in a heated state. It retains its mechanical characteristics during temperature changes. But the magnitude of thermal deformations is slightly lower than that of the heat-resistant version.

- Refractory. It absorbed all the characteristics of the two previous types. But at the same time, it easily tolerates the negative effects of chemically aggressive substances. This refers to waste carbon monoxide that passes through the firebox and chimney.

Now the question is what kind of mortar is needed for laying the stove. The answer is heat-resistant and fire-resistant.

Heat-resistant oven mixture for masonry Source catalogue.brick-concrete-concrete.rf

But as for the foundation, such a complex solution is not needed here. The thing is that this part of the structure is practically not subject to serious temperature fluctuations. After all, the foundation itself is a concrete monolithic structure on which two rows of bricks are laid. This is exactly what we are talking about. For their laying, ordinary cement-lime mortar is suitable. The main thing is to use red solid brick for masonry.

Now about the body of the furnace, or as it is called, the heat-storing part. In essence, this is a stove made of red solid brick of the M150 brand, inside of which there is a firebox. The latter folds separately, and more about it below.

So, in the heat-accumulating part of the structure, the heating of the bricks is small - up to +600C. But it is here that the bricks are exposed to intense exposure to carbon monoxide and acidic condensate. For masonry it is better to use ordinary clay mortar. Let’s immediately say that this mixture is simple in composition, the preparation method is specific. More about him below.

Next is the firebox, which is assembled from fireclay bricks. Here the temperature reaches +1200C, so a fire-resistant mortar is used for masonry - clay-clamotte.

Chimney mortar - lime Source i1.ytimg.com

Now the chimney consists of several parts:

- Source. Here the temperature does not rise above +400C, so the brick and mortar are exactly the same as in the heat-storing part of the furnace.

- Fluffing is a transition through the ceiling of a house. Temperatures in this part are low, but a certain structural strength is required. Therefore, for masonry we choose solid bricks and lime mortar.

- Chimney located in the attic and above the roof. High temperatures have no effect here. But there are special requirements for strength, especially for the external part. Because it is affected by wind loads. For construction you will need ordinary red brick and lime mortar.

- Pipe fluffing . Everything here is the same as in the previous paragraph.

Please note that each part uses its own brick and mortar. This is what allows you to save a lot on the purchase of building materials.

Manufacturing recommendations

Construction stores sell ready-packed mixtures for masonry. They consist of high quality clay mixed with fine sand.

To make masonry mortar with your own hands, you have to take sand and clay from the area. Stove makers sometimes use several types of raw materials from different areas. In order not to make a mistake and not to bring the wrong material, it is useful to consult with local craftsmen.

Which clay to choose and how to determine its quality

Clay is a finely dispersed rock with a particle size of thousandths of a millimeter . The chemical formula of the bulk of the rock is Al2O3 . This material is very plastic, susceptible to mechanical stress, clay paste will withstand the thinnest modeling. The volume of raw materials swollen with water increases up to two times .

The composition of clays includes oxides of iron and other metals, plant residues, hydrocarbons, carbonates, chalk particles, and iron sulfide. Impurities give this rock its different colors .

Fatty clays are finely dispersed and highly plastic . When dried, the raw material cracks greatly, although the dried pieces are highly durable. Such rocks contain from 3 to 15% sand.

Lean (sand-enriched) clays, on the contrary, have low plasticity . When dried, they become fragile, destroyed due to the high content of granular material and are close in composition to sandy loam. They contain more than 80% sand.

Clays of normal (medium) composition do not crack after drying and do not crumble under mechanical stress.

The quality of raw materials is determined experimentally. There are several ways to determine the fat content of clays:

Method 1. From clay that was soaked a day ago , roll sausages up to one and a half millimeters thick and up to 20-22 cm . They wrap a cylindrical object with a circumference of about 50 cm .

Oily, viscous clay stretches smoothly and easily without breaking. When the raw material has a normal composition, small cracks will appear on the flagellum due to stretching. A rope of thin clay mass will break when stretched.

Method 2. Dry material is poured with water and softened to a liquid dough . The soaked mass is stirred with a wooden spatula and lifted up. Oily, viscous clay forms a layer on the blade that strongly adheres to the wood. Normal clay falls off the mixer in chunks. Skinny - everything falls off, only moisture remains on the stirrer.

Method 3. Press the newly rolled clay sphere . If the material has a greasy composition, cracks will appear on the sphere when it is flattened to half its diameter. On raw materials of normal composition, cracks will appear when flattened by a third of the diameter, on thin clays - when slightly flattened.

Method 4. The clay is soaked and kneaded. The amount of water should be small, as for dumplings, elastic dough. 40-50 mm is rolled out of this material and a cake 25-30 mm . The samples are dried for a couple of days.

- Oily, plastic clay will develop cracks after drying.

- If the raw material has a normal composition, there will be no cracks.

- On lean clay, saturated with coarse impurities, there will be no cracks, but the ball will be fragile and will crumble under mechanical stress.

If a ball is dropped from a meter high , oily (and normal) clay will not break. A ball molded from thin clay saturated with coarse fraction will break into many pieces and grains of sand.

What sand to prepare

Only fine sand with a grain diameter of up to 1.5 millimeters . Sand of a mixed composition (quartz, feldspars, pieces of other minerals, mica) or pure quartz sand is suitable for masonry.

A few words about fireclay

The question of what kind of solution the stoves are placed on involves one material that many consider to be a mineral. This is fireclay. We must immediately make a reservation that this is a mixture of high-alumina clay and several minerals: garnet, zirconium and others.

Fireclay is produced by deep firing of the prepared mixture. In this case, they burn even after complete removal of water from the mixture. The main task of the technology is to pelletize and sinter the components.

It is this material that is used in the process of making fireclay bricks, where the first one performs the functions of sand. For household stoves, bricks with a water absorption of 15-20% are suitable. As for solutions, here you can use fireclay in the form of a mortar - this is an unshaped mass. Or in the form of broken fireclay bricks, which are sold on the market as sand or crushed stone. Mortar is better.

Mortar is an unshaped mass of fireclay Source i.stroy-ka.ru

See also: Catalog of projects of houses with a stove for permanent residence

Properties of masonry mortars for furnaces

Before making a mortar for laying a stove, you need to understand that the properties and characteristics of the mixtures mentioned above determine their place of purpose in the stove structure. Therefore, more specifically about them:

- Clay. This is a cheap material that can cost you nothing if you find the right clay. But kneading it is a labor-intensive process. Here are the characteristics of the solution: strength and heat resistance are average - up to +1100C, fire resistance - absolute, maximum gas density. Can be used if the stove is built indoors.

- Lime. To prepare, you need to know one important nuance - you use lime that is slaked completely to the last grain. If this is not done, then there is a high probability that these grains will create conditions for the appearance of cracks in the masonry. And this reduces the quality of the seam. As for the characteristics, then: fire resistance and heat resistance are below average, strength is above clay. The solution is not hygroscopic, so it can be used for stoves built outdoors.

Clay mortar for the oven Source www.diy.ru

- Cement-lime. Used to lay the foundation of the stove. Strength is high, gas density is low.

- Clay-fireclay. Exactly the same characteristics as clay, but higher heat resistance - up to 1200C. Used in the construction of fireboxes.

- Cement-chamotte. This is the most expensive solution of all, because only high-quality materials must be added to it. As for the characteristics, there is a difference: strength is comparable to cement-lime, heat resistance is like clay-fireclay, fire resistance is sufficient for combustion chambers.

Let us immediately make a reservation that all these solutions are difficult to mix by hand.

How to repair cracks in metal stoves

Cracks also appear on metal structures. If they are barely noticeable, then the smoke that often appears in the room when the stove is fired may indicate them. Putty-sealant will help eliminate the defect. The main component of the drug is silicone. Fire-resistant sealants contain iron oxide, which is why the product has a reddish tint. Such compositions can withstand maximum temperatures.

Neutral sealants are used between concrete and metal joints. Once dry, they lose their alcohol and become hard.

Important!

You cannot use sealants that contain acid; they trigger the corrosion process on the metal.

To make a quality repair, you will need 2-3 types of putty. The first ball is clay, then fireclay and lime, taking into account the composition of the material from which the stove is made. Correctly selected components will help extend the life of the stove.

Video description

The video shows how to prepare a clay mortar for laying a stove:

What is gas density - this is a characteristic of a solution, which shows that dense gases from fuel combustion cannot pass through the thickness of the applied mixture by diffusion. It should be noted that gas density is not hygroscopicity. The thing is that water vapor is more mobile, so it easily passes through the material. Hence the concept of “breathable” structures. For example, a cement-sand mortar does not allow vapor to pass through when it dries. But carbon monoxide still passes through it. Therefore, it is very important that the solutions used in the construction of furnaces must be selected in accordance with both hygroscopicity and gas density.

Removing Impurities

Almost all quarry clays and sands contain impurities and require purification. of plants, roots, grains of sand, pebbles, and pieces of crushed stone are removed from raw materials in various ways

How to remove impurities from clay

Impurities greatly degrade the quality of the masonry. Purification of raw materials is carried out in three stages:

- manual sampling of plant remains, roots, crushed stone, pebbles;

- sifting through a metal sieve with a hole size of 1.5 mm;

- soaking clay;

- rubbing through a metal fine-mesh sieve.

Photo 2. The process of sifting clay through a metal sieve. You need to press it with your palm so that all the particles pass through the mesh evenly.

In practice, to clean clay for mortar, craftsmen do without the labor-intensive process of soaking the raw materials.

How to remove impurities from sand

The sand is considered prepared when the water passing through it becomes clear . To prepare the material, you need to do the following :

- are manually selected from the sand .

- After a rough sampling, the material is sifted through a metal sieve with a mesh size of 1.5 mm .

- The sand is placed in a burlap bag (or net) and washed with running water . A hose is used for flushing; water is supplied under pressure.

Stove heating was half forgotten with the rapid arrival of the steam heating system in all houses. However, the lack of regulation of the heat transfer level created problems of both a financial and domestic nature. Unbearable heat or insufficient warmth did not suit everyone; a person wanted to establish a comfortable temperature in the house, not common for everyone, but the right one for himself. The ongoing construction of private houses, cottages, country houses, baths, saunas, and garages required the owners to find a practical solution to the heating issue.

It turned out that the stove is an ancient creation - a wonderful invention of mankind. It’s not for nothing that every Russian home always knew the saying “dancing from the stove.” This meant that she was in charge here. They cooked food on it, treated people, provided warmth, and dried shoes and clothes. Romance, nostalgia and practicality revive this miraculous structure. In this article we will look at what clay to use to prepare mortar for laying stoves.

How to choose the right components

How to make a mortar from clay for the stove so that it does not crack. It is clear that the quality of the final result always depends on the components of the mixture. Therefore, we will deal with each separately and outline some of the nuances of choice.

See also: Catalog of companies that specialize in installing stoves, fireplaces and equipping gazebos and grill houses

Clay

This is the main component. It is found in large quantities on any private plot. But here the question arises: is all the clay suitable for laying a stove? Moreover, when choosing this material in one place, you may encounter several of its types, arranged in layers. So what kind of clay is needed?

Fatty fireproof clay Source www.banikaminy.ru

Let us immediately make a reservation that all the above-described characteristics of solutions: strength, hygroscopicity, gas tightness, and so on, are determined by the properties of the clay. And the main property of the latter is fat content. Furnaces require material of medium fat content. Very oily clay cracks when dried, thin clay has low strength. For information, fat content is determined by the quantitative ratio of sand and two elements: silicon oxide and aluminum. Of course, organics also contribute their own characteristics.

Attention! If oily clay is found on the site, then it’s not a problem. It can be thinned by adding sand.

How to determine fat content. This can be done without laboratory tests. This will require a piece of material less than half the size of a fist. It must be kneaded with wet hands until it becomes plastic. Then the ball is placed between flat plates, for example, two planks or pieces of sheet iron. Pressure is created until the test sample cracks. Now the thickness of the resulting cake is measured. If this parameter has decreased by 1/3 of the diameter, then such clay can be used in kiln making.

And one moment. Not everything that comes across the site can be considered clay. There are so-called deception minerals that are very similar to clay. For example, bentonite, shale, marl and others.

Selection of clay mortar components

To prepare a high-quality solution from clay, you need to select all the components correctly.

You will need several basic components:

- Clay. This is the most important ingredient, it is the one that gives the mixture the necessary properties: viscosity, heat resistance, fire resistance. Not all types of material are suitable for this event: different options (especially those found in nature) contain many additives that can spoil the final result. It is not always possible to get rid of such impurities, and it can also be a very labor-intensive task. And since the main factor when constructing furnaces is tightness, the selected material is pre-tested and carefully checked.

- The standard method is to add sand. Its quantity depends on the measurements taken and may vary. Sand is poured into the prepared container, then clay is applied and covered with sand again. A shovel is used to knead the ingredients. If liquid comes out from above, it means a little more sand is required. Clay that is too dry should be diluted slightly with water. The composition is considered ready after it slowly slides off the shovel and has a uniform structure.

- With medium fat content, clay can be diluted without sand. The material is laid on the prepared platform in layers, wetting is carried out each time. When the height reaches 30–35 cm, mixing begins; for this, the back of the shovel is used: it is struck on the clay. The kneading continues until a homogeneous mass is obtained. The readiness of the mixture for masonry is checked as follows: a thin layer of the composition is applied between two bricks and left for some time. Then you need to lift the top piece, and if the second brick holds, then you're done.

You can determine the quality and readiness of the solution using tactile sensations. The resulting material is rubbed by hand: when a homogeneous rough layer is formed on the fingers, the mixture can be used. Externally, the composition should resemble thick sour cream, then the stove will be reliable and will serve for many years.

Video description

The video shows how you can determine the fat content of clay:

Sand

This building material is another component of masonry mortar for stoves. What sand can be used in this case:

- white quartz

- yellow , it consists of feldspar, suitable for all parts of the stove except the firebox.

If you buy sand on the market, then the best option is sifted sand of different fractions. It is this that creates the high strength of the masonry.

Now let's look at the question of how to make a mortar for the oven so that it does not crack, from clay and sand. To do this, you will have to conduct an experiment, for which you will need clay - 5 pieces. We add sand to four of them in different proportions: 25%, 50%, 75% and 100%. The solution must be mixed well. We leave one in the form of pure clay.

From these pieces, sausages of 30-40 cm are made, which are screwed, for example, onto the handle of a shovel. Then you need to wait until the samples dry. Sausages made from fatty clay do not crack, or only the top crust cracks. Samples made from lean material will crack completely, falling apart into pieces.

River sand for clay mortar Source www.diy.ru

Furnace inspection

To analyze the condition of the stove you do not need to have the professional skills of a builder or stove maker. The main thing is to detect all cracks and assess their size. If there are no major defects in the masonry, then removing the old coating and applying a new one will be sufficient. In addition, you need to remove part of the mortar between the bricks in the place where the crack formed. After these procedures, the masonry is covered with mortar so that the patches are not noticeable.

In the case of large defects, some of the bricks will have to be dismantled and replaced with new ones. The danger of a crack can be determined by the characteristic burning smell from the cracks and the release of smoke. Repairing large cracks is a painstaking and lengthy process. It is best to entrust such restoration to a professional.

Solution preparation technology

Which mortar for laying a stove is better - homogeneous. Therefore, it is very important to knead it correctly. Especially when the process is carried out using small-scale mechanization. The thing is that during the process of mechanical kneading, so-called gaps may appear inside the mixture. These are areas with a lot of clay milk. The latter will subsequently resolve, but the homogeneity of the material will be disrupted.

Some craftsmen beat clay. There is no need to do this for ovens. The main task is to strictly follow the technology. And it's simple:

- sifting components;

- mixing components;

- settling the resulting solution.

Kneading is usually done with shovels. Here it is important to carry out the operation until the mixture is completely homogeneous.

How to plaster a brick oven

So, having dealt with the question of what mortar is used for laying a brick oven, we move on to considering another position. Namely, what solution to cover the stove with so that it does not crack.

Firstly, you need to give time for the brick structure to shrink. Secondly, before starting plastering, the stove must be heated. The goal is to expand it in volume. Thirdly, a mesh is laid on the surface, which will strengthen the plaster layer. After which you can proceed to the main process.

The better to plaster. There are many options - these include ready-made mixtures and those prepared independently. The simplest is the clay mortar used for laying. Popular experience shows that it is necessary to add salt and wood ash to it. Two ingredients will not only increase the strength of the mixture, but also increase its heat resistance.

Plaster of a brick oven with a mesh attached to it Source avatars.mds.yandex.net

Before you prepare a solution from ash to putty the stove, you need to prepare all the ingredients. Here the ratio is:

- clay should be twice as much as sand;

- salt is added at the rate of 30 g per 1 liter of clay-sand mixture;

- ash at the rate of 50-60 g per 1 liter.

Features of material selection

The process of constructing modern stoves is divided into several stages:

- The first stage is the arrangement of the furnace foundation using a concrete composition;

- The second stage is the laying of a furnace from refractory bricks using a clay-based masonry compound;

- The third stage is lining the furnace with a plaster composition.

The most important is the stage of direct masonry and the preparation of a reliable base, which must have high performance characteristics - heat resistance, adhesion, water resistance, strength and durability.

To equip modern stoves, several types of masonry mortars are used: clay, lime and cement.

Masonry mortars can be simple or complex. Simple ones consist of one type of binder and filler; complex mixtures include two or more binders and several aggregates. Binding components are lime, clay and cement.

To prepare the mortar for masonry, you will need the following tools:

- Mixer;

- Kneading container;

- Sieve;

- Trowel;

- Master OK;

- Plastic spatula;

- Construction thermometer;

- Scales.

Briefly about the main thing

The technology for preparing mortar for laying a brick oven includes the main section - selection of components. It should be noted that the furnace itself consists of several parts that are subject to different thermal, chemical and mechanical loads. Therefore, each part has its own solution, which has its own characteristics. More often, clay mixtures are used to build brick ovens. And for the firebox they add fireclay.

Ratings 0