Advantages of metal stoves

Iron stoves have a number of advantages. These include:

- Heat dissipation. Wood-burning stoves made of metal warm up and begin to give off heat much faster than brick products.

- Small dimensions. Installation of metal stoves is possible if there is a minimum

- a lot of free space in the room.

- Mobility. Iron products can be easily moved from one place to another if necessary.

- Simplicity. Anyone can use a metal wood-burning stove.

- Functionality. Many modern models are equipped with a hob and oven. This allows you to cook food on them.

- Saving. An iron stove can be used to heat a house without the cost of additional equipment (radiators, pipes, etc.).

The advantages of these products also include the fact that, in addition to their main functions, they give the room a respectable appearance and comfort.

How to make a sauna stove with your own hands - details from the master

The design of the stove is primitive, but has a number of significant conditions.

The difference between an ordinary heating stove and a sauna is that the second one contains additional elements, such as a heater and a water tank. Many craftsmen opt for making a bathhouse stove with their own hands, without buying it in a store. The construction process is not simple and requires a lot of time.

First you need to familiarize yourself with the main components of sauna stoves, and these are:

- material;

- energy carrier used;

- firebox location;

- heater heating system.

Operating principle

Using a metal stove in a home or non-residential premises requires regular monitoring of the operation of the device. The loaded fuel is enough for a certain period of time. Therefore, it is necessary to constantly reload firewood into the firebox. Home ovens may differ in design, but the principle of operation is the same for all models.

The principle of operation of a metal stove for the home

Firewood is loaded into the combustion chamber. During the combustion process, air enters the combustion chamber through a specialized hatch (blower). The blower is equipped with a door, with the help of which the amount of supplied air is regulated. The more oxygen supplied to the combustion chamber, the faster the fuel burns. Products resulting from combustion are released into the atmosphere through a smoke duct.

Depending on the model, ovens can be additionally equipped with hobs and ovens. The flame in the combustion chamber quickly warms up the cooking surfaces. For aesthetic purposes, many manufacturers make the combustion chamber door from heat-resistant glass. So, you can see the process of burning wood while working.

The design of a unit capable of warming and feeding

The industrial heating and cooking stove is very different from its classic predecessor. In it, the designers managed to combine the following functions:

- Heating unit

- Fireplace

- Hob

This allowed us to save a lot of space, fuel and costs for purchasing decorative elements. After all, a modern oven has small dimensions, is multifunctional in terms of cooking and can become the main element of any design.

Such units have become an integral attribute of country life, thanks to the successful combination of several functions. The fuel for them can be firewood, peat and even coal. Of course, wood-burning stoves are most often used, due to the availability and low price of wood waste.

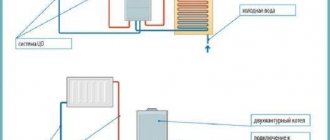

Heating and cooking stoves can be used to heat several rooms. In this case, air ducts or models with a water circuit are used, which are connected to the heating system. And even despite the fairly high cost, their use is economically justified, since by purchasing the unit you will not have to purchase another stove and fireplace. But there is also an opportunity to save money; if the heating and cooking stove is assembled with your own hands, then its cost will reach a minimum value.

This equipment also has its own peculiarity. Unlike standard devices, which are not capable of maintaining heat in a room for a long time, these models can operate for up to 10 hours in smoldering mode, thereby not reducing the air temperature.

Structurally, they are a metal unit that runs on solid fuel. And the operating principle of this model is based on the process of pyrolysis. This allows you to use firewood economically with a guaranteed high level of efficiency.

But despite the peculiarities of their functioning, almost anyone can assemble heating and cooking stoves with their own hands. It won't take much time or cost much, so the choice is yours. The only thing you need to do is find the instructions for heating and cooking stoves online and carry out all masonry work in accordance with them.

Application and fire safety measures

A metal stove can be installed in any room. It can be wooden, brick, concrete or a room made of any other material. The main condition for installing the device in a house (or other room) is the presence of a chimney. It must be performed separately from the centralized ventilation system.

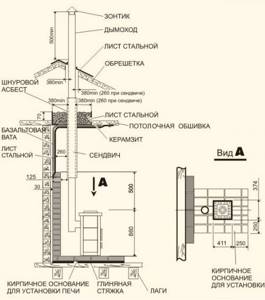

Installing a metal stove in the house

If you use a product of large size and weight in your home, you will need to take care of the installation base. A heavy iron stove can damage a wooden or even concrete floor. A foundation must be made. It can be made of various materials. The best option would be to make a concrete foundation. To increase the strength of the base, before pouring concrete, it is necessary to install a frame of metal reinforcement.

Factory stove models meet fire safety requirements. You can easily obtain permission from the fire inspectorate to install such a product. There are models of metal stoves, the installation of which does not require obtaining permits from the fire inspectorate.

Attention: in order to avoid a fire, it is necessary to equip the wall near which the stove is installed with a screen made of heat-resistant material!

Models of metal heaters: photos and drawings

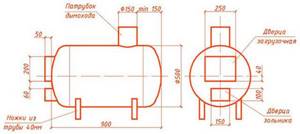

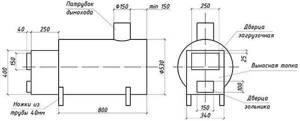

First, let's look at the project of a regular metal heater along with a water tank. To construct it, you will need sheet iron with a thickness of about five millimeters. On the drawings, mark the dimensions of the furnace - 500 by 600 by 800 mm and a height of about 400 mm, respectively.

Such a stove can be loaded with up to 150 kg of fuel, thanks to which a steam room with an area of approximately 12 square meters will be steamed at a temperature of 100 degrees.

Its walls can be single or double, equipped with an air gap. The liquid tank can be placed wherever you deem necessary.

Tip: cover the heater stove with bricks to reduce the heat that is transferred in the form of infrared radiation from the stove to the steam room.

Bath stove combined with kitchen

Another good option for making a homemade metal sauna stove is a combined design with a kitchen stove. It is suitable for those types of premises where there is a relaxation room after the bath, where you can cook and eat something, or for a bath room that is attached to a summer kitchen or to a residential building next to the kitchen.

The firebox of the stove located in the kitchen should be connected to the ash pan on the heater. There should be a door on it, thanks to which it can be heated when the kitchen stove is not used for its intended purpose.

The steam room and the kitchen are separated from each other by a brick partition; also, in order to prevent burns from the side of the bath, it should be covered with a sheet of metal and a wooden partition. A flame tube is then passed through the furnace.

A drawing of such a design should include the following elements:

- stove in the kitchen;

- heater;

- kitchen stove firebox door and backfill pipes;

- firebox door on the stove;

- steam room;

- chimney;

- kitchen area;

- sheet steel and wooden fencing for partitions.

Types of stoves for home

Metal devices, depending on the duration of combustion, the type of fuel loaded and technical characteristics, are divided into several types. These include chamber products, channel products and long-burning devices.

[ads-mob-1][ads-pc-1]

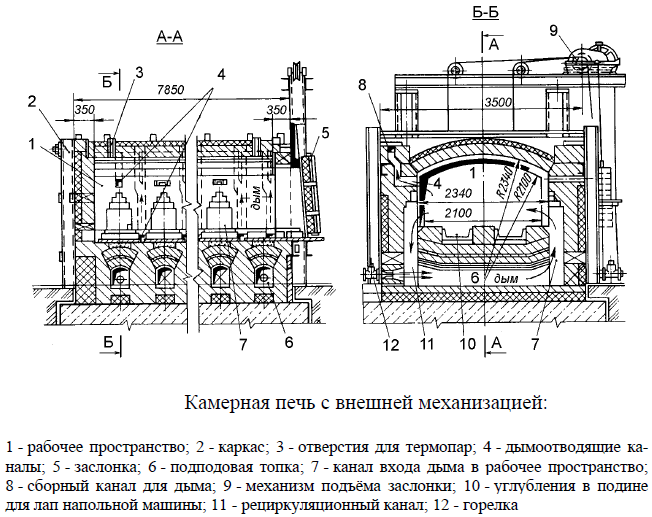

Chamber furnace

This type of construction is made of steel or cast iron. There is a combustion chamber inside. Fuel is loaded into the chamber through a special hatch. The bottom of the firebox is made in the form of grates, through which burnt fuel spills into the ashpit. The ash is removed through a door located in the ash pan. This door also regulates the air supply to the combustion chamber.

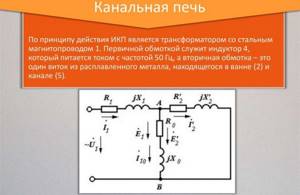

Channel product

Channel devices are cast iron or steel stoves. The combustion chamber of such devices is equipped with special partitions. They are located horizontally and prevent the rapid escape of formed gases into the smoke channel. Thus, gases, mixing with oxygen, burn out, and the efficiency of the metal furnace increases.

Long burning stove

This type of device differs from others in that fuel loading must be carried out much less frequently. The air into the combustion chamber of such a stove is supplied not from below, but from above. Thus, gradual combustion of the upper part of the fuel occurs.

Heater stove - manufacturing guide

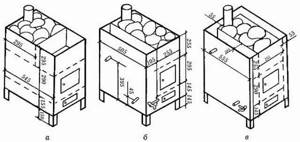

We bring to your attention 3 common designs of metal stoves for baths:

- a simple horizontal stove made from a cylinder, heated inside the steam room;

- heater made of 530 mm pipe with remote firebox;

- vertical sauna boiler “three in one”.

The first option is attractive due to its ease of manufacture, small size and mobility. For homemade products, you will need an old propane cylinder with a diameter of 300 or 500 mm and scrap metal. The second heater is distinguished by an additional section with a door built into the opening of the steam room wall, and an open heater. The third model is a whole boiler, consisting of three compartments - a firebox, a closed heater and a tank for heating water.

The drawings show options for heating units made of sheet iron

We weld a simple stove

The first thing to do is to correctly cut the cylinder cap along the factory seam. To do this, unscrew the gas valve with an open-end wrench and fill the container with water, after which you can use the grinder.

Assemble the heater according to the presented drawing, observing the following order:

- Cut openings at the end of the lid for mounting doors and in the housing for the chimney pipe. Make frames for the loading and ash doors from metal strips, and weld them to the openings.

- Assemble the grate by welding and place it on the corners fixed inside the cylinder. Weld the cut cover back into place.

- Make the sashes as shown in the photo. Place them on the hinges and attach the latches.

- Attach legs and a chimney pipe to the body.

After assembly, the gas cylinder sauna stove is melted outside in order to burn off all the old paint. Then it can be degreased and repainted using the heat-resistant composition of the KO series.

Manufacturing a unit with an external firebox

To make such a stove, you need to prepare metal parts and cut the pipe to size, following the drawing:

Perform further work according to the instructions:

- Cut a hole in the top of the pipe, weld the chimney pipe to it, and weld the legs at the bottom of the firebox. Install the grates as described in the previous section.

- Make the front section and weld it to the firebox. Weld a blank metal disk to the rear end of the housing.

- Make doors with handles insulated with basalt wool and install them in place.

All that remains to do on top of the finished stove is to weld a frame for the heater from corners covered with a coarse metal mesh. After firing, staining and installation in the bathhouse on site, fill the mesh with special stones from the list:

- basalt;

- river pebbles;

- gabbro-diabase;

- Soapstone chlorite

How a similar sauna stove is made in practice is described in detail in the video:

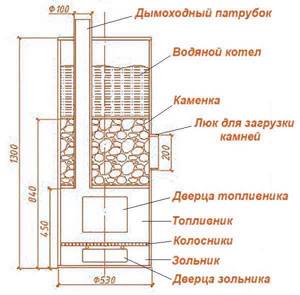

Making a vertical boiler

The peculiarity of the round unit shown in the drawing is the presence of 3 chambers - fuel, heater and water tank. Their size can vary according to your wishes, for example, the larger the size of the firebox you make, the longer 1 stack of firewood will burn. Enlarging the heater will allow you to accumulate more heat, which is released for a long time after the fuel burns out.

The boiler assembly procedure looks like this:

- Cut blanks for partitions, bottom and lid from metal with a thickness of at least 5 mm. Prepare the ends of the pipe and weld the round grate bars.

- Make openings in the body for the doors and hatch for loading stones.

- Make holes in the partitions for the chimney and install them inside the pipe. Secure the tank lid to the hinges.

- Make doors from semi-circular cut out pieces and place them on the awnings.

- Install a flue duct and a water drain valve at the bottom of the tank.

If desired, even in this furnace you can make a remote firebox. To do this, you need to increase the loading and ash channel by welding metal blanks of the required width to the side of the pipe, as shown in the photo above. The correct assembly of such a heat generator is shown in detail in the following video:

Famous manufacturers

The Russian market offers a large selection of metal, cast iron and stainless steel stoves. Products from the following foreign manufacturers are in great demand:

- Trend.

- Magnum.

- Thorma.

- Alma Mons.

- Konig Feuer.

- Efel.

- Ferlux.

- Olimp.

The Harmony model from the Belgian manufacturer Efel has proven itself well. It is equipped with a hob and has enough power to heat a large house. The time interval between fuel loadings is about ten hours.

There are many models and domestic manufacturers:

Cinderella stove Termofor

- Termofor;

- Ligov;

- Teplodar;

- Eco fireplace;

- Ermak.

Domestic models come in various types, sizes and shapes. Some can be transported independently and moved from one place to another. Others are permanently installed and have a high mass. Many of the models are equipped with hobs, ovens and transparent doors made of heat-resistant glass.

Fuel and material of construction

A homemade stove can be assembled from different types of metal:

- Heat-resistant steel. It is used for the manufacture of industrial furnaces for foundries and metalworking enterprises. The thickness of the sheets is from 1.5 to 3 mm. Service life - 30 years. Individual elements are fixed with special rivets.

- Structural steel. Withstands heating up to 600 °C for two hours, then begins to deform. If you make a stove from structural steel, you need to choose sheets with a thickness of 4 mm or more.

- Cast iron. Has a low thermal conductivity. Cast iron stoves heat up quickly and retain heat for 4 hours after the wood burns out. The suitable thickness of cast iron sheets for making stoves is from 6 to 25 mm.

- Surrogates. The cheapest, short-lived option. The oven is made of a metal barrel or aluminum can.

How to choose a stove for a wooden or country house

The walls of a house made of wood have lower thermal conductivity than those made of stone or concrete. A low-power metal stove is perfect for a wooden house. For a wooden house, you can purchase a steel or cast iron product. Power calculations should be made based on the heated area.

Stove for a wooden or country house

To install on a wooden floor, you must choose a product with special legs. Installation can be carried out either in the middle of the room or against the wall. Before installation, it is necessary to equip the wall with a heat-resistant screen. The stove is connected to the chimney. The best option for a wooden house would be to use a corrugated chimney.

For country houses, you should choose products with enough power to heat the room. A compact metal stove will provide uniform heating of a small house. A good option for a country house would be to purchase a long-burning device. This will eliminate the need for frequent fuel loading. You can purchase a stove with a built-in hob and oven.

Cons of metal devices

Despite all the advantages, metal stoves for the home also have some disadvantages. These include:

- Frequent loading required. Fuel must be loaded after a certain period of time;

- High heating temperature. The walls, ceiling, and floor at the installation site must be equipped with heat-resistant screens.

From the above it follows that metal stoves for the home are an excellent solution when it is necessary to heat residential or non-residential premises. In addition to their main function, they can be used for cooking.

[ads-pc-2][ads-mob-2]