Paradoxically, in the modern world there is still not a central gas pipeline everywhere. And to heat their rooms, people have to use wood or electricity. But there is another way - heating the house with gas cylinders. This is a good alternative to solid fuel and electric heating if it is impossible to connect a private home to the central gas pipeline.

Although heating with liquefied petroleum gas propane or propane-butane is somewhat more expensive, in terms of its characteristics such fuel is practically no different from gas passing through the main line. A gas stove for heating a house from a cylinder is often used in a private house or country house, where the heated area does not exceed 100 sq.m. Let's consider the main features of balloon heating.

When is liquefied gas heating used?

There are no direct prohibitions or restrictive measures on autonomous heating of a private home with gas cylinders. However, heating a home with liquefied gas from a cylinder is not always rational, since obtaining thermal energy in this way requires significant expenses.

Heating a house from a gas cylinder is beneficial only if:

- heated room area up to 100 m2;

- organizing good thermal insulation of the home;

- minimizing heat loss.

The arrangement of heating a private house with gas is carried out using ordinary 50-liter cylinders with propane or butane, which are compressed to a liquid state.

In summer and winter, different mixtures of flammable substances are used:

- SPBTL (flight combination);

- SPBTZ (winter mixture).

In winter, the tanks must be constantly monitored, as interruptions in the fuel supply are possible due to the difference in boiling temperatures of the mixture components (propane -40°C, butane 0°C). As a result, at a temperature of, for example, -10°C, the pressure in the vessel will drop below the level required for the normal functioning of the system. Then the cylinder will have to be heated to at least 0°C so that the butane begins to evaporate.

Attention! It is strictly forbidden to heat cylinders that are located in a private house at subzero temperatures with heating elements or heating cables.

Differences between liquefied and natural gas

Everyone knows that methane (CH4) predominates in the composition of a liquefied hydrocarbon mixture (hereinafter referred to as LPG). Its hydrogen (H) content is about 55%, so methane releases more heat per unit mass when burned than any other organic substance. LPG for boilers, water heaters and internal combustion engines is a homogeneous mixture of propane (C3H8) and butane (C4H10). The priority of natural gas over LPG mainly lies in its cheapness - this parameter prevails even over the high efficiency of methane during combustion.

Physical properties of propane-butane:

- heat release during combustion – 6.4 kW/1 dm3;

- under pressure, natural gas easily passes into the liquid phase and vice versa;

- LPG is pumped from storage into standard cylinders or gas tanks;

- for combustion in nozzles and cylinders of internal combustion engines, propane-butane is supplied in a gaseous state;

- As LPG is used, condensate accumulates at the bottom of the tank, as an inevitable element that occupies useful volume.

The containers into which LPG is pumped are never filled to capacity. 20% of the tank is always left empty to allow propane-butane to go into gaseous form. In standard cylinders, the net capacity is 40 liters, with the ability to pump 50 liters.

Advantages and disadvantages of balloon heating

Heating a private home with bottled gas has both advantages and disadvantages over other heating options.

First, we present the undeniable advantages of heating with liquefied gas:

- high efficiency with significantly lower labor costs compared to solid fuel heating;

- the ability to convert a gas boiler from a conventional cylinder to mainline equipment;

- absolute autonomy and independence of the functioning of the balloon system;

- long service life of equipment (15-25 years);

- presence of demand for cylinders in the secondary market - containers are easy to sell if they are not needed.

In addition, cylinder heating allows you to heat water in a private house for domestic needs.

We also list the main disadvantages of such a heating system:

- cylinders must be refilled regularly, approximately every 2-3 weeks, which is inconvenient and costly;

- if the system is not organized correctly, gas consumption increases significantly;

- the need to create suitable conditions for storing containers.

Thus, organizing a heating system on cylinders can be very dangerous if certain operating conditions of the equipment are not followed. Therefore, vessels can only be stored in a ventilated area with no basement underneath. It is best to place the cylinders in a separate building.

Components for cylinder heating systems

Heating using liquefied gas is done using the following components:

- heating equipment with a gas burner;

- reducers for connecting cylinders;

- fuel containers with a capacity of 50 liters;

- ramp;

- rubber-fabric sleeve for connecting the pipeline to the boiler;

- shut-off valves.

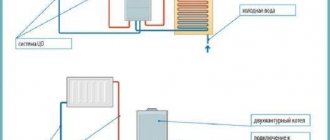

The connection diagram is very simple, so it can be implemented by hand. When choosing a suitable gas boiler, give preference to units operating at minimum pressure and maximum efficiency. Consider what type of fuel the boiler is designed for. There are units that run only on liquefied gas. But if in the future you plan to connect the main gas supply, then it is better to prefer universal models that can operate on different types of fuel.

The gas boiler burner must have narrow nozzles that are designed to operate under high pressure bottled gas conditions. Units designed to use mains gas have wide nozzles. If liquefied fuel is supplied through such devices, an accident may occur.

Boilers designed to operate on LPG (liquefied petroleum gas) have special nozzles and a gas valve. To independently convert a conventional boiler to operate using liquefied fuel, you will need to purchase the necessary parts.

How to connect the cylinder to the boiler?

To assemble a heating system on gas cylinders, the following equipment is required:

- gas boiler with a special burner for liquefied fuel;

- gas cylinders;

- gearboxes;

- ramp for connecting several containers;

- shut-off valves;

- pipes and hoses for connecting the system.

As a rule, a gas boiler with a water circuit is used as a heat generator. Moreover, a special boiler model is not required; you can simply replace the burner or nozzles. The power of the heating device is selected in accordance with the area of the room, but the efficiency of the device should be as high as possible. An excellent choice would be a gas condensing boiler.

Attention! It is prohibited to install cylinders in a basement or basement. It is better to place them in a metal box with holes for ventilation.

Vessels can only be placed in a horizontal position. It is better to place a metal box on the north side of the site in a shaded place.

For the boiler to function correctly and efficiently, it must be connected to 4-5 cylinders at the same time. To equip a gas pipeline, you will need a pipe with a wall thickness of 2 mm. At the place where it is installed, a sleeve is installed in the wall, the diameter of which is 20-30 mm larger than the cross-section of the tube. The space between the sleeve and the pipe is filled with polyurethane foam.

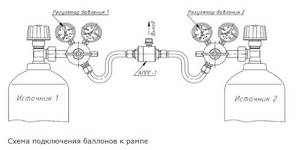

The cylinders are connected to the system through a reducer, which converts the liquid back into a gaseous state. This can be done in two ways: one reducer for all vessels or one pressure regulator for each cylinder. The second option ensures complete safety, although it is more expensive.

To increase the interval for refilling containers, it is better to connect several vessels to the boiler at once through a ramp, which divides the cylinders into a main bundle and a spare one. First, gas will come from the main group of tanks, and when the fuel runs out, the boiler will switch to the reserve group. When the main link is updated, the heater will reconnect to the main group.

Attention! Follow the most important safety rule: it is prohibited to fill the cylinder more than 80% of the volume, since the mixture of propane and butane has a high expansion percentage, and when the volume is filled to more than 85%, there is a high probability of the vessel exploding.

When assembling and installing equipment, pipes and hoses, all connections, connectors and fittings must be checked for gas leaks using normal soaping.

Organization of heating from gas cylinders

An integral part of a gas heating system is the use of a gas boiler or gas water heater. This equipment runs on either pure liquefied propane or a mixture of it with butane. The treated gas takes liquid form under high pressure, after which special metal cylinders are filled with it.

Heating in a private house with gas cylinders is one of the most common methods of organizing a temporary heat source in situations where a central gas pipeline is planned in the near future. In combination with electric convectors, the cost of organizing and operating the system is significantly reduced.

When choosing a heating system using liquefied gas, you need to take into account the parameters of the area of the house and the level of thermal insulation of external walls. Heating a country house from a gas cylinder is effective and profitable for objects no more than 150 m², built conscientiously - without cracks or holes in the roof. Otherwise, gas consumption will be too high, as will the total cost of it.

This depends not only on the size of the building, but also on the design features of the installed system.

There are several most common types of cylinders, classified according to their characteristics based on GOST 949-73. The most popular ones are with a capacity of 5, 10 and 50 liters.

Fuel consumption to warm an area of 100 m² for six months, using standard gas equipment with 6 cylinders, will require approximately 3.5 - 5 tons. The use of additional automatic sensors that regulate the operating mode of a gas boiler can almost double the efficiency. With their help, the system will switch to economical mode until the desired level of air temperature in the room is reached. Or in accordance with the specified timer parameters.

What you need to connect

To organize an autonomous heating system, you will need to purchase several components, which include:

- gas boiler equipped with nozzles;

- a reducer responsible for converting and maintaining pressure;

- a ramp providing connection between gas cylinders and other elements of the system;

- shut-off valves necessary to control the flow of gas.

In addition, a separate place must be prepared for installing the system. It must comply with all standards and safety requirements for gas heating from bottled gas.

Connection diagram to the boiler

The gas boiler is connected to bottled gas using gearboxes responsible for regulating the fuel pressure. It is allowed to use both one common gearbox and separate devices for each container. The second option is safer, but will cost a little more.

The rate of fuel consumption per hour when using a gearbox should be about two m³. At the same time, connecting several cylinders at once makes it possible to reduce the frequency of refilling. A ramp is needed for the connection. This is a special manifold that allows you to effectively distribute the fuel contents among the main and reserve tanks.

When the system starts, the reserve from the main group will first be consumed. When the fuel in it comes to an end, the ramp, notifying the owner with a special signal, will automatically switch to the reserve one. When filling the 50-liter cylinder with gas is completed and they are again connected to the ramp, the system will again switch to the main group.

The profile thickness of pipes used to organize an autonomous heating system using gas must be at least 2 mm. Wall wells must be filled with polyurethane foam. And the sections of pipe passing through them are covered with an additional cover. The boiler is connected to the pipes through a flexible hose, and the connection to the gearbox is through a rubber hose.

Gas consumption from cylinders

However, do not forget that in this mode the system functions only during the warm-up stage. The rest of the time, with the correct settings, fuel consumption is reduced by 3 - 4 times, and amounts to no more than 10 - 11 kg per day to maintain the temperature at + 22ºС.

Principles of cylinder refilling

The main factor to consider when filling standard cylinders is the expansion of the gas when heated. Because of this, it is allowed to fill a standard 50-liter cylinder only to 80% of the total volume, preventing the structure from exploding in the event of an unplanned significant increase in temperature. The same applies to fuel production - the overall level of depletion should not exceed 90%.

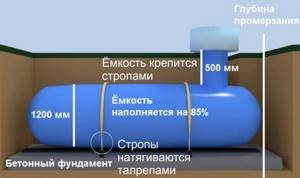

Can the cylinder be replaced with a gas holder?

Instead of conventional 50-liter cylinders, it is allowed to use a more capacious steel container for storing liquefied gas - a gas holder. The volume of some of these tanks is often enough for the entire heating season.

However, heating a home with liquid gas cylinders is considered more convenient, since it is much easier to deliver fuel in more compact vessels. In addition, for a gas tank it is necessary to carry out a large amount of work on digging the site, which will result in additional financial investments.

At the same time, the use of a gas holder eliminates the need to simultaneously connect several containers at once, since one cylinder cannot provide sufficient evaporation for normal operation of the boiler.

Gas cylinders in the country and boiler

Many areas, including country houses, are far from gas mains. Gas cylinders are a good option for creating a heating system in your home.

The whole system is quite complex and includes:

- boiler;

- cylinders;

- reduced gas burner;

- pipeline fittings;

- gas pipeline

The choice of boiler is carried out in the same way as in the case of a gas main.

But there are three important differences in choosing a boiler:

replacing the “original” burner with one that runs on reduced cylinder gas; choose a unit with low pressure to obtain high use of gas from cylinders; the highest possible efficiency (in the case of using a highway, it is not so important).

It is advisable to attach several cylinders to the boiler in order to “fidget” with them less often

Gas heating with cylinders in the country requires special safety measures: it is important to install them in some warm building, but not in the basement. If you install cylinders outside, the fuel pressure will decrease, which will lead to the boiler burner turning off.

And if installation is carried out in the basement or near living rooms, then the dangers lie in a possible fuel leak and consequences.

Rice. 2 Multi-vessel system

Storage of gas cylinders in the country should be carried out in a separate room (Fig. 2), where there is a ventilation system and a flat concrete floor.

For approximately 1 month of heating a dacha, you will need 2 cylinders per area of 50 square meters. m. and for 100 sq. m – 3 cylinders.

Pressure control reducer

The pressure in the cylinders is constantly changing, and its value depends on many factors:

- number of cylinders;

- composition and temperature of the mixture;

- remaining liquefied gas;

- distance of a group of vessels to the boiler.

The reducer is used to convert and maintain stable gas pressure in a vapor state.

You need to select a gearbox for a heating system based on two main characteristics:

- performance;

- operating pressure.

The rationality of heating a private house with gas cylinders depends on the fuel consumption of the boiler. Therefore, the performance of the gearbox should not be less than the pickup capacity of the heating device.

The operating pressure of the reducer is also selected in accordance with the characteristics of the boiler equipment. If the pressure produced by the reducer is too high, the operation of the heater will be disrupted. The pressure regulator is made for 20, 30, 37, 42, 50 and 60 mbar.

When connecting vessels using flexible hoses, you will need a reducer with a herringbone fitting. And when connecting cylinders using combs and rigid pipes, you will need fittings with threaded outlets.

In addition to their main purpose, automatic devices are equipped with protective elements that are triggered if the pressure rises to a critical level. Then the relief valve opens.

What you need to connect

To install a heating system on gas cylinders you will need:

- Gas boiler equipped with a burner for liquefied gas;

- Gas cylinders with a capacity of 50 l;

- Gearboxes;

- Ramp, if several cylinders are connected;

- Shut-off valves;

- Gas pipeline in the form of pipes and hoses for connecting equipment to the system.

When choosing a gas boiler, you should pay attention to models with the lowest operating pressure and high efficiency. Many boiler models are already equipped to work with natural and liquefied gas. If a connection to the main gas pipeline is not expected, then it is better to choose just such a boiler to operate on LPG.

Otherwise, additional equipment is purchased: nozzles for the burner or an entire burner for liquefied gas, and in some models, a gas valve. The natural gas boiler burner is designed for lower pressure in the system and has a valve with a large hole, which can lead to an emergency.

How much fuel is burned?

Heating a house whose area is approximately 100 m2 with liquefied gas can be done using a boiler with a power of 10 kW. In order to obtain 1 kW of thermal energy, it is necessary to consume 100-120 g/min of liquefied gas at 100% boiler load. If the cold period extends to 7 months, then the approximate estimated fuel consumption for the entire season will be about 5 tons.

But in reality, the volume of expenses will be almost 2 times less, thanks to the automation, which switches the equipment to economy mode when the air temperature in the premises has reached the set value or guided by the timer settings.

If we compare the costs of heating a summer house or private house from a main gas pipeline, then heating with liquefied gas is about 5-6 times more expensive. But nevertheless, in the long run, it is cheaper than heating from electricity.

If we take into account the prices for liquefied gas, then heating a country house or cottage using cylinders is not the worst alternative to electric and liquid fuel systems. Especially in cases where there are problems with solid fuel in the region or it is quite expensive.

Heating with liquefied gas is the most rational solution if there are plans to gasify a populated area in the near future, since then there is no need to purchase a boiler. In addition, there is an opportunity to practice using a gas boiler.

How to calculate gas consumption?

To calculate fuel consumption, you need to know the power of the heating equipment. When determining it, they use the rule that for every 10 square meters of heated area, a boiler power of 1 kW is required.

Autonomous heating system for a private house with a gas boiler

Thus, to heat a house with an area of 100 square meters, you need a boiler with a power of 10 kW. To generate 1 kW of thermal energy, approximately 0.12 cubic meters of gas per hour are consumed. To heat such a house for one hour you will need 1.2 m³ of fuel. Knowing this number, it is easy to calculate the daily fuel consumption. It will be 28.8 cubic meters.

At first glance, it seems that gas consumption is quite high. But these values are valid only for continuous operation of the boiler during the first warm-up of the system immediately after its startup. In the future, the equipment will operate in automatic mode and fuel consumption will decrease.

As a rule, to maintain the temperature in a house with an area of 100 square meters within 22°C at sub-zero temperatures outside, you will need about three cylinders of fuel per week. If at night the temperature is maintained 4-6 degrees below daytime, then fuel consumption will be reduced by a whole cylinder.

If the containers are used to heat a summer cottage for seasonal residence, then the operation of the boiler can be adjusted so that during the absence of the owners in the building the temperature is maintained within +5°C. This will ensure economical fuel consumption. As a result, to heat a small house for 7-10 days you will need only one cylinder of liquefied fuel.

How to store gas cylinders in winter?

In the case when the cylinders are located outside the house, then in winter, at subzero temperatures, the pressure of the liquefied gas drops, and the boiler may simply turn off. In order to avoid this, the cylinders must be installed in a special cabinet that is insulated with non-flammable materials and equipped with good ventilation.

Detached non-residential buildings with a minimum level of heating are also well suited for this purpose. When using cylinders, the following safety rules must be observed:

- Gas containers must not be heated with open fire;

- There should not be a cellar or basement near the cylinders, because during a leak the liquefied gas sinks down, it has no odor and can accumulate to an explosive concentration;

- It is highly recommended to install a gas leak detector;

- storage of full cylinders is permitted at a distance of at least 10 meters from residential premises;

- It is prohibited to store empty cylinders in the house;

- Once every 4 years, cylinders must be checked for leaks and integrity.

Thus, heating a house with gas cylinders is not a profitable heating method. However, this is an excellent solution as a temporary measure until it becomes possible to connect to the central gas main.

Let's get to the numbers

1. If our cost of connecting natural gas was about 250 thousand rubles, then the cost of operation and the cost of heating a country house with natural gas will be somewhere around 4 thousand rubles per month. Just so you understand, these numbers are taken empirically. More than 5 thousand facilities that we gasified ourselves and our partners gasified. Clients we have spoken with. We take these numbers from real life, from practice. There are many payment methods on the Internet. How much is spent on heating for what area, at what temperature, with what fuel source. This is all theory. We give you figures from practice. Therefore, you can, after making sure of, so to speak, your acquaintances, friends and neighbors, recalculate these figures. If you do not have the opportunity to connect natural gas, then you need to consider one of the alternative heating sources.

2.The next item we have is heating with liquefied gas. In order to heat your country house with liquefied gas, you need a container - a gas holder and equipment that runs on this liquefied gas. What is needed for this? In order to install the equipment, your expenses will be about 200-250 thousand rubles. This amount includes equipment that runs on liquefied gas. Bury the container underground and run the line to your home. But please note that this amount does not include the first gas filling. The cost of heating a house using this system and this type of fuel will be 8 thousand rubles per month. We take the average figure for the year. The heating season in Russia is about 8 months, from September to May. That is, from September to May, you will spend about 8 thousand rubles per month to heat a house of 150 square meters.

3.Now we move on to the next type of fuel - diesel fuel. The cost of equipment to heat a house using diesel fuel is about 100 thousand rubles. And the cost of heating, if you calculate on average per month, let’s also take the annual average from September to May, will be about 15 thousand rubles. What is included in this system? For 100 thousand rubles you purchase a container that you install in your boiler room, into which diesel fuel is poured. Then, using a pump, it is supplied to your boiler, which burns it, and you receive energy to heat your home. You will spend 15 thousand rubles on diesel fuel or diesel fuel to heat a house of 150 square meters.

4. The fourth type of fuel is electricity. In fact, there is electricity in almost every country house. Without electricity supply there is no point in starting any construction at all. You can also heat your country house using electricity. The cost of equipment for heating with electricity is about 50 thousand rubles. These 50 thousand rubles include an electric boiler, which hangs on your wall, and with its help your home is heated.

The cost of heating with this type of fuel will be about 30 thousand rubles per month. The figure is also a monthly average. During the year the main consumption is from September to May. Please note that 30 thousand rubles for heating with electricity is still an underestimate. Because those who heat themselves with electricity will confirm that this figure can be several times higher. Because the cost of electricity varies, and its consumption also varies depending on how much and with what you need to heat.

We will also repeat that we are considering four main sources of energy for heating a country house. These are the sources that allow you to live autonomously and independently. Without participating, without being constantly present in the house, in order for this system to work. That is why we did not include firewood, pellets and everything connected with this in this list. Because this heating system requires your constant presence, control, and so on.

Advantages

Numerous reviews from owners of private houses, cottages, and garages explain the growing popularity of bottled gas heating by the following factors:

- environmental friendliness and compliance with all state standards and regulations;

- autonomy and safety of heating;

- stability of operation and pressure level;

- economical fuel consumption and ease of control;

- possibility to heat water for household needs

Reasons for high performance

Heating from a gas cylinder has high efficiency due to the fact that the energy carrier easily passes from a liquid aggregate to a gaseous state. Therefore, the heating system is completely independent, which gives the owners of a private house or cottage the opportunity to use it at their own discretion and in any conditions.

Nuances of use

It will be possible to use gas cylinders for space heating even at the stage of building a house - this is convenient in case of construction in the cold season. To ensure safe use of the energy carrier, it is recommended to follow certain operating rules. For example, during sleep it is recommended to turn off the gas supply or at least reduce it.

Additionally, this will reduce energy consumption

Gas cylinders require periodic refilling: special attention must be paid to its quality. Some station employees do not fill the cylinders completely, which is why owners are forced to overpay - be careful if you use the services of such stations

Types of propane boilers

When choosing a propane boiler, you need to understand the main types of such units, their operating principles and characteristics.

LPG gas boilers available on the secondary market are of 3 types:

- Single-circuit.

- Dual-circuit.

- Condensation.

In terms of purpose, they are practically no different from each other, but the principle of operation, design and design features look different.

Features of single-circuit devices

Single-circuit units are used only for heating purposes, so they are in demand in buildings where water heating tasks are solved in other ways. Such models cost much less than their dual-circuit counterparts, which is due to their limited functionality.

The main module is equipped with a closed combustion chamber, and when a flame occurs, it is enriched with oxygen from the outside. Combustion products are discharged to the street using a specially equipped chimney.

Nuances of double-circuit products

Installations with 2 circuits are used for efficient heating of residential buildings of any size, as well as for heating water. The fuel mixture is heated through 2 burners, which are ignited by an igniter.

After a fire, a temperature sensor is activated, transmitting all the necessary information to automated units. If the temperature exceeds the permissible values, access to the chamber is closed.

If there is a closed combustion chamber, it is additionally equipped with a coaxial chimney with forced draft. This is necessary to organize a uniform flow of oxygen and stable combustion. Waste products enter the ventilation or chimney ducts and exit outside.

How condensing units work

Condensing units are designed to supply hot water and heat the building, but the principle of their operation differs from the 2 previous options. After entering the heat exchanger, the cold liquid warms up and enters a closed circuit.

Units of this type are high-tech equipment with economical consumption of the fuel mixture. The exhaust gas warms up to +40°C, and efficiency indicators reach 97%. Heat loss values are minimal - up to 0.5%. After this, half of the water is sent to communication channels, and the rest is sent to taps for washing, laundry and other household needs. Having completed the full cycle, the liquid from the radiator is returned to the heat exchanger.

How to calculate a heating system using gas cylinders

To understand the practicality and cost-effectiveness of this heating system, you should carry out preliminary calculations and answer an important question: for what period of time is one cylinder enough?

The sequence of calculations based on average statistical readings:

- The boiler power must correspond to 1 kW of energy per 10 m2 of room. For a private house with a total area of up to 100 m2, it is necessary to purchase a gas boiler with a capacity of at least 10 kW. Installing heating radiators, instead of ordinary multi-section radiators, will facilitate faster heat transfer throughout the entire area of the house.

- For the gas boiler described above, at least 0.86 kg/h of liquefied gas will be required, taking into account the fact that the efficiency of the boiler must be at least 90%.

- The heating season usually takes no more than 6 months, sometimes 7 (if April is too cold). 7 months – 5040 hours. Of course, the boiler will not operate at the same power all this time; for greater efficiency, you should alternate operating modes.

- 1 cylinder with a capacity of 50 liters holds 21.2 kg of liquefied gas. The calculation is made: 5040 is multiplied by 0.86 kg/h and the resulting value is divided by 21.2 kg of gas. The final value (rounded down) is 204 cylinders for the entire heating season. This figure will be even greater if, instead of cylinders with a capacity of 50 liters, you use products with a capacity of 27 liters.

Such calculations are very superficial, because no user will constantly keep a gas boiler at full power. But, based on these values, which should also be multiplied by the price of gas (add transportation and refilling of cylinders), you can decide whether it is worth installing a gas-cylinder heating system.