Homemade boiler for heating water from a boiler

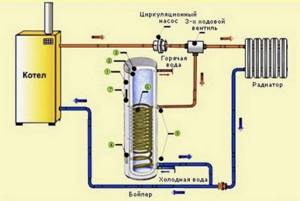

The preparation of hot water for domestic needs can be done from a boiler using an indirect heating boiler.

Its recommended volume is small - 50 - 100 liters, provided that the internal heater is powerful enough, which is not difficult to ensure. It is important that hot water will be cheap, unlike electric boilers. After all, fuel is usually used for heating, the energy of which is several times cheaper than electricity. Therefore, borrowing 5 - 7 kW to heat up the average volume of the boiler is no problem. We are actually talking about less than a kilogram of coal... All that remains is to make a boiler that can heat water from the boiler...

Typical production of a metal boiler

To make a boiler, you need two main things - a metal container and a coil. An important requirement is environmental friendliness, the absence of any mastics inside... since there will be hot water used for household needs, including bathing.

Most often, for cheap manufacturing, alloy steel with a thickness of 2 - 4 mm, or a stainless steel tank is used. If you find a thick-walled pipe of large diameter, this means there will be fewer welds - just weld the covers and also weld the connection pipes.

If sheet metal is available, then there will be an order of magnitude more welding work; it will be important to make the right rectangle and ensure exceptionally high-quality seams, which is not easy.

Power and coil

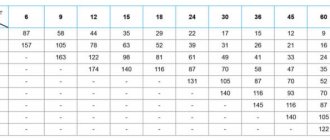

An indirect heating boiler must be powerful in order to provide almost instantaneous heating. The acceptable power for a flow-through heater is 15 – 20 kW, which provides an “endless stream” of hot water.

To develop such power, it is enough to place 12 meters of corrugated stainless steel gas pipeline with a diameter of 20 mm in the boiler. At the ends it is flared and connected to the pipes with union nuts with a mechanical seal.

To hang the coil, plastic (polyethylene) stands are installed on the bottom, and the coil is attached to them with garters. Considering that cold water will accumulate at the bottom, it is recommended to place the heating coil no higher than 15 cm from the bottom. In this case, the cold supply pipe is 25 - 30 from the bottom.

Boiler from a cylinder

Craftsmen create 100 liter boilers from gas cylinders, 50 liters each. They are first filled with water (gas displacement), the upper part is cut off with a grinder, then pipes for the coil and cold water supply are welded in the lower cylinder, and in the upper cylinder there is a hot outlet, as well as a connection for the safety group (thermometer, valve and pressure gauge). All that remains is to weld the tanks together, and an excellent large indirect heating boiler is ready. But you can, in principle, get by with one 50-liter cylinder, taking care only of the power of the coil for flow-through heating...

The fittings are ¾ inch pipes with threads on both sides. They are welded into the side of the tank in such a way that the coil is attached from the inside and the connecting pipes from the outside.

It is also recommended to weld a fitting under the drain valve into the bottom to drain the sediment, and also weld the legs. The tank rests on 3 - 4 legs and is attached with a clamp at the top to the wall for stability.

The video shows the process of making a water heater from a single cylinder with an electric heater inside.

Thermal insulation

It is advisable to insulate the boiler, which is heated by the boiler, in order to supply hot water for its intended purpose, and not turn the device into another radiator that warms the house. And the rapid cooling of water may not be very acceptable when manually adjusting the heating.

It is better to thermally insulate with felt 10 mm thick in two layers. This is an environmentally friendly material that does not produce excess when heated (expanded polystyrene quickly decomposes into styrene when heated..., cheap mineral wool releases formaldehyde). You can lay 6 mm thick foil foamed polyethylene on top of the felt, and glue the seam with tape, or create another finish. But even in this form, the boiler “is already suitable for a boiler room.” The length of the connecting fittings is selected taking into account the thickness of the insulating layer.

Automation

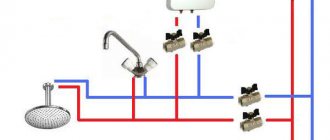

The indirect heating boiler is controlled using a three-way valve with a thermal head and a remote control sensor, which is located on the circulation pipeline of the hot water supply system. As soon as the temperature in it drops below, say, 40 degrees, the valve is activated and redirects part of the coolant from the heating to the boiler coil.

Electrical control from a thermostat is also possible. Typical DHW circuit with an indirect heating boiler.

The DHW system may have a circulation pump that circulates hot water through the taps. Therefore, there is no need to drain the cold water - I opened the tap and hot water immediately came out.

If you don’t want to install heating automation, you can use manual control using a balancing valve. Part of the heat flow will be directed to the boiler and heat it to the temperature set by the user - a simple scheme, but a viable one.

Thermal insulation

To minimize heat loss, the tank should be wrapped in a layer of thermal insulation.

For this purpose, use:

- construction foam;

- isolon;

- polyurethane foam;

- foam;

- mineral wool.

Some craftsmen use a foil-based backing for the laminate. The water heater is wrapped in this case like a thermos. The insulation is attached using wire, glue or strip ties. We recommend insulating the entire building.

The lining will not only ensure long-term preservation of hot water, but will also shorten the duration of heating of the tank, which will reduce coolant consumption. Without well-equipped thermal insulation, the water in the device will quickly cool down.

Often they resort to the construction of a double tank: a small tank is placed inside a large one. The space created between them also performs a heat-insulating function.

To secure the container, hinges are welded to the top of its body, and a metal corner is installed on the wall to which they are attached.

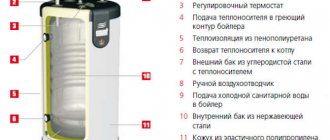

Design and principle of operation

The simplest indirect heating boiler is a container into which pipes are inserted. When the boiler is turned on, the coolant begins to circulate through the pipes, simultaneously heating the water. The tank initially contains cold water, which heats up as the boiler operates and can be used for its intended purpose.

This is a kind of storage boiler in which the task of the heating element is performed by a pipe with coolant. Considering that the efficiency of the boiler is used to heat water, the costs for this type of hot water supply are minimal.

Device diagram

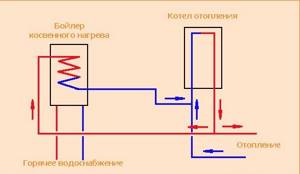

As can be seen in the diagram, an indirect heating boiler is a storage tank connected to the boiler by a pipe system. A coil is installed in the tank itself, through which hot coolant circulates and heats the water. Due to the constant movement of the coolant, the temperature in the tank is kept at a certain level. Even when water is used up and new water is added, it heats up in a short time and is ready for use again.

The advantage of using such a device is that hot water can be supplied simultaneously to several points, and the temperature is stable everywhere. If we take a double-circuit boiler or instantaneous water heater as an example, then when you turn it on you need to wait a while for the water to heat up. If 2 points are connected at once, then while one has hot water, the other has cool water, since the power of the heating element is not enough to instantly heat water in such a volume. An indirect heating boiler, built on the principle of water accumulation, eliminates such disadvantages and maintains a constant water temperature.

What kind of gas is in the cylinders?

The gas cylinder used to heat water contains gases such as propane and butane. They are by-products of oil, gasoline and gas refining. The cylinders may contain only technical butane or a mixture of butane and propane, which is available in summer and winter.

Compression of these gases converts them into a liquid of a smaller volume (and therefore such a gas is called liquefied), and as the pressure decreases, this liquid begins to turn into a vapor state. Since an increase in temperature causes a strong expansion of liquefied gases, the cylinder is usually filled to 85% of its volume, so there is always a layer of vapor gas above the liquid gases.

How does a gas water heater work?

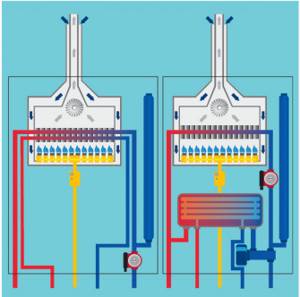

The basic principle of operation of a gas heater is simple: cold water passes through a heat exchanger, which is heated by a gas burner. Water circulation is ensured by a built-in pump. Modern models are equipped with a multi-stage security system and control electronics, allow smooth adjustment of water temperature and are able to maintain flow stability regardless of pressure changes. The outlet water temperature is from 35 to 60 °C, this is more than enough for water procedures, since temperatures up to 40 °C are considered comfortable. To supply the heating system, water can be heated to 80 °C.

The device turns on either automatically when you open a water tap, or by simply pressing a button.

Most often, in country houses, double-circuit gas boilers are used, which allow solving two problems at once: heating the room and supplying hot water. They are triggered by a temperature sensor that responds to a decrease in room temperature. The fundamental feature of a double-circuit boiler is the priority of hot water supply over heating. When you turn on hot water in the bathroom or kitchen, the heat supply to the heating system stops or slows down. With high-quality thermal insulation of the house, this does not lead to a noticeable decrease in the temperature in the room: for the house to become noticeably cold, there must be no heating for at least 2-3 hours.

In the warm season, when heating is not needed, the boiler can be switched to single-circuit mode.

The heating area for double-circuit gas boilers is determined at the rate of 1 kW of power per 10 sq.m of area. That is, a 20 kW device used in heating mode heats about 200 sq.m of living space.

The construction pricing reform should have been completed 1065 days ago.

Good afternoon In the standards of the GESN-2001 collection No. 12 “Roofs” 12-01-002-08, 09, 10 propane gas consumption is 11.8; 6.9; 3.4 kg accordingly are indicated erroneously. The most commonly used burners have an average propane consumption of 6 kg/hour. Based on this, propane consumption (code 542-0042) should be taken at the specified standards in the following amounts: standard GESN-12-01-002-08 - 41.4 kg, 09 - 27.6 kg, 10 - 14.4 kg. QUESTION: is there official confirmation of these figures?

6 kg/hour - what kind of consumption is this, where did it come from? According to the passport or something? Excuse me, have you ever been on a roof or waved a torch? I was and waved a lot... The operating mode in the summer is this: 30% at idle (while you are preparing the next roll, cutting it, trying it on, moving on) and with connections - all 50%. In winter, however, the consumption increases sharply - 1.5 or 2 times (you have to warm and dry the base and warm the freezing cylinders). Try to negotiate with the Customer for compensation for gas, but in practice, during roofing work, the cost of gas is a small part of the cost of the work, so you shouldn’t push too hard.

The customer, as a rule, agrees, and then the switchgear comes and says: “Who are you to add gas to the state price?” That's how it was for me. And I read about such an expense in Grand Stroy-Info in the “Consultations and Explanations” magazine. It was all written there, however, without reference to an official source. So I’m wondering how the inspectors will react to this?

And there is no official source. Even in the standard database, propane butane costs are left unchanged. So refer to “Consultations and Clarifications” No. 2-2004, pp. 12-13.

DIY instantaneous water heater

Such units are compact in size. Some varieties are installed in front of the mixer on the pipe. The heating element is a gas burner or heating element. The design differences are as follows. For the first device, you will need to build a chimney, for the second, you will need to connect an electrical line of sufficient power.

To make your own flow device, you will need the following tools:

- electrodes;

- hammer;

- grinder equipped with a nozzle for removing corrosion;

- hammer;

- welding machine;

- core;

- drill with metal drills.

The following materials are required:

- electric water heating element with a power of 4 kW;

- thin sheet steel;

- nut and bolt M14.

- steel pipe, slightly larger in length and diameter than the heating element;

- anti-corrosion paint.

Attention! The water heater assembly process is shown in the video below.

First of all, you will need to clean all metal objects from corrosion. After this, a rectangular fragment, slightly larger than a pipe, is cut out of a steel sheet. Two holes are drilled on it, very slightly larger in diameter than the size of the heating element’s leg. To measure them correctly, you should attach the ends of the contacts, smeared with white paint, to the sheet. This will create a marking for drilling.

Then the end of the pipe and the plate are connected by welding. In this case, you should hold the part so that the holes made in the previous step are in the middle. As soon as the side plug is attached, the part of the plate protruding beyond the diameter of the pipe is cut off.

The next step is to mark two points on the same line with a core at a distance of 2 cm. In these places, holes of 19 mm in diameter are drilled. Pipes for supplying and removing water will be welded here. To ensure grounding, an M14 nut must be welded to the pipe for subsequent connection of the conductor.

Then the heating element is placed in the pipe, attaching its legs to the holes made earlier and securing it with rubber nuts and washers.

After this, you will need to weld the opposite edge of the pipe. To do this, you should cut a square fragment from a steel sheet, larger in size than the diameter of the pipe. Perform welding by turning the device over and securing it on a flat surface. Once the device has cooled, make holes to mount it on the wall.

Important! Before final installation, check the functionality of the created mechanism.

Schemes and sizes

Flow devices can be closed or open. A homemade water heater of the first type can supply several water pressure points, while the second type can supply only one. Their operating principle is designed to connect heating only when the water is turned on.

Gas units are divided into types, depending on the type of ignition (hydroburbine, piezoelectric element or electronic unit). They don't need mixers.

The design of the device consists of several elements.

- Flow sensor. This component monitors the pressure in the pipeline. Since a lot of energy is consumed to heat water, the pressure must be high. Otherwise, the heat will be directed to the heater elements.

- Temperature sensor. This is a thermostat that controls the heating intensity. When the temperature reaches a certain point, the homemade unit automatically turns off.

- Water node. It is a pipe through which water passes during the heating period.

- Control block. An electronic board that connects and controls the heating mode.

Gas units are also equipped with a closed combustion chamber that heats the heat exchanger. A fan can be used to provide air flow into it. The chimney releases gases. To protect the unit, various sensors are additionally installed: pressure, draft, burner attenuation.

Important! Making your own instantaneous heater that uses gas can be difficult and unsafe. Even factory devices are installed with the participation of a specialist.

A storage water heater consists of a tank and a heating source, as well as pipes, a valve and a temperature control device. A homemade boiler can be easily made from any large container. For a family of four, the optimal volume is 300 liters.

What can the device be made from?

A good and inexpensive homemade boiler can be made from a gas cylinder. It's better to take a new container. But a used one will also work. A previously used cylinder must be treated with a nitro primer and then rinsed thoroughly. This will help remove the gas smell.

Note! To thoroughly clean a used cylinder, you will need to cut it and then assemble it by welding.

Other necessary things are:

- slotted screwdriver;

- welding;

- tap;

- spanners;

- electric drill.

Heating is carried out using a heating element with a built-in thermostat. The power of the mechanism can be 2-6 kilowatts. Additionally you will need:

- two pipe fragments with a diameter of approximately 20 mm and a length of 10 cm;

- an electrical cable with a cross-section of at least 2.5 square meters and a distribution box;

- check valve;

- FUM tape or tow;

- two shut-off valves.

Housing assembly

You need to cut off the neck of the gas cylinder, and in its place weld a thread for the heating element. Next, two holes are made in the bottom of the cylinder for hot and cold water outlets.

Pipes are cut to different lengths. The section of hot water supply pipe should be several centimeters shorter than the height of the cylinder in order to draw hot water from the very top of the boiler. To supply cold water to the boiler, it is enough to take a pipe a few centimeters long.

A hole is cut out in the side surface of the cylinder for the barometer, and it is carefully sealed with polyurethane foam.

Pipes are welded into the body. Corners are also welded onto the cylinder so that the finished boiler can be mounted on the wall.

Next, all welding points are foamed. The body is insulated by wrapping it with heat-insulating material. It can be secured with tape.

You need to wrap the gas cylinder twice, first placing bars on the first layer of insulation and foaming the space between them.

This way you minimize the air gap. The lid and bottom of a homemade boiler can be insulated with foam rubber to avoid large heat losses.

To protect the boiler, you can use a thin sheet of galvanized steel. The water heating element is sold at any hardware store. To soften water, buy a heating element with a magnesium anode.

Features of choice

In one of the articles we wrote how to choose an indirect heating boiler, so we will consider the features of choosing gas instantaneous water heaters. What parameters should you pay attention to first?

Rated power

To make the right choice, calculate in advance the required amount of hot water depending on the number of consumers. Speakers can be divided into three types based on power consumption:

- Low power - from 17 to 19 kW. Such devices are suitable for servicing two consumers and two intake points (for example, a washbasin and a shower). They give out about 8 liters per minute.

- Average - from 22 to 24 kW. Installed in private homes for 3-4 users.

- High - from 28 to 30 kW. Can be used for bathroom fittings and other purposes at the same time. Provides good pressure and heating.

Pay attention to the efficiency indicated in the document. There may be useful and consumed power - you need useful. Otherwise, you risk buying equipment that will not meet your needs.

Ignition type

The convenience and safety of operation depends on this criterion.

- Manual ignition . One of the first and budget models. To start heating, you need to hold the button and bring a match to the igniter. This method is inconvenient and unsafe.

- Piezo ignition . The difference with the first option is that a spark appears when the button is pressed. Mechanical activation is convenient if the device is nearby.

- Electronic type . As soon as you open the faucet, a spark appears and starts the process. It lights up when the batteries are fired.

- Hydrogenerator . The built-in mini-turbine rotates with the flow of water and generates current. The flame appears when the tap is opened. The higher the pressure in the system, the more efficiently the turbine will operate and heat.

Modulation system

The flame intensity of the burner can be adjusted by the user or by an electrical relay. Modulating burners regulate power automatically. This is convenient if pressure drops are observed in the system. In this case, the device independently adjusts the heating strength - the water coming out is the same temperature.

Type of radiator (heat exchanger)

Their quality and service life depend on the material of manufacture. There are heat exchangers from:

- Become. They are distinguished by significant weight and resistance to corrosion.

- Highly purified copper. To the above qualities you can add high heat transfer.

- Copper. The radiator heats up unevenly, so cracks appear in it quite quickly due to temperature changes. Some manufacturers coat the product with heat-resistant paint, but still such a heat exchanger does not last long.

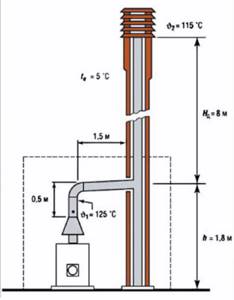

Removal of combustion products

Since heating in a flow-through heater occurs due to gas, its combustion products must be discharged somewhere. Combustion chambers are divided into:

- Open. Such devices are equipped with a chimney and ventilation. The air that supports combustion comes from the room. They have a high efficiency. But not all apartments can have a chimney.

- With a closed camera. The output is carried out using a fan through a coaxial pipe. Since there is no need to install a chimney, you can save money.

Important to consider! If you have plastic windows installed, they may interfere with natural ventilation. As a result, the ignition may not work or function unstably. Way out of the situation: installing a ventilation valve. It crashes into the window part.

Operational safety

If you take a gas water heater for an apartment, take care of your safety. To do this, make sure that the equipment is equipped with devices that control its operation.

- Traction sensor. Triggers when the chimney malfunctions. It closes the fuel start valve, eliminating gas poisoning.

- Ionization detector. Turns off the device when the flame goes out.

- Electronic control unit. Controls the operation of nodes, allowing you to set optimal parameters to avoid overloads.

- Flow sensor. Starts the burner when the mixer is opened.

- Safety valve. Triggers when there is increased pressure in the system, releasing excess pressure.

- Pressure detector. If there is insufficient pressure in the line, the burner will not turn on to avoid damage to the radiator.

What else should you take into account when choosing? First of all, the features of the room.

- The presence of a chimney to remove combustion products.

- Amount of water consumed and points of collection.

- Availability of free space for installation, ease of use.

- Design of the room and equipment.

It is better to entrust the installation of the device to a specialist. He must determine the draft and bring the pipes to the column.

If we compare gas and electric, the latter are easier to install. However, gas is cheaper to operate. Below we have collected the best water heater models.

Idea to note

If you have a non-working kettle, then you can build a water heater by removing the following parts from the body:

- a spiral that is located under the heating pancake;

- on/off button;

- temperature sensors;

- power cord.

Take a small metal or plastic box and screw all the parts to its base, then solder the button and sensors. Attach a hose to one of the spiral outlets and secure the entire structure with self-tapping screws. Turn on the water and check operation. This option is perfect for a summer house, since the output of warm water is small.

To summarize, we can say that the cost of manufacturing a homemade instantaneous water heater depends on the presence or absence of any parts. And then you can use your imagination as you please. The main thing is to understand the essence and schematic structure, as well as the technical features of the system.

Watch the video in which the user clearly demonstrates how to make an instantaneous water heater with your own hands:

How to choose a geyser

The purchase of instantaneous water heaters is made taking into account the needs of the user - the volume of hot water consumed, the composition of the family, the number of water intake points. The right choice will ensure comfort in using the equipment and significantly extend its service life. When studying our official website of geysers, we recommend paying attention to the following criteria:

- Performance - small-capacity models up to 13 l/min are suitable for installation in apartments; more productive options will be ideal for private homes or small commercial establishments (for example, a bar or cafe).

- Water intake points - if you plan to use hot water only for washing dishes in the kitchen, it is enough to choose a model designed for one water intake point. When using a shower or bath, it is better to give preference to multi-point heaters.

- Type of ignition - can be automatic, with water heating when the tap is opened, or on piezoelectric elements that require a preliminary press of a button.

In addition, geysers on our official website may have electronic or mechanical control, vary in size and the presence of additional functions. Taking these characteristics into account will help you choose the optimal solution specifically for your premises.