Rating of the TOP 12 best floor-standing gas boilers of 2020-2021

This rating includes the best floor-standing gas boilers for heating according to experts and ordinary users.

| Place | Name | Price |

| TOP 3 best floor-standing gas boilers in price-quality ratio | ||

| 1 | Lemax Premium-30B 30 kW | Find out the price |

| 2 | Lemax Premium-30N 30 kW | Find out the price |

| 3 | BAXI SLIM 1.150 i 14.9 kW | Find out the price |

| TOP 3 best floor-standing single-circuit gas boilers | ||

| 1 | Lemax Leader-25N 25 kW | Find out the price |

| 2 | Lemax Wise 25 25 kW | Find out the price |

| 3 | Lemax Premium-20 20 kW | Find out the price |

| TOP 3 best floor-standing double-circuit gas boilers | ||

| 1 | ATON Atmo 10ЕВМ 10 kW | Find out the price |

| 2 | Protherm Bear 30 KLZ 26 kW | Find out the price |

| 3 | Lemax Premium-20B 20 kW | Find out the price |

| TOP 3 best floor-standing energy-independent gas boilers | ||

| 1 | Lemax Patriot-10 10 kW | Find out the price |

| 2 | Lemax Premium-16 16 kW | Find out the price |

| 3 | Siberia 17 17.4 kW | Find out the price |

Characteristics

Wall mounted units

The most modern models that are installed on the wall. Such boilers are compact and convenient for heating small rooms.

The power of the device is 12-42 kW, allowing you to heat an area in the range of 50 – 400 m². Such models provide not only heating, but also hot water heating.

Wall-mounted gas boilers have a control system for the operation of the device and a built-in burner. The burner is ignited according to 2 types - piezo ignition or electric. In the first case, the ignition process is manually controlled, in the second - automatic.

Burners in wall-mounted gas boilers are installed either conventional or modulating. Modulating ones independently regulate the gas supply for the operation of the installation.

Floor standing boilers

Traditional heating installations that have gained popularity among the population. To install a floor-standing boiler, a certain area is required. Such mini boiler houses are distinguished by their reliability and high power. They are installed to heat large rooms.

The boiler heat exchanger is made of 2 metals - cast iron or steel. Cast iron is more durable because it is not subject to corrosion, but it is also more fragile. The gray cast iron used for the burners in the new models makes them more durable and less fragile than their predecessors. Steel is lighter than cast iron, but for successful operation it is necessary to comply with measures to prevent corrosion.

There are boilers with forced-air and atmospheric burners. In the first version, the burner is sold separately; such installations have high efficiency and high cost, with a power of about several thousand kW. The second option is cheaper, the burner is included in the boiler package, power is 10-80 kW.

Single-circuit installations

These are exclusively heating units. To obtain hot water intended for domestic needs, you must purchase a boiler separately. The calculation of the volume of the latter depends on the number of residents.

Dual-circuit devices

The most popular model. These boilers work not only for heating, but also for heating water. The cost of one such device is higher than the cost of a single-circuit boiler, but if you consider that in addition to a single-circuit boiler a boiler is needed, then the price of a double-circuit gas installation is significantly lower than the total price that needs to be paid for a boiler and a single-circuit boiler.

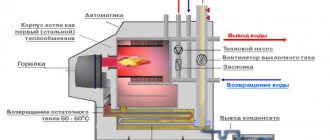

Forced ventilation boilers

These models have built-in fans that remove burnt gases from the boiler. To operate this type of device, it is necessary to make a special hole in the wall to which the exhaust pipe is connected. Through the pipe, with the help of a fan, exhaust gases from the boiler are discharged into the atmosphere.

Such devices are used in rooms where there is no chimney.

Units with natural air exhaust

These boilers remove gases using natural draft. The hood passes through the chimneys that are in the house. When installing the boiler, the pipe is connected to the house chimney. In this case, additional arrangement (as in the case of a forced ventilation boiler) of the draft hole is not required.

Boilers with condensate processing

New generation devices – boilers with condensate processing. When fuel burns, water vapor and carbon dioxide are produced. During the process of removing combustion products through the chimney, water vapor condenses in the chimney. The condensate has a high temperature, so it is removed from the chimney in the receiving device and pumped out by a pump at certain intervals into the heating circuit. Using condensate to operate the unit allows you to increase the efficiency of such models by 6%. from a similar boiler, without this function. Such boilers are most in demand in Europe, and in some countries the installation of such models is encouraged at the state level. Unfortunately, such boilers are still little known in Russia. Condensing boilers are economical because by using additional condensate energy they reduce gas consumption by up to 30%

How to choose a floor-standing gas boiler?

Focus on the following parameters:

- Power . An average power reserve will allow the boiler to last not 1 or 2 years, but significantly longer. Add 25% to the optimal power indicator, and the result will be the very figure from which you should build.

- Material of manufacture . Gas boilers made of cast iron last the longest. But get ready to shell out a hefty sum for such a boiler.

- Device type . A condensing boiler is cheaper and more economical.

- Management . Choose a model with manual temperature control: sooner or later you will want to choose the appropriate indicators yourself.

- Safety . The boiler must have protection systems: gas control (which turns off the unit if there is a gas leak), protection against hypothermia and overheating.

Popular manufacturers of gas boilers: Neva, Lemax, ZhMZ, Navien, Protherm, Baxi, Viessmann, Buderus, Vaillant.

Popular models

Finally, it is worth saying a few words about the most common and well-known models of gas boilers.

If you choose a gas-fired floor-standing boiler - which is better in terms of quality - there are many high-class models here: Viessmann (Germany), BAXI (Italy), Bosch (Germany), Protherm (Slovakia), Ferroli (Italy), Vaillant (Germany), etc. etc. Floor-standing models of Russian production: Siberia (more details: “How to choose a Siberia gas boiler - types, characteristics, advantages”), Lemax Premium, Aton SAAB, TermoMax and others.

There are no fewer quality wall-mounted models on the market (many of which are produced by the same manufacturers): Vaillant (Germany), De Dietrich (France), Ariston (Italy), Wolf (Germany), ACV (Belgium), Viessmann (Germany), Nova-Florida (USA), BAXI (Italy), Buderus (Germany) and a number of others. Russian wall models: Lemax, Neva, NevaLux, Danko, TermoMax, etc.

Of course, if we talk about quality, foreign manufacturers are at their best here, but the price of their products is much higher. The advantages of Russian-made gas boilers, in addition to low cost, can be considered ease of maintenance and repair, as well as adaptability to pressure drops in the main line. Taking into account these nuances, the specific choice always remains with the end consumer.

Review of the best models in terms of price-quality ratio

Lemax Premium-30B 30 kW

The Premium series boiler is a Russian unit, powerful and reliable. In the first year of its release to the market, it received a lot

flattering reviews from customers.

The controls are electronic and intuitive, capable of heating a large living area. The unit itself is dual-circuit, compact, and takes up little space. The build quality is excellent. Heat exchanger material is steel coated with anti-corrosion enamel, fuel is natural gas (flow rate - 3.5 cubic meters per hour).

There is protection (gas control), a thermometer and overheating protection. Warranty period - 3 years. This model has proven itself well in 2021.

Specifications:

- Maximum thermal power: 30 kW;

- Heated area: 300 sq.m;

- Efficiency: 90%;

- Weight: 88 kg;

- Dimensions: 556x961x470 mm.

pros

- easy to buy spare parts for repairs;

- powerful;

- economical;

- no problem with cheap fuel.

Minuses

- makes noise during operation.

Lemax Premium-30N 30 kW

Single-circuit boiler with good power, packed in a steel box (steel thickness - 2 mm).

No electrical connection required. Burner - micro-flare injection POLIDORO, Italian automatics. Anti-corrosion enamel can withstand temperatures up to 950°C and does not deteriorate even under aggressive environmental influences.

The temperature regulator is fixed on the front panel of the boiler. The top panel can be easily removed. There is a gas control function. Warranty - 3 years.

Specifications:

- Maximum thermal power: 30 kW;

- The approximate area of the heated room is 300 sq.m;

- Efficiency: 90%;

- Weight: 77 kg;

- Dimensions: 556x961x470 mm.

pros

- low gas consumption;

- there is enough power to spare;

- you can choose a comfortable thermal mode yourself;

- affordable;

- pleasant appearance;

- easy setup.

Minuses

- There is no protection against overheating and freezing.

BAXI SLIM 1.150 i 14.9 kW

Single-circuit floor-standing unit with average efficiency and good protective functions: gas control, air vent

, safety valve. There is frost protection, flame modulation, automatic ignition and underfloor heating.

There is a display on the front panel. The heat exchanger is made of cast iron. The combustion chamber is open. An indirect heating boiler with additional piping can be connected to the boiler.

The warranty period is 24 months. The fuel can be either natural or liquefied gas.

Specifications:

- Dimensions: 350x850x520 mm;

- Thermal power: 8.50 - 14.90 kW;

- Weight: 93 kg.

pros

- electronic control;

- reliable;

- economical;

- pressure gauge;

- pump blocking protection.

Minuses

- high price.

Advantages and disadvantages

The advantages of floor-standing boilers include:

- no restrictions on the power of the unit;

- strength, reliability of all components and parts;

- ease of installation;

- stability of operation, the ability to maintain a given mode regardless of external conditions;

- no unnecessary additions;

- powerful models can be connected in a cascade of up to 4 units, forming high-performance thermal units.

The disadvantages of floor structures are:

- large weight, size;

- the need for a separate room;

- for atmospheric models it is necessary to connect to a common house chimney

IMPORTANT!

In addition to a separate room, for floor-standing boilers it is necessary to ensure the possibility of connecting to a vertical chimney or leading a horizontal pipe through the wall.

Review of the best single-circuit models

Lemax Leader-25N 25 kW

The stylish boiler is made in red and white colors and does not require a network connection. Has all the necessary programs

protection, reliable and high quality.

The cast iron heat exchanger perfectly maintains the temperature and, thanks to its high heat transfer, warms up the home well. The starting system operates smoothly and the controls are simple.

The temperature regulator is installed on the front panel. The micro-torch burner ignites without problems. Fuel is natural gas.

Specifications:

- Max. thermal power: 25 kW;

- Heated area: 240 m²;

- Dimensions: 515x856x515 mm;

- Efficiency: 90%;

- Max. thermal load: 30 kW.

pros

- automatic Nova;

- gas control;

- overheat protection;

- pressure gauge

Minuses

- very heavy (115 kg).

Lemax Wise 25 25 kW

Ergonomic boiler with low gas consumption (for this level of units) and a set of protective programs, reliable

and relatively inexpensive. There is a convenient display and power indicator.

The installed automation system, made in Italy, is resistant to voltage surges, does not make noise, and allows you to connect additional devices (for example, a turbo nozzle, circulation pump, etc.).

The warranty period is 24 months.

Specifications:

- Max. thermal power 25 kW;

- Efficiency: 90%;

- Weight: 116 kg;

- Dimensions: 515x860x520 mm.

pros

- gas control protection;

- it is possible to connect external control;

- auto diagnostics;

- flame modulation;

- frost protection;

- power-on indication.

Minuses

- heavy weight.

Lemax Premium-20 20 kW

Inexpensive and quite simple, but with a standard set of functions, a boiler for a house with an area of 200 sq.m.

The heat exchanger is made of high-strength steel. Powerful, with good heat dissipation. Gas consumption is economical, the removable panel allows you to clean it yourself.

The model is equipped with automatic ignition. Safe: functionality includes gas control, protection against draft blowing and protection against heat exchanger overheating. It does not take up much space, as it is small in size. Chimney diameter is 130 mm.

Specifications:

- Boiler warranty: no more than 3 years;

- WxHxD: 556x961x470 mm;

- Gas consumption: 2.4 cubic meters m/hour;

- Thermal power (maximum): 20 kW.

pros

- intuitive control panel;

- the boiler is easy to operate;

- affordable price;

- high efficiency.

Minuses

- makes noise.

The best equipment: consumer opinion

According to the owners of gas heating systems and specialists servicing the equipment, the best among foreign manufacturers are the German brands Bosch, Wolf, Buderus, Vaillant, the Slovak brand Protherm, the Italian BAXI and the Korean Navien.

Among domestic manufacturers, the Conord Plant from Rostov-on-Don and the Zhukovsky ZhMZ have proven themselves well. Let's look at several models recognized as the best.

Bear 30 KLOM from Prothrem

Floor-standing single-circuit device with an open chamber and a cast iron heat exchanger. Equipped with a modulating burner made of stainless steel. It is possible to arrange forced removal of flue gases.

The heat exchanger is equipped with a condensation protection system; if necessary, its sections can be replaced. The boiler is compact in size, has a cooling circuit, an automatic control system and two operating modes “Summer-Winter”. Device power 26 kW.

EcoVIT VKK INT 366 from Vaillant

A single-circuit boiler operates using condensing technology. Capable of heating up to 340 sq. m, power – 34 kW. If it is necessary to provide domestic hot water, it is well compatible with an external storage boiler. The model has an efficiency of more than 100%, which makes it very economical.

Floor-standing boiler Comfort from the Zhukovsky plant is an excellent budget solution for providing heat to your home

Equipped with a multi-sensor control system and a closed-type modulating burner. An economical electronic ignition is used for ignition. The boiler can be connected to external control, which allows it to be integrated into the Smart Home system or controlled remotely.

AOGV-23.2-3 Comfort N from Zhukovsky plant

Inexpensive domestic boiler with improved environmental performance. Fully adapted for operation in Russian conditions, capable of stable operation at low gas pressure.

Non-volatile, can be built into systems with gravitational or forced circulation. Equipped with a dial thermometer and piezo ignition. Extremely easy to operate and maintain. The burner is easy to clean and replace.

The following article on this issue will provide an overview of popular models of gas boilers operating on liquefied gas.

Review of the best dual-circuit models

ATON Atmo 10ЕВМ 10 kW

Trouble-free unit with mechanical control. High quality assembled. The combustion chamber is open, efficiency is 90%. Material

heat exchanger - high quality steel. Only natural gas is suitable as fuel. Automation - EUROSIT.

The coolant temperature range is 50-90 °C. The model operates completely silently, is easy to set on fire and rarely breaks. Chimney diameter - 110 mm. Capable of heating an area of about 100 sq.m.

Specifications:

- Thermal power: 10 kW;

- Weight: 44 kg;

- Dimensions: 380x760x385 mm.

pros

- thermometer;

- gas control;

- inexpensive;

- long warranty period.

Minuses

- small heated area.

Protherm Bear 30 KLZ 26 kW

Massive double-circuit boiler with a full set of amenities: pressure gauge, thermometer, auto-ignition, gas control

, flame modulation, autodiagnostics. Included: built-in circulation pump and expansion tank.

In case the pump is blocked, special protection is installed. Indicators in the DHW circuit are 40-70 °C. Natural gas consumes 3 cubic meters. m/hour, liquefied - 2.4 kg/hour. A single-phase network extension is required.

Specifications:

- Thermal power: 18.20 - 26 kW;

- Parameters: 505x1385x730 mm;

- Weight: 155 kg.

pros

- warranty period: 730 days;

- electronic control;

- built-in boiler;

- overheat protection.

Minuses

- very heavy.

Lemax Premium-20B 20 kW

Budget model made of steel, impact-resistant and durable. The gas supply stops automatically if

failure, as well as the burner is switched off when abnormally high water temperatures are detected.

Long warranty period (3 years). There is overheating protection, a thermometer on the body and gas control. The volume of gas consumed is 2.4 cubic meters. m/hour. The coolant can withstand a maximum of 90 degrees. Capable of heating 200 sq.m. premises.

Specifications:

- Dimensions: 556x961x470 mm;

- Weight: 83 kg;

- Claimed power 20 kW;

- Unit parameters: 556x961x470 mm.

pros

- inexpensive;

- large heated area;

- durable body;

- good build.

Minuses

- susceptible to corrosion;

- the main parameters can only be adjusted manually.

What is the difference from the usual?

The difference between a non-volatile boiler is the absence of all components that require power supply. There is no built-in circulation pump or turbofan.

Control is carried out using mechanical devices - valves, mechanical sensors, regulators. This makes the design very simple and reliable, but all processes occur naturally.

For example, smoke removal is carried out using a stove draft in the chimney. The air is taken directly from the room. These features make the operating mode dependent on a host of external factors.

For example, the draft in a chimney varies depending on the weather, direction and strength of the wind. Drafts can disrupt the flame. In addition, the room needs good ventilation, since the boiler actively burns oxygen.

Many users solve these problems by installing external devices - a circulation pump and a turbo nozzle to enhance and stabilize the thrust. This makes the operating mode more intense and smooth.

Review of the best non-volatile models

Lemax Patriot-10 10 kW

Russian boiler with a closed combustion chamber and an improved protection system. The functionality is simple, but it gets the job done

. For individual heating of a small area, its power is quite enough.

Small steel heat exchanger. It consumes little gas and heats up well. The assembly is good. Mechanical control. The maximum coolant temperature is 80 °C. Weighs 50 kg. Chimney diameter is 250 mm.

Specifications:

- Service life: 3 years;

- Max. thermal power: 10 kW;

- Fuel: natural gas only;

- Dimensions: 595x740x360 mm.

pros

- durable;

- qualitative;

- affordable.

Minuses

- It cannot be used as a gas water heater, only for heating.

Lemax Premium-16 16 kW

Another inexpensive but high-quality model for those who only care about warmth and not “bells and whistles.” Neatly assembled box

covered with an inhibitory anti-corrosion composition and heat-resistant enamel.

Practical and reliable energy-independent model for an area of up to 120 sq.m. Can be installed both in residential and non-residential premises. The temperature sensor is located on the top panel for user convenience. Weight - about 60 kg. Thermal power - 16 kW.

Specifications:

- Allowable heating area: 160 sq.m;

- WxHxD: 416x744x491 mm;

- Warranty period: 3 years.

pros

- easy controls;

- economical model;

- quickly warms up the home;

- convenient to clean.

Minuses

- a bit expensive for boilers of this level;

- volatile

Siberia 17 17.4 kW

A relatively cheap, domestically assembled miniature heating unit with Italian “stuffing”.

The media temperature sensor is located on the control panel. Weighs more than 50 kilograms, the heat exchanger has thick steel walls. Piezo ignition with flame control.

It is not capricious in maintenance, breakdowns (according to customer reviews) occur very rarely. High quality build. The combustion chamber is open. Compact, takes up little space.

Specifications:

- Thermal power: 17.40 kW;

- Area: 200 sq.m;

- Highest carrier temperature: 90 °C.

pros

- attractive design;

- compact;

- automation and burner made in Italy;

- inexpensive;

- high efficiency.

Minuses

- makes noise when ignited.

Pellet boilers for heating a country house

It's no secret that wood pellets are a type of environmentally friendly fuel. Granules are obtained by pressing waste from the wood industry.

Pellet heating boilers operate in automatic mode. The fuel is located in the bunker and enters the combustion chamber using a screw (along the screw surface). The temperature of the coolant of the entire system will depend on the amount of fuel burned.

Pellet boilers for home heating can be divided into three types:

1. Boilers with an efficiency of 95% have volumetric burners, which are made of heat-resistant cast iron or steel and are a cylindrical container that is built into the boiler firebox. Pellets are fed into the burner automatically using an auger. Boilers are fired manually or automatically.

2. Boilers, the efficiency of which is up to 85%, are equipped with torch-type burners. The unit is equipped with a fan that blows hot air. Pellets, under the influence of air flow, enter the combustion zone and turn into burning coals. The gas releases to the coolant fluid and is removed from the boiler through the chimney.

3. Boilers with an efficiency of over 95%, or gas generators. The coolant is heated in the boiler by burning gas. The gas itself is produced in a gasification chamber. Pellets are loaded onto a reactor grid, which is installed in the gasification chamber. When exposed to high temperatures, fuel decomposes into resins, water vapor and oils. Resins and oils, in turn, decompose into gases, which, due to rarefaction, enter the combustion chamber located at the bottom of the reactor.

The power limits for solid fuel boilers range from 15 to 500 kW. If the minimum power for a living space is sufficient, then you can use a pellet fireplace. Boilers with a power of up to 500 kW have a short service life and low efficiency when compared with other heating equipment. For example, in Europe they have already begun to produce boilers with a power of 2 MW, but at an extremely high cost. Pellet boilers have a lot of positive aspects: high efficiency, reasonable cost of equipment, ease of use and automatic operation. In addition, pellets are environmentally friendly fuels; their consumption is minimal.

Floor-standing or wall-mounted gas boiler - which is better?

Let's look at the main differences between floor-standing and wall-mounted boilers:

- The efficiency of wall-mounted boilers is 90-94%, lower floor-standing boilers are 88-90%. This means that the lower the efficiency, the higher the energy consumption. Most floor-standing boilers are convection boilers. Their price is lower, they are also inexpensive to repair, but they are also less efficient. Boilers that are attached to the wall can be either convection or condensation. In condensation systems, the heat generated from combustion products and gases passes into the coolant, and not into the atmosphere, i.e. it is used efficiently (this requires the construction of a condensate drain, but this work is simple).

- The service life is affected by the material of the heat exchanger, and not by the number of structural elements and their connection in certain variations. Heavy cast iron is often used - a thick and very durable material that is not afraid of corrosion and is very durable. Such a boiler can operate for at least 20 years, or even 25. Copper or steel are used in suspended structures. Steel is cheaper than copper, but is thin, and will last 12-13 years. Whether it’s copper: units with copper elements last 5-8 years longer and conduct heat better, but they also cost significantly more.

- Fun fact: manufacturers generally prefer to create entire boiler rooms in miniature from wall-mounted boilers, and use floor-standing boilers to a minimum. Regarding dimensions: do not think that the larger and more massive the boiler, the better it works. Most often it happens just the opposite.

- Each region has its own nuances of power supply: a non-volatile boiler will continue to operate even in your area “the lights will be turned off.” Half of all floor-standing boilers on the market are non-volatile, and there are plenty to choose from. But wall-mounted ones require connection to the electrical network, without exception.

- Automation in wall-mounted boilers is better, so these types of models are safer and more convenient to use. They also have overheating protection, self-diagnostics, freeze protection and a lot of other useful functions. Floor-standing ones boast automatic ignition (rarely), overheating protection and gas control.

- Wall-mounted structures cannot work with some coolants, for example, antifreeze on copper and steel heat exchangers has a simply destructive effect. But the same antifreeze is perfect for floor-standing boilers.

- One- or two-stage burners are installed in floor-standing boilers (they can operate either in on/off mode, or with adjustment at 50 or 100% power), in wall-mounted boilers - modeled ones (the indicators can be adjusted by the user himself as he pleases). The situation with chimneys is this: since almost all floor-standing boilers have atmospheric burners and open combustion chambers, the chimney for them must be removed separately . The wall-mounted units have a convenient coaxial chimney.

- Mounted boilers are cheaper and there is more choice than floor-standing boilers. And they are easier to maintain.

From the above, we can draw the following conclusion: the most reliable are floor-standing mini-boilers, since they are unpretentious even with a serious “minus” outside the window and they have a more durable heat exchanger.

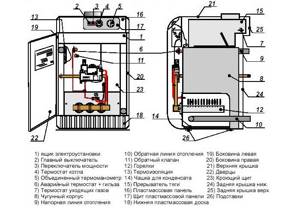

Device and purpose

All types of heating devices have common main components. Different units may differ from each other only in certain details.

If you look inside the thermally insulated casing of such equipment, you will find the following components:

- heat exchanger;

- burner;

- combustion chamber;

- automation;

- three-code valve;

- main and secondary heat exchangers.

The shape of the burner, as well as its direct design, may vary depending on the fuel from which the unit operates. In gas versions, this part is a chamber. In its internal part, fuel combustion occurs, resulting in the release of heat and oxidative products.

The main task of the burner is to release the energy required to sufficiently heat the coolant. Above the burner there is usually a heat exchanger - a container in which the coolant is present. Following along its walls, combustion products give up their heat to water, which is then sent into the pipes of the heating system

It is important to know that already cooled combustion products go straight into the chimney, after which they are discharged outside

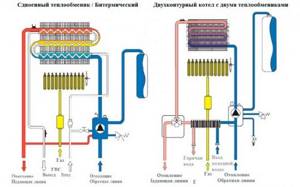

Depending on the specific configuration of the device designed to transfer heat, the following models are distinguished:

- with double;

- with bithermic heat exchanger.

Thus, dual versions have two heat exchangers in their structure. One of them is responsible for the heating circuit. It is usually assembled from copper tubes and plates with surfaces covered with a protective layer that protects them from the formation of destructive corrosion. The main function of this part is heat transfer.

As for the second heat exchanger, it is responsible for hot water supply. This element is made up of plates that transfer heat directly into the heated water environment. Due to their structure, these types of gas boilers with two circuits are called plate boilers.

As for bithermic specimens, they are a “pipe-in-pipe” structure. In them, the internal part is responsible for preparing hot liquid, and the external part is responsible for heating the living space.

The type of ignition plays an important role for floor-standing gas equipment. This part is responsible for gas combustion.

Ignition is divided into 2 main types:

- electric;

- piece

Types of floor-standing gas boilers

There are several types:

- Single-circuit - in their connection diagram the boiler and the boiler do not depend on each other, i.e. this unit will act exclusively as a heating device. To warm water for, for example, washing, you will have to buy a boiler separately and invite a specialist to connect it to the boiler. A single-circuit boiler is inexpensive.

- The double-circuit one has 2 heat exchangers inside, due to which it heats water for domestic needs. It costs more.

- A condensing boiler is a high-efficiency unit, which means little money is spent on maintenance. But the boiler itself is expensive. In such a device, heat is released during the process of steam condensation.

- Convection is an option with low efficiency. The energy released when the gas burns heats the water. This unit is inexpensive, easy to install and easy to work with.

Convection or condensation?

The traditional method of heat transfer from a gas boiler is heating the coolant in flow mode. It passes through a heat exchanger, and the gas burner heats the liquid according to the specified operating mode.

This type of boiler is called convection boiler. Relatively recently, a new design of units appeared - condensing. It uses preheating of the coolant from the heat released during condensation of the exhaust smoke.

The temperature of the liquid increases by a small amount, but this is enough to reduce the heating mode of the main heat exchanger.

As a result, a positive effect is achieved:

- fuel consumption is reduced;

- the load on the burner and heat exchanger is reduced;

- The service life of the boiler increases.

With properly organized operation of the unit, fuel savings reach 20%. However, there are some specific conditions that sharply limit the scope of application of condensing boilers.

The reason is that the condensation process can only occur when the temperature of the walls of the condensation chamber is higher than the return flow temperature. This is only possible on underfloor heating systems or radiator circuits with a low degree of heating.

It is calculated that the operation of the first stage is possible only if the difference between the outside and inside of the house is no more than 20°. For Russia, such a ratio is simply impossible. If condensation is not possible, the boiler operates as a conventional convection model.

How to choose the power of a gas boiler?

Calculating the boiler power is also not difficult. The ideal is taken to be a normally insulated room with ceilings no more than three meters high, with pressure in the gas pipeline of approximately 14-15 mbar, excluding water heating. In this case, 1 kW is required per 10 square meters.

You should also take into account the region of residence (especially average winter temperatures), how many doors and windows there are in your apartment (house) (the so-called thermal conductivity is of interest here). Remember that the lower the minimum power of the unit, the more economical it will work.

In some cases, a boiler is required whose power is 1.5-1.7 times greater than that required under ideal conditions. Therefore, if you are not sure that you can calculate everything correctly, contact a specialist: he will draw up an individual project, taking into account all the features of your home and the environment.

Technical parameters of a high-quality heating device

Gas installations have a number of technical parameters that distinguish one device model from another. These include:

- equipment power is one of the main characteristics of the boiler, which can vary from 10 to 700 kW;

- type of combustion chamber - there are closed and open chambers;

- The main fuel of the installation is liquefied natural gas;

- single-circuit and double-circuit models;

- effective heating area – varies in the range of 20 – 800 m2;

- The boiler efficiency reaches up to 90%;

- fuel consumption is less than 2.4 m3/h;

- when using hot water supply, water consumption reaches up to 300 kg/h.

Based on these indicators, it can be argued that the equipment is energy efficient and provides an optimal level of space heating at minimal costs. Automatic ignition ensures ideal uninterrupted operation of the entire system as a whole.

The equipment diagram is shown below.