Why use a burner?

Gas burners are necessary to supply gas in metered quantities to the combustion zone and maintain the specified thermal characteristics during combustion.

The fuel entering the outlet is mixed with air and burned. The main requirement for such mechanisms is low-toxic combustion with a minimum amount of harmful gases.

The devices operate automatically and can be used for domestic systems and industrial boiler rooms. The main elements of burners are: mixer, burner nozzle and stabilizing device.

Components are also used to automate gas ignition and dosing modes depending on the specified settings.

Bartolini Pullover K

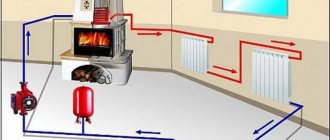

The gas heater can be used in different types of premises: apartments and houses, outbuildings and garages. It can become either the main or additional source of heat. This device is quite mobile - it moves easily on wheels. The heating element will be a special Catholic panel.

It is created from special fiberglass, and the rally catalyst will contain platinum powder. Using this method, there will be no emissions of unpleasant odors in the room when the heater is operating. The fuel for the device is liquefied propane-butane. The design itself is such that the gas cylinder is placed inside and covered with a special casing. The heater also includes special protection elements:

- sensor for monitoring the burner flame indicator;

- sensor for monitoring the state of air in the room (automatic shutdown when the amount of carbon dioxide is exceeded);

- rollover protection (automatic shutdown in case of tilt).

Additional qualities:

- there is a power regulator;

- Piezo ignition.

Main advantages:

- silent operation process;

- reliability;

- high-quality production - Italy.

Disadvantages: heavy weight and size.

Atmospheric boiler burners: operating principle and important parameters

In atmospheric burners, air for preparing the gas-air mixture is supplied naturally. The combustion chamber type can be closed or open.

In closed chambers, air supply and flue gas removal pass through a coaxial pipe using a fan.

Such a chimney includes two pipes:

- external for air supply (diameter 15 cm);

- internal for drainage (diameter 8 cm).

When using an open chamber, air is taken from the boiler room. Natural draft is provided by the chimney, and exhaust gases are removed through it.

The operation of an atmospheric burner is accompanied by noise, so it is recommended to choose models that are designed to reduce noise levels.

For an atmospheric burner, the main parameters are:

- method of supplying components;

- degree of heating of the mixture;

- flow rate of combustion products;

- nominal flame length.

Ceramic type heaters

These devices are already quite suitable for use in residential buildings. The level of security during their operation is several times higher, due to a different operating principle.

A special gas burner is also built into such a device; it creates numerous, but small-sized flames that heat not the air in the room itself, but a special ceramic emitter. At the same time, it heats up to fairly high temperatures (varies from 600 to 800 degrees) and becomes a source of infrared rays (infrared gas heaters for summer cottages).

One of the advantages of such equipment is that the thermal energy in them can travel over vast distances without dissipating through the air , but, being absorbed by optically opaque objects (including the human body), causing them to quickly heat up. Heated objects, including walls, floors, furniture, and ceilings, will spread their heat through the direct process of heat transfer with the air in the room. There are no fans in it, that is, the operation of the device is almost silent.

Such heaters can be connected to mains gas or run from a gas cylinder. The design of many models of such devices provides for the hidden placement of gas cylinders.

The store offers a wide selection of ceramic gas heaters for the home. With all this, models may differ from each other in their power and dimensions, as well as in their external design and installation method in the house.

You can buy a very small heater that can be placed on the table. Such a device is well suited for creating a heating zone, for example, in a place where a person regularly rests.

Gas convectors. Such devices can have both open and closed combustion chambers. Closed-type models for gas combustion take oxygen from the street and remove combustion products also to the external environment through a special tube laid through the wall. They are well used in homes and cottages and can be an alternative to a gas boiler. Models with an open chamber are not very suitable for houses or require the use of a special vertical chimney.

How to choose the right burner

The choice of burner for a boiler is influenced by the following factors:

1. Power. The burner power value must be greater than the boiler combustion power. However, the difference in performance should not be significant.

Large differences in power will lead to an overestimation of the minimum level of boiler performance during operation.

2. Type of power control. There are several main types of regulation:

- single stage. When the maximum temperature of the coolant is reached, the burner turns off and turns on when the temperature drops to the minimum level;

- two-stage. There are two stages of combustion: large and small. After heating the coolant to the set temperature, the burner switches from the second combustion stage to the first to maintain the temperature.

It is preferable to use such burners for low-power boilers. They reduce the number of switches on and off the device and minimize the impact of aerodynamic shocks on the walls of the boiler;

- smoothly stepped. When switching from one stage to another, the volume of the gas-air mixture increases gradually, which allows for a smooth increase and decrease in power during operation of the gas burner;

- modulated. It is possible to configure several intermediate control points (standard - three).

Recommended for installation on large and medium-capacity boilers, where it is necessary to accurately maintain the operating power of the burner and boiler.

Low power boilers can be equipped with any type of burner. For large and medium-power appliances, it is recommended to choose burners with modulating or smooth-step control.

This will allow you to set the exact value of the boiler operating power and reduce the load on the walls of the combustion chamber. The use of such burners prevents sudden changes in pressure and increases the service life of the equipment.

3. Fuel type. You should decide in advance on the type of main and reserve fuel. If it is necessary to use additional fuel, then it is necessary to install a combination burner.

4. Gas pressure in front of the burner and the diameter of the gas fittings. Burners with a small diameter may not provide the required volume of gas to operate the burner at the required power.

Gas burners for boilers - types and features

Heating a house with natural gas is a simple matter, since this fuel has many advantages over conventional wood or coal.

But to achieve high efficiency indicators, it is necessary to competently organize the process of gas combustion in the boiler chamber - modern gas burners for boilers provide a fairly accurate fuel-air mixture, where the gas burns completely. When gasifying old areas, most residents think about the question of what gas burners can be used for KCHM boilers or how to choose the right gas burner for a boiler that was originally intended for wood and coal.

High-quality models contain quite a lot of technological innovations in their designs, which allows them to maintain optimal combustion and a wide range of flame power control.

Review of popular manufacturers

1. The most popular European manufacturer of gas and liquid fuel burners is Weishaupt. Weishaupt burners (Germany) have an operating power range from 12.5 kW to 22 MW.

Unlike other manufacturers, they can operate in low gas pressure conditions. Designed to operate on natural and liquefied gas; the use of biogas and associated gas is also acceptable.

For non-standard types of fuel, the chemical composition of the fuel must comply with the manufacturer's requirements.

2. A good price-quality ratio is offered by the burner manufacturer Cib Unigas (Italy). These are automatic installations with a power from 20 kW to 65 MW.

The company manufactures burner devices with a monoblock (built-in fan) and two-block design (the fan is equipped with an external unit). Thanks to this technology, two-block burners can be used in boiler rooms where there is no possibility of air intake.

3. A wide range of burners is offered by the European manufacturer Elco (Germany-France). The operating power range is from 14 kW to 2.1 MW.

The company uses in its production a patented flame tube design (multistage injection), which ensures stable and energy-efficient fuel combustion quality. Thanks to built-in silencers, Elco units have low noise characteristics.

How to choose a good device?

The main characteristics of such products are:

- Thermal power.

- Characteristics of the gas that will be used in the product.

- The relative length of the flame leaving the burner.

- Design gas pressure in the furnace.

- Operating adjustment: ratio of theoretical thermal power to minimum.

- Limit adjustment: the ratio of the highest thermal power to the lowest.

- Chemical composition of the fuel.

- The noise level produced by the product.

When choosing a device, you need to keep the following factors in mind:

- Simplicity of design. In this case, the cross-sections of the paths for the passage of gas must be the same and create minimal resistance to the gas.

- Room size. For small rooms, an atmospheric device will be sufficient, but for larger rooms the power of such devices may not be enough.

- Manufacturer of the product. Domestic and foreign (mostly products made in Germany are on the market) units have approximately the same cost, but some similar devices are designed for installation in specific types of stoves. For example, the domestic product AGG-15 is suitable for use only in stoves with a long channel for the fuel mixture.

Photo 2. Gas nozzle AGG-26, suitable for furnaces with a long channel.

Type of heating device.

Important! You need to know where the fuel will come from to the heating device: from individual cylinders or from the main pipe. This is also taken into account when installing the stove

The price of the question - what should the buyer prepare for?

The main pricing factors for burners are power, type of regulation and type of fuel. Low-power burners running on natural gas are considered the most affordable.

The price for burners from European manufacturers with a power of up to 50 kW with single-stage regulation is 18-22 thousand rubles. The price of models with higher performance varies in the following ranges:

- up to 200 kW – 25-31 thousand rubles (smooth two-stage);

- up to 350 kW – 67-75 thousand rubles (smooth two-stage or modulated);

- up to 550 kW – 120-125 thousand rubles (smooth two-stage or modulated).

Along with the gas burner, gas fittings are purchased, without which it is impossible to organize a safe supply of gas to the device in the required quantity and with a given pressure. It also ensures quick shutdown of gas in emergency situations.

The reliability and efficiency of the entire heating system depends on the choice of burner device. That is why it is recommended to choose high-quality equipment that fully matches the parameters of the boiler.

Main types of devices

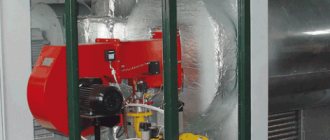

It seems that the principle of construction of such heaters is the same, and is also based on a burning flame that warms the air. At the same time, warm air fills the room and provides the required temperature. But it's not that simple. The operation of many modern equipment is based on the use of newer technologies for the generation and movement of heat when creating. So both the instructions and operating features of different types of gas heaters can differ greatly from each other.

All gas heaters can also be divided into several groups:

- warm gas guns (strong heat fans);

- infrared outdoor heaters;

- catalytic gas devices;

- ceramic gas products;

- gas convectors for stationary use;

- Convenient portable gas devices.

Despite the rather distinctive principle of device design and operation, all equipment of this format is characterized by approximately the same set of advantages and disadvantages.

The advantages of the device include:

- Network or liquefied natural gas is considered more affordable in price than all other energy carriers. This type of heating will not require the user to spend money on operational repairs. Some types of designs include a connection to the power supply, for example, to ensure full operation of fans and the functioning of the main control units. Energy consumption in such devices is minimal, so it does not affect the family budget in any way.

- The design of many gas heaters is quite simple and does not have any complex components. This helps to increase the reliability and safety of using such equipment.

- Modern models of heaters have a high efficiency, that is, this indicates their efficiency and economy. Some models of heaters are distinguished by a high level of mobility - they are very small, easily moved from one place to another and transported by transport. Some types of devices can even be taken with you outdoors, on a hike, or fishing.

- The operation of such devices causes almost no harm to the ecological system - the products of complete combustion of gas are considered harmless.

- These devices are usually easy to use.

- Warming up of the room takes place in a short period of time - the devices are not inert in operation. Gas heaters respond very quickly to changes in their settings.

- More modern models in this class include a multi-level protection system that helps protect a person and minimize the possibility of a threat developing.

- Many devices are distinguished by high performance capabilities - they can work efficiently for more than ten years.

Of course, like all devices, such heating devices also have their drawbacks. These include:

- In any gas heater for a summer residence, the fire hazard cannot be completely eliminated, since in this case highly flammable fuels are used, and their operation occurs with high-temperature heating. Such devices require special care and compliance with all safety rules. You cannot leave them unattended if there are small children in the family.

- Unburnt natural gas is considered quite toxic, so even a minimal leak can result in severe poisoning. It is this fact that imposes additional requirements for careful use.

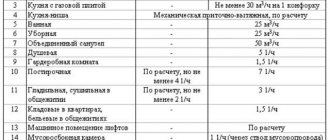

- Gas combustion must occur with a regular supply of oxygen; in many devices it is taken directly from the room itself where the heater is located. This means that you also need to take into account the supply and exhaust ventilation system so that the room does not have a heavy and uncomfortable atmosphere for humans, which in some cases can even be harmful to health. And also the requirements for creating ventilation refer to additional air circulation if there is also a gas stove in the room. If with water or electric heating such indicators are sometimes not paid any attention, then in the case of using gas heaters, a neglectful approach to the ventilation system is extremely dangerous.

However, when used correctly, such devices become good and safe assistants that help quickly increase the temperature in a cold room and ensure a comfortable stay at the dacha.

How to do it yourself?

Let's consider an example of manufacturing a gas burner for a boiler unit operating on solid fuel. It is better to use a valve from an oxygen cylinder made according to the standard, VK-74.

To create a burner you must complete the following steps.

- The outlet pipe should be equipped with a fitting, which will be connected to the reactor using a hose.

- We mount a cap on the inlet pipe part connected to the cylinder, where there is a small hole for connecting to the nozzle. It can be found on the stove or in a blowtorch.

- Now a steel pipe with a length of one hundred millimeters and a wall thickness of two millimeters is welded to the cap.

- There should be a distance of one and a half centimeters between the nozzle and the cap, through which access to oxygen will be provided. For this reason, you first need to attach 3 small pieces of wire to the cap, and then the pipe itself.

The burner is ready. All that remains is to make a base on which the device will be placed for installation in the combustion chamber.

In addition to making the burner itself, you should follow certain recommendations when lighting it:

- first we open the gas supply;

- bring the match to the nozzle;

- open the main valve.

It should be said that the power of a homemade burner is easy to regulate using a valve.

An unexpected problem is the boiler clocking.

As you know, if you constantly turn on and off any device without a good reason, it will quickly fail. This is the fate that most often befalls automatic gas boilers. The automation is unable to adapt to changing conditions; it activates heating every 10 (or even 5) minutes. The equipment cannot withstand such surges and literally burns out in a few months. Oddly enough, this phenomenon especially affected wall-mounted gas boilers, which are sensitive to temperature changes.

This phenomenon quickly took root among users of gas boilers and craftsmen under the name “clocking” - too frequent repetition of the heating-cooling cycle.

Dear Sirs! We begin the “Useful Articles” section by considering the most common case for the thermal market of the Russian Federation, which we consider when selecting ELCO or FBR burner devices for reversible steel hot water boilers from various manufacturers.

After studying this article, you will be able to independently select burner devices for the designated type of boiler.

In any case, the staff of the technical project www.prof-kotel.ru is always at your disposal, since the scope of technological solutions for a particular technical task is very extensive, which will not allow you to describe all possible options within one article.

In the contacts section you can contact us in any way convenient for you.

Let's consider the selection of a gas burner device for a reversible boiler under normal conditions using a specific example: “We ask you to select a burner device for boilers with a power of 850-900 kW. Fuel type: natural gas, low pressure.” The first thing we start with is to determine the most likely and popular model of a hot water boiler on our market. From the presented model range of the manufacturer Unical, the most likely*, based on the current model of the Russian heat market, will be the Ellprex 870 reversible boiler. In the model range of the manufacturer Unical there are several models that fall under the power indicated in the example, from the most simple and popular boilers of the Ellprex 870 series to the ultra-high-tech modular type condensing boilers MODULEX EXT 900.

* More than 90% of industrial boiler houses in the Russian Federation are manufactured on the basis of reversible fire-tube boilers, which is due to the simplicity of the design and the low cost of such a product. We will talk about the main pros and cons of reversible boiler models in a separate article.

After the formation of the initial initial commercial offer, which includes the most likely and popular equipment, our company’s specialists clarify the need to offer other, more technologically advanced, and, as a result, more expensive boiler models and burner design options for the selected model. We consider the algorithm for issuing an initial proposal with subsequent clarification to be correct, due to the fact that you have an initial figure from which you can build, taking into account the total budget of the boiler room.

Using the factory technical characteristics of the manufacturer Unical, we determine the data on the boiler model necessary for selecting a burner device:

| Hot water boiler type: | Steel, reversible | ||||

| Boiler rated power, kW: | 870 | ||||

| Boiler combustion power, kW: | 950 | ||||

| Natural gas consumption, Nm3/h: | 102,15 | ||||

| Back pressure in the combustion chamber of the boiler, mbar: | 5,7 | ||||

| Minimum length of burner flame head, mm: | 270 | ||||

| Diameter of the burner flame head, no more than, mm: | 270 | ||||

| Boiler combustion chamber length, mm: | 1 690 | ||||

| Boiler combustion chamber diameter, mm: | 684 |

Initial data for selecting a burner device under normal conditions:

| Environmental conditions: | ppooooooooooppppppppppppppppppp | ||

| Altitude above sea level*, m: | 200 | ||

| Combustion air temperature, °C: | 20 | ||

| Atmospheric pressure, mbar: | 1 013 | ||

* Altitude above sea level is one of the most important basic conditions for selecting a burner device. We talk about the influence of altitude above sea level on the selection of a burner device in a separate article.

Type of fuel:

— natural gas, 9.3 kW*h/Nm3;

Natural gas pressure: low * mbar.

* The most common, but very significant flaw when requesting a burner device is that the wording “low” . Below, when choosing a gas train and gas line options for it, we will reveal the technical and economic difference, which proves the importance of indicating the numerical value of the natural gas pressure.

ATTENTION! All work with gas-using complex technical equipment must be carried out by trained personnel who have the appropriate permit and qualifications to carry out this type of work.

Selecting the ELCO burner model:

We have identified the main technical characteristics that are necessary for selecting a burner device.

When choosing a burner device from the ELCO model range, guided by the technical documentation of the manufacturer of burner devices ELCO, we select the most likely model that is suitable for the working fields of the boiler from the technical specification: VG5.1200 DP R (where R-Reverse, a model designed for reversible steel fire-tube boilers ).

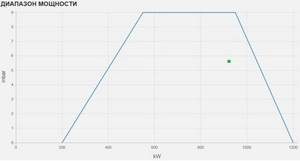

Let's check our preliminary choice by placing the burner operating point in relation to the boiler:

Based on the working field of the VG5.1200 DP R model, we see that the working point with coordinates of 950 kW and 5.7 mbar is located inside the field of the ELCO burner model VG5.1200 DP R that we had previously selected and has a sufficient margin to ensure that the peak loads of the boiler are covered , which is especially important in the winter season when negative temperatures occur below normal in the climate zone where a particular object is located. This means that the VG5.1200 DP R model ideally satisfies the technical task.

The previous model of the ELCO burner device series VG5.950 DP R (up to 950 kW) and the subsequent VG6.1600 DP R (up to 1700 kW) will not be able to provide optimal operating conditions for the Ellprex 870 boiler / burner pair due to either insufficient power, as is the case with VG5.950 DP R, and more power than required for the boiler with VG6.1600 DP R selected for the technical task, which will make it problematic to regulate the rated power of the boiler in the range of (30) 40 - 100 (110)% of the nominal as in large , and the smaller side.

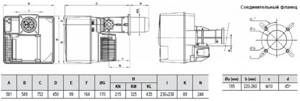

Selecting the length of the flame head of the burner device:

The next step to solve our technical problem of selecting a burner device is to select a flame head of the burner, the length of which will most optimally correspond to the technical characteristics of the Ellprex 870 boiler.

As we can see from the technical documentation of the ELCO manufacturing plant, for the VG5.1200 DP R model there are three options for the length of the flame heads, namely:

Short flame head of the KN burner with a length of 215 mm and a diameter of 170 mm;

The average flame head of the KM burner is 325 mm long and 170 mm in diameter;

Long flame head of the KL burner with a length of 435 mm and a diameter of 170 mm.

The manufacturer Unical for the Ellprex 870 boiler model has given a size indicating the minimum length of the flame head of the burner is 270 mm.

Taking into account the fact that we are selecting a burner device for a reversible boiler, the maximum length of the flame head of the burner device should not exceed +60 mm to the minimum value of 270 mm for our case due to the fact that the manufacturer Unical gives a working value of the minimum length of the flame head of the burner devices that will ensure normal operation of the boiler/burner pair.

ATTENTION! Various manufacturers of boiler equipment, especially domestic ones, provide different information on selecting the length of the flame head of the burner for both reversible and three-pass models

Please always pay attention to the dimensions provided by boiler manufacturers when choosing a burner flame head, taking into account what these dimensions are, how and from what they are calculated.

This point is very important, since if we choose a flame head of shorter length than is necessary for a specific model of a reversible boiler, we will receive an excess heat flow from the torch of the burner device, which will fall on the fireclay thermal insulation of the front door of the reversible boiler and directly fall on the tube sheet the second passage of the exhaust gases, which will lead to premature wear of both the door and the tube sheet of the boiler convection bundle.

If the length of the flame head is excessive and lies outside the section established by the boiler manufacturer, then the flame head of the burner will be located inside the heat flow of the torch, which will lead to excessive vibration of the boiler / burner pair and burnout of high-voltage ignition / ionization cables, which will lead to an emergency stop of the burner device .

That is, when choosing the length of the flame head of a burner device for our specific purpose, we must fall into the range from 270 mm to 330 mm.

The only option that satisfies our inequality 270 < ... < 330 mm is the average flame head of the ELCO VG5.1200 DP R KM burner = 325 mm.

In our case, we optimally fall into the designated segment 270 < 325 < 330 mm, which will allow us to install the selected burner model on the Ellprex 870 boiler without installing a spacer between the counter flange of the burner device and the front door of the boiler.

Checking the diameter of the flame head of the burner device:

The diameter of the KM burner head, which we selected above the ELCO VG5.1200 DP R gas burner, is 170 mm.

The diameter of the front door embrasure of the Unical boiler of the Ellprex 870 series is 270 mm.

Thus, we see that the flame head of the KM burner VG5.1200 DP R fully satisfies the condition 170 < 270 mm, which means it can be installed on the boiler without any modifications to the front door of the boiler.

ATTENTION! If the diameter of the flame head of the burner you have selected for any pressurized boiler is greater than the diameter of the embrasure provided by the boiler manufacturer, inform the boiler manufacturer about this.

Without agreement with the boiler manufacturer, any modification is prohibited and constitutes an unlawful intervention in changing the design of the boiler, which removes all warranty obligations from the manufacturer.

Checking the dimensions of the burner flame with the dimensions of the boiler combustion chamber:

Having determined the appropriate model of the ELCO VG5.1200 DP R gas burner, we must check the compatibility of the dimensions of the burner torch with the overall dimensions of the firebox of the Unical Ellprex 870 boiler.

When performing this selection section, we must take into account the operating features of reversible boilers and burner devices working with them, as well as the fact that the configuration of the reversible boiler can be with a solid bottom or the second-pass convective beam can be located along the entire diameter of the combustion chamber .

Unical Ellprex boilers are modern models of reversible boilers, their second-pass convection beam is located at the top of the boiler, the combustion chamber has a solid bottom.

For our configuration of the combustion chamber of the Ellprex 870 reversible boiler, it is necessary to take into account that the torch of the burner device must have an elongated, narrow pattern. This condition is met by ELCO burners of the R-Reverse series, that is, burners that are specially designed for use in the combustion chambers of reversible boilers.

We do not recommend using burners with a highly turbulent (FREE FLAME technology) short and, as a result, wide flame pattern, since a too short but wide flame will lead to overheating of the upper part of the boiler combustion chamber, shift the heat flow to the front door of the boiler and overheat the convective beam the second passage of exhaust gases, which will lead to premature failure of the boiler.

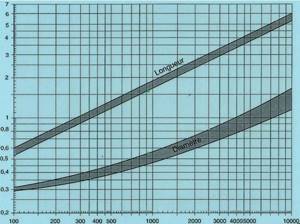

The overall dimensions of the burner device torch can be determined from the diagrams that each manufacturer of burner devices builds when testing new models and certifying them.

Each diagram is constructed at N.U. and 15% oxygen excess based on multiple open pipe measurements at zero back pressure.

According to the presented diagram, we must take the lower curve in length and the upper curve in diameter, since we have a reversible boiler.

For our case, the combustion power of the boiler is 950 kW, we line up the points on the diagram, obtaining a flame length of ~1,600 mm and its diameter of ~560 mm.

We must have the following inequalities:

Combustion chamber length > torch length;

Combustion chamber diameter > flame diameter.

Let's check the values we received:

1 690 > 1 600 mm;

684 > 560 mm.

Both inequalities were satisfied, and therefore we conclude: in terms of the overall dimensions of the torch, the gas burner device we selected, ELCO VG5.1200 DP R KM, is suitable for the Unical Ellprex 870 reversible boiler according to its technical characteristics.

Selection of a gas train for the VG5.1200 DP R KM burner for the Unical Ellprex 870 boiler:

The last step when selecting a gas burner device for a water heating, steam, condensing, etc. for a pressurized boiler is the choice of a gas train and an optional composition for the gas supply line.

DANGER! NEVER, under any circumstances, carry out any type of work with gas-using equipment without qualified personnel authorized for this type of work. We recommend concluding an agreement with a service organization that has the right to carry out this type of work.

In our technical problem, which we took as a fairly common example, a low value of natural gas pressure is conventionally indicated.

When selecting a gas train and components for it, a very common, but very important flaw; now we will understand why we take so seriously when selecting burner devices the exact value of the natural gas pressure in front of the burner gas train.

Low pressure of natural gas, this can be a value of 20 mbar or 50 mbar. Both values fall under the definition of “low” natural gas pressure, but there is a significant difference between them in the gas fittings to the burner device.

Let's look at two options in our example:

Option 1.

— natural gas, 9.3 kW*h/Nm3;

Natural gas pressure: low, take a value of 20 mbar.

When selecting a gas train for a burner structure, our task is to solve the inequality: Pin > Pf + Pb, where:

Pin — value of natural gas pressure at the inlet to the burner gas train, mbar;

Pf is the resistance of the boiler combustion chamber, mbar (provided in the technical documentation of the boiler manufacturer);

Pb - pressure loss in the gas train of the burner device, mbar (determined according to the nomogram of the burner manufacturer).

For our case:

Pin = 20.0 mbar;

Pf = 5.7 mbar (value for boiler model Ellprex 870);

Pb = 22.0* mbar for the gas train presented in nomogram s65 (according to the nomenclature of the manufacturer ELCO this is Siemens VGD40, DN65).

*For the burner model VG5.1200 DP R, the manufacturer ELCO provides 4 options for gas trains, which are selected depending on the aerodynamic resistance of the boiler combustion chamber and the supplied natural gas pressure.

When selecting ramps for low-pressure burner devices, always start with the largest diameter of the fittings, which always has the most universal working pressure range.

Pressure loss nomogram Pb, mbar for VG5.1200 DP R burner with Siemens gas trains:

Solving the inequality 20.0 > 5.7 + 22.0 we see that the condition is met, since 20.0 < 27.7 mbar.

Please take into account that even a slight discrepancy in natural gas pressure in solving the inequality (in our case 7.7 mbar) will not be able to ensure stable operation of the burner device and ELCO is no exception.

This statement is given based on the practical experience we have accumulated over many years of working with gas-using equipment and based on the fact that the pressure of natural gas is never static, there are always deviations.

Also, do not forget about drawdowns in gas networks that occur on the coldest days of the winter period, precisely at the moment when the peak heat output of the boiler-burner pair is required.

We cannot consider a larger diameter gas train with lower losses for our case, since DN65 is the largest diameter offered by the manufacturer ELCO for the VG5 DP series of burner devices.

Thus, for our specific case, we must provide a natural gas pressure in front of the gas train with a pressure of Pin=28 mbar. The inequality will look like: 28.0 > 22.0 + 5.7, that is, the condition is met.

Option 2.

— natural gas, 9.3 kW*h/Nm3;

Natural gas pressure: low, take a value of 50 mbar.

Let's solve a similar inequality: Pin > Pf + Pb, where:

Pin = 50.0 mbar;

Pf = 5.7 mbar (value for boiler model Ellprex 870);

Pb = 29.0 mbar for the gas train presented in the nomogram s2″ (according to the nomenclature of the manufacturer ELCO this is Siemens VGD20, Rp2″).

Pressure loss nomogram Pb, mbar for VG5.1200 DP R burner with Siemens gas trains:

Solving the inequality 50.0 > 5.7 + 29.0 we see that the condition is met, since 50.0 > 34.7 mbar.

The conclusion we get when considering the Siemens VGD20, Rp2″ gas train is that the ELCO VG5.1200 DP R s2″-Rp2″ KM series burner will work normally with the Unical Ellprex 870 series boiler at natural gas pressure in front of the gas train FROM 35 mbar.

It is worth noting that both options we considered with the obtained values for the Siemens VGD s65, DN65 FROM 28 mbar ramps and s2″, Rp2 FROM 35 mbar fall under the definition of a “low” value of natural gas pressure.

If you have the opportunity at your facility to increase the pressure in relation to our case under consideration to 35 mbar, it is better to do this, because:

- firstly: we have a larger range of operating pressure of natural gas in the event of pressure drops, and therefore more stable operation of burners with selected boilers, especially in the cold season, when peak loads on boilers may be required;

- secondly: gas fittings of a smaller diameter have a lower cost, as do the gas supply pipeline itself and its components in general.

Comparing the cost of selected gas trains and their components in current prices for 2021 according to the ELCO global price list, we obtain the following prices in €:

| № | Product | Qty | Price | Product | Qty | Price | ||||||

| 1 | 3833482 Gas train VG5.950/5.1200 DP/DP R, s2"-Rp2", with external gas filter Rp2" | 1 | 3 900,00 | 3833483 Gas train VG5.1200 DP/DP R, s65-DN65, with external gas filter DN65 | 1 | 5 630,00 | ||||||

| 2 | 3122326 Anti-vibration insert Rp 2″ | 1 | 135,00 | 3142060 Anti-vibration insert DN65 | 1 | 285,00 | ||||||

| 3 | 3142102 Ball valve Rp 2″ | 1 | 145,00 | 3142062 Gas rotary valve DN 65 | 1 | 510,00 | ||||||

| 4 180,00 | 6 425,00 | |||||||||||

Thus, we see that the difference in the pressure supplied to the gas train between 28 and 35 mbar will increase the price of the burner gas fittings by ~1.54 times!, but both values fall under the formulation of the “low” value of natural gas.

In this connection, when forming a technically intensive task for selecting a burner device for a boiler, it is important to determine the value of the natural gas pressure in front of the burner gas train, since if we take an expensive and more universal version of gas fittings with a large diameter, then we significantly overpay for the versatility of the solution.

If we take a gas train, a less expensive gas train with a smaller diameter, as a result with narrower working fields for natural gas pressure, we will not be able to obtain gas flow and normal operation of the burner with the boiler.

We looked at an example of selecting a gas burner device for a reversible boiler under normal conditions using a specific example based on the initially set technical task: “We ask you to select a burner device for boilers with a power of 850-900 kW. Fuel type: natural gas, low pressure.”

Taking into account the above algorithm, we obtain a solution to our technical problem:

— Water-burning reversible steel boiler Unical series Ellprex 870;

— Gas burner device ELCO series VG5.1200 DP R s2″-Rp2″ KM (natural gas pressure FROM 35 mbar);

— Or gas burner ELCO series VG5.1200 DP R s65-DN65 KM (natural gas pressure FROM 28 mbar).

This article provides the basic steps for selecting gas burner devices for hot water reversible boilers under normal conditions.

It is impossible to describe in one article and clearly explain the entire complex of dependencies on the type and type of equipment, possible technical and technological solutions to a particular problem.

In subsequent articles we will consider the influence of altitude above sea level on the choice of burner device, we will solve problems for the selection of burner devices for diesel fuel or the selection of combined burner devices. Let's consider the influence of types of boiler equipment on the selection of burner devices, etc.

We hope that this article will be useful to you in practical application when forming your complex proposals within the framework of the various types of boiler houses you produce, where the main equipment is boilers and burner devices for them.

In any case, our company’s personnel are always at your disposal to solve almost any technical problem.

We will be happy to answer your questions and provide any necessary comments!

Timberk TGN 4200 SM 1

A ceramic heater is a universal and mobile device that is quite budget-friendly. Its mobility is due to the compactness of the body, as well as the presence of a wheelbase for quick movement. The capabilities of the equipment help to successfully use it for heating rooms of various types and purposes.

The heater does its work from a propane cylinder (up to 12 liters inside), which easily fits inside the metal body of the heater. The device is connected via a reducer, clamps or a gas hose. The room is heated using infrared radiation, which occurs when a gas burner heats ceramic plates. The material leads to complete combustion of fuel, and the air does not contain combustion products.

To ensure high protection of use, the device includes a gas control and a sensor for monitoring the concentration of carbon dioxide in the room. Piezo ignition and power regulator are used as an additional control element.