It's no secret that heating a room with gas is very expensive, tariffs are rising, and the quality of services provided leaves much to be desired, so many people are switching to alternative heat sources, namely buying a stove to heat a house or any other room. Let's reveal the advantages and features of convector ovens.

There are several types of such stoves: metal, cast iron, brick.

- The first type consists of steel , which is able to withstand high temperatures. Such a stove heats the room very quickly, but the metal layers are extremely thin and the heat quickly disappears. For better effect, use stainless material. Another weakness of this design is that its seams can burst when heated, it all depends on the quality.

- The second option consists of cast iron . They are an excellent additional source of room heating. Such devices are very compact and can be easily installed in any part of the house. A chimney is installed on it, which goes outside the room, removing combustion products. Warms very quickly and effectively.

- The third is brick stoves , they are the most popular and reliable. Their chimney has a serpentine shape, which allows rational preservation of the combustion product, which is a source of heat. Such a stove heats up slowly, but the brick itself retains heat for a very long time. They are very multifunctional and can be used as a fireplace or cooking area. Accordingly, its price is higher.

What are convection ovens made of?

Typically it consists of the following elements:

- The firebox is the place where the heating material (wood) burns.

- An ash pan is a place where the combustion product (ash) accumulates.

- The grate is a metal grate on which coals are placed.

- Kamenka is a place for sauna stoves where stones are placed.

- Chimney - serves as a device for removing combustion products.

- Features and disadvantages.

Principle of operation

Convection ovens can use almost any type of fuel to heat your home. This can be agricultural waste, firewood, fuel oil, pellets, briquettes, etc.

In fact, the type of fuel does not matter, because the principle of operation always remains the same and heating occurs due to the rapid supply of hot air through special holes in which pipes are welded into the body.

The supply of cold air is ensured by the fact that there are structures in the lower part through which cold air is drawn in. When the oven is heated to high temperatures, air circulation occurs very quickly.

The role of convection in heating a room

Heat in the house appears due to heated air. Even infrared emitters heat objects in the room, which, in turn, release energy to the surrounding air. But its thermal conductivity is too low, so heat transfer can only be accomplished through convection, that is, the movement of the air masses themselves.

The heated air rises upward under the influence of buoyant force. Cold air from neighboring areas enters the freed space. The air cools at the top and gradually falls down. This is how natural convection occurs, thanks to which uniform heating of the room space is possible.

Air movement in the room

In the process of transferring heat from the working fluid (let's call the heated elements of the furnace) to the coolant, whose role is played by air, convection will play a key role, ensuring effective heat exchange and increasing the overall share of useful energy. It’s worth mentioning right away that this is not the only way to transfer heat from the stove to the room. Do not forget about radiation and the penetration into the room of some combustion products that have a high temperature.

Good to know: How to build a muffle furnace for your home yourself

If there were no convection, then heat from the furnace would be transferred by conduction. The nearby layers of air would have a high temperature, but further the heating process would stop due to low thermal conductivity. Convection ensures the entry of a new batch of cold coolant and its removal after heating. This principle is used as the basis for the operation of convection ovens.

Device

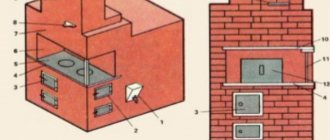

The heating design consists of several important elements:

- gate;

- mounting location for the chimney;

- surface for heating food (optional);

- convection pipes;

- secondary air supply jets;

- fuel supply door;

- gas guide flaps;

- holes for hot air outlet;

- grate;

- hole for cold air entry.

What properties should a convector wood stove have when heating a dacha?

Of course, convector systems are multifunctional and suitable for almost any purpose related to heating a home.

But, for example, a living space and a country house are two completely different environments that require an individual approach when choosing a stove. Sudden temperature changes should be taken into account, so the stove needs to be heated stronger or weaker - it all depends on the situation and meet certain standards:

- It should distribute heat evenly throughout the day.

- The outside temperature should be 90-95 degrees.

- With low fuel consumption, the room temperature should remain stable.

- The entire oven should heat evenly.

- It should not have cracks, as this can lead to the release of harmful gases directly into the house.

- The size of the firebox should be taken into account; the larger it is, the longer the combustion process will take place and the heat will be retained for a longer time.

- The mechanism itself must function stably for 20 years.

- The appearance of the stove is also very important for the overall atmosphere.

The most economical options

The quality of home heating determines not only the reliability of the structure, but also what materials are used and in what quantities. The most common option is considered to be stoves with a gas-generating effect .

They contain a large amount of firewood, the top layer slowly smolders, and the bottom one waits its turn. This result can be obtained as a result of pipe draft with blower valves. Their efficiency in heating a house is 75-85%. Wood-burning gas stoves are well suited for summer cottages. Gas-generating furnaces with a large column are considered to be another option for economical heating. Firewood, peat, coal or other combustion materials are placed in it at full height. Fill everything with fuel on top and cover it. Combustion air is supplied from above through a pipe.

The process of burning material occurs at the top, gradually moving lower. The combustion rate in the stove can be adjusted using a damper . It operates with wood for up to 2 days (without refueling), and with coal it can heat a house for up to 5 days.

There are stoves with automatic loading of wood. Such designs supply fuel on special disks 10–15 cm thick . The mechanism itself is a very complex system.

Wood-burning stoves with a water circuit are another type; their smoke channel is lined with heat transfer material. Thermal gases pass through special valves, giving off heat to the water. To install it, you need to build a foundation with a heat-insulating pad.

Species and types

The operating principle of such furnaces is the same, but there are several types of this design, which differ from each other in a number of characteristics.

Firebox type

- Wood-burning (solid fuel). If this is a brick version, then it is a fairly large structure that is laid out in houses on a separate foundation. Their design initially includes convection channels next to the firebox. Essentially, an empty space and a hole at the bottom are left around the firebox, through which cold air will be drawn in. If these are metal structures, then they will not have much weight and require the installation of a foundation. They are already completely ready, so the buyer only has to choose the appropriate option based on the thickness of the metal layer, as well as the dimensions of the structure.

- Gas. There are also two options available here. This can be a stationary convection oven for cooking and heating the room. It is installed in a selected location in the room in such a way as to heat the house. There is also an alternative option in the form of a special fireplace that can be installed in any room. This design runs on bottled gas, but it is also possible to connect a main gas pipeline to this structure.

- Electric convection oven. One of the most common stove options. They are also called electric convectors, which can heat a room very quickly and efficiently. The advantage of this type of design is the possibility of its transportation due to its compact dimensions and the presence of mains power.

Material

A convection oven can be made from materials such as:

- Cast iron. This is a common material from which both the external and internal parts of the structure can be made. Thanks to this material, its high performance and attractive appearance are ensured.

- Hardened metal. This is also a popular solution for pre-fabricated stove structures. It is important that the thickness of the metal sheet in places that are subject to the greatest thermal load is not less than 4 mm. In this case, the product will serve the buyer for many years.

- Brick. This is the heaviest option, which requires independent masonry and does not have ready-made solutions. That is why it is worth paying attention to the issues of laying the foundation. It is also important to correctly calculate the dimensions so that its power is sufficient to meet the needs of several selected rooms.

Convection ovens for the home - pros and cons

The main advantages of convection ovens are as follows:

- Rapid heating of the room, thanks to the ability to actively mix warm and cold air masses in the room.

- Possibility to choose a model with a long combustion mode.

- Compact and undemanding to install.

- Light weight due to the use of steel in production.

- Relative reliability and predictability of the result (when compared with brick kilns).

However, there are also disadvantages to this class of heating devices:

- The presence of hot surfaces that can cause burns.

- Short heat release time after heating.

- High requirements for chimney installation to maintain draft and avoid condensation.

As always, there are applications where wood- or coal-fired convection ovens can be very useful, and others where they are not profitable.

Such heat generators can best be used for heating small rooms or private houses, especially country houses. In a situation where the fastest possible heating of a cold room is required, which, for example, is visited only on weekends.

It is not at all profitable to use convection ovens where heating of several separate rooms is required, especially those located on different levels/floors. In this case, it seems much more appropriate to use a heating boiler with a radiator system, or to use gas or electric convectors.

More on this topic on our website:

- Individual gas heating in an apartment - we install an autonomous gas boiler for heating the apartment. If you look into the Internet archives and start reading ancient forum topics about installing gas heating in apartments, there will be no reviews for one simple reason...

- A homemade boiler for water heating is an excellent “substitute” for expensive equipment. Its working scheme, as well as its appearance, depend on factors such as: available...

- The direct work associated with installing a boiler or other heating system is quite complex, as it has its own specific features that are important for the activity. Over such installation processes...

- There are many heating devices that have high power and can be used to integrate into a heating system. To organize the heating system of a private home, as a rule,…

Advantages and disadvantages

Advantages:

- no need to use electricity (except electrical);

- high level of efficiency, more than 80%;

- it is possible to control the level of combustion;

- There are options on sale for heating up to 100 or even more cubic meters;

- can be used for a home, cottage, hangar or change house;

- long operating time from one bookmark;

- high level of efficiency on any fuel;

- possibility to purchase an option with a cooking panel.

Flaws:

- some stoves can emit hazardous combustion products and are suitable for installation only in non-residential premises;

- if you want to install it in a residential building, it will be difficult to coordinate such an installation with firefighters;

- ash flies out through the pipe and pollutes the surrounding area.

Summarizing

In conclusion, we suggest taking a look at the table, which shows the comparative characteristics of the two materials according to some parameters. The assessment was carried out using a five-point system.

After choosing one of the two options, renting a diesel generator for your dacha will no longer be necessary, which will save the family budget. For a more detailed discussion of the topic, visual instructions were created. You can get acquainted with it by watching the video in this article.

A convection oven for home use for preparing baked goods, casseroles, cookies, and various dishes. Food is cooked at low temperatures due to constant air circulation inside the chamber.

How to choose?

To choose a quality device, you need to decide on your needs and pay attention to the option that best suits them.

For a summer residence, it is recommended to choose solutions that have a surface for heating food. For home use in small spaces, electric options are the best. They will be a mini oven with convection.

When purchasing, you should pay attention to such indicators as:

- power;

- dimensions;

- material of manufacture;

- presence of a hob;

- installation safety;

- fuel used.

Models for home

- Flames KP-2. This stove has small dimensions, its weight is only 44 kg and there is a 40 liter combustion chamber. It is suitable for use in cabins, because it helps to uniformly heat the room.

- Flames KP-4. This oven is slightly larger in size. It has a power of 4 kW, so it can be used for medium-sized rooms. It has a simple design and attractive appearance.

- Furnaces of Professor Butakov. This option is suitable for heating your own home. It can be installed in the basement. The design works with solid fuel and consumes very little of it.

- Teplodar Matrix 100. This design has the advantage of being compact. At the same time, it can quickly heat about 100 cubic meters of area. It has a glass heat-resistant door and a two-channel afterburning system.

- Heater 100. There are also smaller models, so you should choose the appropriate option based on your needs. This stove can heat up to 100 cubic meters. The body is made of hardened steel. Best suited for household use.

Brick heating structures

The main advantage that stone stoves for summer cottages can boast of is their ability to retain heat for a long time. This is true when you have to stay in the building overnight on frosty days. However, it takes a long time to melt the structures, which is not very convenient for short-term use.

Relevance of application

Dimensions, efficiency, manufacturing complexity and other parameters were taken into account.

- In first place is a Dutch oven for a summer house, as it has compact dimensions, which means it can be actively used in many rooms. Due to the presence of vertical channels, it has high thermal output.

- The second position is occupied by the Swedish brick heating structure. It can fit in almost any building, of course, if these are not country houses made from block containers.

- Third place goes to the Russian stove due to its impressive size and complexity of manufacture. This option is more suitable for residential buildings than for country houses.

Attention! After selection and installation, a universal stove for a summer residence must be finished without fail. In the cladding process, completely different materials can be used: tiles, plaster, tiles or whitewash.

Classification of structures

Depending on the purpose, heating, cooking and combined structures are distinguished. In the first case, only heating of the premises is carried out, in the second - only cooking. In addition, the structures can be combined directly with each other.

Ovens can be classified by the thickness of their walls, which can be thin or thick. The heating and cooling time depends on their size. For a country house, it is recommended to choose thin-walled structures, since they do not require a massive foundation.

As for the configuration, the designs can be rectangular, square, corner, round and even T-shaped. The choice of shape is usually made taking into account the interior design.

Design possibilities

Using various types of finishing, the aesthetic characteristics of a brick structure can be formed. Unlike metal analogues, there are a great many options for improving external data.

If necessary, the cladding can be easily replaced, radically changing the perception of the heating structure.

- Facing bricks can add a touch of modernity to the appearance, which is why they are very often used for finishing. Ideal for styles that feature predominantly straight lines.

- Ceramic tiles, with their variety of colors and installation variations, can completely transform a design. Imitation of other materials, such as wood, looks interesting.

- Decorative plaster provides the opportunity to create coatings with an aesthetically attractive texture. The result is exquisite products.

- Handmade tiles allow you to create exclusive designs, which, after finishing work, act as the main source of attention.

Addition! Other materials that can withstand elevated temperatures can be used as the main finishing. There are no special restrictions when carrying out cladding.

Conclusion

A high-quality home convection oven can be used both to heat a room and to cook food on a special panel. At the same time, a household convection oven has significant differences from one intended for industrial use. Household heating can heat up to 100 cubic meters. In rare cases, options up to 600 cubic meters are purchased, but this is only relevant for large private houses.

There is also a separate type of combi oven in which food is prepared. This is a common technique for restaurants, but the principle of steam generation in it is the same as in standard ovens of this design. Before making a choice, you need to take into account your needs and the dimensions of the device, as well as determine the location for its installation.

Main advantages

The use of technologies that make it possible to increase the efficiency of a heater without increasing the amount of fuel burned has opened up new opportunities for manufacturers of heating devices. A convection oven for home or industrial premises has some key advantages that allow it to attract the attention of consumers.

- Independence from electricity (with the exception of electric convectors) is in demand among residents of suburban areas that experience long-term power outages. Indeed, in the most difficult conditions, a metal stove can be heated with almost any type of fuel. The only recommendation is not to use plastic products or any paraffin-containing materials, as this can lead to premature cleaning of the chimney.

- Uniform heating not only affects the degree of comfort, but also reduces the time it takes to warm up the room. Today there is no more effective phenomenon than convection. Therefore, this type of heat transfer is used twice: when transferring energy to cold air and when distributing heated air throughout the room.

- Convection ovens are one of the few types of devices that allow you to effectively control and regulate the intensity of combustion.

- The possibility of using long-burning technology increases the interval between adding fuel portions to ten hours.

Good to know: How to build a Russian housekeeper stove, Podgorodnikov model

The list of positive qualities is not exhaustive, since the task was to identify precisely the distinctive features of the design.