Fuel briquettes Ruf

Ruf is a manufacturer of fuel briquettes consisting of sawdust and waste of good hard and soft wood. However, the composition does not contain bark or other illiquid materials from the wood industry.

Ruf fuel briquettes do not contain glue-based chemicals. And this is their main advantage. This is due to the technology of producing briquettes using a special set of technical devices.

As for production technology, Ruf briquettes are produced in two stages:

- Drying, which is necessary to reduce the percentage of moisture in wood chips and sawdust.

- A hydraulic press that performs the actual formation of forest material into briquettes.

The output is briquettes that resemble bricks in appearance.

Fuel briquettes Ruf

Technical characteristics of Ruf fuel briquettes.

| Parameter | Meaning |

| Calorific value | From 4200 to 4500 kcal/kg |

| Maximum ash level | 1 % |

| Humidity level | 7-13 % |

| Average density of briquettes | 750-800 kg/m³ |

It is unlikely that these indicators will be informative for the average person. As an example, we give the parameters of other types of fuel according to some of the characteristics.

| Type of fuel | Calorific value, kcal/kg | Ash content, % |

| Brown coal | 3910 | 40 |

| Coal | 4800 | 20 |

| Briquette Ruf | 4350 | 1 |

This information is enough to understand that Ruf fuel briquettes are quite effective. This is confirmed by reviews from owners of country houses.

Detailed information about the types of fuel briquettes can be found in this article.

Reviews

On the Internet you can find many reviews about fuel briquettes from this manufacturer. And mostly good. Users note the following positive qualities of Ruf fuel:

- No characteristic crackling or flying sparks.

- High thermal output with prolonged combustion.

- Good resistance to moisture.

- Practicality in use.

- You can increase the heat output of the boiler if you place briquettes and logs evenly in the combustion chamber. In addition, fuel consumption will decrease by an average of three times.

- Ruf fuel briquettes made from birch dust do not leave soot and tar scale on the walls of the firebox, which in turn makes boiler maintenance much easier.

- The manufacturer's briquettes do not require much storage space. In addition, the warehouse will always be clean.

You can read about peat briquettes in this article.

Disadvantages of traditional solid fuel

Pini Kay fuel briquettes were developed in Germany, but today they are supplied by many manufacturers. They are nothing more than compressed wood waste. This fuel comes in the form of neat bars with an internal hole. In this form, it is sent to the furnaces of solid fuel boilers and wood stoves.

Traditional firewood has a number of disadvantages. First, let's note their imperfect shape - this creates problems in storing fuel. Individual bars differ in size from other bars, some of them contain knots, which prevents them from being stacked neatly. Thus, when using firewood in a boiler or stove, you need to take care of purchasing neat logs - they usually cost more.

We also note the low calorific value of wood - this indicator depends on both the type of wood and the level of humidity. And the higher the humidity level, the worse the firewood burns and the less heat generated. The approximate calorific value at a humidity of about 10-15% is 3800-4000 kcal. In the case of Pin-Kay briquettes, this figure is much higher.

Fuel briquettes Pini Kay

Fuel briquettes from this manufacturer are popular due to their unique characteristics, and have many positive user reviews.

It is worth saying that Pini Kay fuel briquettes should be stored isolated from other materials and substances. If the following conditions are met, products can be stored for a very long time:

- it is required to store briquettes in a covered warehouse at a temperature from plus 5 to plus 40 °C;

- relative humidity should vary between 30-80%;

- briquettes should not come into contact with water and aggressive media;

- To extend their shelf life, it is better to remove products from the sun.

Fuel briquettes Pini Kay

Technical characteristics of fuel briquettes Pini Kay.

| Parameter | Meaning |

| Density | 1200 kg/m³ |

| Bulk density | 1000 kg/m³ |

| Ash content | 3 % |

Reviews

Reviews about fuel briquettes from this manufacturer are mostly positive and are as follows:

- Pini Kay fuel briquettes do not pollute the surface that comes into contact with them during transportation and storage.

- Universal shape and small size, allowing briquettes to be tightly stacked on pallets.

- Low ash content of 3%.

- High density, exceeding the parameters of wood by 2.5 times.

- High bulk density. This option is of interest to many buyers. They compare the figure to 300 kg/m³.

Conditions and course of the experiment

The object of inspection is a one-story private house with an area of 150 m² with an individual heating system from a solid fuel boiler. The walls are 300 mm thick and made of white sand-lime brick, with an air gap inside. There is no insulation of external fences; the windows are standard metal-plastic.

The remaining experimental conditions look like this:

- The heating system is closed, two-pipe. It is divided into 2 branches - radiators and heated floors. The initial water temperature is 43 °C.

- The average daily ambient temperature is 4–5 °C. The building is cold, warming up for the first time during the heating season.

- The heat source is a long-burning solid fuel steel boiler DIZ-24 (24 kW), equipped with a turbocharger and an automatic unit for maintaining the set temperature.

- The scheme uses a small capacity buffer tank (150 liters).

Note. Before the experiment, the boiler and coolant were heated to 43 °C by burning small logs.

Task: alternately load 3 types of fuel into the firebox and check the burning duration of each fill at a constant heating mode. The loading size is the same - 10 kg, the automation is set to maintain the water temperature at 50 °C.

Goal: to determine what will burn faster - firewood or briquettes, how significant the difference will be. The secondary goal is to compare the combustion process of three types of fuel:

- dry firewood from barn storage;

- round briquettes from sunflower husks;

- briquetted peat.

For reference. The type of wood used is small elm (otherwise known as birch bark), the stacking density of freshly cut logs with a moisture content of 50% is 600 kg/m³.

We deliberately did not burn “wood” briquettes made from sawdust. The reasons are obvious: the products are noticeably more expensive than peat and agricultural briquettes, and their combustion properties have been repeatedly tested. If you are interested in this type of solid fuel, we recommend watching the video:

The approximate density of pressed husks is 1800 kg/m³, peat briquettes are 2200 kg/m³. These data are for reference and do not play a big role in the experiment, since the fuel was supplied in the same amount - 10 kg. Let's start with burning wood.

The result of burning wood

During the inspection, the logs were cut into 4 logs and loaded into the firebox, where several hot coals remained. The controller started the fan and the firewood ignited within 1 minute. A total of 10 kg of wood was enough for 1.5 hours of boiler operation, after which the coolant temperature began to decrease.

The weight of each portion of fuel is 10 kg (with a bucket - 10.5 kg)

Points worth noting:

- dry firewood produces little smoke and burns very evenly;

- the temperature jump after turning off the fan does not exceed 3 degrees (up to 53 °C);

- small ash residue.

The process of burning dry wood is quite predictable. If you fill the entire chamber of a heat generator of this model (112 liters) with such fuel, 1 fill will be enough for at least 8 hours. Wet (freshly cut) firewood decays faster: it gives off less heat and is therefore more exposed to fan blowing.

A typical picture when burning dry wood is a slight smoke

Briquettes from sunflower husks

Since the pressed husk contains a proportion of vegetable oil, combustion differs in some ways:

- Immediately after placing 10 kg of cylindrical “sausages”, a sharp jump in temperature in the firebox is observed.

- While the oil vapors are burning, the pipe is actively smoking. At this stage, it is not recommended to open the loading door - a powerful flame from a sudden supply of oxygen can burn your face.

- After the boost is automatically turned off, the coolant temperature rises another 6-7 degrees (up to 57 °C), then decreases to normal.

- Until the bulk of the sunflower briquettes burn out, the fan is turned on only for blowing, which is enough to maintain the water temperature.

- When the oil vapors finally burn out, the amount of smoke from the chimney is noticeably reduced.

- The ash residue is insignificant.

At the initial stage (on the left) there is a lot of smoke, then it is practically invisible (on the right)

For reference. The purge mode lasts 10 seconds and turns on at intervals of 5 minutes. The goal is to free the boiler chamber from smoke.

The burning time of a portion of agricultural briquettes was 2 hours 10 minutes, which is 40 minutes longer than firewood. A caveat: you need to learn how to use fuel correctly - at the initial stage, the “sausages” emit a large amount of heat. By the way, in boilers with a mechanical draft regulator (without turbocharging), the effect of primary heating is less pronounced.

This is what the remains of a briquette look like at the after-burning stage, the boiler water temperature is 50 degrees

Combustion of pressed peat

In appearance, peat briquettes resemble coal briquettes, but differ in their square shape. The products also get dirty on your hands, so it is better to load them with gloves. Typical combustion moments look like this:

- under the influence of supercharging, peat ignites well and produces a stable, powerful flame;

- when the set coolant temperature reaches 50 °C, the fan stops, heating “jumps” to 53-54 °C;

- peat briquettes smoke more strongly than dry firewood;

- the amount of remaining ash is approximately 5-10%.

We couldn’t capture the smoke from the peat bricks in the photo because it was dark outside

Note. Peat contains a certain amount of loam, which turns into ash. The size of this share depends on the fuel manufacturer.

The operating time of a solid fuel boiler using peat briquettes is phenomenal - at least 3 hours, which is twice as long as burning the same amount of firewood. An unpleasant nuance is ash content and black dust that sticks to your hands.

Fuel briquettes Nestro

The production of Nestro fuel briquettes is carried out on hydraulic presses with the creation of back pressure by a collet. These products can be in diameter from 50 to 90 mm, and in length - from 50 to 100 mm. Packed in bags.

Since the Nestro fuel briquette is a compressed fuel, it requires little storage space. In addition, the high density prevents the penetration of moisture inside and subsequent rotting, so they can be stored for a long time.

To ignite Eurowood, very little splinter or liquid is required. A couple of briquettes are usually enough for a fireplace. After ignition, they burn with an even flame and emit a woody smell, and after combustion, beautiful coals remain that retain a high temperature for a long time.

Fuel briquettes Nestro

Reviews

Briquettes from this manufacturer have a wide range of applications. They are used in the operation of industrial equipment and in railway transport. Buyers like the presence of a technological hole inside the briquettes, as they allow the fuel to burn more intensely. In this case, additional ventilation is not needed. This makes it possible to use the products in equipment characterized by low traction.

As for the advantages and disadvantages, we can point out similar features characteristic of the Ruf Eurofirewood. The price of this fuel is low, since the production process itself is not expensive. Consumers indicate that Nestro products are inferior in technical characteristics to the Pini Kay brand.

Why compare cheap firewood with expensive briquettes?

For residents of regions rich in forests, where wood processing enterprises are located, such a comparison is irrelevant. Firewood and sawdust in those parts are inexpensive or available for free. But we decided to compare them with briquettes for the following reasons:

- There are practically no forests in the southern and desert regions. Hence the higher price of firewood purchased by owners of country houses and dachas.

- In these areas, it is advantageous to press any type of combustible mass - coal dust, agricultural waste and peat. Thanks to the development of such production, the cost of briquettes is reduced and they become an alternative to firewood.

- It is more comfortable to heat with pressed products than with wood raw materials, as our experiment will show.

The last reason is conflicting reviews from homeowners about various fuels on thematic forums. A user who does not understand this issue is unlikely to be able to figure out which types of briquettes are best to use for a stove, fireplace or boiler. We will present conclusions and expert opinion on this matter.

Fuel briquettes Nielsen

Nielsen fuel briquettes are produced in Denmark. The pressing technology is different from Ruf technology. On Nielsen machines, pressing is carried out using an impact press. Since the pressure exerted on the material is high, the calorific characteristics of these products are higher.

Calorie content mainly depends on the density of the briquette, and not on its composition.

A briquette emerges from the pressing machine as a continuous cylinder, after which it is cut into bars by an automatic machine. The packaging is made with shrink film, which provides additional protection from the external environment.

Fuel briquettes Nielsen

Due to the different shapes, these machines can produce several types of fuel:

- Round cylinders without a hole in the middle.

- Round cylinders with a hole in the middle (suitable for fireplaces, baths, saunas), in addition to the natural increased heat transfer, due to the additional draft due to the hole, create a uniform and beautiful fire, which also increases heat production in a special way.

Nielsen Euro firewood with a hole has the disadvantage that it has a shorter burning time than fuel without a hole.

Two types of products are fired around the perimeter, this does not allow moisture to be absorbed.

Reviews

These Euro-firewoods have relatively high density and heat transfer rates, and at the same time low humidity and ash content. There are practically no negative reviews from consumers.

Nielsen birch fuel briquettes are a good fuel option that incorporates the best qualities from the entire line of Ruf, Nestro and Pini Kay.

For buyers who use briquettes for home heating in stoves or solid fuel boilers, the most acceptable option in terms of price and quality will be briquettes in the shape of a Ruf brick and in the shape of a Nielsen cylinder. Products from the Pini Kay brand are suitable for lighting a fireplace.

Fuel briquettes are a convenient material for kindling. This is confirmed by their price. It is well known that transportation costs for fuel delivery are included in the cost of the material. Here's an example: a truck with a body volume of 80 m³ can transport about 8 tons of firewood at a time when packed tightly, while fuel briquettes can transport about 22 tons. Draw your own conclusions!

Food for thought and recommendations

We do not persuade anyone to give up wood heating in favor of briquettes. The purpose of the publication is to convey useful information, help homeowners save money and gain comfort. What conclusions emerge from the comparison:

- The attractiveness of firewood is its low price. The main thing is that they are not too raw.

- The previous section indicates the cost of firewood delivered in the form of logs. The latter need to be sawn into logs and split into logs. If the household does not have a chain saw, you will have to pay extra for sawing.

- Due to their low density, logs take up more space than briquettes.

- Pressed waste burns much longer than wood and gives off more heat. The number of visits to the boiler room will decrease.

It is better to heat homemade stoves with wood or put a small amount of briquettes

An important nuance. High-calorie fuel briquettes pose a danger to homemade stoves. When the firebox is fully loaded and the chimney is open, the steel body of the stove is often deformed from the effects of high combustion temperatures.

Pressed products are not flawless. Fuel from agro-industrial waste contains vegetable oil, which settles on the walls of the chimney in the form of soot, and peat leaves ash. To find the optimal solution and clearly select briquettes for a stove, boiler or fireplace, take part of the weekend and conduct a similar experiment with a variety of fuels. Combine “bricks” with firewood, watch the results and count the money - this is the sure way to economical heating.

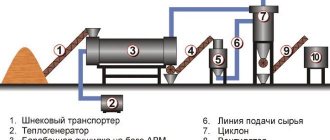

Equipment for the production of briquettes from sunflower seeds husks

The technology for manufacturing fuel briquettes from biomass (which includes sunflower husks, rice, buckwheat, etc.) is as follows:

- The raw materials are washed and dried.

- Grind.

- They are compressed.

- Cool.

- Packing.

Equipment is selected accordingly. You will need a dryer and a crusher (hammer or shredder), but most importantly - a press (piston, extrusion or screw). Facilities for transporting raw materials and finished products to the shop floor, cooling facilities and packaging equipment may also be required.

The main equipment for the production of any briquettes is a press

Advantages of firewood compared to briquettes

- A major advantage of briquettes compared to firewood is their ability to generate stable heat over a longer period of time. Although the heat intensity is less than when using firewood. Therefore, if you want to quickly warm up the room with European wood firewood, as with ordinary wood, then you will not succeed.

- People who are used to spending the evening with a book or a cup of strong tea by the fireplace will most likely be disappointed. This fuel will not be able to please them with the crackling characteristic of ordinary firewood, which creates that unique feeling of home warmth and comfort. With the help of classic firewood, it is very easy to obtain the necessary “sound accompaniment”, since they contain water, but briquettes do not have it.

- When using Euro firewood, you will have to put up with the unpleasant smell of ash. Ordinary firewood will not give you such an unpleasant surprise, since wood ash does not emit a tart odor.

- Fuel briquettes, which are offered in stores today, are a rather fragile product that easily turn into crumbs. If you do not want to lose precious fuel before your eyes, then you should choose strong, high-quality briquettes.

Now it has become a little clearer about the advantages that firewood and fuel briquettes have. It remains to get an answer to one more question that worries many owners - which fuel is the most economical?