How to make briquettes with your own hands

Now that the advantages of Euro-firewood become obvious, the question naturally arises whether, if there is a sufficient amount of raw materials, it is possible to make fuel briquettes for the stove yourself.

In principle, there is nothing complicated about this. If you imagine the production technology in the form of separate operations, then you can organize the production of briquettes in a small utility room. Conventionally, if there is a sufficient amount of raw materials, for example, sawdust and shavings from a nearby woodworking shop or sawmill, this can be done with a small amount of tools and accessories.

First of all, you need a container for soaking the wood pulp. A regular bath will do for this. Its capacity is enough to soak 200-250 kg of sawdust.

As a mixer, you can use a hand drill with an attachment for preparing the solution. Although an electric construction mixer or even a concrete mixer is best suited for this.

The most expensive equipment for the job will be a press. The density of the product, and therefore its heat capacity and burning rate, will depend on this machine. As a press, you can use a mold for making paving slabs or cinder blocks, only here you will have to carry out additional modernization to reduce the shape of the resulting block. Another option for obtaining the desired form of fuel may be to use an industrial meat grinder. True, you still need to tinker with it - make a mold for forming a briquette and adjust the speed of the auger so that it actually compresses and does not grind the wood pulp.

As a binder, you can use natural or synthetic glue, for example, CMC wallpaper glue - when diluted with water, an excellent binder is obtained for forming a briquette.

Once you have this set of tools, you can start making briquettes - first soaking the sawdust and adding binding glue. After this, the briquette is formed under pressure and finally dried. Thus, the result is a completely competitive environmentally friendly fuel.

The question is the price!

The cost of fuel briquettes can vary depending on their quality. They can be divided into two groups:

- Briquettes of the highest quality. They are characterized by high density: 1400 kg per cubic meter. They burn longer, give off more heat and leave a minimum of ash. They have a dense structure without cracks.

- Briquettes of normal quality. Their density is about 1000 kg per cubic meter, have a layered structure and are more susceptible to damage. In addition, they have less heat transfer, burn out faster and leave behind more sediment.

The difference in quality and price comes from the manufacturer’s costs for equipment: the more the briquette is pressed, the better quality it will be and the faster the machine on which it is made wears out. This factor of rapid wear and tear is included in the cost of the product.

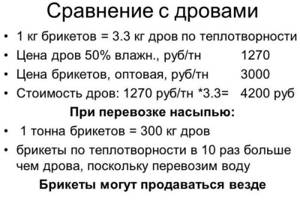

Comparison of the cost of briquettes with firewood

Obviously, high quality briquettes will cost more than regular briquettes. But at the same time, even briquettes of the highest quality will cost less than ordinary birch firewood, and even more so of ordinary quality.

If they seem too expensive, even taking into account the savings compared to firewood, you can make them yourself. To do this, you will need to collect all the branches and twigs from the site, mix them with clay and fill them with water. There should not be too much water so that bars can be formed as a result.

The resulting mixture is poured into molds, compressed and left to dry in the sun for several days. Of course, such a product will be significantly inferior to real briquettes, but it will save money. In addition, the area will become cleaner.

What is better to choose regular firewood or “euro”?

Fuel briquettes, like any manufactured product, have both their positive and negative sides. Compared to firewood, briquettes boast the following advantages:

- They burn on average 4 times longer than conventional firewood, which allows them to be consumed in much smaller quantities.

- They literally burn to ash, leaving behind it in the amount of 1% of the original mass of the material. By the way, after burning wood, coal remains, amounting to about 20% of the initial amount of material. By the way, the ash from burnt European firewood can be used as a fertilizer for the soil: seedlings in this place will grow better due to the increased amount of potassium.

- The heat transfer of Euro-doors is significantly higher than that of conventional ones: the difference is 2 times.

- Capable of maintaining heat literally throughout the entire combustion process. That is, if with ordinary firewood the heating power decreases as it burns, and the coals die out within 15 minutes, then with European firewood the level of heat transfer does not change even when only coals are left from the briquette, which continue to burn for another hour. This property is extremely useful for those who like to go outdoors with a barbecue.

- The fire from burning briquettes does not spark, and practically does not emit smoke or odor. Thus, Euro firewood does not harm the environment and does not cause discomfort when being near it.

- When burned, Eurowood does not emit substances that are harmful and dangerous to human health. The fact is that ordinary firewood contains fungi and mold, which die when burned, but create toxic smoke.

- As a result of burning fuel briquettes, soot does not form on the walls of the chimney.

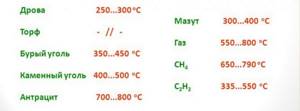

Table of ignition temperature of fuel materials

- The compactness of briquettes allows you to significantly save on space: they are delivered in the form of neatly stacked stacks. Firewood can be of different shapes and sizes, which makes it almost impossible to stack them neatly. Moreover, the firewood is usually “dumped” out of the truck onto any free space on the site, after which you will have to carry it to the shed yourself and lay it out there.

In general, all the positive aspects of fuel briquettes could be summed up in one word: efficiency. Although, there are several points that favorably distinguish fuel briquettes from ordinary firewood that have nothing to do with price. For example, one of the very big advantages is cleanliness and order. Conventional firewood produces a lot of dust, chips and other debris. Briquettes do not have such difficulties. However, does this mean that briquettes are definitely better than firewood?

Gas heating

A fireplace with an atmospheric burner designed to burn natural or liquefied gas allows owners not to bother with fuel preparation and does not require cleaning the chimney and firebox. The combustion process is automatically regulated by the system, and the thermostat controls the temperature. You can install a gas fireplace on any floor of the house, having received permission from the regulatory authorities. To operate, it requires a chimney or hood.

The calorific value of gas is 8500 kcal/m3, but the efficiency does not exceed 50%. You can increase the efficiency of your fireplace by installing an infrared burner.

Advantages

Briquette fuel has become increasingly in demand since its introduction. And this is quite understandable, since its advantages over other heating methods are obvious:

- high productivity - they give off twice as much heat as wood;

- comfort - they are easy to ignite, do not produce sparks, burn to the ground, without forming any burning that pollutes the room and air;

- burning duration - with good air access it lasts approximately 2.5 hours, and with a supporting smoldering mode, the briquette stack can burn for up to 7 hours, providing the room with heat;

- waste-free – there are practically no burnout products from “Eurowood”;

- smokelessness is one of the main advantages of this heating. There are absolutely no risks of harm to health, because practically no carbon dioxide is released during the combustion process.

Important! The most important thing about briquette fuel is that it is completely safe for humans

Coal for a good boiler

The combustion temperature of coal can reach 1400 o C, the ignition temperature is 600 o C - these properties are used when conducting energy-intensive processes in ferrous and non-ferrous metallurgy, where coal and anthracite are traditionally used. The combustion of coal (brown) is accompanied by increased heat transfer to heat metals up to 1200 o C. At the same time, studies show that when coal is burned, up to 40% of volatile gases are released, and after their combustion, up to 14% of ash remains.

Coal briquettes for heating have significantly lower values for these indicators, while maintaining high combustion heat characteristics (up to 5500 kcal). A briquette is a compressed mixture of crushed coal fractions and fixative fillers with a density of 1.4 g/cm 3 . High calorific value and the absence of coal dust have made coal in briquettes a popular type of fuel used in private households and in enterprises where there is no centralized heat supply. Coal slag, formed during the combustion of fuel, can serve as fertilizer for plants in the area adjacent to the house.

Advantages and disadvantages of artificial fuel

Eurofirewood got its name because of its regular geometric shape and is an alternative type of solid fuel (wood or coal). They are convenient for heating stoves, fireplaces, and using for solid fuel boilers and other types of heating appliances. In order to decide which type of fuel to give preference to, you should consider all the advantages and disadvantages of briquettes over firewood. To produce briquettes, waste from the food and wood processing industries is used. They include:

- sawdust;

- husks of cereals (rice, buckwheat) and industrial crops (sunflower);

- peat;

- straw.

Ideal drying of the fuel material determines good combustion, compact and aesthetic appearance. No glue is used in the production of briquettes, so such products are environmentally friendly and safe for humans.

Why are briquettes better?

Their main advantage over firewood is their affordable price and high heat output. For example, the heat transfer of firewood at a humidity of 20% is about 3000 kcal/kg, and a briquette is 5000 kcal/kg. Compared to firewood, the moisture level of briquettes is 3-4 times lower, this is achieved due to the fact that they are almost completely dried. High density ensures excellent heat transfer; they also emit less soot and ash and do not pollute the chimney; they burn evenly, which is achieved due to a uniform and homogeneous structure.

Pressed products take up less space, are compact, and if you compare what is better for heating - firewood or fuel briquettes, then it is worth considering the disadvantages of each type of fuel.

It is very difficult to visually distinguish between a good briquette and a low-quality briquette, since it is simply impossible to determine its composition externally. Soft wood waste and low-quality wood can be added to briquettes, which as a result significantly reduces heat transfer.