The heating system requires the use of high-quality and wear-resistant materials that are not afraid of high pressure and frequent temperature changes. All of the above stated characteristics correspond to polyethylene pipes for heating.

Cross-linked polyethylene for heated floors

In order to give polyethylene flexibility, chemical and mechanical resistance, it is cross-linked by electron flow. There are several different methods for producing cross-linked polyethylene, and depending on the technology, the technical characteristics of the material change, however, the main advantages and disadvantages are still common.

Advantages of cross-linked polyethylene

Unlike ordinary polyethylene, cross-linked polyethylene does not soften or deform when exposed to high temperatures. It is this property that allows the material to be used for heating and underfloor heating systems. In addition, cross-linked polyethylene (PEX) has the following advantages:

- Complete absence of corrosion;

- Pipes do not become overgrown or silted;

- Light weight;

- Easy installation and transportation;

- Resistant to large changes in pressure and temperature;

- Does not crack;

- Excellent sound insulation;

- Resistance to negative temperatures;

- Has molecular memory;

- It is environmentally friendly for humans and any other living organisms;

- Inexpensive cost;

- Strength;

- Long service life (according to manufacturers, it is about 50 years).

Cross-linked polyethylene for heating

Areas in which pipes made from this material are used

Polyethylene pipes are widely used for plumbing systems. Their main qualities are ease of installation, strength, and high wear resistance. Disadvantages include instability to high temperatures; the maximum value of water inside the system must be forty-five degrees, otherwise the pipes will be deformed.

To eliminate this drawback, a new material was invented - cross-linked polyethylene, which is referred to in international documentation as PEX.

Cross-linked polyethylene can be used in many areas:

1.water supply.

2.gas networks.

3. drainage systems.

4. heating.

5.equipment of warm water floors.

The ability to withstand high temperatures determines the main area of application: hot water supply. Cold water pipes are cheaper to install from other types of plastic, but if you want the highest quality installation of the system, you can use pipes marked PEX.

Reference! Polyethylene products are produced in coils of two hundred, four hundred or six hundred meters. The pipes have a scale on which you can measure the desired length and easily cut it.

Main disadvantages of the material

The positive qualities of cross-linked polyethylene have made it indispensable for heating systems and underfloor heating. However, there are still some disadvantages, among which it is worth highlighting:

- Lack of resistance to ultraviolet rays;

To reduce the destructive effect of ultraviolet radiation on cross-linked polyethylene, the pipes are coated with a special protective varnish.

- Possibility of mechanical damage, for example, by rodents;

- No resistance to surfactants;

- Destruction under the influence of oxygen.

When oxygen gets into the inner layers of the pipeline, it quickly collapses. It is for this reason that many manufacturers add a protective layer against oxygen, the so-called oxygen barrier. This reduces the risk of damage to the product, but causes an increase in its cost.

Advantages and disadvantages of polyethylene pipes for water supply

PEX pipes have a significant number of undeniable advantages:

- Possibility of use in a wide temperature range, from +120 to -50 degrees C.

- Resistance to changes in internal pressure in the water supply system.

- Elasticity and the ability to restore its original shape after mechanical deformation.

- Increased strength, resistance to impact and abrasion.

- Durability of operation reaching over 50 years.

- Resistance to aggressive external influences - corrosion, fungal infections, damage by insects and rodents.

- Environmental safety of cross-linked polyethylene.

- Smooth internal surfaces prevent deposits from forming on them, leading to blockages.

- Light weight structure.

- Easy to install.

At the same time, cross-linked polyethylene also has a number of disadvantages, which should also be taken into account when choosing a product:

- Sensitivity to ultraviolet solar radiation.

- Multilayer pipes with a damaged anti-diffusion layer can delaminate as a result of air entering the structure.

- The rigidity of a PEX pipe is somewhat lower than that of its metal-plastic counterparts, so to fix it, in order to avoid sagging, more fasteners will be required.

PEX pipe design and production method

The cross-linked polyethylene pipe is a multilayer structure that consists of five balls. The main layers are as follows:

- Inner ball of cross-linked polyethylene;

- Glue ball;

- Oxygen barrier;

- Glue ball;

- External ball of cross-linked polyethylene.

PEX Pipe Construction

It is this five-layer construction that ensures the high temperature resistance of the material, because it does not deform even when the transferred liquid reaches 95 ° C. That's why PEX is an excellent choice for heating and underfloor heating.

To manufacture the pipeline, the extrusion method is used, which consists of extruding the required shape from molten polyethylene. After this, all pipes undergo vacuum calibration. Products are supplied for sale in coils or cuts depending on the diameter.

Product Specifications

The unique properties of cross-linked polyethylene put it on par with many solids. Key material characteristics include:

- Melting point – 200 degrees;

- Combustion temperature – about 400 degrees;

- Tensile strength – 350 – 800%;

- Density – 940 kg per cubic meter.

Pipeline made of molecularly cross-linked polyethylene is produced in a wide range of diameters. Manufacturers offer sizes from 12 to 250 mm, but the most popular among consumers are diameters 16 – 25 mm.

PEX stitching methods

There are about 15 methods of cross-linking polyethylene, but three of them are most widespread.

Today, the following stitching methods are in demand:

- Peroxide (PEX-a);

- Silane (PEX-b);

- By radiation method (PEX-c).

A more expensive, however, and higher quality cross-linking method is peroxide. It is thanks to it that it is possible to bind about 85% of free molecules. This allows the material produced in this way to have increased resistance to mechanical stress and have a higher melting point.

PEX is the best method for producing cross-linked polyethylene; all other options are just an attempt to reduce the cost of the material.

Conclusion and useful video

As a conclusion, I would like to remind you once again that multilayer polyethylene pipes are much more resistant to various influences. Therefore, it is best to use them for installing hot water supply systems. Here they will show themselves at their best. Assembling cold water pipes with low pressure from multilayer, expensive PEX pipes is absolutely illogical. Other, more budget-friendly materials, such as HDPE or polypropylene, can easily cope with similar loads.

Reinforced heating pipeline

One of the latest innovations on the market of materials for heating and underfloor heating is a reinforced cross-linked polyethylene pipe. It is even more durable and heat resistant than regular PEX. The main difference in production technology is the introduction of nylon threads into the pipe walls, which occurs at the stage of extruding the mold from hot molten polyethylene.

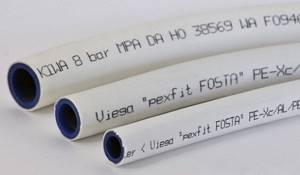

PEX-c cross-linked polyethylene pipes

Reinforcement methods can be as follows:

- Nylon thread;

- Kevlar;

- Aluminum foil.

The reinforced pipeline can withstand even such loads as a pressure of 30 atmospheres and does not crack when torsioned or bent. But the cost of the products is higher, because production requires expensive equipment.

Key manufacturers of cross-linked polyethylene

Cross-linked polyethylene is the most suitable material for installing heating systems and heated floors. Today, a whole group of foreign and domestic companies is engaged in the production of high-quality and durable products. Key producers are:

- Rehau (Germany);

- Valtec (Italy);

- Uponor (Sweden);

- Tece (Germany);

- Bir Peks (Russia).

- STOUT (Spain)

Rehau is a world leader in the production of cross-linked polyethylene pipes for heating and underfloor heating.

Rehau cross-linked polyethylene

The Rehau company has taken a leading position in the world market today. It is its products that have proven themselves excellent due to their excellent quality and good performance characteristics. The price of the products is not the cheapest, so many developers are looking for more budget options for their home, for example, STOUT brand products.

STOUT is professional plumbing equipment for the installation of heating and water supply systems. The products are manufactured in the same European factories where other premium brands order their products.

The main items of the STOUT product range are covered by a 5-year warranty. All parts of the system fit together perfectly, are easy to install and maintain, and are adapted for operating conditions in Russia.

XLPE pipes

XLPE pipes

Different manufacturers use different methods for cross-linking polyethylene: PEX-a, PEX-b, PEX-c. Today, peroxide (PEX-a) is recognized as the best crosslinking method; it is for this reason that it is recommended to choose products from the Rehau, Uponor and STOUT brands, which are produced using this technology.

Major manufacturers of polyethylene pipes

On the modern construction market you can find a large number of different polyethylene pipes from a variety of manufacturers. Therefore, any person who decides to install a pipeline on their own involuntarily has the question: “Which brand should I prefer?”

The most reliable manufacturing companies, according to experts, are:

- "Rehau", "Vega", TESE, Polymutan (all Germany).

- KAN (EU).

- Virsbo (Sweden).

Among the budget options, it is worth paying attention to the products of such companies:

- "Aquatherm Polska" (Poland)

- DAK-K (Ukraine).

Features of material installation

Installation of heating and underfloor heating using cross-linked polyethylene can be carried out using two main methods:

- Using compression fittings;

- Using press fittings.

A simpler installation option, which also allows you to repeatedly disassemble the structure at the joining point if necessary, is installation using compression fittings. To install a heated floor using this technology, you must perform the following steps:

- Place the crimp nut on the pipeline.

- Put on the split ring.

- Place the pipe onto the fitting.

- Tighten with a wrench.

Installation of cross-linked polyethylene

Attention! Be careful when tightening the ferrule nut as excessive force may damage the pipe.

Installation of heated floors using press-on fittings creates a permanent connection. It is necessary to prepare the press for installation in advance and follow the instructions below:

- Place the clamping sleeve.

- Insert an expander of the appropriate size into the pipe.

- Insert the pipe into the fitting fitting.

- Press the sleeve onto the fitting.

- Wait a few seconds and get a strong and reliable connection. Thanks to the molecular memory of the material, the pipe will be impossible to remove from the fitting.

Methods for connecting polyethylene pipes

Polyethylene pipes are quite technologically advanced and easy to install. You can create a water supply network from PEX pipes with your own hands, without the involvement of expensive specialists. Pipeline installation is carried out in three main ways.

Method: compression

The compression method does not require expensive tools; all work is done manually. A crimp nut is pulled onto the end of the pipe, then a shear ring is placed, which is fixed 1 mm from the end edge of the pipe. Then the compression fitting itself is pulled onto the end.

The same operation is performed with the end of the second pipe being joined, after which both halves of the fitting are joined and fastened together using a crimp nut. It should be twisted by hand using muscle force. Keys should be used only as a last resort, so as not to damage the plastic structure.

Method: crimping

The crimping method for connecting PEX pipes is carried out using a special hand tool - an expander. A crimping ring is put on one end of the pipes being joined, then using an expander, this end is expanded until the fitting fits freely into it.

The same operation is performed with the end of the second pipe. After a few minutes, the stretched ends of the polyethylene pipes return to their original size, tightly encircling the fitting. For greater reliability, a crimping ring is attached to the top.

Method: electric welding

The most expensive, in terms of financial costs, is the electric welding method of joining cross-linked polyethylene. To connect the pipes you will need special electric couplings. They are a regular external fitting, but inside of which a spiral of high resistivity metal conductor is laid. Two terminals extend outward from both ends of the spiral. A special welding machine is connected to them, heating the internal spiral to the required temperature.

The welding machine is an automatic device that reads information from the barcode of the electric coupling and independently selects the heating mode. After welding is completed, it signals the end of the process. As a result, the influence of the human factor on the result of work is completely eliminated. But this method is very expensive, and therefore it is not always cost-effective to purchase such a device for a one-time installation of a plumbing system inside a house.