The German company Rehau has been producing pipes and various fittings since 1948. The company's products are recognized all over the world. For the manufacture of pipes, the latest material is used - cross-linked polyethylene, which ensures the durability and reliability of the products. In addition, experts note that not only professionals, but also ordinary people can install Rehau pipes. What does this require? Read on.

Types of pipes for various systems from Rehau

Features of Rehau pipes

The production of pipes using new technology determines the fundamental features of the products, which consist in the following aspects:

- increased sound insulation. Cross-linked polyethylene is able to absorb sounds produced by water flow;

- Rehau pipes are installed using a unique method that allows you to create the most durable connection;

- the material from which the pipes are made is universal. Pipes can be used to create hot and cold water supply and heating systems, and can be used to install heated floors. The maximum liquid temperature in the pipe is 95ºС;

- pipes are practically not subject to cracks and deformation due to mechanical damage, so they can be laid under plaster or covered with other structures;

- high degree of thermal insulation, which helps to save natural resources;

- any pipe can withstand changes in liquid temperature and internal pressure;

- complete safety for humans. The company's products are certified;

- A special coating on the inner walls of the pipes prevents the formation of plaque and a reduction in throughput.

Materials that give Rehau pipes unique qualities

From Rehau pipes and various fittings, pipelines of any complexity and purpose can be constructed.

The only drawback of Rehau pipes is the high cost of products and fittings.

Types of products and their advantages

Rehau produces pipes with a wide variety of characteristics in order to satisfy a wide range of customer needs. The products differ in diameter, color and purpose.

You can easily get acquainted with the types of products in specialized stores.

Today on the market there are the following types of Rehau pipes:

- Stabil is a universal line of pipe products that are suitable for both cold and hot water supply. To make these pipes, polyethylene is used, which has a small aluminum layer inside. During installation of the system, special layouts or corrugated tubes are sometimes used.

- Pink - these products are used only when installing a heating system. In this case, molecular cross-linked polyethylene is used. Another difference between these pipes and the rest is the pink color.

- Flex - such flexible tubes can be used for both heating and water supply. They are not afraid of corrosion, rusty deposits and scale, resist impacts, and last a long time.

- His - can be used for cold or hot water supply. Installed according to the general scheme.

The diameter of Rehau pipes can range from 17 to 63 mm. Due to their flexibility and strength, products from this manufacturer can be used to create plumbing, heating and sewer systems, and to install heated floors.

Their advantages include a high level of noise and heat insulation, strength of connections, versatility of use, wear resistance, the ability to operate under pressure and temperature changes, safety for humans, confirmed by relevant certificates.

Perhaps the only drawback of Rehau products is their rather high price.

Pipe installation

To install Rehau pipes with your own hands, you need:

- purchase the necessary tools;

- Please read the pipeline assembly instructions first.

Tool required for installation

Before you begin installing pipes, you must:

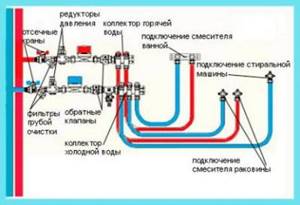

- purchase the required number of pipes, connecting fittings and adapters. To calculate the necessary materials, a water supply diagram is drawn up;

Approximate layout of hot and cold water pipes in a city apartment

- prepare a tool for installing Rehau pipes:

Expander for pipe installation

press clamp with additional nozzles of different diameters. Since the installation of the type of pipe in question is somewhat different from conventional welding, the procedure requires such a specific tool for installing Rehau pipes;

Manual press used for connecting pipes, REHAU RAUTOOL

pipe cutting tool. Standard pipe cutter, used for all types of plastic pipes;

Plastic pipe cutting tool

tape measure, marker for marking pipes.

Standard measuring tool used in construction

All tools can be purchased individually or as a set. The average cost of a set is 2,500 rubles.

Pipeline assembly process

Installation of Rehau cross-linked polyethylene pipes begins with pipe preparation. Preparation consists of two steps:

- pipes of various sizes are cut according to the previously prepared drawing;

The process of cutting a pipe to the required size

- the fittings necessary for assembling a certain section of the pipeline are prepared.

If heating is being installed using Rehau pipes, then it is more advisable to immediately prepare all sections of the system, and then first check the correctness of the sections according to the diagram.

To check, all pipes and fittings are placed on the floor in a certain order. This is especially true for heating in city apartments, since it is necessary to turn off the heating in the entire house.

When cutting pipes, you should be guided by the old Russian proverb - “measure seven times, cut once.” Errors in pipe cutting may result in the inability to install a piping system indoors.

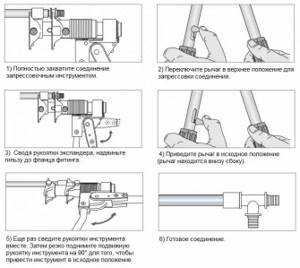

The joining of pipes and fittings to each other is carried out using sleeves, which are fixed as follows:

- A nozzle is selected for the expander, the diameter of which fully corresponds to the diameter of the pipe used. In this case, the handle of the tool must be fully extended (the ends of the handle are located at right angles to each other);

- the nozzle on the expander should hold firmly and sit on the pin until it stops;

- A sleeve is placed on the section of pipe that needs to be connected to the fitting. The diameter of the sleeve used must also correspond to the diameter of the pipe;

Each sleeve has a chamfer. When installing, it should be directed towards the future connecting seam.

- a pipe is put on the other end of the nozzle installed on the expander. When the expander handle is compressed, the pipe expands;

The process of expanding the pipe for further installation

- the extended end of the pipe is connected to a fitting that must be installed in this place;

Inserting the fitting into the prepared end of the pipe

- a previously installed sleeve is supplied to the fitting;

- Using a press clamp, the sleeve is pushed into the fitting until it stops. A strong and reliable connection is ready.

Fixing the fitting with a press clamp

When arranging the connection of pipes and fittings, even the slightest distortions should not be allowed. All connecting parts must be positioned strictly horizontally to each other. Otherwise, the connection will be unreliable.

Step-by-step diagram of working with a press clamp

Installation of Rehau pipes for heating, gas or water supply must be carried out in compliance with all safety standards. First of all, you need to take care of protecting your eyes (using a mask) and hands, which are not recommended to be inserted into moving elements.

The video below of installing Rehau pipes will allow you to observe the process from the outside in order to more accurately clarify all the most important aspects.

Anyone can install pipes from the German manufacturer Rehau. The main thing is to have the necessary tools and strictly follow the instructions above.

Necessary tools for work

Before you begin installing water or heating pipes, you should prepare the necessary tools and materials. And also purchase the required number of pipes, fittings and adapters.

Before you begin installing Rehau pipes, you should first prepare the tools for the job

To connect Rehau pipes, you need the following tools:

- A pipe cutting device that can be used to cut plastic products;

- Marker (pencil) and tape measure for marking;

- Press clamp with various replaceable attachments;

- Expander (expander) - also with attachments.

All these tools can be purchased as a set, or individually.

Preparation for installation work

The collector outputs should be the first elements that require increased attention. Only their correct processing will ensure complete tightness in the system.

Before installation, the workplace must be completely free of dust and debris, as well as the equipment. Welding, threading and gluing are the methods that are most widespread during installation. You just need to purchase the appropriate type of fitting, depending on the installation method you choose.

Watch video: Bir Pex systems

Absolutely all parts used during installation must be intact and clean. A visual inspection is required before purchase. This will ensure the quality of the finished product. Their transportation deserves special attention.

High-tech products: characteristics and methods of installation

All manufactured products are certified and tested, so rehau pipes are highly durable and reliable. Modern and environmentally friendly materials are used as raw materials in production, such as:

- cross-linked polyethylene;

- bronze;

- brass;

- stainless steel;

- ethylene vinyl alcohol;

- polyvinyl sulfone PPSU and -defluorite PVDF;

Pipe installation is carried out using technology specially developed by the company. The process includes:

- press fitting, which can be metal or plastic;

- sliding sleeves.

More detailed information is presented in the video.

The main advantage of this installation method is:

- when connecting, the structure can be safely hidden under plaster or plaster; you will never need access to it;

- installation of the entire system does not require special knowledge and skills, all work is carried out using a special tool that assembles everything perfectly in a matter of minutes; a professional tool is also developed by the company;

- no need to waste time cutting threads or removing the top layer of material;

- no need for welding, soldering or gluing.

What are the dangers of unprofessional installation?

Installation of Rehau pipes in an apartment, which is carried out by non-specialists and without the use of professional equipment, can lead to the most disastrous consequences. If pipes burst, flooding of the living space and all areas adjacent to it is ensured.

If the gust occurs on the heating system, then in winter you are faced with complete defrosting of the system and the difficulty of restoring it. If you order the Rehau pipeline installation service in, then you will not encounter any of the unpleasant consequences.

The work performed by professionals has several distinctive characteristics:

- the pipeline laying scheme is the most optimal and does not interfere with other systems and normal life processes for the owners of residential premises;

- each pipeline connection is of high quality and has smooth seams;

- for installation, the correct type of pipes has been selected, which is compatible in parameters with the system being installed;

Installation features

When making pipe connections, even the smallest distortions are not allowed. All elements involved in the connection must be placed in the same axis, forming a clear straight line, otherwise the connection will turn out to be of very poor quality.

The laying of REHAU pipes for water and gas supply, as well as heating systems, must be carried out in accordance with all safety rules. The most important thing is to protect your eyes and hands. In the first case, you can use a protective mask, and in the second, you should refrain from touching the moving parts of any tool.

Additionally, you can clearly learn about the installation of REHAU pipes by watching the corresponding video, which shows all the nuances and the most important aspects of the work.

In conclusion, it is worth noting that the installation of pipes from the German manufacturer REHAU is quite simple, so anyone can cope with the entire list of work. The main thing is to acquire the entire list of necessary tools and fully adhere to the recommendations described above.

What are the main advantages and features

- Presence of reverse shrinkage. The products are able to resist high pressure, and after prolonged exposure they return to their original shape. Other materials with similar parameters simply stretch after some time and become completely unusable.

- Increased heat resistance. Such pipes operate normally at temperatures up to 120 degrees.

- Availability of prices.

- Ability to resist freezing.

- Tolerates high temperatures and pressures.

- Convenient installation.

- Light weight.

- Bir Pex, Rehau and other companies have a high level of sound insulation. Thanks to this, the room itself is protected from extraneous sounds. Pressure surges are completely absorbed by the system itself.

- Long service life combined with high strength. You can forget about rotting and corrosion when working with this material.

- Environmentally friendly. Polyethylene does not emit harmful substances, even when it is highly heated.

- Elasticity.

Characteristics

Let's take, for example, one of the series - Raupink.

Heating pipe Rehau RAUTITAN pink (RAUPINK)

Maximum permissible values:

- Pressure (working) at ten atmospheres.

- Short-term temperature at one hundred and ten degrees Celsius.

- Temperature (working) – ninety-five degrees.

Minimum acceptable values:

- The service life is fifty years.

Another popular heating series, Rautitan, has the following characteristics:

Maximum permissible values:

- Pressure (working) at ten atmospheres.

- Short-term temperature at one hundred degrees Celsius.

- Diameter (outer) – 1.6-4 cm.

The advantages of such products:

- Pipes can be supplied pre-insulated.

- Temperature elongation is of little importance.

- Can be directly connected to a heating device.

- Retains shape when bending.

- Even if the aluminum shell is damaged, the strength properties are maintained.

- The inner PEX layer is durable.

Heating pipe Rehau RAUTITAN pink (RAUPINK)

Such pipes can operate at a maximum pressure of ten bar and a temperature of ninety-five degrees.

And only in emergency situations can products withstand one hundred degrees for a short time.

Installation process

The installation technology includes several steps.

- We screw a nozzle with the required diameter onto the expander.

- After that, we put crimp rings on the pipes themselves with our own hands. And we do this so that the place where the pipe expands is not occupied.

- An expander must be inserted into the pipe. It expands when the installer presses a special handle. The next step is to rotate the pipe itself or the expander by 30 degrees. And then press the handle again. You can repeat the operation to consolidate the result. After this, proceed to using the fitting.

- The shutter is removed from the press with your own hands. Next, pull out the pins used for fastening. The next step is to thread the nozzles, which are secured with pins. The shutter snaps shut.

- The connection takes on a finished form. The product must be removed from the press.

Cross-linked polyethylene and its advantages

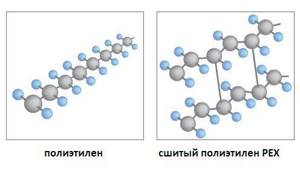

In production, the company uses high quality polyethylene, in which the linear bond is cross-linked with peroxide within its structure. This material is marked PE-Ha, thanks to which the products have high strength and heat resistance. Polyethylene is able to restore damaged areas due to the fact that the bond between the molecules is not broken. The video shows the production technology of polyethylene products.

Main advantages of the material:

- all products are certified and tested;

- is highly resistant to corrosion processes, the pipe walls do not crack, break or chip;

- the material does not allow dirt to accumulate inside the pipes, which eliminates the formation of growths;

- the pipeline operates without noise;

- has greater resistance to high temperatures inside the system, the design can withstand 100 degrees, and with slight heating of water, 200 degrees;

- retains its shape at low temperatures and is shock resistant;

- high resistance to chemicals;

- environmentally friendly material that cannot harm human life and health;

- service life is more than 50 years;

- installation does not cause any problems; you can do it yourself.

Installation of cross-linked polyethylene pipe

Materials

Before starting work, prepare the necessary tools and consumables. You will need:

- Vise.

- Fittings: couplings, adapters, elbows, tees, sliding sleeves (when installing a sliding sleeve, you do not need to use rubber gaskets, which increases the reliability of the design).

- Expansion device.

- Roulette.

- Pipe cutting tool.

Rehau pipe - design

Installation

The installation is similar to the installation of any pipes, however, there are certain nuances:

- There are special Rehau tools for installation. This tool is needed to simplify the process.

- Installation of products is carried out using threaded or welded connections, as well as shaped products and fittings.

- There is a company development - a connection with a movable sleeve. It can be covered with plaster.

If you choose heating pipes from the Rehau company, then installation will be simplified, and the pipeline will serve reliably and for a long time. And if you still have open questions about the installation nuances, you can additionally watch the video. This will avoid mistakes.

Materials for heating systems from Rehau

Pipe composition and varieties

The photo shows universal polyethylene pipes with various fittings.

Rehau heating pipes are made from cross-linked polyethylene. However, some clarification is required here: there are many companies that produce products from this material, but not all can boast of the same level of quality. What is the secret of the German company?

The fact is that cross-linked polyethylene can be obtained in various ways - by heating in the presence of peroxides, treatment with silane with catalysts, bombardment with electrons and X-rays, nitrogen technology.

Accordingly, the materials are called PE-Xa, PE-Xb, PE-Xc and PE-Xd. The highest quality cross-linking – up to 85% – is achieved only by peroxide technology (PE-Xa); it is this technology that is most often used in the manufacture of materials from the German brand Rehau.

Polyethylene molecules are cross-linked by forming loose bonds due to the removal of individual hydrogen atoms.

Important! Some models may use PE-Xc as a stiffer material as an inner layer to increase resistance to high pressure. It should also be remembered that oxygen tends to equalize its concentration and penetrates through various permeable membranes, which include polyethylene

It should also be remembered that oxygen tends to equalize its concentration and penetrates through various permeable membranes, which include polyethylene.

To counteract this effect, pipes with a special structure have been developed:

Materials with a layer of butt-welded aluminum. The structure of the product looks like this: PE-Xc – Al – PE-Xa. These are universal pipes of the Rautitanstabil series, which are suitable for drinking water supply systems and heating systems; Materials with a layer of ethylene vinyl alcohol. Here the structure is slightly different: PE-Xa – EVOH – PE-Xa. This arrangement is suitable for universal and pure heating pipes, used in products of the Rautitanflex (universal) and Rautitanpink (pure heating) series.

Rehau metal-plastic pipe for heating and water supply of the Rautitanstabil series.

Important! It should be understood that the high price of the company’s products is due to the use of expensive and high-quality materials, as well as high production technologies

Characteristics and Features

The material allows you to create the most unusual and complex systems.

The technical characteristics of the products of this brand allow them to be used in various conditions, including for radiator wiring, coolant supply lines and heated floors:

- Product composition: PE-Xc – Al – PE-Xa, PE-Xa – EVOH – PE-Xa;

- Maximum operating temperature – 95 °C, normal operating temperature – 70 °C, permissible short-term peak temperature – 110 °C;

- Maximum operating pressure is 10 atmospheres, short-term surges up to 20 atmospheres are possible;

- Guaranteed service life is at least 50 years.

Rehau Rautitan Pink heating pipe is supplied in coils.

The features of the products include such qualities as the shape memory effect (the material tends to return to its original shape when deformed), the ability to bend pipes of small diameters without tools, noise-absorbing effect and thermal insulation activity.

Also, cross-linked polyethylene provides minimal thermal expansion values compared to other types of plastics, which is very important for heating pipelines.

The products can be used for all types of radiator wiring.

Of course, for PE-X the qualities characteristic of all plastics are relevant: low density and weight of the pipeline, chemical and corrosive inertness, high impact strength, low internal surface roughness, elasticity and the ability to withstand water hammer.

You can create collector units and complex systems.

Important! Separately, it should be said about the method of installing connections, but we will do this in the next paragraph

Installation of the Rehau heating system

Installing channels from the manufacturer in question is quite simple. To solve this problem, you need to buy the appropriate tool and carefully read the instructions for assembling the pipeline.

The step-by-step execution of the task is as follows. Buy the required number of pipes and connecting elements. Draw a diagram of the future system. Prepare the tools that will be useful for the job.

You'll need:

- Expander with a set of special nozzles for channels with different cross-sections.

- Press clamp. The set should also include nozzles for working with structures of different diameters.

- Pipe cutter for working with plastic products.

- Yardstick.

The assembly of the pipeline must begin with the preparatory stage.

It includes two points:

The connection of channels and fittings is carried out using sleeves.

Select a nozzle suitable for the expander. It must fit exactly in size. It is important that the handle of the tool is 100% retracted at this moment. The ends of the handle should be placed at a strictly ninety-degree angle.

Make sure that the nozzle on the dilator is attached firmly and sits all the way on the pin. A sleeve is placed on the part of the channel connected to the shaped part. Moreover, its diameter must fully correspond to the dimensions of the structure used. The chamfer of the sleeve should be directed towards the future connection.

A pipe is put on the second part of the expander nozzle. When the instrument is brought together, its structure will expand. At this moment it needs to be docked with the shaped part. The installed sleeve is brought to the fitting.

Using a press clamp, it is pushed into the connecting element. You need to do this all the way. This is the only way to achieve reliable and durable joints.

Try to avoid the occurrence of various distortions of channels and fittings to them. It is important that all components are connected strictly horizontally in relation to each other. Otherwise, problems with the operation of the system may arise in the near future.

In order for the installation of the water supply and heating system to proceed correctly, all existing norms and rules must be strictly observed. Be sure to use protective masks that will reliably protect your eyes. In addition, be sure to use gloves.

Almost anyone can cope with the installation of Rehau structures. Installation of this equipment does not require special knowledge and skills. The main thing is to perform each stage correctly.

Usage

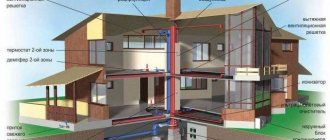

Rehau pipes are often used for heating systems, “warm floors,” water supply, sewer systems and “central vacuum cleaners.”

Installation of rehau pipes

It should be noted that the use of products in each area involves a different type of material and production technology.

Moreover, the company has developed a special program - RaubasicPress, which can offer two system options:

- With RE-Ha product and movable sleeve.

- With product PE-Xb.

Rehau polyethylene pipes can be used for hot or cold water supply due to the fact that their operating characteristics are no worse than metal-plastic ones. This is due to the high level of stitching performance.

As for Rehau pipes for sewerage, they can be used for internal and external systems. Installation is carried out using fittings and fittings. Therefore, the process does not take much time.

Rehau plastic products can be used for underfloor heating. Thanks to the use of cross-linked material and a minimum number of components, installation time and costs are reduced by a third.

Connecting pipes to a radiator “from the wall”

Units for connecting radiators from the wall >>>

Set of L-shaped connecting tubes made of stainless steel from REHAU

A very aesthetically pleasing connection to a wall radiator can be installed using L-shaped stainless steel connection pipes. In this case, the connection of universal RAUTITAN stabil/flex pipes, as well as RAUTITAN pink heating pipes, is carried out using a well-proven connection method using sliding sleeves.