Insulation is an important stage in the finishing of any private home, but in a bathhouse this operation becomes of key importance. A steam room is a room with special conditions in which extreme temperatures are combined with high humidity. No matter how well the sauna is built, if careful thermal insulation has not been done at the finishing stage, the sauna will not be able to function properly; cold will penetrate into the interior and heat will escape outside. To maintain the required temperature indicators, it is necessary to insulate it well. In this matter, you can rely on the professionalism and experience of specialists, or you can insulate the bathhouse from the inside with your own hands. The article provides step-by-step instructions for thermal insulation of a bath room.

Why is thermal insulation needed?

The bathhouse has many useful properties, but many of them may not be available if the internal insulation is not properly organized. In such a situation, even competently implemented construction work will not save you: if the walls of the building are not able to retain the heat created by the stove, the comfort of taking bath procedures will noticeably drop. The only way out is to reduce the time between kindlings, which, accordingly, will provoke an increase in financial costs for paying for energy resources.

A more correct solution is to insulate the bathhouse; fortunately, there are a number of effective technologies for this. It is best to do this during the construction of the building. However, if this important stage was missed for some reason, some methods of internal insulation can be implemented after construction is completed. The main difference between thermal insulation of a bathhouse and a similar procedure in an ordinary house is that in the first case, it is necessary to maintain the high temperature created by the stove for as long as possible inside the room. This requires a better approach to carrying out work.

Good thermal insulation means maximum energy efficiency for steam rooms and baths Source silpovoyage.ua

How to insulate a bathhouse from the inside

A successful choice of thermal insulation scheme and method of installing insulation makes it possible to solve most of the problems and “childhood” diseases of the bathhouse. Many craftsmen even recommend that when buying a country house with an old bathhouse, not to change anything inside the steam room except the decorative cladding of the walls and floors.

You can, of course, take the most expensive route and install the most powerful insulation on the walls and ceiling, with a thickness of at least 200 mm. This scheme is suitable for a steam room built in a very dry and frosty climate, northern latitudes, or even for steppe or desert areas. For the middle zone, very powerful insulation will lead to dampness and soaking of the bathhouse box; drying it after completing the process of visiting the steam room will be difficult and time-consuming.

Therefore, when building a new bathhouse, the insulation is often mounted on “black” walls. The insulation is installed in the steam room according to a temporary scheme and sewn up from the inside with ordinary wooden shingles or boards. After installing the stove and several thorough warm-ups of the bathhouse and steam room, it becomes clear how correctly we managed to choose the thickness and material for insulation. While everything is open, the thickness of the material can be reduced or increased. Experienced craftsmen manage to accurately select the size and power of thermal insulation so that the stove does not overheat and the condensation disappears in 30-40 minutes.

Polyurethane foam is not the best material for insulating walls from the inside of a bathhouse

Which material is better

In the old days, insulation of baths was carried out exclusively with natural materials. We are talking about felt, hemp, flax, red moss, etc. The undoubted advantage of these insulation materials is their complete harmlessness to people. Even under conditions of a significant increase in temperature (which often happens in a steam room), they do not emit any harmful substances or toxins.

Natural materials also have significant disadvantages:

- The complexity of the installation process. Despite the simplicity of the procedure for caulking a bathhouse using moss or tow, it takes a lot of time and effort. As a result, we have to increase payments to craftsmen.

- Weak biological resistance. Natural materials are susceptible to rotting and fungus formation: in conditions of constantly high humidity, this only gets worse. Insects and rodents often live in the thickness of the insulation, so regular inspection and refilling of the thermal insulation layer will be required.

Modern artificial insulation materials have more attractive performance characteristics.

Modern insulation materials Source in.pinterest.com

Although their degree of environmental friendliness is somewhat lower, their service life is an order of magnitude longer. This is explained by their absolute inertness with respect to constant moisture and high temperatures. If we add here low weight, ease of installation and low cost, it becomes clear why synthetic materials have now practically replaced natural analogues. The most commonly used materials are polystyrene foam, basalt fiber, mineral wool and glass wool. Before insulating a bathhouse from the inside, you need to familiarize yourself with the characteristics of each of these materials.

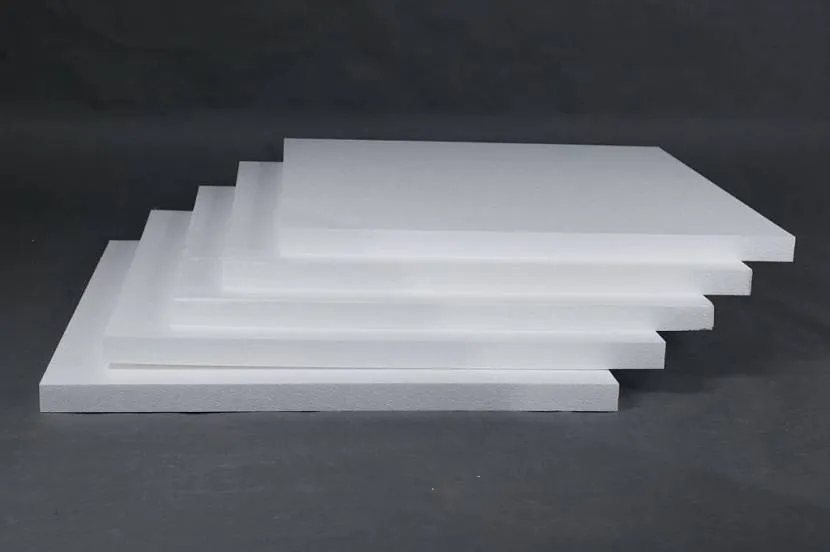

Expanded polystyrene

It has excellent thermal insulation characteristics with low weight and low cost. Expanded polystyrene foam resists moisture well, but in high temperature conditions there is a real risk of deformation and even fire of the slabs. If we add here the release of toxic substances when heated, it becomes clear why they try not to use this material in baths (except for the external design of the dressing room).

Expanded polystyrene is the closest relative of polystyrene foam, but with improved characteristics Source festima.ru

Basalt fiber

An excellent option for insulating a bath. The raw material for the production of basalt fibers is molten rocks.

This explains the following characteristics of the material:

- It doesn't burn at all.

- Tolerates mechanical stress and high humidity well.

- Has the ability to absorb noise.

- Provides excellent thermal insulation.

- Can be used for decades without loss of performance characteristics.

Installing basalt insulation is very simple, because... it can be cut into pieces of the desired size. The only drawback of this material is its high cost.

Basalt fiber compresses well, and after laying it occupies all the required volume Source house-stroy.ru

See also: Catalog of companies that specialize in insulating country houses.

Mineral wool

It is produced under approximately the same conditions as basalt fiber. The difference between them concerns the raw materials used: in this case, it is not rock, but metallurgical waste. In this way, it is possible to significantly reduce the cost of the finished material.

In addition to being cheap, mineral wool has other advantages:

- Low level of thermal conductivity. Thanks to this, the heated room retains its heat for a long time.

- Moisture resistance. The material can be used at consistently high humidity.

- High sound insulation performance.

The disadvantages of mineral wool include its low resistance to mechanical stress. This introduces certain difficulties into the installation procedure.

Mineral wool is offered in slabs or rolls Source bliz-ar.ru

Glass wool

The material consists of the finest threads of inorganic glass intertwined. As a result, numerous air layers and pockets are formed inside the glass wool, preventing heat from escaping through the thickness of the insulation. You should also highlight the good vapor permeability and low cost of the material. It is available for sale in rolls of different thicknesses and widths, which makes it easier to select the optimal level of insulation. In addition to rolls, glass wool is sold in the form of mats and slabs.

Work with glass wool is carried out in protective clothing Source lestnitsygid.ru

What to choose

An analysis of the characteristics of materials for thermal insulation leads to the conclusion that the best option for insulating a bathhouse from the inside is basalt fiber and mineral wool. To save money, the choice is mainly made towards mineral wool. Moreover, manufacturers managed to solve the problem of its fragility through the use of foil.

See also: Catalog of bathhouse projects presented at the “Low-Rise Country” exhibition.

Use of mineral wool

The question of whether it is possible to insulate a bathhouse with mineral wool is usually resolved positively.

After all, mineral wool is an almost universal modern insulation material with many positive technical characteristics. Among them are:

- reliability;

- moisture resistance;

- heat resistance;

- fire safety;

- resistance to rotting;

- easy installation.

Therefore, mineral wool can be used as bath insulation both outside and inside, including a steam room.

Warming procedure

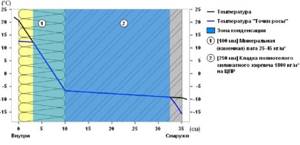

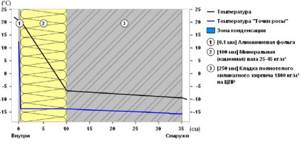

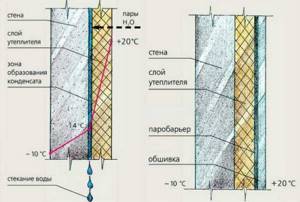

You have to work in high humidity conditions. This means that the moisture resistance of the heat-insulating material alone is not enough in this case: you additionally have to use a vapor barrier film. Thanks to this, it is possible to avoid moisture condensation inside the insulation (condensation reduces the thermal insulation characteristics of the material and contributes to rotting of the walls). In addition to film, aluminum foil is often used as a vapor barrier in baths, which enhances the insulation effect by reflecting heat into the room. To create a continuous protective surface, the joints of the foil sheets are decorated with metallized tape.

Walls

The nuances of thermal insulation of bathhouse walls largely depend on the material they are made of. Concrete, stone and brick foundations in any case need insulation. The goal in this case is not only to reduce heat loss, but also to protect the walls themselves from damaging moisture.

In addition to insulation, foil is often used, which reflects heat Source one-stroy.ru

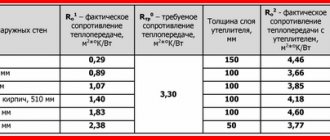

When selecting the thickness of insulation, the following is taken into account:

- The thickness of walls made of stone, concrete or brick.

- Features of the local climate.

As a rule, experts recommend laying insulation with a thickness of at least 100 mm. As for the insulation from the inside of a bathhouse made of timber, it is carried out only for walls thinner than 20 cm. For additional protection of more substantial structures, a waterproofing film and clapboard cladding are usually used.

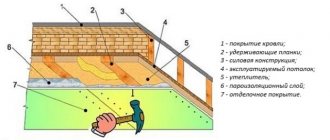

List of stages:

- Arrangement of sheathing on an insulated surface. The wooden blocks used for this must be well dried and treated with antiseptic impregnation.

- Decorating with fiberglass the spaces between the individual cross members of the frame.

- Installation of insulation for a bath on the walls from the inside. To do this, use slabs of basalt or mineral wool cut to size.

- Laying a vapor barrier material on top of the insulation.

- Finishing. For this purpose, natural lining is most often used in baths.

Finishing with clapboard is not only practical, but also very beautiful Source goodhome.by

How to properly insulate a bathhouse

The interior space of a modern bath building is conventionally divided into several main zones, depending on the air temperature inside the room, and most importantly, on the degree of saturation of the atmosphere with water vapor. The higher the humidity and temperature difference, the more difficult it becomes to insulate the walls in the bathhouse.

The division looks like this:

- The coolest and relatively dry room in the bathhouse is the relaxation room. Temperature 22-30oC, humidity 60-70%. Here we insulate the bathhouse from the inside with our own hands according to the standards accepted for residential premises. Excess moist air and heat are easily removed by ventilating the bath;

- Rooms with an average heat load are the dressing room and dressing room. It should be dry and warm here, otherwise things or a supply of firewood will quickly become saturated with water vapor and the odors of the bathhouse atmosphere. The air temperature is 30-35 ° C, the humidity from the inside is not higher than 60%, the ventilation is quite weak and is provided only by the operation of the stove;

- The steam room and washing compartment are the most stressed in terms of heat and humidity. Depending on the design of the bathhouse, humidity can range from 60-90%, air temperature - 70-100°C for the steam room and 30°C for the washing compartment.

In the first two cases, insulation and waterproofing are carried out according to the standard scheme; the thickness of the insulation on the wall of the bathhouse under the cladding, as a rule, does not exceed 50 mm. This is enough to ensure normal heating of the bathhouse even in frost down to -15-20°C.

In the latter case, the thickness of the insulation from the inside should be at least twice as thick, the thermal insulation layer is selected within the range of up to 100 mm for the middle zone and 150-200 mm for areas with real frosts down to -40 ° C.

Thermal insulation option for sauna

For the ceiling, insulation from the inside is done at a level of 50-75% of the thermal insulation capacity of the walls; for the floor, the thickness of the insulation is selected individually, depending on the structure of the foundation.

Important! Insulation of bathhouses for washing and steam rooms is most often done with one layer of thermal insulation.

Often the washing room and the steam room are made in one compartment of the log house; they are separated only by a thin partition made of stone or brick. This way solves the problem of heating the sink. Despite the moderate temperature inside the washing compartment, it is impossible to insulate the inside with a relatively thin layer, as in the rest room. Due to the large amount of moisture in the air, the walls and floors of the sink quickly cool and lose heat, and, as a result, the steam room of the bath quickly cools down.

Scheme of condensation formation from inside the room without foil - at the top, and with foil, at the bottom

This must be kept in mind when deciding on remodeling the bathhouse premises. Often the size of rooms is rearranged, internal partitions are moved to increase the volume of the steam room due to a dressing room or sink. Therefore, if possible, it is best for the dressing room, locker room and steam room with a sink to insulate the bathhouse from the inside with your own hands according to the same scheme. For the rest room, insulation is in any case carried out colder in order to ensure uniform and intensive removal of heat and water vapor from the room, and thereby make the living conditions more comfortable.

Insulation from inside the rest room

Features of insulation products

Manufacturers offer various membrane films that protect materials from high humidity. Experienced builders recommend purchasing vapor barrier upholstery with a reflective foil layer that does not allow heat to escape. The following types with a foil layer are distinguished:

- polypropylene;

- kraft paper;

- roofing felt;

- membrane;

- foil;

- coating

This film is installed with a large overlap (10-15 cm), and the joints are taped with foil tape for construction work.

In specialized departments of stores there is a wide selection of waterproofing products - foil-coated kraft paper, construction membrane and other products. Although you can save money and purchase regular plastic film or roofing felt.