One of the most important conditions for living in an apartment is a good heat supply, for which either a centralized heating system or autonomous equipment installed by residents is responsible. However, the efficiency of heating directly depends on the correct thermal insulation of the premises.

Let's look at how to insulate a wall in an apartment to increase the air temperature and at the same time reduce energy costs for heating. For this purpose, we provide two detailed instructions on thermal insulation with popular types of insulation, in which each step is illustrated with photographs.

Also in this material we will consider less popular methods that can be used to insulate walls from the inside.

Brief overview of other methods

They also use other technologies, among which there are both outdated, but cheaper, and modern, requiring considerable investments.

Liquid thermal insulation

Liquid heat-insulating coatings can be used to insulate rooms both outside and inside. One of these products is AKTERM Concrete. This is ultra-thin insulation based on water dispersion. It contains an acrylic binder and evacuated microspheres. This determines the scope of application of the product - the composition can be applied to concrete, brick, metal, wood, plastic, foam blocks and limestone. In addition, indoors it is possible to apply AKTERM Concrete to plaster and putty.

AKTERM Concrete – insulation from the inside

Application area:

- insulation of window slopes;

- insulation of basements, balconies or loggias;

- the need to protect walls, ceilings and floors from freezing;

- AQUATERM Concrete is used in the “warm floor” system. It can successfully replace traditional foil;

- as protection for roofs and attics from overheating during the hot season.

One of the advantages of AKTERM Concrete is its economical consumption. For the product to fully perform its functions, applying a layer of 1 mm (maximum 2.5 mm) is sufficient. This means that 1 liter of thermal insulation will be enough to properly treat 1 square meter of surface.

Advantages:

- properly applied thermal insulation coating will last more than 12 years;

- there are no solvents or volatile substances in the composition, therefore AKTERM Concrete can also be used in residential premises - apartments, private houses;

- applicable in children's rooms;

- has no smell;

- effectively protects against freezing and retains heat;

- fireproof product;

- the coating does not collapse under the influence of direct sunlight;

- easy to apply with any tool - spatulas or brush. Airless application is also possible.

An important point for those who decide to use AKTERM Concrete to insulate walls in their home or apartment - the product is compatible with acrylic-based primers and water-based paints.

How to apply thermal insulation compounds:

- The first stage is surface preparation. It is necessary to clean the walls, ceiling or floor from remnants of wallpaper and plaster. Remove dust. For this purpose, you can use a regular vacuum cleaner. Upon completion, apply AKTERM Primer (deep penetration primer) to the surface.

- The second stage is processing. The finished thermal insulation is applied with a spatula or brush onto a prepared, dry and grease-free surface. It is important to observe layer-by-layer application. The first layer is 1 mm. It dries in 24 hours. If necessary, then apply 1 more layer. It is important that the material is completely dry.

- The fourth stage is the final one. The final color of the finished thermal insulation coating is white. But if desired, it can be painted with water-based paint. This can be done only after AKTERM Concrete has completely dried.

Working with liquid thermal insulation materials is not difficult. But it is important to choose high-quality products that will not only retain heat for a long time, but will also not contain substances harmful to the body. This is especially true in situations where it is planned to insulate residential premises (bedroom, children's room, etc.) using thermal insulation.

For personal safety during the preparation and application of AKTERM Concrete, you must use personal protective equipment:

- eyes are covered with transparent glasses or a special shield is used;

- gloves on hands;

- It is advisable to change into clothes that you won’t mind throwing away after work.

If the composition gets into your eyes or exposed skin, rinse them with water.

Key Features:

- long service life, more than 12 years;

- reduces heat loss;

- reliable protection against freezing;

- applicable in residential areas;

- homogeneous mass without separation;

- the coating does not contain organic solvents and volatile compounds, is fireproof, non-toxic, making it suitable for use both outside and inside residential and industrial premises;

- dries quickly;

- easy to apply with a brush, spatula, or airless application apparatus;

- without smell;

- has a durable finish;

- tinting in light colors is possible according to the ral classic system;

- Weather and UV resistance.

Material Compatibility:

- surfaces – concrete, processed metal, plastic, brick, gas blocks, foam blocks, wood;

- primers – acrylic based;

- paints are water based.

Installation of polystyrene foam or polystyrene foam

With the advent of EPS, it became impractical to use conventional non-pressed polystyrene foam (PSB), since it has deteriorated characteristics.

Namely:

- burns and melts, releasing hazardous substances;

- has fragility, due to which pieces break under mechanical pressure;

- not protected from rodents.

In terms of parameters, it is inferior to extruded polystyrene foam, and this can be seen in the table of physical and technical properties of expanded polystyrene boards:

For example, the compressive strength of EPPS is 0.25-0.50 MPa, and that of PSB is only from 0.05 to 0.1 MPa (at 10% linear deformation), water absorption for EPPS is 0.2% of the volume, and PSB has as much as 2.0

However, light and thick slabs are still used when it is necessary to quickly and inexpensively insulate a room. We recommend using this material for cladding garages and utility rooms, that is, non-residential premises.

Spraying liquid ceramic insulation

To provide a “cold” wall with additional thermal insulation, substances are used that are applied according to the principle of painting, that is, using a special sprayer, spray gun or brush. We talked more about ways to insulate cold apartment walls in this article.

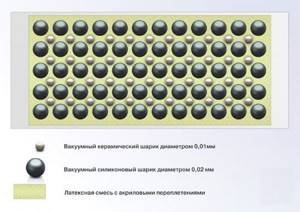

Schematic representation of the composition of the liquid-ceramic mixture: vacuum microspheres of various diameters and a latex binder mixture enriched with antifungal and anti-corrosion additives

Advantages of liquid ceramic spraying:

- moisture resistance;

- mechanical stability;

- elasticity;

- ease of application;

- environmental friendliness;

- minimal load on structures.

The main advantage is the thinness of the applied layer while maintaining important thermal insulation characteristics.

In terms of efficiency, a 1-mm layer of LCD is equal to a 50 mm thick basalt wool slab and can increase the temperature in the room by 3-4 degrees. Builders love the sprayer for its ease and high speed of application.

After applying the liquid-ceramic mixture, additional hydro- and vapor barrier is not needed. A thin layer can withstand temperatures from -60 °C to +250 °C, and, subject to application technology, lasts up to 30 years.

Cork and polystyrene foam wallpaper

Of course, gluing with one layer cannot be compared with a full-fledged heat-retaining “pie”, however, wallpaper is actively used in corner apartments and in rooms on the first floors.

Expanded polystyrene wallpaper resembles ordinary non-woven wallpaper, has a thickness of 0.3-1.0 mm, is sold in 10-meter rolls, and is glued using the same principle - end-to-end. However, special glue is designed for them.

Cork is environmentally friendly, lightweight, easy to process, and also serves as a finishing decorative coating. However, its thermal insulation properties are minimal.

In terms of efficiency, 6-mm PPS wallpaper replaces a brick wall with half-brick masonry, resists the formation of fungus and mold, and performs an additional soundproofing function

Disadvantages of the material: like PPS boards, wallpaper moves the dew point closer to the living space and is a flammable finish, like paper wallpaper.

In addition to the listed materials, eco- and glass wool, particle boards, wood concrete, foamed polyvinyl chloride and polyethylene insulation, fiberboard, honeycomb plastic boards, reflective thermal insulation with a foil layer - materials such as Penofol or Armofol are used.

Each of the listed insulation materials has the right to life and, in suitable conditions, performs its functions perfectly. We discussed in more detail all the popular types of insulation that can be used for the walls of a house from the inside, their pros and cons and characteristics in our other article.

When choosing a material, you need to focus on the technical properties, cost and complexity of installation - sometimes the installation technique causes difficulties for untrained amateurs.

Mounting options

There are various ways to attach the material. The most common are frame mounting and glue installation. The first option does not require careful leveling of the insulated surface and makes it possible to attach finishing materials without any problems. For plasterboard cladding, it is necessary to construct a frame. You can also insulate walls with plywood or plastering. In this case, the construction of a frame is not required . When choosing a method of insulation, you need to take into account the base of the walls .

Frame mount

This option is more labor intensive. But it is reliable and protects the insulation from mechanical stress.

Before starting work, the walls are cleaned and treated with an antiseptic. After this, a frame is constructed from wooden beams or aluminum profiles. The racks are attached to the walls using self-tapping screws. Depending on the width of the insulation, the pitch of the elements is selected. For mineral wool, you need such a step that there is 58 cm in the light. For foam plastic and penoplex, the distance in the light should be 60 cm.

Upon completion of installation of the frame, the insulation must be laid between the posts and additional installation must be carried out using glue; the joints are filled with polyurethane foam. After this, finishing work can begin.

When performing insulation using mineral wool, it is important not to forget about moisture insulation. The waterproofing material is attached to the insulated surface before installing the wool, and the vapor barrier covers the material and protects it from internal steam. The layers are fastened with a construction stapler .

How to deal with ice or frost?

In particularly difficult situations, ice or frost forms on the inner surfaces of the walls. This indicates insufficient wall thickness, a poorly functioning heating system and many other problems. That's not the point. The difficulties that arise must be dealt with somehow. The properties of insulating compounds may no longer be sufficient. Therefore, they should be used in combination with slab insulators.

Materials made in the form of slabs are different. These are expanded polystyrene, mineral wool, fiberboard, tiles made from shavings or concrete. Work begins with cleaning the wall surface from wallpaper or paint. Then let the wall dry. Now comes the turn to create recesses, the diameter of which is 2 cm. The depth is 5-7 cm. Wood plugs based on a gypsum or cement mixture are driven in there.

Wood slats with antiseptic properties are also mounted on the wall structure being treated. The thickness of the products depends on the corresponding insulator indicator. The slats are nailed to the plugs. The pitch is determined by the width of the slab insulation.

When everything is ready, a heat insulator is inserted between the slats. For better adhesion, it is possible to glue the slabs to the wall with a special compound. It contains ordinary cement and a polyvinyl acetate emulsion. Quantity – 20% of the cement material. Other components are bitumen and synthetic adhesive.

Why do they do this?

The most significant and taken into account reason for the method of thermal insulation inside, and not outside, is the banal simplicity of performing such work. If everything is carried out from the facade, then much more operations will be required, including disassembly and subsequent assembly of the decorative coating. Inside, you can combine the creation of a heat-insulating layer with cosmetic repairs. However, this cannot be done and the results of such work can be very disastrous. So what are the disadvantages of insulating walls from the inside?

In what situations can this be done?

Having figured out why many people regret insulating from the inside, it is necessary to analyze situations when the method of creating thermal insulation structures from the side of residential premises can still be applied. They are infrequent, but still occur:

- Impossibility of carrying out work on the outside of the walls. This happens in high-rise apartment buildings. Sometimes there is no money to hire steeplejacks, whose work is expensive and you have to create the insulation incorrectly.

- The appearance of the building's façade cannot be changed. This is also not uncommon. If nothing can be changed on the external structures of the house, you have to use internal insulation.

- Insulation technology involves creating a continuous coating that does not allow moisture to pass through. This is a modern method of insulation with sprayed polyurethane foam. However, even this method does not guarantee that negative consequences will not affect you.

Taking into account all that has been said, you can safely make a choice in the direction of external insulation. The question of which is better - insulating walls from the inside or outside should not arise at all. Definitely only external insulation. Even taking into account the fact that in most cases, work on the outside will be more expensive and more difficult to complete.

Proper insulation

To avoid the formation of condensation due to temperature changes in winter, you should strictly follow all technical requirements for insulation from the inside.

The main point when insulating is the creation of the correct heat-insulating layer. A good vapor barrier can protect the insulation from moisture, which will significantly increase its service life.

To insulate with your own hands, you need to do the following:

We purchase rolls of good quality vapor barrier film and waterproof tape for insulating seams at joints.

Insulation should be chosen with low vapor permeability. If this figure is higher than at the walls, this will help the evaporation go towards the street.

When gluing, the surface of the insulation must be thoroughly coated with glue, properly pressing it against the wall.

Installing an additional valve on the window frame will allow for additional air ventilation.

Accurate calculation of the required insulation thickness will allow you to avoid disruption of the steam-heat balance.

Before you begin installing the heating system, it is necessary to “prepare” the walls. Preparation consists of treating the walls with soil mixtures. They will help prevent mold growth.

When the wall is completely dry, you can begin installing the system.

Vapor barrier of mineral wool insulation.

must be attached to the frame on top of the insulation .

The film is secured to the wooden bars of the frame with staples using a stapler. The film is glued to metal profiles using double-sided tape or mounting adhesive.

The film is laid with an overlap of panels (at least 100 mm) and an overlap on adjacent walls, ceiling and floor (ceiling), window and door openings. The joints of the film panels are placed on the frame posts and taped with construction tape.

The junctions of the film with building structures, pipes, and electrical installations are sealed using liquid sealants.

The sealant is applied to the junction, the film is pressed against it and the film is secured from displacement with construction tape, and it is nailed to the wooden surfaces with staplers.

It is not recommended to use only tape for sealing, since gluing rough surfaces with tape does not provide the required tightness.

Next, sheets of plasterboard are attached to the frame with self-tapping screws and the wall is finished.

Continued: to next page 2

Thermal insulation. Insulation. Minvata. Styrofoam. Expanded polystyrene. Penofol. Wooden bars. Drywall. Plywood. Profile for gypsum boards

Read page: Page 1, Page 2

How else can you insulate the walls of a house from the inside?

- Alternative materials . This group includes insulation materials forgotten by time. These are straw, reeds, linen mats, cork, sawdust, clay and gypsum panels. Today, not only craftsmen, but also manufacturers practically do not remember such insulators. The main difficulty for the owner of his home is to find such natural materials.

- Additional materials . Additional materials include vapor barrier and means for creating a ventilated gap. So, galvanized rolled metal or timber with wood boards (preferably solid) can be used for lathing. The latter are subject to mandatory treatment with long-lasting protective compounds (the composition must contain antiseptics and fire retardants).