Answers from experts

Dmitry Koltsov:

It is not advisable to let the screed dry completely, but at least turn it on immediately to dry the screed some more.

Fire Horse:

Will you wait a month?)

Vladislav:

Usually this is written in the instructions for the floor - maybe 24 hours, maybe 48 hours or more... I know that some wet ones are not allowed for up to 1 month!

Marina Bashtovaya:

The drying time of the cement screed is 72 hours; after drying, you can turn on the heated floor.

Scarifier:

The standard defines 28 days; in fact, this can be done within a week.

Tymurat:

A month, I once turned it on as they advise you here, a week later it was autumn and the glue had not dried completely, 30% of the tiles flew off, and they were covered in dew drops from the inside

Eduard Sovereshny:

I read a lot that the most effective and economical heated floor comes with thin porcelain stoneware, the thickness can be from 3 to 6 mm, heats up quickly, good heat transfer, there is information here .termosib /

P-18:

The cement screed does not dry out but sets. For maximum strength, it is also sprayed with water...for at least 72 hours.

Ivan Maltsev:

Don’t talk nonsense, dear ones. The screed was done by the guys from the company Rovny Pol - .rovnypol, they told us everything

Warm floors made with semi-dry screed are turned on only after a month, and then depending on the humidity in the room. Fortunately, they saved us from this stupidity, the heat workers didn’t warn us, but the screeders, on the contrary, told us everything. Otherwise, cracks could appear... and this is awesome how bad it would be

The hot water needs to be turned on gradually and the temperature gradually increased. To avoid deformation of the semi-dry screed. Be more careful

Sergey Sokolov:

I recommend contacting TSM.

MrWait:

The heated floor can be turned on until the screed reaches 100% strength, this happens on day 25-30

Tasha Sinichka:

eco-h is a good site, everything is described in detail!

Very Samara:

Screed on a heated floor must be done with plasticizers. This allows you to avoid cracks until full strength is achieved. Source s stroy.it/usefulinfo/screedusefullinfo/plitonit-estrich/

Elena Ermakova:

If the screed has hardened, this does not mean that the screed is completely dry and the heated floor can be turned on. A month after the work is completed, use it as usual. Order semi-dry screed in Nizhny Novgorod s gintechnologi /

Vladislav:

If these are thin mats that go into tile adhesive and tiles are immediately glued onto them, then on the third day, and if these are mats that are under a screed, then as recommended above - until they dry completely.

Andrey Volkov:

in 3 weeks

Alexander Pashnyuk:

It says in the instructions - after the cement floor has completely dried

Tymurat:

After 3 days I turned it on, now I know the best way to glue the tiles back onto a mixture of PVA and cement.

boosia:

in 45 days

Caring for semi-dry floor screed

When is the best time to dig a well in the Moscow region?

As the screed dries, the cement gains its strength within 21-25 days, from the very minute the mixture was made. For all the same chemical processes occurring at the moment of screed formation, water is needed, since the solution must harden and not dry out. It is possible to dry the floor screed only after the required strength has been achieved, otherwise the screed may crack.

To prevent early drying out, it is necessary to take care of the floor screed, this means that within 3-5 days, from the very moment when the screed was filled, it will need to be spilled with water, but not too much. A simple plastic bottle, preferably 2 liters or more, is suitable for this. Make 5-10 holes in the bottle cap and that’s it. Take water and wet it. A small watering can is best suited for these purposes.

For a good result, the screed is covered with plastic film by the workers who make the screed; it can not be removed for about 1 week. After this period, the screed needs to dry naturally, for as long as possible, so the film can be removed and thrown away.

When the semi-dry floor screed dries, it is forbidden to dry it quickly using various types of equipment, as there is a possibility that it may crack and cracks may form. It is also not advisable to create drafts for 10-16 days, as this causes rapid evaporation of moisture in the cement mortar. In other words, the windows in the room must either be closed, or if there are no windows, they must be sealed with plastic film.

In order for the screed to dry more or less evenly and naturally, certain conditions must be met, namely, the temperature in the room should not be lower than +5 degrees, and there should also be no large drafts.

And while the screed is drying, you need to follow the following tips for its operation:

— pedestrian loads (up to 120 kg) are possible within one day after completion of work

— loads over 120 kg are possible after 5 days

During the operation of the screed it is prohibited:

- drop sharp and heavy objects, so to speak, sharp loads

- when the screed is installed on a heated floor, you cannot turn on the system for up to 1 month from the date of installation of the screed

— you cannot install tours, stepladders, scaffolding within 15 days from the date of installation

Poor quality maintenance of the floor screed means the presence of drafts at the site. Most people, when they feel moisture in a room, very often open the doors and windows, wanting to ventilate and dry them as quickly as possible, so this is the main mistake. Since, for uniform drying, the screed requires gradual acceptance of moisture, and not its weathering by drafts. Also, the room requires a normal temperature range of 15 to 22 degrees, since at elevated temperatures the water from the screed also quickly evaporates, which will accordingly lead to its destruction.

And lastly, you need to understand that a semi-dry screed is still sand and cement, which means early loads can deform it. This is especially true for impatient owners or workers who are trying to make room for themselves as quickly as possible. If you still need such urgency, then the best option is to lay penoplex or 2 cm (if the loads are not significant), or 3 cm, or even 5 cm (if the loads are significant), this way you save your time on the screed Nothing will happen. But still, if possible, then the screed should be allowed to dry for at least 25 days and only then begin any work with it.

How long does it take to turn on the floor after pouring the screed?

So, at least a month should pass from screeding to switching on. During this time, the fill will dry completely. This holding period assumes that the launch will not cause irreparable consequences, such as a short circuit or floor deformation. To avoid having to redo it all over again, the first thing to remember is that it is absolutely impossible to turn on the heated floor at full power.

To extend the life of the heating system, after the screed and tile adhesive have dried, turn it on for 18-20 days at a temperature of +35 ⁰C and only then set the required heat indicators. So, from the start of actions to create a flat surface to the free use of the heated floor, 50-55 days should pass.

Common Mistakes

Strict requirements for when to turn on the system after laying tiles will not guarantee a perfect job. Owners often make gross mistakes that lead to complex problems.

The most common mistakes when installing heated floors:

- Cables or mats are laid over the entire area of the room. This can cause overheating of areas under large furniture (wardrobes, sofas, beds, washing machines, etc.).

- Shortening wires. This is prohibited - the electric floor will simply fail.

- Turn on the heated floor to check its functionality until the screed or glue has dried. It is safer to check the resistance of the system cables.

- Laying heating elements on a dirty surface. Even the presence of dust in the cable grooves will negate all the work.

- Walking on wires. This can damage the conductors, which will disable the electric heated floor.

- Bricking the temperature sensor. This device should be located in a sealed corrugated pipe, so easy access to it is provided if replacement is necessary.

- Negligence. To ensure that the work has been done correctly, you need to measure the resistance before laying the elements in the screed and after drying.

- Use the system activation to speed up the drying of screed or tile adhesive. Such actions completely damage the cable.

- Neglect of tightness. Heated floor elements must lie tightly in the grooves; the presence of air pockets leads to damage to the system.

- Lack of a diagram or plan for laying heated floors. It is not necessary to draw; you can photograph the finished outline, thereby protecting yourself from damage to the cable when installing plumbing or drilling in the future.

Expert recommendations

If you decide to install an infrared floor under a tiled covering and doubt your abilities, it is better to seek help from an experienced specialist. Thus, you can not only get a functioning heating system, but also learn some tricks and in the future do this work yourself.

The main recommendations are patience and compliance with the rules, as well as the use of only high-quality building materials and heating elements. The above mistakes should never be repeated.

In order for the floor to warm the room well and last a long time, it must be installed correctly. Cables should only be laid in clean, primed grooves in already dry screed.

If the system is filled with concrete mixture, then the voids should be filled. Before and after pouring the screed, it is necessary to measure the resistance of the cables. This way you will be sure that the wire is not damaged. There is no need to rush into turning on the heated floor.

After waiting the required period, you need to gradually warm up the surface itself and the ceramic coating. It is mandatory to use a heating mat underneath the tiles. By following these recommendations, you can get an effective and aesthetically pleasing warm floor covering.

We hope that this article will help you in arranging home heating.

Screed for water heated floors - what you need to know about it

Before you begin laying the structure, you should determine how high the room allows you to raise the floor covering above the base. In low-ceiling housing, the height of the screed above the heated floor cannot be large, as this will reduce the already limited space. In such rooms it is much more practical to install electric film heating systems, which have a thickness of within one millimeter. You can lay tiles on top, and then a special glue will act as a screed. However, using electricity is not always profitable, and in most cases it will be more economical to install a water system.

The masters of the site REMOSKOP.RU have prepared for you a special master class on the topic of DIY floor screed. Step-by-step instructions with exclusive photos and video materials.

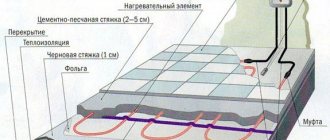

The design, based on laid plastic pipes, looks like this: a layer of film waterproofing, insulation on top, then foil and on top - laying of pipes according to the “spiral”, “snake” or “double snake” scheme, then the screed is poured and the coating is installed. The thickness of the screed under a warm floor can depend on many factors, including the height of the thresholds and the diameter of the pipes; in addition, a large layer of concrete will take longer to warm up, so pouring should be done from 7 to 10 centimeters. A screed for a water-heated floor does not deteriorate its properties at all due to accidentally occurring cracks; it’s a different matter if the heating system is made from a cable that is negatively affected by voids. Cavities are also unfavorable for the operation of film heating elements, so during pouring it is advisable to pierce the concrete layer with a metal rod.

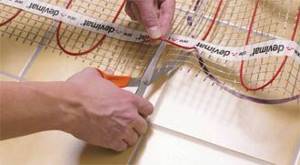

To prevent the pipes from floating in the thickness of the screed while it is in a liquid state, the entire system must be secured either directly to the insulation boards or to the reinforcing mesh. The pitch between the pipes is maintained within 15-16 centimeters. If the system is electric, everything is much simpler, since the cable is initially attached to the mesh with a special adhesive tape in increments of 8-10 centimeters, and thermal sensors are attached between the turns, which should send a signal to the control unit about the temperature along the entire length of the heating element. Filling should begin from the far wall towards the door, filling the space between the beacons, alternating with empty areas. Then, as the solution dries, after a day, the beacons are removed, and the remaining space of the room is filled.

Surface strength

Many people are interested in what load-bearing capacity warm floors have. It should be noted that the basis of this system is a concrete screed, which gives it quite high strength. You can dance or play sports on such a surface, it will not suffer from this. However, it is advisable not to install heavy furniture in the place where the cable passes - this may cause a disruption in heat transfer.

Almost any material can be used as a finishing coating. You can lay tiles, carpet, etc. on a warm floor. The only exception is parquet and laminate. Wood is a good heat insulator, so a heated floor will not be beneficial. Wooden cladding can be laid on an infrared film floor.

“Territory of Comfort” will help you choose and install a warm floor.

m or turn it on if necessary? In theory, when reaching a given temperature, the floor spends more electricity than maintaining it. When leaving for work, should you turn it off?

It's the same with a country house. Does it make sense, coming to the dacha only on weekends, to heat the house for the rest of the week, assuming that there is no water anywhere and there is no need to maintain a small plus.

We probably need to clarify so that there is no confusion 1. The floor is in the apartment. A country house in itself; it has no heated floors.

2. The question is complicated by the fact that we have a 3-phase meter. The main idea: the floor reaches operating mode (within 1-2 hours) at night, during the cheapest tariffs. Then, in the morning and afternoon, it turns on only occasionally to maintain the temperature. It seems to me that a heated floor will spend as much per day on maintaining it as it does on reaching operating temperature in the first 1-2 hours. No?

If the economic component is important to you, then the less often the floor is turned on, the cheaper it costs.

If its temperature is important to you, then you don’t need to turn it off.

stop it