Stone wool has long been considered one of the best insulation materials among the entire variety of mineral wool. It is made from gabbro-basalt rocks and is regularly used in construction work. It allows you to make a reliable heat and sound insulation layer. Today, TechnoNIKOL stone wool is considered one of the most popular materials on the building materials market.

Cotton wool "TechnoNIKOL"

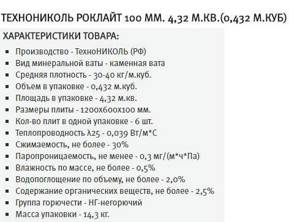

TechnoNIKOL stone wool - technical characteristics

Technonikol stone (basalt) wool is a non-flammable modern insulation made from gabbro-basalt rocks, which has ideal energy-efficient characteristics and serves as sound and heat insulation in various buildings (private houses, apartments, offices, industrial buildings, etc. .).

Thanks to its porous structure, this TechnoNIKOL insulation is capable of several times reducing the cost of natural gas and electricity for heating in the winter, and providing the necessary coolness in the summer.

Let us consider in more detail why basalt wool from this manufacturer has such high technical and economic characteristics and what types exist and it is better to use one or another type.

Scope of application of TechnoNIKOL mineral wool

Due to its physical properties and technical properties, insulation from the Technonikol company, which is manufactured in Ukraine, is widely used in the following areas:

- for sound insulation of apartment and interior partitions assembled using gypsum plasterboard profiles and sheets;

- for insulating the facades of buildings for any purpose during subsequent plastering or opening with a decorative coating (bark beetle, Venetian plaster, etc.);

- for insulation of various types of roofs (ventilated, single- and double-sloped, attic floors, etc.);

- for insulating floors using logs and OSB sheets;

- for insulation of pipelines, ventilation ducts, high-pressure steam pipelines whose temperature does not exceed 700 C.

Main types of basalt-based mineral wool TechnoNIKOL

As can be seen from the above list, the scope of application of this thermal insulation material is quite extensive, this is due to the fact that the manufacturer produces a wide range of products for each specific task. Let's take a closer look at each type of product.

Insulation Technolight

Technolight mineral insulation is used for sound and heat insulation of various structures that are not subject to constant loads. These include roofing coverings assembled from rafter legs, battens, counter-lattens and hydro- and vapor barriers.

It is also permissible to use this type of material for internal insulation of walls on a balcony or in an apartment during the preliminary assembly of a load-bearing frame, or as the main sound-proofing and heat-insulating layer of a floor on joists.

Main advantages:

- High fire safety (category NG).

- Low thermal conductivity (0.033 units).

- Excellent vapor permeability (0.3 units).

- Does not interact with concrete and metal structures.

- Prevents mold formation and protects against rodents.

Insulation Technoblock

Technoblock from the TechnoNIKOL company is a type of material for insulating various structures of industrial, semi-industrial and domestic buildings and structures, which serves as an intermediate insulating layer between load-bearing structures and the decorative cladding of the building facade.

This material is not intended for constant exposure to static loads, and demonstrates high efficiency in sound insulation or thermal insulation of load-bearing structures of buildings.

Main advantages:

- Excellent energy savings when heating or air conditioning rooms.

- High degree of resistance to elevated room temperatures (up to 700-800 C).

- High density (up to 45 kg/m3).

- Optimal compression ratio (up to 10%).

- Easy to install and cut using a regular stationery knife.

Mineral plates Tehnoruf

Tekhnoruf is the main insulating material for sound and heat insulation of industrial, semi-industrial or domestic structures, which is used in new construction or reconstruction of buildings and structures.

The main advantage of this particular brand is the ability to install any type of roofing without preliminary preparation of the base using a screed. This is possible due to the high density of mineral slabs, which is 140 kg/m3.

The main technical advantages of Technoruf:

- High density, which according to the manufacturer’s information is 140 kg per cubic meter.

- High content of organic substances (up to 4.5%).

- Low thermal conductivity (from 0.036 to 0.042 depending on operating conditions).

- High strength of the material against delamination (at least 15 kPa).

- It is not subject to combustion and can withstand high temperatures (up to 1000 C).

Mineral slabs for facades Technofas

Technofas is a modern insulation for building facades with a density of 145 kg/m3, produced with overall dimensions of 1000x500mm or 1200x600mm.

This thermal insulation material has a low level of thermal conductivity (from 0.036 to 0.042) and allows for subsequent plastering of the surface of mineral slabs with preliminary gluing with a plaster mesh.

Main advantages:

- Effective protection of buildings and structures from the negative effects of the environment.

- High thermal insulation properties.

- Resistance to combustion due to the use of basalt rocks as the main component, which can withstand temperatures up to 1000 C.

- Excellent resistance to static and dynamic loads (due to high density).

- Technofas does not interact with metal structures and concrete foundations.

Varieties

Today TechnoNIKOL mineral wool is presented in a wide range, which allows developers to choose the most successful option under certain operating conditions.

Rocklight

This thermal insulation material is presented in the form of lightweight hydrophobized basalt slabs. Experts used resin to attach the fibers. The material is not subject to combustion and moisture, and is used to provide heat and sound insulation for structures that are concentrated at different slopes.

The photo shows TechnoNIKOL Rocklight stone wool:

This version of stone wool is in great demand for low-rise construction. The cost is 1300 rubles per m3.

Heatroll

This material is presented in the form of long slabs that are rolled into a roll. In addition to the advantages inherent in mineral wool, Teploroll perfectly protects the house from noise. The material is used to insulate roofs, attics, and floors in residential buildings.

The photo shows TechnoNIKOL Teploroll stone wool:

The cost is 1600 rubles per m3.

Technoacoustic

The photo shows TechnoNIKOL Technoacoustic stone wool:

These boards have excellent moisture and fire resistance properties. The popularity of stone wool is that it has excellent soundproofing qualities. Technoacoustic can be used when arranging residential and non-residential buildings.

Mono can be used to create sound insulation in cafes, restaurants and nightclubs. The cost is 3000 rubles per m3.

Technoblock

This material is non-flammable and has excellent heat and sound insulation qualities. The base is basalt wool with a low phenol content. The material is used to construct the middle layer in layered walls.

The photo shows TechnoNIKOL stone wool Technoblock for fire protection:

The cost is 1800 rubles per m3.

Technofas

This type of mineral wool is also non-flammable. It is used for thermal insulation of house facades for further finishing with plaster. It perfectly absorbs materials that are used for finishing cladding. The cost is 60,000 rubles per m3.

The photo shows TechnoNIKOL Technofas stone wool for plaster:

But what technical characteristics of Isover mineral wool exist and what they are are described in this article.

It will also be interesting to know what the technical characteristics of Ursa mineral wool are.

But what are the properties of polystyrene foam and expanded polystyrene and how these insulation materials differ from each other is described in detail here in the article.

It will also be interesting to know what the table of thermal conductivity of materials and insulation represents. For those who want to know more about the exact materials, it is worth reading the contents of the article.

Thermal insulation material Technoflor

Technoflor is a mineral insulation based on basalt rocks, which will serve as the main insulating layer for any type of floor.

Manufacturer TechnoNIKOL produces 3 main varieties of this material:

- soil (density 90 kg/m3) - for laying on the ground, floating or heated floors;

- standard (density 110 kg/m3) - for installation as the main insulation during subsequent filling with screed or concrete mortar;

- prof (density 170 kg/m3) - for the construction of floors with increased load (industry, warehouses, gyms, etc.) which will subsequently be strengthened with a concrete base.

This type of sound and thermal insulation can withstand enormous compressive loads, which range from 12 kPa (Ground type) to 50 kPa (Prof type).

Advantages:

- Effective heat and sound insulation under increased loads.

- The possibility of subsequent finishing of the mineral coating with a rough or finishing screed based on a cement-sand mixture or concrete.

- High density.

- Effective resistance to high temperatures (up to 1000 C).

- Low water absorption.

Basalt insulation: characteristics and applications

There is a direct relationship between the characteristics and areas of application of basalt insulation. First of all, this concerns its density - the place of application depends on it . But not only.

Composition of basalt insulation

The composition of insulation based on basalt fiber is very simple: it is the basalt fiber itself, which is obtained from the melt of the stone charge, plus the binder that was mentioned above - organic resins, mainly phenol and formaldehyde.

Basalt wool in the form of a slab. Photo by Leroy Merlin

The properties of basalt fiber affect, for example, the vibration resistance of the material if the fibers are short, but the binder, as already mentioned, is not suitable for baths and saunas.

Density of basalt insulation and weight of basalt insulation 1 m3

Recall that density is the ratio of mass to volume. In simple terms, we can say that this is the weight of 1 m3 of basalt insulation.

The density of basalt insulation is the number of basalt fibers per unit volume. The fewer there are, the fluffier the cotton wool, the less it weighs. The more there are, the more densely they are located, the harder the mat.

The industry produces cotton wool of different densities for different needs and applications; let’s look at each of them.

For walls

The density of basalt insulation for walls starts from 75 kg per cubic meter.

TechnoNIKOL insulation for walls 50 mm. 12 slabs 600x1200 mm. Photo by Leroy Merlin

For floor

To ensure that the insulation does not wrinkle under the weight of the screed, it is made especially dense. The density of floor mats is from 125 to 200 kg per cubic meter .

TechnoNIKOL stone wool for flooring 8 slabs 1200x600x30 mm. Photo by Leroy Merlin

For the ceiling

But the ceiling will not withstand such weight; it is advisable to insulate it with fluffy cotton wool, so that a cubic meter weighs in the range from 40 to 75 kg. Moreover, this applies to a suspended ceiling, and if someone has a floor ceiling, then it is advisable to use cotton wool with a density of 15 kg per cubic meter , that is, even the bulk one described above is a lot.

For roofs and attics

The roof is also insulated with fluffy wool, the density is from 25 to 55 kg per cubic meter , and for the attic the lower threshold is slightly higher, it starts from 35 kg per cubic meter .

Insulation TechnoNIKOL GreenGuard Universal 50 mm 8 plates 600x1200 mm. Photo by Leroy Merlin

For facades

The facades are insulated with fairly dense mats - from 80 to 125 kg per cubic meter . If you are going to put a layer of plaster on top of the insulation, and not a ventilated facade, then the mats should be even harder and denser - in the range of 130-160 kg per cubic meter.

Basalt wool Rockwool Rockfacade 1000x600x50mm. Photo by Maxidom

Characteristics of basalt insulation: dimensions

Thickness of basalt insulation

I would like to clarify one point: that indoors, say, inside partitions, basalt wool is no longer used so much for heat conservation as for sound insulation. And this point is worth distinguishing, because the thicknesses for protection from cold or sound can vary significantly in harsh climates.

Basalt insulation 30 mm

In fact, this is not a serious value - 30 mm . This thickness is usually for fire protection, not heat protection. And that’s because fire protection does not have a binder, so the thickness of one mat cannot be large - otherwise it will simply crumble. But since they began to make threads from basalt, stitched mats have ceased to be a problem, and with them the thickness of fire protection.

Foil basalt wool Rockwool Fireplace Butts 1000x600x30 mm. Pechnik Photos

In general, of course, unfounded statements regarding the minimum thickness of thermal protection are unacceptable. decide everything . But we continue to strongly doubt that where a three-centimeter layer of cotton wool is sufficient, it is worth even bothering with additional insulation.

Maybe this thickness is enough to wrap a hot pipe or something similar.

Basalt insulation 50 mm

We can say without a shadow of a doubt that in wall partitions where the problem of sound insulation needs to be solved, 50 mm basalt insulation is used

Note that thickness says nothing about density. Therefore, it should be added that if you use basalt wool for sound insulation, then, firstly, you can take material with the appropriate marking, and secondly, its density will be 30-70 kg per cubic meter , but it is up to the specific manufacturer to decide what is better.

Insulation Rockwool Standard 50 mm. Photo by Leroy Merlin

To insulate walls, this thickness is also used, both on its own and as a layer - when it is necessary to prevent the formation of cold bridges, mats are laid in layers with the seam shifted by half the width of the mat.

As for the density not for sound insulation, then it can be anything at all.

Basalt insulation 100 mm

Also the standard thickness of basalt insulation is 100 mm . It happens that the total thickness reaches 200 mm, and there 100 mm is just two layers with a shift. And in other cases, one layer is enough. Moreover, this applies not only to walls, but also to floors, interfloor ceilings, facades, etc. In fact, everything, as already mentioned, is decided by thermal engineering calculations.

Thermal insulation PAROC eXtra Smart 1200x600x100 mm. Photo by Maxidom

Dimensions of basalt insulation in slabs and rolls

Above we have already named some typical sizes of basalt insulation in slabs and rolls; if you need exactly these, scroll up the article.

Thermal conductivity of basalt insulation

Thermal conductivity is the ability of any material object to transfer heat in the direction where it is colder. It is supposed to be something like a sandwich, where on one side it is hot, on the other it is cold, and in the middle there is a body being examined. The subject of the study is how fast it can handle heat transfer.

And in order not to do this every time, the concept of thermal conductivity coefficient was introduced, measured once and for all for an ideal sample of the material of interest.

Thermal conductivity coefficient of basalt insulation

The first thing you need to know about it is that it does not depend in any way on thickness.

The second is that it still depends on the density, but for cotton wool this point is most likely indicated in reference books in the form of a range of values characteristic of this material. Still, the densest cotton wool weighs no more than 300-350 kg per cubic meter, and a cube of basalt would weigh about three tons (about 2700 kg), so it is inappropriate to compare cotton wool with stone, it is still closer to air.

ISOROC stone wool Super Warm. Teplostroy Photos

So, the thermal conductivity coefficient of basalt insulation is 0.034-0.039 W/(m K).

Service life of basalt insulation

As for the service life of basalt insulation, manufacturers will tell you that it is measured in decades and promise up to half a century .

Of course, stone fiber might not have deteriorated even in half a century (why would it deteriorate?), but you remember that there is still a binder in cotton wool, and it slowly evaporates. And you need a binder so that the thick layer of cotton wool holds its shape and does not crumble.

Consequently, if the binder is removed over time, the fibers will not hold anything, and they will sag under the influence of gravity.

Roll of fire-retardant basalt material. Photo by Maxidom

How long will it take for this to happen? And this depends on the rate of evaporation. For example, in a sandwich chimney pipe this happens quickly. Where the sun will regularly warm up the insulation or heating - not as quickly as in a chimney pipe, but faster than without these factors.

The second important point affecting service life: humidity. The cotton wool itself may have far from exhausted its resource, but if it gets wet, then consider the thermal insulation to be covered. And drying cotton wool is difficult. Therefore, on the one hand, they take care to properly do vapor and waterproofing, and on the other hand, they leave ventilation gaps.

Cotton wool can get wet due to incorrect thermal calculations when the dew point gets inside the insulation, so they usually insulate from the outside and without neglecting the engineering part.

Mice in basalt insulation: do mice eat basalt insulation?

We knew that mice could easily make passages in basalt insulation. And that they can also get cotton wool for nests. And regarding food, they were firmly convinced that you had to be human to voluntarily harm your body.

And then we find out (attention, the information is still not verified! ) that mice eat basalt insulation if dolomite flour is added to it, because mice need it... to strengthen and grow bone tissue...

Well, you understand, yes, that after such news the mice sharply lost our respect, if they had any. How can they miss chalk if they are ready to eat stone with the smell of chipboard!

Customers' opinions (reviews)

Since TechnoNIKOL insulation has been on the construction market for quite a long time, all the main advantages and disadvantages of the material have long been identified by customers and posted on the Internet as reviews, which are presented below.

Positive:

- Excellent sound insulation and energy efficiency.

- The sheets are even with the same density and thickness.

- For the manufacture of TechnoNIKOL insulation, only environmentally friendly materials are used.

- Affordable price and wide selection for specific tasks.

- Ability to withstand high temperatures.

Negative:

- If waterproofing is performed poorly, the material gets wet and loses its properties by about 7-10%.

- Without a reinforced layer, it has poor contact with the base of the insulation.

- When working, you must use respirators or petals.

- Decomposes when exposed to alkaline solutions.

- The sheets have different densities in one package and fall apart during installation.

Anatoly Metrov author of article 4 793

tell friends

Features of thermal insulation of the TechnoNIKOL company

The products of TechnoNIKOL have been on everyone’s lips for a long time. Now, insulation made from basalt fiber and polystyrene has now been added to the range of vapor and waterproofing materials.

- Review of mineral wool products and prices

- Extruded polystyrene foam and its cost

- Reviews about TechnoNIKOL

- Product advantages and disadvantages

Range

A review of TechnoNIKOL insulation products shows that there are no particularly advanced technologies here. The division into separate series of basalt products occurs depending on the density of the fiber weaving. And certain technical characteristics are regulated simply by adding a certain amount of impregnation.

It is the latter that have led to increased interest in TechnoNIKOL mineral slabs. Thanks to them, stone wool has become less susceptible to moisture. Some buyers note in their reviews that basalt fibers absorb water with difficulty, but they remove it back quite well. This is a real breakthrough for mineral wool. A simple solution to the problem of rodents and insects that like to bask in the insulation layer was also found. At TechnoNIKOL production, it is treated with compounds that repel uninvited “neighbors”.

The company's product range includes basalt products of all popular forms:

- stitching mats;

- cylinders with a foil layer for thermal insulation of pipelines;

- hard slabs.

Detailed description

Before purchasing TechnoNIKOL stone wool, you need to familiarize yourself with its technical characteristics in more detail.

Coefficient of thermal conductivity

This stone criterion may vary depending on the type of material. Be within the range of 0.034 to 0.047 W/m*S. Thus, it becomes clear that 10 cm of insulation can retain thermal energy just as well as 38 cm of timber or 140 cm of brick.

The photo shows the thermal conductivity of TechnoNIKOL stone wool:

The insulation process using TechnoNIKOL wool is carried out in 1-2 layers.

Density of slabs

This characteristic of the material is determined by the thermal conductivity coefficient. If we consider the material Rocklight and Technolight, then its density is 30-40 kg/m3, but the material Technoflor, which is used to insulate the floor under the screed, this figure is 81-185 kg/m3.

Degree of vapor permeability

This characteristic is also one of the main ones. The lighter the material, the better its vapor permeability. Consequently, the microclimate in the house will be comfortable for living.

In addition, insulation with high vapor permeability rates has a longer service life. This is due to the fact that water molecules do not retain steam on their surface for long. Since TechnoNIKOL wool consists of 99% air, it allows steam to pass through perfectly. The degree of permeability of the material will be 0.3−0.6 mg/(m.h.Pa).

Degree of water absorption and fire-resistant properties

Since specialists used various additives in the production of TechnoNIKOL stone wool, the resulting material can perfectly retain moisture. The water absorption level of the heat insulator will be 1-2%.

Since TechnoNIKOL mineral boards are a non-flammable material, it is advisable to use them for thermal insulation in those houses where there is a high risk of fire. TechnoNIKOL slabs are not combustible, and the melting process occurs only at a temperature of 1000 degrees.

If a fire occurs, TechnoNIKOL stone wool will be able to delay the spread of the flame for some time. Moreover, it protects against fire and other materials that are less resistant to fire. But what is the thermal conductivity of mineral wool and how is it determined. The information in this article will help you understand.

The video shows the technical characteristics of TechnoNIKOL stone wool:

Life time

The service life of TechnoNIKOL mineral wool is quite long even under unfavorable conditions. The minimum service life is 50 years. This result is achieved due to the fact that the material has excellent characteristics. Basalt fibers do not rot or corrode. In addition, rodents are not scary for them. But the service life of the material can only be increased if it is installed correctly. So during installation you must take care of hydro and vapor barrier.

In what cases and where exactly foiled basalt wool is used is described in detail in this article.

What characteristics of basalt mineral wool exist and how positive they are, information from the article will help you understand.

But the video from this article will help you understand how basalt wool differs from mineral wool and what is better to choose for your construction: https://resforbuild.ru/paneli/utepliteli/bazaltovaya-ili-mineralnaya-vata-chto-luchshe.html

You may also be interested in knowing whether stone wool is harmful to health.

Mineral wool products

1. Rocklight.

One of the manufacturer’s most popular and affordable products, which has a relatively low density of 30-40 kg/m3, but at the same time a standard thermal conductivity indicator (0.039 W/m∙°C). Plates made of glued basalt fibers are available in two thicknesses: 50 or 100 mm. But unlike other brands, TechnoNIKOL offers insulation not only 60 cm wide, but also 50 cm wide.

Rocklight is positioned as a universal material for most types of work. But if you carefully study the technical characteristics and reviews of this insulation, there can be no talk of any multi-purpose use here. Rocklight is still suitable for joists or as roof insulation if you choose the right thickness and eliminate possible loads. But it’s still not worth using it in wall structures.

2. Technoacoustic.

These slabs are denser (38-45 kg/m3) and withstand compressive loads better than Rocklight insulation. At the same time, acoustic insulation reduces the level of external noise by 60 dB, which is considered a very good indicator. Such technical characteristics of the mat are ensured by the special chaotic weaving of basalt fibers. Technoacoustic slabs have found application in the construction of interfloor ceilings and internal partitions. Their thickness from 40 to 200 mm allows you to purchase insulation with the required properties for any job.

3. Technolight.

These slabs are designed for frame systems and can only work without external loads. They have two types of different densities:

- Extra (up to 38 kg/m3);

- Optima (up to 42 kg/m3).

4. Heatroll.

Medium-density basalt mats (25-35 kg/m3) have similar properties and scope of application to “acoustic”, but due to their lower weight they are easier to install.

5. Technoblock.

It is used as thermal insulation under facade cladding, that is, on vertical surfaces. Although, at a density of 40-70 kg/m3, mineral wool insulation does not retain its linear dimensions for long. However, bonding the fibers with phenolic resins made it possible to reduce the shrinkage of the Technoblock. The manufacturer also took care of better resistance of thermal insulation to moisture, although the use of a water barrier does not cancel this.

Technoblock basalt slabs are available in the following modifications:

- Standard - according to reviews, this insulation does not behave well on vertical surfaces. At a density of 40-50 kg/m3, the fibers adhere less well to each other, and the ligaments are destroyed simply under the fingers even at the time of installation.

- Optima is a medium-density basalt insulation (50-60 kg/m3), which performs well in frame partitions.

- Prof - with the maximum specific gravity in its group (70 kg/m3) has improved sound absorption.

Please note: all insulation materials of the “light” series, including the much-advertised Rocklight, are effective only in horizontal and flat structures. On vertical surfaces, there is a high risk of mineral wool shrinking and sliding if care is not taken to secure it tightly enough.

6. Technovent.

Opens a list of products with a higher specific gravity. It has a density in the range of 72-88 kg/m3 and compressive strength in different versions from 10 to 15 kPa. This is a sufficient indicator for installation under ventilated facades, for example, made of siding.

7. Technoflor.

Here we can already talk about acceptable rigidity, allowing the use of thermal insulation under a small compressive load. Available in several versions:

- Soil (80-100 kg/m3) – slabs 40-150 mm thick, insulation can withstand pressure up to 12 kPa.

- Standard (100-120 kg/m3) is twice as strong, since it retains about 90% of its volume under a load of 25 kPa.

- Prof (155-185 kg/m3) – has a maximum strength index of 50 kPa.

TechnoNIKOL in the description for this group of products allows the use of basalt wool for the installation of Warm Floor systems, installation under a screed and direct laying on prepared soil.

8. Technofas Effect.

This TechnoNIKOL insulation is used under plaster in facade work. According to reviews, it behaves really well on vertical walls and does not shrink due to its density of 130-135 m3/kg. Another plus is the peel resistance of the layers. But the cost of thermal insulation is one of the highest in the TechnoNIKOL product catalog.

9. Technoruf.

One of the densest and most compression-resistant products of the TechnoNIKOL brand (110-200 m3/kg). The manufacturer suggests using it to insulate flat roofs. The range of slabs is quite large: for two- and single-layer laying of variable hardness. Types marked H are chosen as a base, and Tekhnoruf V is used for a more durable top coating.

In the Galtel version, the basalt insulation has the shape of a wedge of standard width or with sides of 100x100 mm. Full-size slabs allow slopes to be leveled even at the level of the roofing pie, ensuring effective water drainage. Narrow fillets are used to create neat and smooth joints between a flat roof and side walls.

| Insulation | Thermal conductivity W/m∙°С | Moisture absorption,% | Strength kPa | Price per pack, rubles |

| Techno Rocklight 1200x600x50 | 0,039 | 2 | 30 | 380 |

| Technoacoustic 1200x600x100 | 0,035 – 0,04 | 1,5 | — | 860 |

| Technolight Optima 1200x600x50 | 0,034 – 0,042 | 1,5 | — | 680 |

| Technovent Standard 1200x600x100 | 0,036 – 0,039 | 1,5 | 10 | 920 |

| Technoflor Standard 1200x600x50 | 0,034 – 0,047 | 1,5 | 25 | 930 |

| Heatroll 5000x1200x50 | 0,036 – 0,041 | 2 | — | 590 |

| Technoblock 1200x600x50 | 0,035 – 0,037 | 1,5 | 30 | 840 |

| Technofas 1200x600x100 | 0,038 – 0,042 | 1 | 45 and 15 to break away | 1020 |

| Technoruf N30 1200x600x100 | 0,038 – 0,042 | 1,5 | 0,03 | 830 |

Other technical characteristics of TechnoNIKOL insulation are approximately the same for all basalt products:

- Flammability - NG.

- Vapor permeability – 0.3 mg/m∙h∙Pa.

- Operating temperature range: +60-400 °C.

Types of TechnoNIKOL materials and their technical characteristics

TechnoNIKOL basalt wool

1. Rocklight - is a slab of basalt fibers. A low phenol content resin is used as a binder. This increases the environmental friendliness of the material, which undoubtedly pleases the consumer. This insulation is nonflammable, moisture resistant, and retains heat remarkably well. Used for thermal insulation of private houses. They can be used to insulate both horizontal, vertical or angled structures. For example, the walls of attics, frame houses covered with siding, floors and ceilings. The loads are not expected to be very high.

2. Thermal rolls are long mats of stone wool wound into rolls that have good sound insulation properties. They also do not burn, do not get wet and have a low phenol content. They are good for insulating roof slopes, attic walls, ceilings between floors and floors. In addition to protection from the cold, they also protect well from noise.

3. Technoacoustic - as the name implies, it is intended specifically for soundproofing purposes. This is a non-flammable and moisture-resistant cotton wool made from basalt fibers arranged in a special way. Thanks to their location, the material is able to absorb up to 60 decibels of noise. It is used for sound insulation of frame-sheathing partitions, suspended ceilings and floors that are not subject to heavy loads. Moreover, this insulation will be good in an apartment, in a house, and in an office space. And for soundproofing a club or restaurant, it is simply an ideal option.

Sound absorption class for the total thickness of the insulation layer:

- 50 mm - 212 NSV

- 100 mm - 211 NSV

- 150 mm - 211 NSV

- 200 mm - 111 NSV

4. Technoblock - is a low-phenolic slab, which, like previous materials, is not afraid of fire and water, and also protects from extraneous noise. They are used to retain heat and absorb sound in laminated masonry, frame and siding walls.

Table of characteristics of TechnoNIKOL basalt wool

| Options | Rocklight | Heatroll | Technoacoustic | Technoblock |

| Thermal conductivity at 10 0С, (W/m·C) | 0,039 | 0,036 | 0,035 | 0,035 |

| Vapor permeability, not less, mg/(m h Pa) | 0,3 | 0,3 | 0,3 | 0,3 |

| Water absorption by volume, no more, (%) | 2,0 | 2,0 | 1,5 | 1,5 |

| Density (%) | 30-40 | 25-35 | 38-45 | 40-50 |

| Flammability (degree) | NG | NG | NG | NG |

| Compressibility, no more (%) | 30 | 55 | 10 | 8 |

Extruded polystyrene foam TechnoNIKOL

1. XPS TECHNONICOL CARBON ECO – a range of insulation materials intended for use in the construction of cottages and houses with a small number of floors.

2. XPS TECHNONICOL CARBON ECO DRAIN – expanded polystyrene boards with special drainage grooves. It is used to organize foundation drainage, as well as flat roofing. In the latter case, drainage grooves help improve ventilation. And when the foundation is insulated, rain and drainage water flows through them.

PPS slabs

XPS Carbon Eco extruded polystyrene foam is primarily used for thermal insulation of foundations. Polymer boards are available in several versions:

1. Fas - used for cladding plinths and foundations for subsequent plastering. It has a rough surface that increases adhesion to solutions.

2. SP - used for thermal insulation of “Swedish slab” type foundations, therefore the products are given special rigidity, allowing them to withstand bending loads of up to 0.3 MPa.

3. Drain - can be used for roof insulation or when building a foundation in water-logged soils, where effective moisture removal is required. Therefore, drainage grooves are cut into the slabs.

4. The professional series of polystyrene insulation from TechnoNIKOL Carbon Prof are very interesting. They implement a technology that combines low density and increased strength in one material:

- Slope – a set of wedge-shaped EPS slabs for creating inclined surfaces with a slope of 1.7-8.3%.

- Sand is a special insulation material from TechnoNIKOL for the manufacture of sandwich panels.

- Solid - used when forming coatings with very high loads.

- Ts-XPS - designed for laying under a dry screed and already covered with cement-bonded particle boards, supplied to order.

| Insulation | Density, kg/m3 | Thermal conductivity W/m∙°С | Bending strength, kPa | Price per pack, rub. |

| Eco | 26 – 32 | 0,029 | 250 – 300 | 1290 – 2600 |

| Slope | 28 | 0,028 | 350 – 400 | 1160 – 2000 |

| Sand | 28 | 0,03 | 300 – 700 | 1200 – 1840 |

| Solid | 36 – 60 | 0,031 – 0,035 | 700 | 1470 – 1800 |

TechnoNIKOL XPS slabs absorb water no more than 0.2% of their volume during the day. Similarly, EPS is impervious to steam and air (0.005-0.011 mg/m∙h∙Pa), but has a relatively small range of permissible temperatures: -50-75 °C.

Such properties determine the main scope of application of thermal insulation when carrying out work in the basement of buildings. It can also be installed in roofing structures. But do not forget that such coatings will require the organization of good ventilation in residential premises, and the flammability group G3-G4 is not conducive to the free use of polystyrene on roofs.

Reviews and opinions

“I have a cold garage - one brick walls are clearly not enough. Of course, there is a potbelly stove, but in winter the effect is felt only if you are near it. I don’t see the point in laying anything serious, so I just lined everything from the inside with TechnoNIKOL basalt insulation. It turned out quickly and inexpensively. The normal temperature remains inside for another two days after the stove goes out.”

Anton, St. Petersburg.

“I used TechnoNIKOL Rocklight mineral wool products for the first and last time. The top and bottom sheets of the packaging could be thrown away immediately: they are thin and simply fall apart in your hands. Those slabs in the middle correspond to the dimensions declared by the manufacturer, but are completely uneven in density - somewhere thick, and somewhere empty. So I’m very disappointed in the quality.”

Denis, Kazan.

“The neighbor suggested installing TechnoNIKOL for the facade under the plaster. It’s good that the salesman in the store was smart - he suggested that alkaline solutions should not be applied to the insulation. So we had to abandon the cement finish in favor of a more expensive polymer finish - we couldn’t save money. But the result is really good. I heat the dacha irregularly, but there is no dampness or mold on the walls. In my opinion, this is already a plus. The façade also looks fine, as long as it hasn’t sagged or cracked anywhere.”

Igor Vladimirovich, Nizhny Novgorod.

“At work I often come across TechnoNIKOL products. And to those who leave bad reviews, I can say one thing: what you paid for is what you got. These insulation materials have such a peculiarity - all slabs and mats of low cost are, to put it mildly, of low quality. But it’s worth turning to normal and expensive models, and - oh, miracle! – it turns out that TechnoNIKOL does not shrink, does not fall apart into fibers and retains heat perfectly. In general, don’t try to save on your own comfort.”

Mikhail, Moscow.

Summary: Pros and Cons

A review of basalt and polystyrene insulation materials produced by TechnoNIKOL shows that in terms of thermal insulation properties, the difference between them is small. But other technical characteristics should be taken into account when selecting materials for work in different parts of the building:

1. For roofs, walls, interior decoration and structures where there is at least a minimal risk of fire, you should prefer basalt products of suitable density.

2. For the foundation, plinth, and floors, it is better to choose TechnoNIKOL extruded insulation.

Basalt materials are good because they are light in weight and have sufficient flexibility, which simplifies self-installation. They are non-flammable and environmentally friendly.

Their disadvantages include hygroscopicity and the inevitable loss of insulation volume after 10-15 years, which is why gaps will appear in the insulating shell that allow cold to pass through. And in general, the technical characteristics will noticeably deteriorate. Also, reviews of TechnoNIKOL products are full of complaints about the heterogeneity of mineral wool. The light series especially suffer from this: Rocklight, Technolight, Heatroll. EPS also has a low density, but at the same time its strength indicators significantly expand the possibilities of using insulation for load-bearing structures and operating roofs.

Pros and cons of basalt insulation

We always say that similar things are revealed by comparison. The pros and cons of basalt insulation are revealed, say, against the background of glass wool or slag wool.

Advantages: it does not chip like glass wool, does not contribute to rusting like slag wool, and has a significantly higher operating temperature than they do.

Insulation Izba Light Super 50 mm. Photo by Leroy Merlin

Disadvantages: binders based on organic resins are harmful to human health, mice easily settle in stone wool, the binder evaporates over time, and the fibers then settle (bad for vertical locations).

Basalt insulation: environmentally friendly and harmful to health

Since we have already mentioned organic resins, let's say this: all manufacturers who produce certified products must prove that the evaporation of phenol and formaldehyde does not exceed MPC standards . And the MPC standards are precisely responsible for the environmental friendliness of basalt insulation and the absence of harm to health within the limits specified there.

However, there are situations where evaporation is higher than usual. This happens where the room temperature is high , for example, in steam rooms of baths. Therefore, special stone wool is produced for steam rooms.

Basalt insulation without phenol and formaldehyde

But this, by the way, is a question that we were not able to fully clarify: yes, there is stone wool on sale, which can be used to insulate steam rooms in baths, but we don’t know whether this basalt insulation is really free of phenol and formaldehyde. Perhaps the concentration of resins there is simply reduced.

We believe that if a replacement for harmful resins was found that was adequate in price and quality, then all stone wool would be made with such a binder, and not just for baths.

The real absence of a binder is possible only where it is not needed - in stitched mats . And they are on the market.

Thermal insulation based on stone wool

Non-flammable, hydrophobized heat and sound insulating materials made of mineral wool based on basalt group rocks.

Stone wool produced by TechnoNIKOL is divided by area of application. The range includes thermal insulation for plastered and ventilated facades, pitched and flat roofs, floors, walls, etc.

In 2008, TechnoNIKOL Corporation introduced innovative thermal insulation to the market - double-density slabs. TECHNONICOL products are distinguished by high heat-saving ability, fire safety, good sound absorption, hydrophobicity, strength and resistance to deformation. All thermal insulation materials of the TECHNONICOL brand are produced in accordance with technical specifications, certified and environmentally safe. TechnoNIKOL stone wool production plants are equipped with high-tech production equipment. A Scientific Technical Center (STC) has been created, the main goals of which are: in-depth analysis of the properties of raw materials, materials, finished products, technological processes, information in order to use the most modern and effective methods to produce products of the highest quality. To achieve maximum satisfaction of both external and internal consumers, the company actively uses the principles of total quality management. Environmental safety is closely related to production safety. The labor protection system at the enterprise is set at the highest level.

Where can I buy? Who will install it? Proven solutions for your construction. TechnoNIKOL systems. Insulation of facades

Non-flammable, hydrophobized heat and sound insulating materials made of mineral wool based on basalt group rocks.

Stone wool produced by TechnoNIKOL is divided by area of application. The range includes thermal insulation for plastered and ventilated facades, pitched and flat roofs, floors, walls, etc.

In 2008, TechnoNIKOL Corporation introduced innovative thermal insulation to the market - double-density slabs. TECHNONICOL products are distinguished by high heat-saving ability, fire safety, good sound absorption, hydrophobicity, strength and resistance to deformation. All thermal insulation materials of the TECHNONICOL brand are produced in accordance with technical specifications, certified and environmentally safe. TechnoNIKOL stone wool production plants are equipped with high-tech production equipment. A Scientific Technical Center (STC) has been created, the main goals of which are: in-depth analysis of the properties of raw materials, materials, finished products, technological processes, information in order to use the most modern and effective methods to produce products of the highest quality. To achieve maximum satisfaction of both external and internal consumers, the company actively uses the principles of total quality management. Environmental safety is closely related to production safety. The labor protection system at the enterprise is set at the highest level.

Where can I buy? Who will install it? Proven solutions for your construction. TechnoNIKOL systems. Insulation of facades

Popular posts

- Chair for dressing table Chairs for dressing tables in Moscow - 189 Products Company from Moscow, delivery 29643 a In…

- Silicone sanitary sealant Silicone sanitary sealant white in Moscow - 1491 products Company from Moscow, delivery (tomorrow) 140...

- Shelf in the hallway Currently, there are a huge number of different options for shelves in the hallway, and this is directly ...

- TechnoNIKOL insulation characteristics TechnoNIKOL - technical characteristics of the material and its wise choice In the cold season, you want…