Types and characteristics

The brand produces different types of cotton wool, suitable for different conditions.

Each type has its own technical characteristics. Since wool varies in hardness and density and, accordingly, in areas of application, the characteristics can differ significantly for different types. Soft cotton wool,

made of thin fibers with a lot of air space between them, it is used to insulate frame walls, ventilated facades and other surfaces that will not be subject to heavy loads.

Medium hard wool

has a higher density than soft. Its use is advisable to isolate ventilated facades and ventilation ducts, where there may be high-speed flows. It can be used in the same cases as soft. But since its price is higher, this will increase the cost of work.

Tough

used for surfaces experiencing heavy loads. For example, it is needed to insulate a wall before reinforcement, or to insulate a floor when pouring it with a warm screed.

Interesting foil version

. During installation, the side with foil faces the inside of the room and reflects heat, preventing it from escaping outside, which provides the effect of double thermal insulation. Foil coating can be either one-sided or double-sided. Foil wool is an almost universal material; it can be used for a wide range of jobs.

There are also cylindrical insulation materials specially created for pipes. Their use is justified for pipes with a diameter greater than 5 cm.

Cotton wool is produced in rolls, slabs, or in the form of a shapeless mass. To apply this mass, pneumatic equipment is required.

, “Master Technoblock” insulation is deservedly popular.

, as it has excellent characteristics. It is produced in slabs, the dimensions of which can be 1200x600x30 mm or 1200x600x100 mm; There are other configurations as well. This is quite an expensive material, but its quality justifies the price.

Its advantages:

- is waterproof;

- is a breathable material;

- it has a long service life;

- not subject to ignition;

- has sufficient density;

- it is easy to install;

- it copes well with the functions of heat and sound insulation;

- rodents and insects do not grow in it.

The material exists in three types, which differ in density.

At Technoblock Standard

it is 40-50 kg/m3. When loaded, it compresses by 10%.

"Optima"

– denser material – 60 kg/m3. Its compression is 8%. It has a remarkable property: its shape is completely restored after load.

The densest – “Technoblock Prof”

with a compression of 5% and a density of 65-79 kg/m3.

In domestic construction, Technoblock Standard is often used. When building housing, it is used as a central layer in layered masonry; it is used to insulate frame walls, facades, basements, attics, and garages. It is easy to cut with scissors or a knife and is easy to install.

This insulation is not flammable, but its optimal temperatures are from -60 to +200 ° C. It has a very long service life, which significantly exceeds 50 years. Technical characteristics are maintained throughout the entire period of operation.

Before laying the insulation, the surface must be cleaned and a frame for laying thermal insulation must be mounted on it. The adhesive composition should be applied both to the wall and to the insulation. Waterproofing is usually applied on top of the insulation, and plaster is applied to it.

“Technolight” is also often used

. The line is also available in three versions depending on density, and is also produced in slabs with variations in size.

"Technolight" is used for structures that do not experience large external loads, since the density of these insulation materials is less than "Technoblock". For example, “Technolight Extra” has a density of 30-36 kg/m3. However, the quality does not suffer; the insulation has excellent properties and is inexpensive.

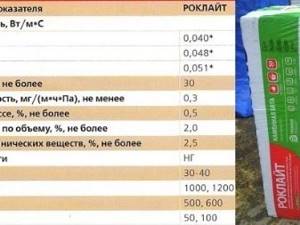

A table in which the manufacturer enters all the necessary characteristics of the materials usually helps you choose the appropriate option.

Varieties

There are several types of TechnoNIKOL wool on the modern construction market, so specialists have the opportunity to choose the most suitable option for certain operating conditions. Let's look at each type in detail.

Rocklight

This insulation is made up of lightweight hydrophobized basalt slabs. The fibers were bonded by specialists using resin. Rocklight is not afraid of high temperatures and water. It is rational to use it for sound and heat insulation of buildings concentrated at different angles.

Rocklight

This type of TechnoNIKOL wool is actively used for insulation of low-rise structures. The average cost varies between 1350 rubles per meter³.

Heatroll

It consists of long slabs rolled into rolls. In addition to the standard advantages of mineral wool, Teploroll is an excellent sound insulation. Heatroll is most often used to insulate roofs, attics and floors in residential buildings. The average price is 1650 rubles per meter³.

Heatroll

Technoacoustic

This type of TechnoNIKOL is characterized by high fire and moisture resistance. Technoacoustic is popular among specialists due to its good soundproofing quality. Residential and non-residential premises can be equipped with cotton wool.

It is often used for sound insulation in the construction of cafeterias, restaurants and nightclubs. The price starts from 3,000 rubles per meter³.

Technoacoustic

Technoblock

The technoblock is resistant to combustion and performs well as a sound and heat insulator. It is based on basalt wool with a low concentration of phenol. They equip the middle layer in layered walls. The price starts from 1,790 rubles per cubic meter.

Effect of insulation

Technofas

Another non-flammable type of stone wool is TechnoNIKOL. They are used to insulate the facade of the house, which will then be finished with plaster. It absorbs well the materials used for finishing cladding. Technofas is the most expensive type of TechnoNIKOL wool. For a cubic meter you will have to pay more than 59,000 rubles.

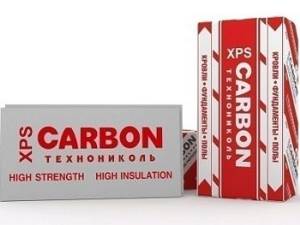

Expanded polystyrene TechnoNIKOL - advantages and varieties ↑

Expanded polystyrene TechnoNIKOL outperforms other insulation materials in density, thermal conductivity, and moisture resistance. The material is also very light, it is easy to work with and carry out delivery and loading and unloading operations. Disadvantages include a lower degree of fire resistance. At a certain temperature, polystyrene foam burns, releasing toxins.

Expanded polystyrene TechnoNIKOL is positioned as an environmentally friendly material

There are many varieties of TechnoNIKOL insulation, they differ in characteristics and scope of application:

- CARBON ECO: a universal type used for insulating low-rise buildings.

- CARBON ECO DRAIN. The slabs have drainage grooves that help drain rainwater when insulating the foundation, or for better ventilation when finishing the roof.

- CARBON ECO FAS. Improved adhesion qualities, used for finishing facades.

- CARBON ECO SP. It is used for arranging foundations made using Swedish plate technology. It has increased rigidity and a low degree of thermal conductivity.

- Professional insulation materials designed for insulation of multi-storey buildings, roofs, foundations, etc.

Insulation of roof and ceiling

Insulation of a horizontal surface is possible in two ways.

In the first case, a vapor barrier membrane and a layer of dense (from 150 kg/m3) mineral wool are laid on the floor slabs. A cement-sand mortar is used to screed the insulation on top.

The second option fully complies with the “ventilated facade” technology. Install the cake: vapor barrier, insulation between the joists, waterproofing membrane, counter-lattice, finishing layer of OSB panels, plywood, chipboard or floorboards.

If the attic is not intended for people to be there, the finished floor is not laid.

Sloping roof slopes must be made using ventilated facade technology.

Extruded polystyrene

Extruded polystyrene

TechnoNIKOL Corporation's product range includes extruded polystyrene.

Purpose and places of use

The material is produced in the form of plates and has improved thermal insulation and strength characteristics. This allows it to be used at various stages of construction.

Expanded polystyrene insulation:

- walls, floors, ceilings of buildings;

- roofing and attics;

- walls of basements and ground floors;

- blind areas.

Polystyrene is a good sound insulator and can be used in interior partitions.

Raw materials and manufacturing method

Technology for the production of extruded polystyrene foam

The material for production is polystyrene granules, which are produced by the chemical industry from petroleum products.

In industrial lines, polystyrene is heated to the melting temperature and fed to the extrusion head using screw devices. Under the influence of hot steam and high pressure, polystyrene foams, after which it is fed to the molding line, where it is given a flat shape.

After secondary foaming, the mass is molded on stretching machines, and after cooling, it is cut to the required size.

As a result of extrusion, a material is obtained consisting of many air bubbles enclosed in an individual shell. The shells are tightly welded together, which makes the extruded polystyrene waterproof and weakly absorbs moisture - all places of possible penetration are closed to it.

Technical specifications

For insulation, the main parameters are thermal conductivity, ability to withstand moisture and strength.

Parameters of extruded polystyrene:

- thermal conductivity 0.029 - 0.031 W/(m•K);

- water absorption - 0.2% by volume;

- vapor permeability - 0.014 mg/(m•h•Pa);

- operating temperature - -70 – +70 °C;

- thickness - from 30 to 100 mm;

- length 1180, width 580 mm.

You can walk on polystyrene laid on a horizontal surface carefully - any dents that appear will disappear after a short period of time

Advantages and disadvantages

The positive and negative properties of a material are directly related to its structure and technical characteristics.

The advantages of the products include low thermal conductivity, compression resistance, and non-flammability. The material does not rot and does not support the spread of fungi and mold.

We advise you to study - How to choose a parquet board - criteria and parameters that need to be taken into account

The absence of cavities and moisture in the material makes it resistant to negative temperatures - styrofoam does not freeze.

I consider the low vapor and air permeability of the slabs to be the negative aspects.

Low weight ensures ease of installation - the sheets can be easily raised to any height, and reliable brackets are not needed for fastening.

The high extrusive properties of the material ensure reliable adhesion to the plaster.

Polystyrene is produced with grooves and with careful installation there are no cold bridges.

The disadvantages include:

- destruction from sunlight (ultraviolet radiation);

- high price;

- release of harmful substances when heated;

- possible infestation of rodents.

The whole complex of positive and negative qualities is taken into account when choosing extruded polystyrene as thermal insulation.

Advantages and disadvantages

The high consumer demand and popularity of TechnoNIKOL mineral wool are due to a number of undeniable advantages of this material.

- Low thermal conductivity and high heat-saving qualities. Thanks to their fibrous structure, the slabs are able to act as a reliable barrier to airborne, impact and structural noise, while providing high sound absorption and eliminating heat loss in the room. A slab with a density of 70-100 kg/m3 and a thickness of 50 cm is capable of absorbing up to 75% of external noise and is identical to brickwork one meter wide. The use of mineral wool allows you to reduce the cost of heating the room, which leads to significant savings.

- The high resistance of mineral slabs to extreme temperatures allows the material to be used in any climatic conditions without restrictions.

- Environmental safety of the material. Mineral wool does not release toxic substances into the environment, and therefore can be used for both external and internal work.

- Mineral wool is not of interest to rodents , is resistant to mold and is immune to the effects of aggressive substances.

- Good vapor permeability and hydrophobicity ensure normal air exchange and do not allow moisture to accumulate in the wall space. Thanks to this quality, TechnoNIKOL mineral wool can be used to insulate wooden facades.

- Durability. The manufacturer guarantees from 50 to 100 years of impeccable service of the material while maintaining its working properties and original shape.

- Fire resistance. Mineral wool does not support combustion and does not ignite, which allows it to be used for insulation of residential buildings, public buildings and warehouses with high fire safety requirements.

- Easy installation. Minslabs are easy to cut with a sharp knife, do not become painted or break. The material is available in sizes convenient for installation and calculation.

The disadvantages of TechnoNIKOL mineral wool include increased dust formation of basalt models and their high cost. There is also low compatibility with some types of mineral plaster and general heterogeneity of the structure. Vapor permeability, despite a number of positive characteristics of this property, requires the installation of a vapor barrier. Another disadvantage is the impossibility of forming a seamless coating and the need to use personal protective equipment when installing insulation.

We recommend: Which boiler is more profitable - gas or electric?

Advantages and disadvantages

Domestic products have many advantages:

- Low thermal conductivity. Heat loss in the premises will be minimized, which will be especially noticeable in the cold season.

- Resistance to deformation. During operation, the insulation does not shrink and does not change in size.

- No formaldehyde. Brand insulation does not release toxins into the air, so it will not cause harm to health.

- Easy to install. Insulation with the corporation's products is carried out quickly and does not require the involvement of outside specialists.

- Corrosion resistance. The brand's insulation materials are passive to biological and chemical activity.

- Fire resistance. TechnoNIKOL thermal insulation is a kind of barrier to spreading fire.

- Resistant to decomposition. Regardless of weather factors, the brand’s insulation is not subject to rotting.

- Rodent resistant and durable.

Depending on the type, its service life is up to 50 years.

Brand insulation reduces home heating costs. Regardless of changes in the temperature regime of external factors, their surface temperature will remain unchanged. No specialized equipment is required for installation. Some types of material can be installed on soft soil. Other options (for example, “Extra”) are an intermediate layer for subsequent protective and decorative plastering using a special reinforcing mesh.

Each type of material from the produced range is tested for compliance with established GOST standards for the main types of characteristics, which include:

- compressive and bending strength;

- thermal conductivity under different conditions;

- water absorption;

- vapor permeability;

- flammability;

- flammability;

- toxicity level;

- operating temperature;

- geometric indicators (dimensions).

For each of the indicators there is a marking indicating the data and a mark with the test values. This allows the buyer to become more familiar with the characteristics and choose the right option for a specific foundation, climate of the region, type of foundation and construction material. Any brand insulation is certified.

The disadvantages of some types of insulation include several factors:

- Some of them must be protected from UV rays and precipitation during transportation.

- They can be stored under a canopy in the open air. However, this is only allowed if there is secure packaging. In this case, a prerequisite is the presence of bars and pallets.

- After 10 years of operation, some types of thermal insulation material lose their original properties.

- Variants with lower density in individual series are marked by heterogeneity of structure. This is especially true for mineral wool.

- The difference in quality between budget and expensive types of material is obvious. In an attempt to save money, the quality of insulation and durability are lost.

- Alkaline solutions cannot be applied to them.

Roofing materials "TechnoNIKOL"

TechnoNIKOL products include waterproofing materials, roofing coverings, insulation materials and additional elements of a new generation. They are manufactured using modern technologies on advanced equipment equipped with a computer system with strict quality control. Therefore, the Technonikol brand enjoys well-deserved popularity and is widely used in industrial and private construction.

Shinglas tiles meet all the necessary requirements for water resistance, mechanical strength and heat resistance

Roll roofing materials

The corporation supplies its products to the market in different price categories, as they say, for every taste and budget. This is another advantage of TechnoNIKOL products, among which you can easily select the necessary products for different categories of buyers.

In particular, TechnoNIKOL roll coatings are divided into the following types:

- Economy class. Products of this category are produced by double-sided application of a binder bitumen composition (bitumen + mineral filler) onto a polyester or fiberglass - fiberglass or fiberglass - base. The top is covered with a protective layer of coarse-grained slate, polymer film or fine-grained sand. The leader in this group of products is “Bikrost” - high-quality waterproofing that meets international standards.

- Standard. Products in this line are manufactured using the same technology as economy products. But some brands have added an SBS modifier (styrene-butadiene-styrene), due to which the products have better tensile strength and absolute waterproofness. Therefore, such coatings are more expensive. They are used on low-budget construction sites for the installation of hydro- and vapor barriers. Fused roll materials “Linokrom” and “Bipol” are popular among private developers.

- Business Class. Products of this type are also presented at their merits - “Ecoflex” waterproofing is produced with the addition of an APP modifier to the binder component, which provides it with high heat resistance (not lower than +130 °C). The Uniflex modification contains a much larger amount of polymers and is therefore more plastic.

- Premium Premium-class products are characterized by a considerable service life - up to 30 years, fire safety ("Technoelast Flame Stop") and decorative properties (colored "Technoelast Decor" based on cross-reinforced polyester) and are used on elite roofs with a high slope and complex design.

When choosing a soft material, pay attention to the indicator “flexibility temperature on the beam R 25 mm or R 10 mm” - the higher its negative value for the same radii, the better. With uniform temperature indicators, the smaller the radius, the better, which means there are more polymers in the material.

This is very important for consumers, since the flexibility indicator determines the maximum air temperature for working with this material in winter. It also characterizes strength - it indicates the minimum temperature at which there will be no ruptures and detachments of the binder component, and therefore no cracks on the front side and crumbling of the material when bent.

Video: laying rolled roofing materials "TechnoNIKOL"

Thermal insulation

In this direction, the corporation implements:

- stone wool and innovative double-density thermal insulation boards made on its basis;

Double-density slabs are characterized by high heat-saving ability, fire safety and resistance to deformation

- fire protection systems;

- high-strength extruded polystyrene foam, which is sometimes even used as auxiliary or load-bearing structures;

Extruded polystyrene foam does not absorb water, does not swell or shrink, is chemically resistant and does not rot.

- diffusion membranes.

Sound and heat insulation products of this line, which are in great demand, are “Technolight”, “Rocklight”, “Technoblock”, “Bazalit L”, Tyvek® Soft and others.

Video: insulation of facade and walls with extruded polystyrene foam

Roofing coverings "TechnoNIKOL"

Let us immediately note the famous brand “Shinglas”. This is a flexible (elastic) tile in the form of small rectangular modules with figured cutting.

Shinglas flexible bitumen shingles are used on pitched roofs of both simple and complex configurations, up to domes

It consists of three main elements: fiberglass - a reinforcing base with high tensile strength, basalt granulate to protect the bitumen layer from UV radiation and mechanical damage, as well as improved bitumen.

Video: open installation of flexible tiles in the valley, part 1 - preparatory stage

Thanks to the basalt topping of the outer layer, a rough surface is formed, which prevents avalanches of snow and protects the roof from fading. The sand-treated bottom layer prevents the tiles from sticking together. And strips of sticky mixture applied on the same side ensure sintering of the shingles on the roof. The result is a continuous, voluminous and amazingly beautiful coating, which is highly reliable, absolutely safe and durable.

Video: open installation of flexible tiles in the valley, part 2 - tiles and aerator

Composite tiles also deserve attention. It is intended for very discerning consumers, for whom prestige and reliability come first. These tiles are made from a combination of natural stone granules (top layer) and aluzinc. Thanks to natural components, the metallic sheen of the material is eliminated and the effect of natural tiles is created.

The elegance of details and smoothness of TechnoNIKOL Luxard Classic composite tile panels ideally complement the architectural ensemble of a country house

Aluzinc, which is part of the tiles, protects against corrosion, sudden temperature changes, and increases the ability to withstand frequent freeze-thaw cycles. The manufacturer's warranty period is 50 years without loss of basic qualities.

Mastics, bitumens, primers

This group of products is represented by mastics for preparing the base (bitumen primers), protective compounds with reflective properties and adhesive mixtures.

They are used for:

- arrangement of a protective layer on new bitumen-polymer, mastic and bitumen roofs;

- restoring the protection of old roll coatings;

- gluing rolled materials to concrete and metal surfaces.

The use of Technonikol mastic materials guarantees savings due to their low consumption and protection of the roof from all kinds of damage and leaks.

TechnoNIKOL bitumen mastics and primers ensure the durability of the roofing covering, its good performance characteristics and the attractive cost of the work carried out

Components

Another area of activity of the TechnoNIKOL corporation is the production of component parts. These include:

- roofing granules and slates - a coating made from natural screenings of various rocks, treated with special compounds and designed to protect covering materials from negative external influences;

- equipment for laying roofing materials - burners, bitumen nozzles, hooks for rolling rolls on the roof, repair kits, equipment for welding membranes, etc.;

- additional roofing elements - aerators, funnels, pressure and edge slats, self-tapping screws, geotextiles.

In addition to roofing components, Technonikol produces a wide range of products for finishing facades, among which facade tiles, resistant to corrosion, ultraviolet radiation and aggressive climatic influences, are quite popular. It has increased tightness and extraordinary durability.

Created on the basis of fiberglass, improved bitumen and natural basalt granulate, TechnoNIKOL facade tiles are distinguished by high performance indicators and visual appeal

Mineral wool

This material is a structure of small fibers and air. Mineral wool is made from rocks. There are large layers of air between the fibers. Thanks to this, the material has excellent thermal insulation properties.

The cotton wool from Teplonikol shows high performance not only in cold weather, but also in hot weather. Indicators and features of mineral wool:

- This is a fire-resistant insulation that will not catch fire even at a temperature of 1000 ºС. If a fire suddenly starts, the material will not even melt. This feature helps to avoid destruction of the building in case of fire.

- Mineral wool slabs can be classified as environmentally friendly products. Fungus and harmful bacteria cannot grow in them. Rodents also cannot harm the finish.

- During use, basalt fiber does not emit substances that are harmful to humans and the environment. Even at high temperatures, such cotton wool remains completely safe.

Is there any harm to health during installation?

Many inexperienced builders often confuse stone wool and glass wool, although in fact these are two different materials belonging to the same class of mineral wool. Because of this, a common myth has arisen that stone wool, like glass wool, is also harmful to health, damaging the eyes and lungs. But this is just a delusion.

The point here is its special structure. The insulation is stone fiber bound with formaldehyde resins; they do not collapse and do not spread harmful substances. Therefore, we confidently declare that this building material is absolutely safe.

Types of TechnoNIKOL insulation

Having studied the manufacturer’s assortment, TechnoNIKOL insulation can be divided into two main types:

- Basalt insulation;

- Expanded polystyrene insulation.

We will tell you about the features of each variety, their technical characteristics, prices, sizes and application features.

Basalt insulation

This mineral wool insulation is produced on the basis of basalt fibers. They are mined by melting rocks or metal production slags. When a rock mass melts under extreme temperatures, a substance is obtained that passes through special holes, the sizes of which vary. The fibers are once again subjected to heat treatment, after which we get rocklight slabs - this is TechnoNIKOL stone wool. Its technical characteristics provide wide application possibilities. Therefore, you should get acquainted with the Rocklight insulator in more detail.

Main characteristics

Technical characteristics of TechnoNIKOL insulation largely depend on the type of material.

https://youtube.com/watch?v=JYHrMfDMNkM

Expanded polystyrene insulation

We have already talked about Rocklight and its comrades of basalt type insulation, so now we will tell you about the technical characteristics and main nuances of TechnoNIKOL xps and more. This is a polystyrene foam insulator obtained by combining styrene and special agents.

To produce the material, the extrusion technique is used. In terms of structure, these are sealed cells that give xps its unique characteristics.

Main characteristics

- TechnoNIKOL xps has a low thermal conductivity coefficient (0.028-0.035). Considering the characteristics of all competitors, xps is one of the leaders in this indicator.

- The products do not absorb moisture, which ensures excellent waterproofing and thermal insulation of the house.

- The density of xps can be different, depending on the type and purpose of polystyrene foam insulation from TechnoNIKOL.

- Carbon fiber is used in the production of xps TechnoNIKOL. Particles of this material are used as a low-temperature agent to melt the raw material. High-performance carbon contributes to low thermal conductivity and flammability, making xps a truly versatile material. It is no secret that polystyrene foam is a flammable material. By using carbon fiber, Technonikol managed to minimize the impact of this drawback. It was possible to achieve high levels of self-combustion time and avoid the formation of burning drops when the material melted.

- Special packaging allows you to store products in the open air, but it is better to do this under canopies that provide protection from snow and rain.

- The thickness of xps depends on the purpose of each individual type of polystyrene foam insulation. This figure can range from 20 to 120 millimeters.

- The temperature range of effective operation of xps is almost similar to rocklight - from -50 to +75 degrees Celsius. This is lower than stone wool, but for normal construction applications this performance will meet your needs.

- The xps material is vulnerable to organic solvents and gasoline, so the insulation must be protected from exposure to these compounds.

- If we are talking about constructing a building with a high risk of fire, then stone wool is a better solution than xps.

- The strength of xps is its resistance to mold, mildew, rodents and other pests. Here, stone wool is not much inferior, by the way.

- Expanded polystyrene insulation from TechnoNIKOL costs from 80 rubles per m2. If we are talking about a product where carbon is added, you will have to pay from 400 rubles per square meter.

We advise you to study - Selection of the best geysers - ratings, comparisons, reviews

How to choose stone wool?

Before purchasing stone wool, you need to find out the amount of material needed and calculate the load that will be placed on the insulation.

We have already said that the prices are high, but you can still save money. The cost will be influenced by the following factors:

- Density of wool;

- Manufacturer;

- Binder and rock category;

- The presence of another layer of coating;

- Quantity purchased.

When purchasing, be sure to look at the instructions; they usually indicate the scope of use of stone wool and its technical characteristics. The most proven ones are TechnoNIKOL and Rockwool. The last company is located in Denmark; insulation materials from this country are of the highest quality, since they have strict certification bodies.

When choosing, check with the seller how the fibers are arranged: horizontally, vertically or in a chaotic order. The first two types prevent the material from deforming, and the latter provides good heat and sound insulation.

Depending on the density, stone wool is usually divided into categories. Stone wool: wall slabs:

- Brand P-75. Suitable for horizontal internal surfaces that are not exposed to load, for insulating pipelines.

- Insulation for walls is wool grade P-125. Suitable for both horizontal and vertical surfaces. It is ideal for insulating ceilings, floors and the inside of walls.

- PZh-175. Stone insulation for walls made of metal profiled sheets or reinforced concrete.

- Insulation wool PPZh-200. The hardest stone wool. This type is used in engineering buildings, protecting them from fire.

Which mineral wool is best for wall insulation?

Insulating a house with stone wool begins with choosing a manufacturer.

Rockwool “ROCKWOOL” is popular both in the domestic and foreign markets. It has the following distinctive characteristics:

- Good level of strength;

- Mineral wool for wall insulation lasts from 15 years;

- The fibers are arranged in a chaotic manner;

- Helps save electricity, as the manufacturer claims;

- An additional layer that increases moisture resistance.

Stone wool "TechnoNIKOL".

- Produced only on the basis of basalt rocks;

- Additional layer for noise reduction;

- Light weight, making work easier.

Insulation for walls stone wool "URSA":

- Special packaging will make it easy to transport and work with the material;

- Does not contain formaldehyde resins, therefore it is recommended for schools, hospitals, etc.

Buying a truly high-quality product can sometimes be difficult. Therefore, you need to know some important points.

Pay attention to where and how the cotton wool is stored. Most often, it is stored in its original packaging and wrapped in shrink film.

Make sure there are no holes or cuts on the packaging. The cotton wool should not be in the open air, but under a canopy. If stone wool is packaged in cardboard boxes (they usually contain expensive insulation materials), then its storage location must be protected from moisture. Even after getting a little wet it will be unusable. Purchase goods only from trusted sellers. Give preference to those stores that are located closer to you - this will reduce the cost of delivery.

Dimensions

TechnoNIKOL Rocklight 100 mm is not the most popular material in the line. The gradation of slab thickness is:

The most popular slabs with a thickness of 50 mm remain, as they allow you to create a layer of the required thickness, for example, 150 mm in places where this is needed and 100 where a smaller amount of insulation is required.

The size of the slab is 1200 by 600 mm or 0.72 square meters.

In one package you supply from 4 to 12 slabs, depending on the thickness. There are 16 packages on one pallet. All packages are carefully wrapped in film. However, the manufacturer recommends storing insulation in covered warehouses. Or, as a last resort, under a canopy. In the latter case, the insulation should be laid in stacks no more than 2 m high.

A complete list of sizes can be seen in the table:

Specifications

The main factors for selecting insulation are thermal conductivity, moisture resistance, fire resistance and environmental friendliness. Thermal conductivity coefficient refers to the ability of a material to transfer heat. The lower, the better the material preserves it. The fire resistance of the material should be maximum.

Environmental safety means that it does not emit harmful substances and does not cause an allergic reaction. Stone wool, including basalt insulation, is one of the best insulation materials from this perspective. All types can be divided into plates and bulk material. All this is mineral wool, but presented in different forms.

The material should not be flammable or absorb moisture, since then it loses its ability to maintain heat. It is desirable that the plates or insulating sheets be large.

Density

The thickness of the layer depends on climatic conditions: the colder it is, the thicker it should be. It is advisable to choose heat insulators with high density and low weight, such as Master. Heavy insulation adds stress to the rafters. The material should not change shape due to sudden changes in temperature, for example, heat or cold.

The compressibility of the plates does not exceed 30%, the moisture content in the mass corresponds to 0.5%. The material may contain organic substances, but their volume is not higher than 2.5%. The thickness usually varies in steps of 10 mm, the minimum value is 50 mm, and the maximum is 100 mm.

Dimensions

Insulation with mineral or basalt wool is carried out in several stages:

- cleaning the surface from debris and contamination;

- installation of guide profiles that are tied at a height of 60 cm;

- use of fastening plates with dowels;

- reinforcement of the plate with special glue.

Roof insulation begins with planning and preparation work:

- window installation;

- connection;

- internal insulation of the roof structure.

The following actions are performed if it is necessary to eliminate roof defects:

- a layer of waterproofing is created; when using conventional membrane materials, ventilation is required;

- laying insulation material in the space between the rafters;

- waterproofing can be attached with staples.

Mounting options

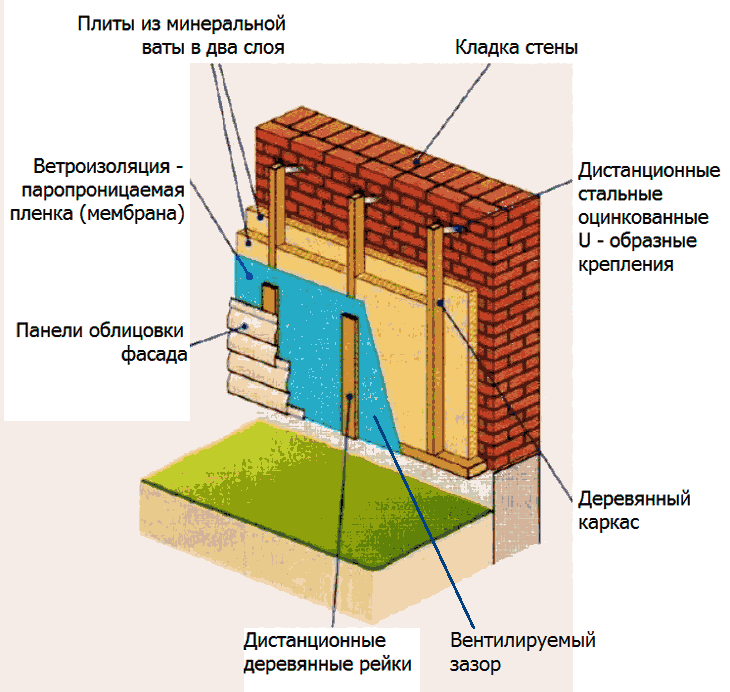

TechnoNIKOL insulation for walls is installed in two ways, “wet” or according to the principle of a ventilated facade.

For the plastering option, slabs with a density of at least 130 kg/m3 are suitable - they usually have sufficient peel strength.

Installation of a “wet facade”

The initial stage of “wet facade” insulation is cleaning the surface of the walls from dust, dirt, oil stains, etc.

The cracks in the masonry are sealed with plaster mortar and unevenness is leveled out as much as possible. Recesses of no more than 3 cm per 1 linear meter of wall are allowed.

Next, there are two options for installing the panels: with glue or only with dowels with a wide head (fungi). In the first, glue is applied to the wall and slab and the mixture is leveled with a notched trowel. TechnoNIKOL insulation for walls is pressed against the wall for a few seconds. For greater strength and in order not to wait for the mortar to set, the slabs are reinforced with dowels of the required size. Within 24 hours the glue dries and further finishing begins.

When fastening only with dowels, a layer of vapor barrier material is laid between the wall and the insulation boards. Joints and seams are sealed with polyurethane foam.

The next stage is applying the first layer of plaster. A special glue is used for the mixture. The first layer is applied, into which the plaster mesh is embedded.

The mesh and glue must match each other - some mesh models dissolve in an alkaline environment. Reinforcing mesh is chosen for outdoor work.

Smooth out the composition. After the first layer has completely dried, the main plaster is applied. To give the surface an attractive appearance, decorative plasters are used, which are subsequently painted.

Insulation with roll materials

The first stage is cleaning and leveling the surface onto which the vapor barrier membrane is nailed.

The sheathing is nailed over the vapor barrier. The pitch of the longitudinal and transverse joists should allow for a tight fit of the insulation for the TechnoNIKOL façade. Rolled material or slabs are secured with dowels with wide heads.

Next, a layer of windproof film is nailed to the joists with a stapler, on top of which a counter-lattice 1 cm thick is mounted. The design is necessary so that there is a gap between the waterproofing and the finishing coating for ventilation and evaporation of moisture from the thermal insulation.

The final stage is the installation of finishing, which includes ceramic tiles, plastic or wood siding, and other options.

Detailed description

Before purchasing TechnoNIKOL stone wool, you need to familiarize yourself with its technical characteristics in more detail.

Coefficient of thermal conductivity

This stone criterion may vary depending on the type of material. Be within the range of 0.034 to 0.047 W/m*S. Thus, it becomes clear that 10 cm of insulation can retain thermal energy just as well as 38 cm of timber or 140 cm of brick.

The photo shows the thermal conductivity of TechnoNIKOL stone wool:

The insulation process using TechnoNIKOL wool is carried out in 1-2 layers.

Density of slabs

This characteristic of the material is determined by the thermal conductivity coefficient. If we consider the material Rocklight and Technolight, then its density is 30-40 kg/m3, but the material Technoflor, which is used to insulate the floor under the screed, this figure is 81-185 kg/m3.

Degree of vapor permeability

This characteristic is also one of the main ones. The lighter the material, the better its vapor permeability. Consequently, the microclimate in the house will be comfortable for living.

In addition, insulation with high vapor permeability rates has a longer service life. This is due to the fact that water molecules do not retain steam on their surface for long. Since TechnoNIKOL wool consists of 99% air, it allows steam to pass through perfectly. The degree of permeability of the material will be 0.3−0.6 mg/(m.h.Pa).

Degree of water absorption and fire-resistant properties

Since specialists used various additives in the production of TechnoNIKOL stone wool, the resulting material can perfectly retain moisture. The water absorption level of the heat insulator will be 1-2%.

Since TechnoNIKOL mineral boards are a non-flammable material, it is advisable to use them for thermal insulation in those houses where there is a high risk of fire. TechnoNIKOL slabs are not combustible, and the melting process occurs only at a temperature of 1000 degrees.

If a fire occurs, TechnoNIKOL stone wool will be able to delay the spread of the flame for some time. Moreover, it protects against fire and other materials that are less resistant to fire. But what is the thermal conductivity of mineral wool and how is it determined. information from this will help you understand

The video shows the technical characteristics of TechnoNIKOL stone wool:

Life time

The service life of TechnoNIKOL mineral wool is quite long even under unfavorable conditions. The minimum service life is 50 years. This result is achieved due to the fact that the material has excellent characteristics. Basalt fibers do not rot or corrode. In addition, rodents are not scary for them. But the service life of the material can only be increased if it is installed correctly. So during installation you must take care of hydro and vapor barrier.

Meet: TechnoNIKOL products

This company, which today ranks with the largest European manufacturers (more precisely, one of the five largest of them), produces not only thermal insulation. It produces the following products.

Roofing materials:

- Roof tiles;

- roofing felt;

- membranes made of polymeric materials;

- primers;

- mastics.

Insulation:

- Expanded polystyrene made by extrusion;

- mineral (basalt) wool, made in the form of slabs.

Basalt wool: composition and features

The finest stone fibers of this material consist of processed gabbro-basalt rocks. Between these fibers there is a large number of air layers. As a result, the level of thermal insulation of the material is simply excellent. It is no secret that it is the air, being without movement, that has great resistance to heat transfer.

But this is not all the advantages of insulation - it is good not only in cold weather, but also when the temperature rises critically. A very impressive characteristic of TechnoNIKOL mineral wool is its fire resistance. This material does not burn, easily withstanding temperatures of even 1000 degrees Celsius. At the same time, it doesn’t even melt! Even if, unfortunately, a fire occurs, basalt wool will protect your home, preventing walls and ceilings from collapsing. It will block the path of fire, without releasing a drop of harmful substances in the event of a fire.

You can find out more about the characteristics of basalt wool insulation in the article: Technical characteristics of basalt insulation, advantages, disadvantages and scope of application.

Extruded polystyrene foam TechnoNIKOL

This type of material is increasingly used for insulating houses both here and abroad. After all, it holds heat very well. For example, to achieve an equivalent effect, you need to take a layer of wood 10 times thicker than polystyrene foam (twenty centimeters versus two). So EPS is cheaper. And it is much lighter than other insulation materials, which reduces transportation costs and facilitates installation. Strength and rigidity allow it to be used where softer thermal insulators cannot cope. But this material is afraid of fire - it not only burns, but also releases toxic substances. So it is necessary to comply with fire regulations by providing adequate protection.

How it is made

When producing TechnoNIKOL mineral wool, the rock is pre-loaded into melting furnaces and heated to a temperature of 1400-1500 degrees. Next, the molten rock mass is poured into a special centrifuge.

Here, spinning tops rotating at speeds of up to 7000 rpm tear it into small fibers. During this procedure, binders are poured into the centrifuge

. At the next stage, the fibers already impregnated with phenol-formaldehyde resin enter the lamella machine and are formed into a carpet of a given thickness.

Mineral wool of the TechnoNIKOL brand is manufactured by the domestic company of the same name, founded at the end of the last century. Currently it includes more than 20 enterprises and 120 retail outlets

operating throughout the country. Mineral wool from this manufacturer is made from high-quality materials using modern equipment, and therefore is extremely popular not only in Russia, but also abroad.

Production Features

A distinctive feature of stone wool is its strict positioning in application. The specifics of manufacturing allow for the possibility of adjusting or changing the technical properties of wool. Thanks to this, for each type of structure it is possible to make a product with the most effective thermal insulation.

KV is made from basalt rock. In order for the stone to begin to melt, it is exposed to very high temperatures. The molten rock is formed into fiber - the basis for cotton wool. The air void, which occupied more than 90 percent of the finished slab, prevents sound and heat from traveling. Thanks to this, TechnoNIKOL cotton wool has:

- high thermal insulation properties;

- physical and chemical characteristics similar to natural stone;

- ease of installation.