Frame houses and summer cottages are becoming more and more popular in our country every year. The main reason is, of course, the cost of construction. Plus, such buildings do not require large expenses for the foundation, since they are light, and the frame takes the main load on itself.

However, frame technology (like any other) also has its disadvantages. And perhaps the most important disadvantage of frame frames is that they are poorly suited for harsh winters and require mandatory insulation. In this article we will look at what new technologies are used in insulation and whether it is realistic to have a warm house with thin walls...

What do you need to know about thermal insulation of a frame house?

The peculiarity of frame structures is that wood and wood panels have a lower thermal resistance than insulating materials placed between the frame elements. Therefore, most of the heat flow occurs through studs, slabs, rails and beams, rather than in areas of external walls or roof structures.

This increase in thermal conductivity is called a thermal bridge. Such bridges can occur at any junction between building elements.

Many other building materials have lower thermal resistance than wood and can be important factors in thermal protection. For example, a steel post inside a timber frame exterior wall will create a significant thermal bridge.

The property that describes the heat loss associated with a thermal bridge is its linear heat transfer. Research carried out between 2005 and 2007 by a team at Leeds Metropolitan University, as part of the Stamford Brook field trial, showed that cavity wall masonry facilitated significant air movement. This air movement can transfer heat from the wall cavity to the outside, resulting in large heat losses from the building.

Therefore, when designing a future home, it is very important to take into account where the thermal bridges will be located.

Materials for coating and cladding of ventilated facades

The following types of protective and decorative coating (facade cladding) are used for ventilated facades:

- Wooden block house;

- Vinyl siding and basement siding or plastic panels;

- Metal (steel, aluminum) siding, flat panels, sheets of profiled flooring (corrugated sheeting);

- Fiber cement panels with imitation of the texture of different materials (brick, stone, wood, etc.) with a thickness of 14 - 16 mm or more.

- Volumetric ceramic slabs;

- Slabs made of natural polished granite;

- Facade porcelain stoneware slabs, polished and matte;

- Composite panels (metal-polymer);

New types of coatings and various modifications of already known systems are constantly appearing on the construction market.

By the way, I note that if corrugated sheeting is used for cladding the facade, then it is advantageous to install it on a horizontal sheathing with corrugations located vertically. without spacers. The channels formed by the corrugations of the cladding will be sufficient for ventilation of the insulation.

Windows and doors on the insulated facade of the house

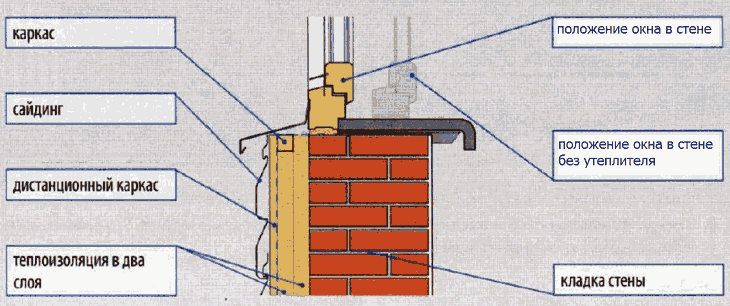

|

| A window in the wall of a new house is located on the border of the insulation. When insulating the walls of old houses, it is necessary to move the window or insulate the slopes from the outside. |

In external walls with insulation on the facade, windows and doors are located at the border with the insulation. When insulating houses that are not new, it is better to replace old windows by changing their position in the wall. If the windows are not touched when insulating the walls, then it is necessary to insulate the slopes outside the house.

The video shows the work on insulating a wall with mineral wool and installing façade cladding.

In systems with a ventilated facade, it is not recommended to use slabs made of polymer insulation - foam plastic, expanded polystyrene.

Such slabs are flammable and vapor-tight, which is a serious drawback for a ventilation facade system. Note also that windproof films are also flammable. Therefore, it is better to do without them.

An interesting solution is used by Polish architects. In Fig. 3, the walls of the house are lined with brick only in the lower part to the level of the windows, where the intensity of external influences on the walls is highest. The cladding of the upper part of the walls is made in a more economical version.

Articles on this topic:

⇒ What is the best way to make walls for a house ⇒ Material for building a single-layer external wall of a house ⇒ Insulated two-layer house wall with external facade plaster ⇒ Three-layer external stone wall with brick cladding

More articles on this topic

- How to make a beautiful spring in the garden

- How to make an entrance vestibule in a private house

- Sound and noise insulation of the ceiling in the apartment

- Septic tanks and wastewater treatment stations Eurolos autonomous sewerage

- Correct wooden house made of construction timber

- Everything you wanted to know about roof windows

- Concrete floor on the ground in a stone private house

- Norms and rules for planning a private house, cottage

What does all this mean for frame buildings?

Today, frame walls typically contain acoustic wood insulation between the studs, and insulated cavity barriers around the entire perimeter. Thus, if you install thermal insulation between the studs, as well as in the cavity between two blocks of walls, you can reduce heat loss to zero.

Achieving this goal may require qualitative changes in current frame construction practices. If the insulation for the walls of a frame house is installed between fully sheathed walls, this may slow down the progress of the assembly, since additional time will be required. It is also quite difficult to ensure that the insulation is dry and does not move around during the rest of the framed wall assembly.

The simplest solution to these problems is to use a bare wall or use insulation on just one wall. With open (or partially open) walls, insulation can be easily installed once the building is fully assembled.

Wet façade insulation work in stages

Step-by-step instructions for wet facade technology are as follows:

- Preparing the wall surface.

Priming insulated walls is an important stage in surface preparation.

This procedure involves cleaning the surface from any existing contaminants. In addition, it is necessary that it be level. The maximum difference per 1 m2 of area should not exceed 1 cm. Irregularities and sinks should be leveled with plaster. If the wall has areas with crumbling fragments, it is necessary to use a bonding primer. It is advisable to prime the entire surface. This will serve as additional protection for the wall. - Installation of the base profile.

Fastening a metal profile for installing insulation.

It will perform two functions: a level and a unit that takes the load of the upper insulation slabs. - Applying glue.

Applying glue to the surface of the insulation

This procedure is performed with a special notched spatula. The adhesive composition is applied to the insulation boards, not to the wall. - Gluing.

The insulation is glued from the bottom up.

It is important to pay special attention to the corners. The procedure is performed from the bottom up along the belts. The slabs located above the base profile must rest on it. When gluing door and window openings, the slabs must be glued so that the corners of the openings are located within one solid slab. For this purpose, special cutouts are made in the insulation. - Fastening insulation boards with plastic dowels with a wide head.

The insulation is attached using plastic dowels with a wide head.

The work is performed after the glue has completely dried. - Applying a base plaster layer, 3-5 mm thick.

The key stage of a wet facade is applying a plaster layer with reinforcement - Laying reinforced mesh. The work is carried out until the plaster sets. It is important that the mesh is recessed into the plaster layer.

- Leveling with finishing plaster.

- Painting.

The final finishing stage is surface painting

Armed with knowledge, materials and the necessary technical

With the equipment you can begin work on installing the wet facade.

Modern thermal insulation technologies

Conventional timber frames struggle to meet the latest thermal standards used in modern residential buildings. Fortunately, the latest insulation technology offers several solutions. Owners of frame buildings can choose one of the panel options or use a technique called the “inside-out method.”

Such panels are divided into 3 types:

- Custom built;

- Factory made, filled with polyurethane foam inside;

- Built-in panels for frame construction.

Panel construction has a number of advantages. These include efficient installation, thermal protection quality with multiple thermal bridges.

The inside-out method also has a number of advantages; it is worth considering, if only because this type of home insulation will cost much less. This does not require heavy equipment; all work can be carried out only with the participation of electricians, plumbers, and carpenters.

Types of mineral wool

Mineral wool is a material, which in turn is divided into several types, differing from each other in properties and characteristics.

Glass wool

This insulation consists of compressed slabs consisting of fibers up to 15 microns thick and up to 5 cm long . Made from melted glass, limestone, dolomite, borax and soda. The result is an elastic and durable material.

NOTE!

Working with glass wool requires extreme caution , since fragile glass threads can dig into the skin, get into the eyes or respiratory tract. Therefore, when using such insulation, you should wear a special suit, gloves, goggles and a respirator.

Glass wool is highly hygroscopic and has the lowest density compared to other types of mineral wool . This material is practically not used for insulating residential buildings. It is often used for thermal insulation of technical rooms and pipelines.

Characteristics of glass wool:

- thermal conductivity coefficient – from 0.03 to 0.052 W/(m K);

- operating temperature range – from -60 to + 450°C;

- vapor permeability – from 0 to 0.6 mg/mh*Pa.

Glass wool

Slag wool

Slag wool is made from blast furnace slag, which is a waste product from metallurgy . The material is based on fibers 4-12 microns thick and 16 mm long. Slag dust and small balls can also be added to the composition.

This type of insulation is most often used for thermal insulation of non-residential premises and temporary buildings . The high hygroscopicity of the material makes it unsuitable for insulating building facades.

Characteristics of slag:

- thermal conductivity coefficient – from 0.46 to 0.48 W/(m K);

- operating temperature range – from -50 to +250°C;

- sorption humidification in 24 hours – up to 1.9%

Slag

Basalt (stone) wool

It is produced by melting volcanic rocks (mainly basalt, but also diabase and porphyrite), followed by processing in a centrifuge, where the plastic mass is converted into thin fibers under the influence of a powerful air flow.

Next, binders and a water repellent are added to them, which gives the material moisture-repellent properties. After this, the basalt fibers are pressed and heat-treated, resulting in high-quality insulation.

IMPORTANT!

This type of mineral wool slabs is the best option for thermal insulation of the facade. Stone wool is not afraid of moisture, has low thermal conductivity, good vapor permeability (due to its cellular structure) and practically does not absorb moisture.

Characteristics of stone wool using Rockwool as an example:

- thermal conductivity coefficient - from 0.032 to 0.048 W/(m K);

- average vapor permeability - 0.3 mg/(mg/mh*Pa);

- maximum heating temperature – up to 1000°C.

Insulation at the stage of building a house

In recent years, frame house-building technologies have advanced significantly. The thickness of the external walls can be already 90-140 mm. This provides additional space for installing insulation. Therefore, choosing insulation for a frame house is no longer such a difficult issue.

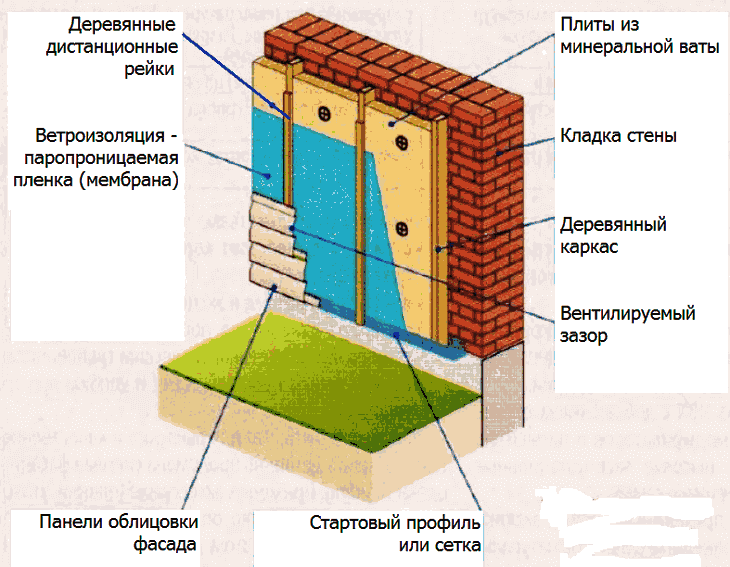

Wooden sheathing design options

The above-described structure of a three-layer wooden sheathing

, from perpendicularly located bars, ensures

the strength and stability of the dimensions of the sheathing

under various influences, as well as

the adjustment of convenient sizes for laying insulation and for the installation dimensions of the cladding

.

If thermal insulation is laid on the wall in one layer 40-60 mm thick, then vertical bars do not need to be installed. In this case, the horizontal bars are attached directly to the wall.

| Window and door openings are framed with sheathing bars. After laying the insulation on the horizontal bars of the sheathing, attach a windproof, vapor-permeable film, and then install spacer strips |

By the way, I note that the horizontal bars of the sheathing prevent the insulation from slipping. This makes it possible to use cheaper mineral wool insulation

lower density.

Single lathing with vertical posts for insulating walls with mineral wool

Sometimes, to save lumber

, the design of the sheathing is being changed. For example, you can make a sheathing without horizontal bars, securing only vertical bars to the wall. The width of the vertical bars is chosen equal to the thickness of the insulation - up to 100 mm. The bars are fixed directly to the wall with dowels.

The cladding is attached directly to the sheathing bars through spacer slats, which set the width of the ventilated gap.

|

| A single lathing with vertical posts is chosen if the facade cladding is made of a fairly rigid material, for example, a block house, and the thermal insulation thickness is no more than 100 mm. |

The disadvantages of this design are the following:

- Difficulty in choosing the distance between adjacent sheathing bars. For example, the width of the insulation boards is 500-600 mm, and the required distance for attaching the siding is no more than 400 mm. Questions arise. With what step should the bars be placed on the wall? Cutting insulation boards or installing siding in violation of technology?

- A block (board) with a width of more than 100 mm is more difficult to attach to the wall. The outer surface of a wide board sheathing without cross braces is more susceptible to deformation, which will inevitably affect the cladding attached to it.

It is better to choose this type of lathing if a fairly rigid material is used for cladding the facade, for example, wooden lining, block house, basement siding, corrugated steel, and thermal insulation is laid with a thickness of no more than 100 mm. Another option for economical lathing

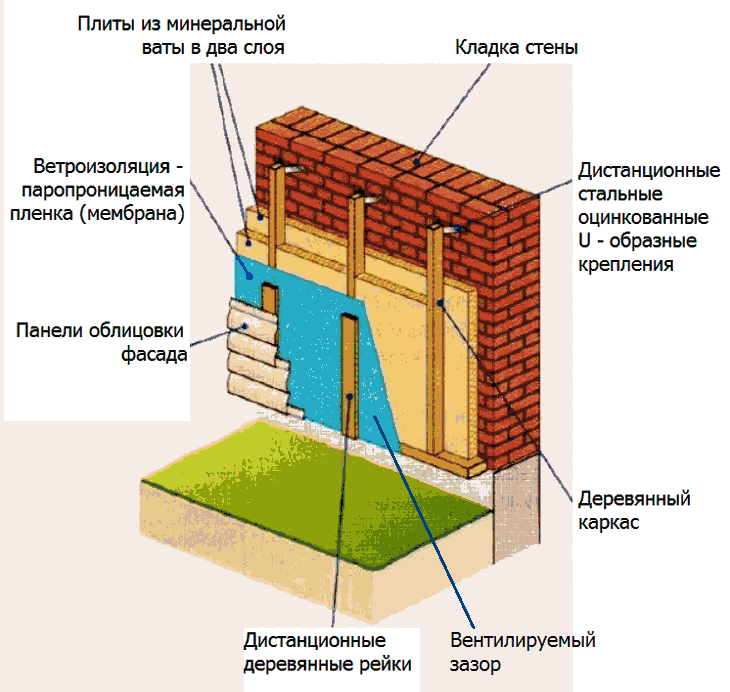

shown in the figure:

|

| It is advantageous to use lathing at a distance from the wall when insulating the wall with two layers of mineral wool slabs. During the installation period, the insulation boards are fixed to the wall using disc-shaped dowels. |

The sheathing bars are secured from the wall at a distance equal to the thickness of the thermal insulation layer using galvanized steel parts. The first layer of insulation is fixed to the wall using disc-shaped dowels for the installation period. The second layer of slabs is placed in the spacer between the frame posts. Distance slats of increased width fix the insulation boards between the frame posts.

In addition to saving lumber, this design has another advantage - there is no cold bridge through the sheathing bars to the wall.

Fire protection of wooden structures and bioprotection of wood sheathing

For wooden sheathing parts, dry coniferous wood should be used.

Applying fire-retardant compounds to wooden parts using a brush

gives an effect for a maximum of the first three to five years.

In the future, it is impossible to renew the coating of wooden sheathing parts with these compounds.

Therefore, it makes sense to treat only the wooden parts of the sheathing, which is installed on freshly laid walls that contain construction moisture, with a bioprotective compound.

In this case, it is also advisable to lay a layer of waterproofing between the wall and the sheathing bar or coat the junction surface with waterproofing mastic.

The role of ventilation in home insulation

When the building's airtightness rating is less than 5 points, it is recommended to install a mechanical ventilation system with heat recovery. Thanks to this system, warm air is removed from non-residential rooms (kitchens and bathrooms), directed through a heat exchanger, which collects heat from the exhaust air and uses it to heat fresh supply air.

All this allows fresh air to enter the home, and moist (and not fresh) air to remain at the source.

The ventilation system will also save on heating bills. This installation requires only 100 W of electricity to operate - this is significantly less than the thermal energy that would be needed in the absence of such a system.

How foam blocks and thermal insulation panels are used for insulation

Foam blocks are produced in the form of facing slabs, which are laid according to the principle of brickwork to prevent the appearance of cold bridges. The foam block is glued directly to the load-bearing wall, and the adhesive mixture acts as an additional waterproofing layer.

For better grip, umbrella dowels are additionally used. Foam and gas blocks are lightweight, which makes them easier to install. Due to the fact that the concrete mixture foams during production, the material can freeze and lose strength. Therefore, it is best used with a moisture-resistant finish. It is not recommended to use foam blocks to insulate facades under plaster.

Decorative panels are a set consisting of insulation and a decorative layer. The basis of the panels is polystyrene foam (penoplex), and the decorative layer is plaster or brickwork. Installed using a special adhesive solution. The main advantage is speed and ease of installation.

In this case, there is no need to additionally insulate the facade with plaster, because the decorative layer is applied in advance at the factory. The panels look attractive and retain heat well. The only downside is that the sheets peel off from the surface, especially if you use the wrong glue. If you use dowel umbrellas for better adhesion, the appearance of the facade will deteriorate. The cost of the panels is about 3,000 rubles/m2 excluding installation.

Decorative panels consist of insulation and a decorative layer

Siding

Such a facade insulation system as siding can insulate any house. And this is its main advantage. In addition, siding is the most budget option. This method is mainly chosen by the owners of panel and frame-panel country houses.

The technology for insulating the exterior of a house with siding is simple. The walls are primed and a layer of fire protection is applied. Then a wooden sheathing, less often made of metal profiles, is mounted to the facade. The main thing here is not to skimp on wood slats. If the fastening is of poor quality, then in the second year your siding panels will go in waves.

Next, mineral wool insulation is installed and a waterproofing film is installed. The last stage is the installation of vinyl panels. The very appearance of these panels is quite diverse in color and texture. You can choose classic slatted vinyl, or imitation logs, timber and even wild stone.

How not to get lost in the huge selection of insulation materials if every manufacturer claims that it has the most reliable and proven product?