Insulation of pipes is the most important condition for the optimal functioning of heating and water supply systems. With the advent of modern technologies, traditional old materials (mineral and glass wool) are being replaced by effective innovative products, one of which is expanded polystyrene pipe insulation.

Although expanded polystyrene (foam plastic) has been known for decades, the technology for producing pipe insulation from it has appeared relatively recently. The method of manufacturing spherical segmental pipes for insulation (shells) from foam plastic on a special machine is quite simple - this contributes to the widespread distribution of foam insulation in the near future and the displacement of other materials from the market.

Rice. 1 Foam pipe shell

Is mineral wool harmful?

Environmentalists claim that the product is harmful, demanding the cessation of production and use in construction.

Research results show that the danger of insulation is caused by the toxicity and carcinogenicity of raw materials:

- in the first case, small fractions of cotton wool are unfavorable for human lungs;

- in the second, harm to health is caused by the release of carcinogens from formaldehyde-based resins used in the production of the material as a binder.

The State Department of Hygiene of the Russian Federation regulates the use of heat insulators as follows:

- allows the use of mineral wool in individual, industrial, housing and civil construction;

- recommends installing insulation in closed structures;

- Only open laying of basalt, glass, and slag wool is prohibited.

Following the recommendations of specialists, you can buy the material, protecting the operation of your apartment or cottage from these harmful influences, significantly saving the construction and repair budget.

According to the classification of the international agency IARC, mineral wool belongs to the third group, that is, they are not carcinogenic to humans along with tea and caffeine. For comparison: the second group (probable concentrates) includes vegetables in brine, exhaust gases, the first (dangerous for the human body) includes asbestos, tobacco, and wood dust.

The main nuances of using thermal insulators

Before purchasing rolled insulation for heating pipes, you need to make sure that its performance characteristics allow the use of this material in an attic or basement.

When the insulation is rigid and made in the shape of a semicircle, it can be used for pipe products of a certain diameter.

A distance of 25 millimeters should be left between the wall and aluminum foil.

The cost of a heat insulator is affected by the thickness of the reflective layer and the material from which its base is made. There is a significant difference between aluminum foil and aluminum coating. The latter option makes the functioning of the heat insulator less effective with low reflectivity.

It is not at all necessary to buy industrially produced foil pipe insulation. You can independently wrap the layer of thermal insulation laid on the pipe with foil if the pipeline is laid in the attic or basement. This material is produced in rolls or in the form of hollow tubes.

The foil is laid face up. A gap of 10-20 millimeters must be left between the foil layer and the pipeline.

Advantages and disadvantages of PPS insulation

PPS shells for pipe insulation for domestic and industrial use have the following advantages:

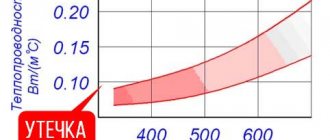

- Low thermal conductivity, allowing for effective heat retention.

- Long service life - the material can be used for up to 50 years in a space isolated from sunlight, EPS does not rot and decomposes very slowly.

- Although ordinary polystyrene foam is not a strong and dense material, when extruded (compressed) its density increases significantly. The manufacturer produces several groups of foam plastics with different parameters; when making shells, they use technology that allows you to select a material suitable in terms of density. The insulator can be made from a popular variety - Penoplex, which has high strength characteristics.

- The shell design is made in the form of prefabricated segments - this allows, if necessary, to easily dismantle the installed insulator and use it repeatedly.

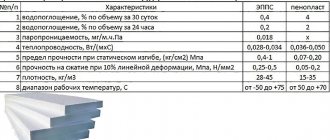

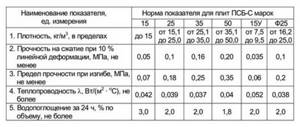

Rice. 4 PS parameters

- Expanded polystyrene practically does not absorb water, so after installation the pipeline is protected from the negative effects of moisture.

- The material is resistant to ambient temperatures from -50 to +80 C and is able to withstand temperature changes over a wide range.

- Polyfoam is not affected by natural chemical elements contained in soil and water (salts of various metals), and it resists mold and mildew well.

- The shell is lightweight and is characterized by a simple and fast installation method - one person can insulate pipes with its help.

- The shell is universal - it can be made to order in any size and used outdoors and indoors.

- The material is harmless to humans; unlike outdated glass wool, the use of special protective equipment is not required when working with it.

- Polystyrene foam is considered an excellent noise absorber - this gives it an additional advantage when used in residential areas.

- The shell is highly decorative; pipes insulated with it do not disturb the interior of the room when open.

- Expanded polystyrene is slightly flammable and does not support combustion; after the source of fire disappears, it spontaneously extinguishes within two seconds.

Rice. 5 Example of insulation of a PPS well

The disadvantages of the material include its following parameters:

- Polystyrene foam quickly decomposes when exposed to ultraviolet radiation, so its surface must be additionally protected in the open air.

- Many common household and construction chemicals degrade polystyrene, so it cannot be painted or coated with most liquid synthetic materials.

- When burning, polystyrene foam emits toxic smoke, causing great harm to human health.

Expanded polystyrene shell

Recently, polystyrene foam shells have been most frequently used. Thermal insulation using such shells is characterized by low labor intensity and allows you to complete the work much faster than using traditional materials. Saving material costs is achieved by the possibility of thermal insulation without the use of preliminary laying of concrete trays. Reusable use and easy dismantling in case of emergency gives an advantage to the use of polystyrene foam shells compared to other materials.

Installation is carried out as follows: the halves of the shells are put on the pipe, then they are shifted relative to each other by 100-200 mm, having previously been fixed in one or two places with adhesive tape. Next, the shells are covered with protective material. If there is a need to cut the shells, this can easily be done with a knife or saw. The joints of the shells are sealed with self-adhesive tape. Expanded polystyrene shells have a simple design and low price - all this makes them the most attractive in choosing materials for thermal insulation.

Expanded polystyrene has low thermal conductivity - 0.032 W/mK. Expanded polystyrene shells do not get wet or break. They have excellent performance at temperatures of +75 degrees. It is possible to use it on pipelines with higher temperatures, however, under such conditions the additional use of a mineral wool gasket is already necessary. With a fairly aesthetic appearance, the shells have a high ability to conserve heat. The products are not susceptible to moisture and are widely used for thermal insulation of pipes in underground pipeline sections.

Expanded polystyrene shells have a number of advantages:

- they are sealed (prevent moisture from penetrating into the insulation);

- reduce work completion time;

- low operating costs for pipeline maintenance;

- long service life.

Expanded polystyrene shells are used for thermal insulation of pipelines in civil and industrial construction. With their help, thermal insulation of air and underground pipeline systems is carried out.

Thermal insulation using polystyrene foam shells reduces the risk of corrosion, thereby increasing the useful life of the pipeline.

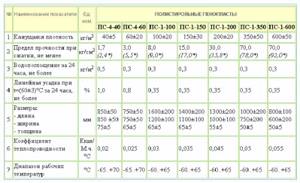

Shells can be made from high-quality material - expanded polystyrene grade PSB - S-25, GOST -15588-86. One of the most important qualities of this material is its more favorable price compared to other materials (for example, polyurethane foam).

But here it is worth noting that shells made of extruded polystyrene foam are superior in quality to classic PPS. It's not just about the dense structure, but also about the durability of the product. The material that we would put in 1st place is the FOAMPIPE segment. A wide range of diameters and thicknesses, fast production times, smart service, smooth geometry of the final product - these are Foampipe shells. Strength characteristics in terms of 15 tons per 1 m2 for an ordinary person indicate that the soil load is not a problem for this product. FOAMPIPE shells are not afraid of moisture and can be safely used when installing underground communications without any protection. The manufacturer has the ability to produce bends and tees.

Foampipe ECO SP extruded polystyrene shells

Shells made of extruded polystyrene foam with a selected quarter “Foampipe ECO SP 150” allow you to solve the problem of pipe freezing and increase the warranty period. A wide range of materials allows you to make a choice for different diameters of pipelines and oil pipelines. The high compressive strength of the shells recommends their use in harsh climates and temperatures down to -50°C.

| Characteristics | Indicators of Foampipe ECO shells |

| Actual density, kg/m3 | 25 |

| Compressive strength at 10% deformation, kPa | 150 |

| Thermal conductivity at λ 25 W/Mk | 0,033 |

| Application temperature | from – 50 to +75°С |

| Produced diameters, mm | 32-1200 |

| Shell wall thickness, mm | 20,25,30,35,40,45,50,60,70,80,90 and 100 |

| Edge shape | selected quarter |

| Color | yellow, gray or white |

| Trademark | Foampipe |

* Products are manufactured according to TU 23.99.19-003-69709663-2020

Download the price list for all FOAMPIPE products:

This might be interesting:

| |

| |

| |

| |

|

LLC GC "TEPLOSILA" - together with you since 2005!

How to properly insulate pipes with polystyrene foam

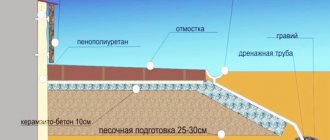

The most difficult insulation work is insulating large-diameter pipes; at your own site, this procedure can be carried out independently using a foam plastic shell. The work is carried out in the following order:

- Along the pipeline route, a trench is dug at the average level of soil freezing (you can get the necessary data from the Internet using special maps for different areas depending on the soil).

- Sand is poured into the ditch with a layer thickness of 10–20 cm.

- The condition of the pipes is checked - they must be dry, moisture under the insulation can lead to corrosion, and installation must also be done in dry weather. The surface of metal pipes is treated with anti-corrosion material.

Rice. 7 Thermal insulation with shell - method of installation on pipelines

- The assembled pipeline system is laid at the bottom of the pit in such a way that there is a gap in the lower part equal to the thickness of the shell.

- A pre-purchased shell corresponding to the diameter of the pipe is installed in such a way that the parts of one half are tightly connected to the others. When installing, it is better to carry out the work together - one person will tightly compress the segments, and the other will fix them with tape. During installation, you can use glue, but the process will take much longer, will be economically unprofitable, and the connection itself will subsequently be impossible to disassemble.

- It is better to cut corner joints at the installation site using a regular hacksaw.

- After installing the shell, its surface is covered with a special protective coating, which is supplied in the kit. If it is not available, the shell can be covered with polyethylene film.

- After installation, the trench is filled with sand 10–20 cm above the pipeline level, then the surface is leveled with earth.

Rice. 8 An example of using polystyrene foam shells for pipe insulation

Installation nuances

First of all, when installing the shell, it is necessary to determine the diameter of the pipeline - so that you can select the appropriate diameter of the shell.

If it is larger than that of the pipe, the insulation will hang on it. If it is larger, the insulation will have gaps: the shell segments simply will not meet.

To fasten the segments (we will consider this option, and not the whole shell - it is the most relevant) the following can be used:

- Wire - in this case, the applied thermal insulation is wrapped with it.

- Glue – joints (both longitudinal and transverse) are lubricated and glued together.

- Groove - halves are connected to each other with a latch. Adjacent segments can be connected either with a latch or with glue.

- Adhesive tape.

The first option is good because it allows you to get a detachable connection: if necessary, you can simply unwind the wire, get a “bare” pipeline, and after completing the inspection (or work) you can put the insulation back.

The glued segments will only have to be cut. However, they can then be glued together, but the quality of the connection will be significantly lower. And every extra gap is a bridge of cold.

Stages of work

Thermal insulation of this type is installed as follows:

- The pipeline is cleared of old and unnecessary insulation (if used and not required).

- The areas that need to be insulated are measured.

- The number of shell segments is calculated.

- The insulation is installed from one “obstacle” (this could be a flange, turn, joint, fittings) to another.

- Each segment is attached using the chosen method (glue, groove, wire, or a combination thereof).

- If several fastening methods are used (for example, groove and tape, or groove, glue and tape, or any other combination), a second (third, fourth) fastening tool is used.

- Each segment is installed so that its transverse joint (cut) does not coincide with the joint of the adjacent one.

- If surface protection is used, it is installed and the joints are sealed.

- If necessary, areas that could not be insulated with a shell are separately insulated (by other methods: heating cable, rolled materials, spraying, paint).

Types of insulation

Mineral wool is produced in accordance with the standards ISO 9229, GOST 31913 from 2007, 2011, respectively. The raw materials for the heat insulator can be blast furnace slag, rock melts, and glass.

Basalt wool is the highest quality product, however, it has a high cost due to the high cost of electricity for heating the furnaces in which the rock is melted.

During manufacturing, different technological structures of the material fibers are specified:

- spatial,

- corrugated,

- vertically or horizontally layered.

Therefore, the characteristics and properties of mineral wool differ depending on the raw materials and manufacturing technology. However, high sound and heat insulating parameters, inertness to aggressive environments, chemicals, and extreme temperatures are present in all products, without exception.

Expanded polystyrene and its types

Rice. 2 Foam sheet - structure

The shell for insulating and insulating pipes is made of polystyrene foam, which is expanded polystyrene foam with an air content of more than 90%. Cylindrical segments of insulating pipes are cut from foam sheets of various thicknesses and brands.

Depending on the manufacturing technology, there are three types of foam plastics (PPS): non-pressed (PSB), pressed (PS) and extruded (EPS).

PSB is produced by foaming polystyrene foam suspension at high temperatures; it has industrial markings, which include, in addition to the letter designation, a digital indication of its density and the symbol C - self-extinguishing. This is a common cheap material widely used in construction to insulate the outer surface of buildings and interior spaces for various purposes.

PS is made after mixing and pressing polystyrene and porofore, after which the pressed blanks are foamed in a water vapor environment. Well-known brands - PS-1 and PS-4 have a higher density and better physical characteristics than conventional PSB.

EPPS - extruded polystyrene foam is produced by adding catalyst gases to polystyrene, leading to its foaming, after which the material is extruded from a special installation (extruder). In the construction industry, extruded polystyrene foam under the Penoplex trademark is widely used, which has the highest strength characteristics of all types of foam plastics.

Rice. 3 Technical characteristics of polystyrene foam PSB

Price for PU shell

Price list for polyurethane foam shells

| Pipe outer diameter, mm | Shell thickness, mm | Price of polyurethane foam shell without cover layer | Price of shell with covering layer - armofol | Price of shell with cover layer - fiberglass | Price of shell with cover layer - galvanized steel 0.4 mm | Price of galvanized steel casing 0.5 mm | Buy polyurethane foam shells |

| 18tr | 45 | 188 | 226 | 226 | — | 179 | |

| 24tr | 40 | 169 | 206 | 206 | — | 173 | |

| 28tr | 40 | 180 | 218 | 218 | — | 179 | |

| 32 | 40 | 191 | 230 | 230 | — | 186 | |

| 38 | 40 | 207 | 248 | 248 | — | 196 | |

| 40tr | 35 | 174 | 212 | 212 | — | 183 | |

| 40tr | 50 | 254 | 295 | 295 | — | 197 | |

| 45 | 30 | 149 | 186 | 186 | — | 174 | |

| 45tr | 45 | 229 | 268 | 268 | — | 190 | |

| 50tr | 45 | 241 | 282 | 282 | — | 197 | |

| 57 | 40 | 219 | 259 | 259 | 380 | 194 | |

| 57 | 50 | 284 | 327 | 327 | 458 | 208 | |

| 57 | 60 | 373 | 421 | 421 | 568 | 234 | |

| 57 | 70 | 472 | 493 | 493 | 647 | 245 | |

| 57 | 100 | 729 | 791 | 791 | 978 | 298 | |

| 60tr | 37 | 215 | 256 | 256 | — | 200 | |

| 76 | 40 | 262 | 307 | 307 | 444 | 220 | |

| 76 | 50 | 334 | 383 | 383 | 529 | 233 | |

| 76 | 60 | 406 | 457 | 457 | 609 | 244 | |

| 89 | 40 | 290 | 341 | 341 | 490 | 239 | |

| 89 | 50 | 369 | 421 | 421 | 578 | 251 | |

| 89 | 60 | 444 | 498 | 498 | 661 | 260 | |

| 89 | 100 | 878 | 947 | 947 | 1157 | 336 | |

| 108 | 40 | 315 | 366 | 366 | 521 | 250 | |

| 108 | 50 | 393 | 447 | 447 | 608 | 259 | |

| 108 | 60 | 468 | 524 | 524 | 689 | 265 | |

| 114 | 40 | 327 | 381 | 381 | 541 | 257 | |

| 114 | 60 | 485 | 541 | 541 | 711 | 272 | |

| 133 | 40 | 355 | 413 | 413 | 584 | 274 | |

| 133 | 50 | 455 | 516 | 516 | 696 | 289 | |

| 133 | 60 | 538 | 598 | 598 | 782 | 294 | |

| 154 | 50 | 473 | 535 | 535 | 719 | 295 | |

| 159 | 40 | 396 | 458 | 458 | 644 | 297 | |

| 159 | 50 | 485 | 548 | 548 | 736 | 300 | |

| 159 | 60 | 611 | 678 | 678 | 880 | 323 | |

| 159 | 90 | 966 | 1042 | 1042 | 1271 | 365 | |

| 168 | 40 | 386 | 447 | 447 | 626 | 288 | |

| 204 | 50 | 590 | 663 | 663 | 883 | 353 | |

| 204 | 60 | 735 | 814 | 814 | 1048 | 376 | |

| 205 | 66 | 831 | 912 | 912 | 1156 | 392 | |

| 219 | 40 | 481 | 553 | 553 | 770 | 347 | |

| 219 | 50 | 625 | 702 | 702 | 933 | 371 | |

| 219 | 60 | 777 | 859 | 859 | 1106 | 394 | |

| 219 | 80 | 1031 | 1117 | 1117 | 1372 | 408 | |

| 250 | 50 | 696 | 781 | 781 | 1035 | 406 | |

| 273 | 40 | 581 | 667 | 667 | 923 | 409 | |

| 273 | 50 | 750 | 840 | 840 | 1110 | 433 | |

| 273 | 60 | 861 | 949 | 949 | 1214 | 424 | |

| 273 | 90 | 1408 | 1510 | 1510 | 1815 | 488 | |

| 325 | 40 | 678 | 776 | 776 | 1069 | 470 | |

| 325 | 50 | 870 | 974 | 974 | 1282 | 493 | |

| 325 | 60 | 996 | 1096 | 1096 | 1396 | 480 | |

| 325 | 90 | 1548 | 1657 | 1657 | 1984 | 524 | |

| 341 | 50 | 908 | 1014 | 1014 | 1334 | 512 | |

| 377 | 50 | 991 | 1107 | 1107 | 1452 | 553 | |

| 377 | 60 | 1130 | 1242 | 1242 | 1576 | 536 | |

| 377 | 90 | 1742 | 1862 | 1862 | 2223 | 578 | |

| 406 | 80 | 1612 | 1734 | 1734 | 2100 | 586 | |

| 426 | 40 | 866 | 988 | 988 | 1355 | 587 | |

| 426 | 50 | 1026 | 1144 | 1144 | 1498 | 567 | |

| 426 | 60 | 1257 | 1379 | 1379 | 1747 | 589 | |

| 426 | 70 | 1497 | 1624 | 1624 | 2005 | 609 | |

| 426 | 100 | 2093 | 2223 | 2223 | 2611 | 623 | |

| 456 | 80 | 1706 | 1834 | 1834 | 2217 | 613 | |

| 459 | 60 | 1342 | 1472 | 1472 | 1862 | 624 | |

| 530 | 40 | 1058 | 1206 | 1206 | 1649 | 708 | |

| 530 | 50 | 1250 | 1392 | 1392 | 1816 | 679 | |

| 530 | 60 | 1526 | 1672 | 1672 | 2110 | 701 | |

| 630 | 50 | 1465 | 1629 | 1629 | 2121 | 787 | |

| 630 | 60 | 1784 | 1953 | 1953 | 2459 | 809 | |

| 669 | 70 | 2058 | 2226 | 2226 | 2729 | 805 | |

| 720 | 50 | 1660 | 1844 | 1844 | 2396 | 883 | |

| 720 | 60 | 1939 | 2121 | 2121 | 2665 | 870 | |

| 820 | 50 | 1803 | 2002 | 2002 | 2597 | 954 | |

| 820 | 60 | 2189 | 2391 | 2391 | 3000 | 974 | |

| 1020 | 50 | 2129 | 2361 | 2361 | 3057 | 1114 | |

| 1020 | 60 | 2578 | 2815 | 2815 | 3523 | 1134 | |

| 1220 | 60 | 3056 | 3334 | 3334 | 4167 | 1333 | |

| 1220 | 80 | 4138 | 4424 | 4424 | 5282 | 1373 |

Price list for thermal insulation bends made of polyurethane foam

| Outer diameter of steel bend, mm | Branch thickness, mm | Cost of tapping without cover layer | The price of a tap with a covering layer - armofol | The price of a bend with a covering layer - fiberglass |

| 28 | 40 | 180 | 218 | 218 |

| 32 | 40 | 191 | 230 | 230 |

| 40 | 40 | 174 | 212 | 212 |

| 45 | 30 | 150 | 186 | 186 |

| 50 | 45 | 241 | 282 | 282 |

| 57 | 40 | 219 | 259 | 259 |

| 76 | 40 | 262 | 307 | 307 |

| 89 | 40 | 290 | 341 | 341 |

| 108 | 40 | 315 | 366 | 366 |

| 114 | 40 | 327 | 381 | 381 |

| 133 | 40 | 355 | 413 | 413 |

| 159 | 40 | 396 | 458 | 458 |

| 219 | 40 | 481 | 553 | 553 |

| 219 | 80 | 777 | 859 | 859 |

| 273 | 40 | 696 | 781 | 781 |

| 325 | 50 | 870 | 974 | 974 |

| 377 | 50 | 991 | 1107 | 1107 |

| 426 | 50 | 1026 | 1144 | 1144 |

| 426 | 70 | 1497 | 1624 | 1624 |

| 426 | 100 | 2093 | 2223 | 2223 |

| 530 | 60 | 1526 | 1672 | 1672 |

| 630 | 60 | 1784 | 1953 | 1953 |

| 720 | 50 | 2129 | 2361 | 2361 |

| 720 | 60 | 2189 | 2391 | 2391 |

The need to insulate heating pipes

Due to the high cost of energy resources, thermal energy must be used rationally, which means that only the rooms that require it should be heated. If uninsulated pipes pass through a non-residential area, such as an attic or basement, then heat is wasted for other purposes. This circumstance leads to a decrease in the performance of the heating system and an increase in the cost of purchasing fuel.

Insulating the outer section of the heating main reduces the likelihood of the coolant freezing in the event of a sharp drop in outside temperature. True, freezing of the heat supply structure is unlikely, but traffic jams may appear.

For this reason, insulation of a pipeline laid outside a building is a prerequisite for the operation of both internal and external sections of the heating system. Correctly selected insulation thickness can ensure protection of heating network elements from various types of damage, serious breakdowns and corrosive processes.

PPU shell for pipe insulation - pros and cons

Advantages of polyurethane foam shell:

reduction of heat loss by 40%;

ease of installation. As practice shows, two people without special skills can insulate about 300 meters of pipeline with polyurethane foam shells in a day;

installation speed;

resistance of polyurethane foam to various types of influences: chemical, mechanical (partial), atmospheric, biological;

environmental Safety;

no temperature restrictions for the duration of work;

the possibility of reusing polyurethane foam pipe shells;

providing quick access to the damaged section of the pipeline;

absence of “winter steaming effect” - moisture does not condense on the pipe placed in a polyurethane foam shell;

long period of operation.

Disadvantages of PU shell:

additional costs for transporting segments;

inadmissibility of use at ultra-high temperatures (above +120 °C). Thus, thermal insulation for polyurethane foam pipes is not applicable for thermal insulation of steam pipelines.

Note. An innovative product from the Hot-shell group is designed for operation at a temperature of +170 °C

Advantages of a heat insulator

The technical characteristics of glass mineral wool are as follows:

- structure – fiber thickness is within 17 microns, the length is twice that of stone analogues;

- heat resistance – maximum 450˚С;

- thermal conductivity – 0.052 – 0.03 units;

- vapor permeability – 0.55 units;

- density – 12 – 18 kg/m3;

- sound absorption – 0.7 units.

Slag wool practically does not differ in properties from its glass counterpart, however, it sinteres already at +250˚C. Stone wool has improved characteristics compared to previous modifications.

For example:

- BSTV basalt heat insulator has the highest vibration resistance - loss of 0.35% of fibers during three-hour vibration;

- for BTV models it is slightly lower - 2% under the same conditions;

- slag wool, glass wool - materials lose 90% of their mass in the first half hour of vibration loads on the insulation material

The characteristics of URSA mineral wool are slightly improved compared to other analogues of glass wool, which the material is. There are three modifications of the material in the manufacturer’s line:

- Geo – raw materials are dolomite, soda, quartz sand, modifiers;

- Pure One - without freons, not scratchy when working with it, antistatic;

- Terra is a new product of professional quality with improved moisture resistance and is not afraid of contact with open fire.

The manufacturer Knauf produces a line of professional materials Insulation, two modifications for individual developers Heat Knauf.

The characteristics of Knauf mineral wool of the second category are as follows:

- format – slabs measuring 1.2 x 0.6 m, rolls measuring 6.15 x 1.2 m, 50 mm thick (Cottage modification) or twice as thick (CottagePlus model);

- fire safety - category NG;

- noise insulation – index 45 units;

- thermal conductivity – 0.037 units.

In addition, the manufacturer’s line includes household insulation materials Dom, Dom+, Dacha, industrial Thermal Plates, Thermorolls. The main difference between professional insulation is a higher thermal conductivity - 0.32 - 0.37 units, and an increased cost of materials.

Isover glass wool has a vapor permeability value of 0.55 units, which is rarely used in practice. On the inside it is covered with vapor barrier membranes that protect against swelling.

More useful when choosing a material are thermal conductivity (0.36 units), fire resistance (category G1 or NG), and density (16 kg/m3). The heat insulator easily fits into structural frames without gaps between slabs and rolls, preventing the formation of cold bridges and displacement of the thermal contour of the building.

Rockwool basalt wool is superior to glass analogues in practicality:

- five times longer service life due to vibration resistance;

- the ability to insulate hot structures (fireplaces, stoves, heating mains);

- a wide range of products (cylinders, plates, mats, foil versions, models with aluminum backing, based on kraft paper).

The manufacturer's line includes rolled material stitched with wire with one and two-sided coating of aluminum foil for the nuclear and petrochemical industries.

Thermal insulation for stoves with stone wool

Stone wool is one of the ways to provide thermal insulation for a stove.

According to the specified technical characteristics, thermal insulation for furnaces can easily withstand temperatures of 700 degrees, and with a short-term increase, it may not melt even at 900 degrees

The main advantages of mineral wool slabs are that they do not shrink after installation, and most importantly, they are completely protected from possible exposure to moisture. Also, mineral slabs are not sensitive to the effects of alkalis and acids; in general, this material has excellent performance characteristics.

It is worth noting that the use of mineral wool for thermal insulation not only increases the resistance of equipment to high temperatures, but also significantly reduces heat loss during the operation of the furnace, which means that the amount of fuel consumed can be significantly reduced.

Which insulation to choose?

Among the many insulating materials for sewer pipes, we recommend paying attention to foam shells. Why? Let's look at an example, comparing it with another popular thermal insulator, mineral wool.

Polystyrene foam or mineral wool?

Let's start with the fact that mineral wool is an environmentally hazardous material. It contains phenol (formaldehyde resins). Plus it is not recyclable. Polystyrene foam, on the contrary, is absolutely safe for health and has no operational restrictions.

Cotton wool cannot cope with mechanical loads and shrinks. Due to shrinkage, cold bridges appear. Foam shells are durable and maintain stable dimensions for a long time.

Mineral wool absorbs moisture, which requires the use of an additional heat-insulating layer. Polystyrene foam has a very low water absorption rate.

The use of mineral fiber wool is prohibited in wet weather. There are no restrictions on the installation of foam shells.

As you can see, polystyrene leaves virtually no chance for cotton wool. This does not mean that it is a bad insulation, but if possible it is better to use shells. If in doubt, here is a complete list of the advantages of such products.

Foam shells - main advantages:

• low weight – there is no additional load on the pipe; • easy installation - even an untrained person can quickly handle it (reducing the time required to complete the work); • structural stability – dimensions remain unchanged, the weight of the soil does not affect them; • resistance to water vapor diffusion; • environmental Safety; • low coefficients of moisture absorption and thermal conductivity (changes during use are very small); • absence of cold bridges due to the presence of a tongue-and-groove lock type connection; • durability – service life up to 50 years; • low price – as a result, a reduction in the cost of installing a sewer system; • versatility - suitable for use in various utilities, ventilation, water supply, sewerage, insulation of wells and gas pipelines.

Types of PU foam shells

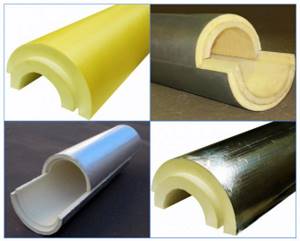

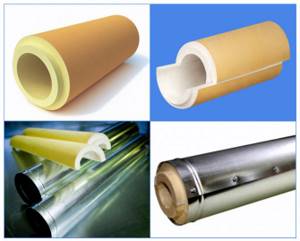

For the production of shells, liquid CFC-free polyurethane foams are used, which acquire rigidity and strength after polymerization. The main difference between the types of shells is the material used to make their shells; the main types of PU shells produced are:

- Without cover. A budget option, suitable for outdoor installation underground and on the surface, in rooms without the penetration of ultraviolet radiation. Uncoated shells are often used to insulate pipelines of external heating networks, placing them in casings made of galvanized steel sheet. If the shell cannot be hidden from sunlight, it is painted or covered with dense material that does not transmit ultraviolet radiation.

- With glassine. Kraft paper or glassine, in addition to protecting the surface layer from ultraviolet radiation, gives the shell an aesthetic appearance and prevents the upper layer from absorbing dirt deposits and breeding colonies of bacteria and microorganisms in the pores. A paper-coated pipeline gives the surface additional rigidity and makes it easier to clean and clean the outer walls from dirt.

- With metal galvanized insulation. Many manufacturers sell their products complete with casings made of sheet metal coated with zinc anti-corrosion coating. The casing is usually produced in the size of the outer diameter of the shells with a longitudinal locking connection; to protect against vandals on unprotected surface pipelines, steel cylinders are often connected to each other using screws screwed in with a screwdriver. Additional galvanized polyurethane foam insulation is used on large-diameter open pipelines in external highways of a city or regional scale.

Rice. 7 polyurethane foam shells without shell, in kraft paper, foil paper and armofol

Fiberglass.

The main advantage of fiberglass in comparison with galvanized steel protection is the high speed of coating pipes with shells. If the thermal insulation is damaged, it is much easier to cut out the defective area and glue a new one in its place than to dismantle and replace the metal casing. Shell pipe insulation in a fiberglass shell is better suited than other types for underground channel and non-channel installation on the shell of pipelines.

b). Folgopergamine. A large amount of heat loss in any type of pipeline is associated with infrared (IR) radiation; many heat insulators use foil to reflect it.

A thin foil layer of foil paper on the PU shell shell protects it from ultraviolet radiation, slightly increases strength, gives the product an aesthetic appearance, makes the surface smooth and dense, and reflects thermal infrared radiation.

Shells with foil-pergamine coating are used for internal and underground channel laying of long pipeline lines, where it is not subject to mechanical stress. Due to the reflection of infrared radiation on large volumes of long pipelines, its use allows obtaining a tangible economic effect.

V). Armofol. A coating made of aluminum foil, reinforced with reinforcement, is used to reduce heat losses in pipes, protect them from precipitation, mechanical damage and reflection of infrared radiation. Foil shells can be used for external and internal installation on long pipelines, where reflection of infrared radiation will save significant financial resources on heating the coolant.

Rice. 8 PPU shells in fiberglass and casings made of sheet steel

Varieties

Depending on the characteristics, polyurethane foam is divided into five main types: hard, elastic, reticulated, integral, foam. They have different areas of application and application technology.

PPU polyurethane foam can be classified according to its release form. It is produced in sheets, rolls, blocks, cylinders. There is also acoustic material. It has a certain relief that increases its noise-absorbing characteristics.

Hard

A special feature of rigid polyurethane foam is its closed-cell structure. Thanks to this, its thermal insulation properties increase. The material has a high density.

It is used for insulating structures and soundproofing rooms. It is also used to make packaging materials for transporting fragile items, home decoration, and much more.

Rigid polyurethane foam in the form of sheets of different sizes is used for flat surfaces. It is easy to process. It is easy to cut a piece of any shape from it. It is attached with glue or dowels.

PPU shells are used to insulate pipelines. It is a half-cylinder, cylinder or small segment. More often it has an additional foil coating to protect it from adverse environmental conditions. Fastened with glue, metal or plastic ties or binding wire.

Prices for sheet polyurethane foam depend on its thickness. 1m2 of the thinnest material will cost 550 - 600 rubles. Slabs 100 mm thick cost 1,700 – 2,000 rubles. Prices for uncoated shells vary from 150 to 7,000 rubles, depending on the diameter.

Reticulated

Modern scientists have succeeded in reticulating polyurethane foam. This process is comparable to a controlled explosion, which results in the destruction of the membranes of the material. The result is a structure with an open cell shape.

Reticulated polyurethane foam is used in water and air filtration systems, as well as to create sound insulation. It is also used to make packaging materials and household items: sponges, washcloths, etc. Installation of the material on the walls is done using glue.

The cost of 1 m2 of reticulated polyurethane foam ranges from 850 to 1200 rubles. The price depends on the thickness of the material and porosity grade.

Elastic

A distinctive feature of elastic polyurethane foam is its resistance to temperature changes and chemicals. The material does not lose its properties after decades of use. After mechanical impact, it quickly restores its original shape.

This type of polyurethane foam is widely used in furniture production and the automotive industry. It is used for furniture upholstery, armrests, pillows, etc. Builders use it to create heat and sound insulation coatings. It is often used as dampers when laying floors or pipes.

Elastic polyurethane foam can be easily mounted using universal adhesive on a surface of any configuration. The price of such coverage ranges from 500 to 800 rubles per 1 m2.

Integral

Integral is called polyurethane foam that has a sandwich structure. It is a gas-filled material enclosed in a dense shell. Combines elasticity and resistance to mechanical stress. It has vibration-isolating properties.

This type of polyurethane foam is widely used in the production of furniture, car body parts, and sports equipment. It is also used to produce façade elements and interior items.

Foamed

When producing such a material, chemical components are mixed in a vacuum space. Foam forms. It can be applied to surfaces of any configuration. After drying, a durable, dense coating is formed that has excellent thermal insulation properties.

Might be interesting

Foamed polyurethane foam is used as a filler for noise-absorbing partitions in the manufacture of anti-vibration shock-absorbing inserts for technological equipment. It has become most popular when creating thermal insulation for attics, foundations, roofs, walls, and floors. It is also allowed to be used to form a waterproofing coating.

Scope of application of PPS casing

The scope of application of polystyrene foam (EPS) insulation affects all sectors of industrial and municipal services; the technique is the most promising and can be used for insulation in the following cases:

- When insulating and protecting main pipelines running underground and on its surface from the effects of negative temperatures.

- For protection and thermal insulation of water, heating and sewer pipes in public and private sectors.

- When insulating air ducts of ventilation and air conditioning systems.

- To protect pipes supplying cold water from freezing when organizing individual water supply in country houses.

- When insulating wells and casing pipes.

Selection of materials

There is a wide range of insulating materials for heat supply lines on sale. To make the right purchase, it is necessary to take into account the characteristics of the room, its parameters and the operating conditions of the heating system.

The main factors influencing the choice of insulation:

- location of the pipeline that needs to be insulated;

- temperature of the coolant moving through the pipes;

- characteristics of the heating main;

- basic properties of materials intended for pipeline insulation.

When choosing, first of all take into account the following performance characteristics of insulation:

- heat resistance;

- thermal conductivity;

- fire safety;

- moisture resistance;

- thickness;

- resistance to decay and microorganisms;

- cost of installation work.

When purchasing materials for pipe insulation, you need to remember that the lower their thermal conductivity, the higher the thermal insulation performance. The degree of moisture resistance is reflected in the quality of protection of metal pipelines from corrosion processes and condensation formation.

The fire resistance of heat insulators must comply with fire safety requirements for heated premises. To calculate the thickness of the material used, special formulas are used.

Application of foil thermal insulation for pipes

According to experts, the simplest way to thermally insulate pipelines in the basement is to use mineral wool, which is covered with a layer of foil, while the thickness of the wool reaches 50 millimeters, and the reflective layer - 10-30 microns.

Before you begin insulating pipes in the attic or basement, you need to study the operating conditions of the materials. For example, foil with polyethylene foam is fragile and is subject to deformation under external influences. Strength indicators can be increased if you prefer thermal insulation with foil for pipes and foam plastic.

In turn, basalt insulation has many common characteristics with mineral wool, but it is heavier because it has a higher density.

It is convenient to install self-adhesive insulation. If the foil is damaged, use aluminum tape. Mylar film with foil and polyethylene foam do not reflect infrared radiation, so such material must have a significant thickness of the foil layer.

The price of thermal insulation of sewer pipes

Companies that deal with sewer insulation determine the cost of the work based on various factors. When compiling prices for thermal insulation for external sewerage, the following is taken into account:

- Scope and complexity of the procedure

. The master will raise the price for a long highway with a lot of turns. If the pipes are buried in the ground, you will have to pay for excavation work. Costs will increase for installation of products that absorb moisture well. In this case, the master will have to waterproof the insulation. - Pipe insulation technology

. The simplest option is to use products coated with insulation in the factory. It is also considered simple to work with a foam shell - just install two halves on the product and compress them until the fastening elements operate. - Turnaround time

. In winter, they try to complete the procedure as quickly as possible, so it will cost more. - Cost of insulation and related materials

. The price of special devices for performing the work is also taken into account (for example, a device for applying penoizol or spraying heat-insulating paint). The cheapest option is to create a box from any material around the pipe and fill it with foam chips. Expensive methods include installing a heating cable with an automatic temperature control system. The cost of the work also includes the dismantling of the old heat insulator.

The comparative cost of materials for sewer insulation and their installation is given in the tables.

Price of insulation for sewer pipes in Russia:

| Material | Insulation price |

| Basalt wool | 110-125 rub./m.p. |

| Glass wool | 70-75 rub./m.p. |

| Styrofoam | 2560-3200 rub./cube |

| Foamed polyethylene for pipes | 25-33 rub./m.p. |

| Penofol | 50-56 rub./m.p. |

| Expanded clay | 60 rub/bag (0.4 cubic meters) |

| PPU shell | 160-230 rub. with a thickness of 24 mm |

| Heating cable | from 1000 rub./m.p. |

Price of insulation for sewer pipes in Ukraine:

| Material | Insulation price |

| Basalt wool | 45-72 UAH/m.p. |

| Glass wool | 25-37 UAH/m.p. |

| Styrofoam | 1100-1800 UAH/cube |

| Foamed polyethylene for pipes | 18-19 UAH/m.p. |

| Penofol | 22-31 UAH/m.p. |

| Expanded clay | 25 UAH/bag (0.4 cubic meters) |

| PPU shell | 74-130 UAH. with a thickness of 24 mm |

| Heating cable | from 280 UAH/m.p. |

The price of thermal insulation of sewerage from steel pipes with a diameter of 108 mm and a length of 10 linear meters. mineral wool mats in Russia:

| Name | price, rub. |

| Primer | 57 |

| Vapor barrier | 112 |

| Mineral wool | 590 |

| Fixation tape | 48 |

| Sheet steel for casing 0.5 mm | 540 |

| Cost of work | 1300 |

| Total | 2627 |

The price of sewerage insulation from steel pipes with a diameter of 108 mm and a length of 10 linear meters. polyurethane foam in Russia:

| Name | price, rub. |

| Steel pipe with insulation | 3200 |

| Cost of work | 1000 |

| Total | 4200 |

The price of thermal insulation of sewerage from steel pipes with a diameter of 108 mm and a length of 10 linear meters. liquid heat insulator in Russia:

| Name | price, rub. |

| Liquid heat insulator | 1360 |

| Cost of work | 1020 |

| Total | 2380 |

The price of thermal insulation of sewerage from steel pipes with a diameter of 108 mm and a length of 10 linear meters. mineral wool mats in Ukraine:

| Name | Price, UAH. |

| Primer | 28 |

| Vapor barrier | 45 |

| Mineral wool | 250 |

| Fixation tape | 23 |

| Sheet steel for casing 0.5 mm | 260 |

| Cost of work | 570 |

| Total | 1176 |

The price of sewerage insulation from steel pipes with a diameter of 108 mm and a length of 10 linear meters. polyurethane foam in Ukraine:

| Name | Price, UAH. |

| Steel pipe with insulation | 1340 |

| Cost of work | 570 |

| Total | 1910 |

The price of thermal insulation of sewerage from steel pipes with a diameter of 108 mm and a length of 10 linear meters. liquid heat insulator in Ukraine:

| Name | Price, UAH. |

| Liquid heat insulator | 450 |

| Cost of work | 1020 |

| Total | 1470 |

How to insulate a sewer - watch the video:

There are a large number of inexpensive insulation materials on sale, the installation of which does not require experience in such work. Therefore, you should not save money and postpone thermal insulation of sewerage pipelines until an emergency situation occurs on the main line - restoring the functionality of the sewerage system will cost more.

Related article: How to make sewer ventilation with your own hands

Self-installation of thermal insulation

Work on insulating heating pipes using thermal insulating polystyrene foam shells is carried out as follows:

- The halves of the material are put on the pipe and their displacement relative to each other is ensured - this is required for an overlap measuring 10–20 centimeters.

- The half-cylinders should be secured in advance with tape. If a surface protective layer needs to be applied, it is attached at the very end.

- To ensure that the shell adheres more securely to the pipeline, the joints must be taped.

- When it is necessary to insulate heating pipes at turns in the main, shaped types of shells are used.

In many ways, the choice of materials for insulating heating system elements depends on the operating conditions of the heating main and its structural design. Thermal insulation work is simple and can be done by any home craftsman if desired.

So, when a stove is built and a chimney is installed for it, this does not mean at all that all work on its construction has come to an end.

Installation of insulation

Installation of insulation

Let's consider the insulation of pipes using the example of installing a heat-insulating shell made of polystyrene foam.

Installing such a shell is quite simple and quick, without requiring special skills or abilities, and includes the following steps:

- The shell halves are placed on the pipes, ensuring their displacement relative to each other, required for overlap. The displacement value can be from 100 to 200 mm, the diameter coincides with the diameter of the pipe;

- The halves to be put on are fastened in advance using tape, and in the case of using a protective material located on the surface, its fastening is carried out after completion of the work;

- In the case when pipe insulation is used to insulate various corners, turns or nodes of the water supply system, it is best to use shaped shells, which do not have any special requirements - they are chosen according to your taste;

- Now you know how to insulate a water pipe using shells. To dismantle the thermal insulation, proceed in the reverse order: first remove the protective layer, then remove the adhesive tape and continue until the pipe is freed from the foam shells.

Insulation for polystyrene foam pipes, manufacturing and use features

The foam shell is made on special machines by cutting out a segment from foam plates using a heated string. The industrially produced insulating shell has the following operational parameters:

- The insulation is produced in the form of a prefabricated cylinder of various lengths and thicknesses; the standard shell for pipes has two or four segments; for wells their number can reach up to 8.

- Standard materials for the manufacture of the shell are PSB-S foam plastics of various densities; for open pipelines, a material with a more durable structure is used.

- The temperature of the pipes on which the shell is installed should not exceed 80 C. With special additional gaskets, the insulation can be used at temperatures up to 110 C.

- The standard size of the shell is 1 meter long, the minimum diameter of the inner circle is 17 mm, the maximum size of the inscribed circle is 1220 mm. wall thickness may vary.

Rice. 6 How to obtain a thermal insulation shell

- All halves of the shell have protrusions that provide a tenon-to-groove connection; glue or tape is additionally used to fix them. The assembled shell can always be disassembled without damage or deformation.

- For external work, a polystyrene foam shell is used, coated with a material that protects its surface from exposure to ultraviolet radiation.

- Computer-controlled machines make it possible to produce shells of the required thickness and diameter to order; some modifications have a groove for laying a heating cable.

THERMAL INSULATING SHELL MADE OF FOAM (POLYSTYRENE) FOR PIPES OF ANY DIAMETER

Nizhny Novgorod "01" July 2021

This Personal Data Privacy Policy (hereinafter referred to as the Privacy Policy) applies to all information that the PenoProfi website, located on a domain name (hereinafter referred to as the website), can receive about the User while using the site, programs and products of the site.

- DEFINITION OF TERMS

1.1. The following terms are used in this Privacy Policy:

1.1.1. “Site Administration” - authorized employees to manage the site, acting on behalf of Penoprofi LLC, who organize and (or) process personal data, and also determine the purposes of processing personal data, the composition of personal data to be processed, actions (operations), performed with personal data.

1.1.2. “Personal data” – any information relating directly or indirectly to a specific or identifiable individual (subject of personal data).

1.1.3. “Processing of personal data” – any action (operation) or set of actions (operations) performed using automation tools or without the use of such means with personal data, including collection, recording, systematization, accumulation, storage, clarification (updating, changing), extraction, use, transfer (distribution, provision, access), depersonalization, blocking, deletion, destruction of personal data.

1.1.4. “Confidentiality of personal data” is a mandatory requirement for the Operator or other person who has access to personal data to not allow their distribution without the consent of the subject of personal data or the presence of another legal basis.

1.1.5. “Site User (hereinafter referred to as the User)” is a person who has access to the Site via the Internet and uses the Site.

1.1.6. “Cookies” are a small piece of data sent by a web server and stored on the user’s computer, which a web client or web browser sends to the web server each time in an HTTP request when an attempt is made to open a page on the corresponding site.

1.1.7. “IP address” is a unique network address of a node in a computer network built using the IP protocol.

- GENERAL PROVISIONS

2.1. The User's use of the site constitutes agreement with this Privacy Policy and the terms of processing of the User's personal data.

2.2. In case of disagreement with the terms of the Privacy Policy, the User must stop using the site.

2.3. This Privacy Policy applies only to the site and does not control and is not responsible for third party sites that the User can access through links available on the site.

2.4. The site administration does not verify the accuracy of the personal data provided by the site user.

- SUBJECT OF THE PRIVACY POLICY

3.1. This Privacy Policy establishes the obligations of the Site Administration to non-disclose and ensure the protection of the confidentiality of the User’s personal data.

3.2. Personal data permitted for processing under this Privacy Policy includes the following information:

3.2.1. last name, first name, patronymic of the User;

3.2.2. User's contact phone number;

3.2.3. email address (e-mail);

3.2.4. place of residence of the User.

3.3. protects Data that is automatically transmitted when visiting pages on which the system’s statistical script (“pixel”) is installed:

- IP address;

- information from cookies;

- information about the browser (or other program that accesses advertising);

- access time;

- address of the page on which the advertising unit is located;

- referrer (address of the previous page).

3.3.1. Disabling cookies may result in the inability to access parts of the site that require authorization.

3.3.2. collects statistics about the IP addresses of its visitors. This information is used to identify and resolve technical problems.

3.4. Any other personal information not specified above (browsers and operating systems used, etc.) is subject to secure storage and non-distribution, except for the cases provided for in paragraphs. 5.2. of this Privacy Policy.

- PURPOSES OF COLLECTING USER'S PERSONAL INFORMATION

4.1. The Site Administration may use the User’s personal data for the following purposes:

4.1.1. User Identification.

4.1.2. Providing the User with access to personalized resources of the Site.

4.1.3. Establishing feedback with the User, including sending notifications, requests regarding the use of the Site, provision of services, processing requests and applications from the User.

4.1.4. Determining the location of the User to ensure security and prevent fraud.

4.1.5. Confirmation of the accuracy and completeness of personal data provided by the User.

4.1.6. Creating an account if the User has agreed to create an account.

4.1.7. Providing the User with effective technical support if problems arise related to the use of the Site.

- METHODS AND TERMS OF PROCESSING PERSONAL INFORMATION

5.1. The processing of the User's personal data is carried out without a time limit, in any legal way, including in personal data information systems using automation tools or without the use of such tools.

5.2. The User’s personal data may be transferred to authorized government bodies of the Russian Federation only on the grounds and in the manner established by the legislation of the Russian Federation.

5.3. In case of loss or disclosure of personal data, the Site Administration informs the User about the loss or disclosure of personal data.

5.4. The site administration takes the necessary organizational and technical measures to protect the User’s personal information from unauthorized or accidental access, destruction, modification, blocking, copying, distribution, as well as from other unlawful actions of third parties.

5.5. The site administration, together with the User, takes all necessary measures to prevent losses or other negative consequences caused by the loss or disclosure of the User’s personal data.

- OBLIGATIONS OF THE PARTIES

6.1. The user is obliged:

6.1.1. Provide information about personal data necessary to use the Site.

6.1.2. Update, supplement the provided information about personal data if this information changes.

6.2. The site administration is obliged to:

6.2.1. Use the information received solely for the purposes specified in clause 4 of this Privacy Policy.

6.2.2. Ensure that confidential information is kept secret, not disclosed without the prior written permission of the User, and also not sell, exchange, publish, or disclose in other possible ways the transferred personal data of the User, with the exception of paragraphs. 5.2. of this Privacy Policy.

6.2.3. Take precautions to protect the confidentiality of the User's personal data in accordance with the procedure usually used to protect this type of information in existing business transactions.

6.2.4. Block personal data relating to the relevant User from the moment of application or request from the User or his legal representative or the authorized body for the protection of the rights of personal data subjects for the period of verification, in the event of detection of unreliable personal data or unlawful actions.

- RESPONSIBILITY OF THE PARTIES

7.1. The site administration, which has not fulfilled its obligations, is responsible for losses incurred by the User in connection with the unlawful use of personal data, in accordance with the legislation of the Russian Federation, except for the cases provided for in paragraphs. 5.2., 5.3. and 7.2. of this Privacy Policy.

7.2. In case of loss or disclosure of Confidential Information, the Site Administration is not responsible if this confidential information:

7.2.1. Became public domain until it was lost or disclosed.

7.2.2. Was received from a third party before it was received by the Site Administration.

7.2.3. Was disclosed with the consent of the User.

- DISPUTE RESOLUTION

8.1. Before filing a claim in court regarding disputes arising from the relationship between the Site User and the Site Administration, it is mandatory to submit a claim (a written proposal for a voluntary settlement of the dispute).

8.2. The recipient of the claim, within 30 calendar days from the date of receipt of the claim, notifies the claimant in writing about the results of consideration of the claim.

8.3. If an agreement is not reached, the dispute will be referred to a judicial authority in accordance with the current legislation of the Russian Federation.

8.4. The current legislation of the Russian Federation applies to this Privacy Policy and the relationship between the User and the Site Administration.

- ADDITIONAL TERMS

9.1. The site administration has the right to make changes to this Privacy Policy without the consent of the User.

9.2. The new Privacy Policy comes into force from the moment it is posted on the Site, unless otherwise provided by the new edition of the Privacy Policy.