Every owner of a house, small or large, wants to give it an original and attractive appearance. But often heavy elements require additional strengthening of the supporting structure.

Also, stucco is quite expensive and not everyone can afford such a pleasure. You can try to solve these problems by installing polystyrene foam façade decor with your own hands.

How to make façade decor from polystyrene foam?

Transforming your own home is a natural desire. Most often this concerns the interior parts of premises: various decorative elements and design solutions are used. But as a rule, not many people care about the outside, and this is not quite the right approach to the matter. The way the façade looks is an important component that forms a unified architectural style. Recently, facade decor made from polystyrene foam has been increasingly used as decoration, the features and varieties of which will be discussed.

Figure 1. Example of facade decor made of foam plastic

Foam plastic for finishing

Facade decor of a building with polystyrene foam

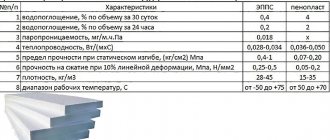

Many are accustomed to perceiving polystyrene foam solely as insulation - it is fragile and flammable, and also has an exclusively white surface. In fact, this is a common misconception; modern technologies make it possible to make dense, non-flammable slabs with a wide variety of surfaces from polyurethane foam.

Today in stores you can find polystyrene foam of three markings:

- Psb-15

- Psb-25

- Psb-35

Psb is an abbreviation for the words polystyrene block, and the numbers indicate the density of the board and the size of the foam fraction.

Expanded polystyrene

Basically, polystyrene foam is labeled PSB-35. This is a high-density board that is absolutely not afraid of temperature changes and even open fire. And for installation you only need glue.

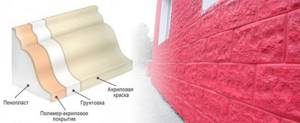

Reinforced facade foam is already covered with decorative plaster or, more correctly, polymer concrete, which greatly simplifies the work process. As a rule, imitation brick is applied to such slabs. The wall of the house retains its natural appearance, but without flaws or construction flaws.

Someone reading this article now will think that they have found the ideal finishing material, but I hasten to disappoint you - it also has a number of its own shortcomings:

- Despite its resistance to fire, when melted it emits caustic, toxic smoke, which should never be inhaled.

- The foam facade can be damaged by any sharp or heavy object, after which the entire segment will have to be replaced.

- Mice love to live in warm façade foam boards, so the walls must be pre-treated with special products.

- Polystyrene for the facade does not breathe at all and does not release condensation that accumulates on the walls.

- It is not advisable to use facade foam boards on wooden houses. Accumulating condensation has a negative impact on the tree.

Facade decor of a private house made of polystyrene foam

Fortunately, there are still more positive qualities:

- Does not require additional finishing.

- Does not rot or form mold.

- Does not require additional vapor barrier.

- Significantly saves home heating costs.

- Durable.

- Cheaper than many finishing materials.

- Simple and easy to install.

Tip: when choosing reinforced foam plastic in a store, you need to carefully check the quality of the coating of each block. Chips or scratches will significantly reduce service life.

If the choice is made in favor of facade foam, then you can move on to installation technology.

Advantages and disadvantages

The facade is decorated not only because it makes the house more beautiful. Such work also has practical benefits. The materials used protect the external walls from precipitation, winds, noise, additionally serving as a heat insulator.

The stucco molding is formed by a programmable machine that uses thermal cutting. This makes it easier to create almost any architectural design. Thus, a specialist, using a special computer program, first models the object, and then “cuts” it out using a machine, observing the exact dimensions and radial mates.

The equipment allows you to recreate an exact copy of the model, which, after cutting is completed, is coated with a protective compound. Sometimes during manufacturing a reinforcing mesh is used to increase the strength characteristics. As a finishing coating, a cement-adhesive layer is used, with a thickness of 1 to 6 mm, which can contain different fillers. It is this that protects the finished part from ultraviolet radiation, water and temperature fluctuations.

Foam facade stucco molding has remained in demand for many years, as it has the following advantages:

- light weight. Here we note that recently facades are increasingly insulated using mineral wool or foam boards. This puts forward a requirement for the finishing, and at the same time for the stucco molding for the facade - it must be light. In this regard, everything is in order - it does not create any special load, and it is easier to transport;

- low price;

- relatively short production time;

- easy to process. Cement, gypsum mortars, liquid polystyrene foam, mastic or glue are suitable for gluing stucco molding;

- does not rot, does not become covered with mold or mildew;

- not afraid of water;

- easy to install;

- protects external walls from freezing.

There are also disadvantages. Expanded polystyrene decorations do not tolerate mechanical damage well and cannot serve as a load-bearing part of the structure (due to their structure). By the way, damaged stucco can be easily restored by masking the defect with gypsum mortar. Recently, facade decor has been produced from foam plastic with acrylic coating, which increases resistance to negative influences.

Material capabilities

Firstly, the possibility of using finishing materials for decorating a private home. Numerous elements are shown on the façade of the large two-story structure. However, this does not mean that foam facade decor can only be used on mansions. In any building you can install individual elements or other details, including those of an exclusive nature.

Foam plastic will help realize any ideas for interior and exterior decoration

The following are the most common decorative elements made of polystyrene foam for the facade:

- moldings;

- cornices;

- rustic;

- columns;

- pilasters.

When performing them, different techniques can be used:

- stucco;

- bas-reliefs;

- thread;

- ornaments;

- patterns;

- vases;

- flowerpots, etc.

Secondly, the cladding can be made from standard parts, exclusive elements, purchased ready-made or made by hand.

Finishing the facade of a house with foam plastic may include the following solutions:

- foam cornice with thread;

- porticos;

- architectural modillions;

- rustication of the basement or the entire corner of the building;

- foam carved window frames;

- console elements;

- portals and flutes.

Thirdly, decorative foam for facades has the following advantages:

- fairly fast and simple production of parts;

- low cost;

- high service life;

- no size restrictions;

- the ability to carry out work independently;

- absence of significant additional mechanical loads on the wall and foundation, taking into account the low specific weight of plastic;

- fairly high compressive strength;

- no risk of rotting and mold;

- high resistance to any climatic conditions in all regions of the country;

- long-term color retention.

Common types of architectural elements made of polystyrene foam

The shapes and decor of the building are constantly being improved. So, now there is a noticeable trend towards reducing the overall weight of the structure. At the same time, those who build a house will never give up interesting and unusual forms, and most importantly, practical ones. When working with polystyrene foam facade decor, you can come up with many original ideas. However, there are elements that have already become classics and have many distinctive features.

Decorative columns

In the current construction conditions, polymer columns are not a structural element, but a purely decorative one. They come in rectangular or round cross-sections and come in a variety of sizes and styles. As for appearance, they, like traditional columns, consist of three parts: base, body and capital. However, even metal supports are decorated with polystyrene foam, or pipes are decorated with it.

Pilasters

If we consider classical architecture, then with the help of pilasters the walls were given the appearance of support. Visually, this element is similar to a column, but in fact it is a decorative protrusion. The part is made not in volume, but in relief form. The pilaster consists of the same parts as the column, and they are assembled separately.

Architectural profiles

Since they differ in appearance and shape, they carry certain functions:

- façade cornice. This is one of the main elements of the facade. Installed in different places: under the roof, between floors. The selected size and shape of the product depend on the geometry of the structure;

- horizontal decorative profile. Visually similar to the facade variety, it only serves as a “separator”. With their help, they divide the house into levels;

- window sill elements. The place of their installation is the base of the window opening;

- corner profiles. They decorate the corners of openings for windows and doors;

- "rustic siding" One of the ways to rusticate the facade of a building. There are several installation methods.

Pediments

This decor is most often found on the following architectural structures: classical Greek temples, Renaissance and neoclassical buildings. As a rule, it is a triangular-shaped part with stucco on each side. Sculptures are often installed along the pediment field to complement the exterior.

Most often these are semi-cylindrical structures. Their role is purely decorative. Foam arches are installed above windows or doors; they are used to decorate “false” windows and columns.

Keystones

In architectural terms, these are cornerstones mounted above an arch or vault. Since now such an element can easily be made from polystyrene foam, it is used to decorate gates, doors, windows, ceilings, etc. The keystone allows you to fully realize the design idea, thanks to the variety of models. It suits both classic and modern styles. Installation of polystyrene foam stones is quite simple. Recently, to increase their strength and rigidity, a special coating has been provided.

Corner elements

This is one of the tricks for decorating the corners of the house, which, as a result, get a more reliable and durable appearance. Most of the manufactured parts are made in the form of tiles, with slightly beveled ribs along which rainwater flows.

Balustrades

Serves as decor for stairs, terraces, balconies and so on. The structure is a parapet supported by volumetric “pillars”. Sometimes it serves as decoration for the houses themselves, which indicates respectability. There is also an option when windows are trimmed with balustrades (they look like supporting supports).

Rosettes

It is a round or oval stucco molding with an ornament in the center (most often it is an open flower or an animal’s head). Often found in richly decorated facades.

Technological stages

Finishing the facade with foam plastic, although it is considered a fairly simple undertaking accessible to anyone, is carried out in several stages, taking into account certain principles.

Decorating with polystyrene foam is a simple task, the main thing is to follow the steps

The following main stages are distinguished:

- preparatory work;

- production or purchase of decorative elements;

- surface leveling;

- installation of foam plastic with its reliable fastening in the right place;

- application of protective and finishing coatings.

The preparatory stage begins with the development of a general facade design project. At this stage, the design style and the number, type and size of decorating elements are determined; a diagram of their placement is drawn. Next, the surface is thoroughly prepared for the application of polystyrene foam:

- surface leveling;

- cleaning the installation site from dirt and grease stains.

Installation of foam decor includes the following processes:

- Alignment of the facade structure on which the decor is planned to be installed. As a rule, such areas include cornices, window sills, certain areas on the wall, and jambs of window and door openings. Leveling is carried out by applying plaster.

- Installation of decor. Facade foam is attached with a special glue designed specifically for this material. In particular, you can o. The adhesive composition is applied to the entire back side of the part, and then it is pressed to the installation site and held until it is stuck with glue. When installing large parts or in cases where they protrude more than 10–12 cm above the wall surface, the fastening is reinforced with dowels or anchors. To install them, holes are carefully pre-drilled in the foam. If such a need arises after installation, then drilling is done after the glue has completely cured (2–3 days). Filling elements are installed in appropriate places on the wall. When installing parts in a vertical position on the wall, it is recommended to ensure that they are pressed for 30–40 hours.

- Sealing joints and seams. This operation is carried out using special facade sealants, which are applied with a facade brush. After the composition has dried, the joints are grouted. Merolith S1 can be recommended as such a sealant.

- When a façade decor made of coated polystyrene foam is envisaged, a number of additional works are carried out. A thin layer of primer is applied to the surface of the plastic. After it has hardened and sanded, the façade elements are coated with acrylic paint in 2 layers.

Decorative wood imitation

A home with such decor becomes cozier and more comfortable. The method is often used to recreate an ethnic style. A visual feature is that the stucco molding imitates the carving technique that was used in Russian huts.

Modern foam production differs from early architectural trends. However, from a visual point of view, the difference is practically not noticeable. If previously the decor was made of stone, concrete and plaster, now more modern and affordable material is available. It is filled with gas, so it weighs very little (density - from 25 to 35 kg/m2).

If desired, you can make decor from foam plastic with your own hands, but for this, at a minimum, you will need equipment for thermal cutting.

Original ideas for decor

Foam plastic decor for the facade is a way to give the building some romantic warmth.

Advice! If you complete the upper part of the residential building with a foam decorative entablature and add decorative columns to it, the house will become a real castle.

Such a house, decorated with figured decor made of polymer material, will become a source of pride in front of your guests. Decorative chips applied to the façade decor made of polystyrene foam can make your home more original.

Among those architectural elements that can be made from foam plastic, we highlight:

- moldings;

- carved cornices;

- console fragments;

- modillions;

- design of the basement of the house

Recommendations for choosing colors

Foam parts are painted with acrylic paint. The finished structure can be repainted if necessary. In general, the entire range of color palettes is available.

There is no need to indulge your imagination too much here. Now there are palettes that have already become traditional in architecture. The most common color is white. Its popularity is determined by two factors: a white house looks “clean, bright and formal”; this option is simply cheaper (since it does not contain pigments). In addition, when repainting you won’t have to rack your brains with shades. If you have no experience in painting facades, then it is better to prefer white. Of course, the desire for innovation can overcome common sense, but in this case it is better to contact a designer who visualizes the house in a special computer program.

Main types of facade decoration of buildings

A large number of different elements are used to decorate facades, among which the most common are:

- Rustic stones. As a rule, they have a wedge shape. The main purpose of these architectural elements is to decorate plinths and various openings - both doors and windows.

- Sandriki. They represent the finishing of the top of window openings of buildings. These are the key details in how an outsider perceives the cladding of a structure. Sandriks can have a variety of forms. Most often they are rectangular. Despite this, in some cases their corners are rounded.

- Brackets. They are used as a support for other elements protruding from the plane of the facade. This creates the impression of monumentality and reliability of the structure.

- Sockets. This is the name given to absolutely any decoration on the facade of a building that has a round shape resembling a flower.

- Balustrades. This is the name given to the fencing of building balconies.

- Moldings. With their help, you can emphasize this or that structure of the structure, if it does not stand out strongly against the background of the wall plane.

- Pilasters, platbands. Necessary for finishing window openings or main entrances to a building. With the help of such elements you can give a distinctive feature to the entire decoration of the structure.

- Columns. As a rule, in their classic design they consist of a base, a trunk and a capital. On the facades of modern buildings they are used only as decorative elements, without supporting heavy structures.

- Rust and façade draft. These horizontal elements divide the wall plane into several parts, giving it a more perfect look.

- Windowsill. It represents the lower part of the frame of almost any window opening.

- Base. This decorative element allows you to give an interesting look to the basement of the structure. In some cases it acts as a low tide.

Thus, facade decor for the exterior of a house can be very diverse. It allows you to give the exterior of any building a truly recognizable and unique appearance.

At the same time, experts pay attention to the fact that when using certain elements there is no need to overdo it. Too much load on the wall with various decor becomes not very attractive to an outside viewer.

What is polystyrene foam façade decor?

Stucco molding is a necessary part of neoclassicism or eclecticism. In ancient times, such decorations were made from marble, plaster, plaster or other materials. Now there is a wonderful opportunity to buy them ready-made and attach them to the facade. Moreover, they will not load the load-bearing part of the structure. Coated polystyrene foam facade decor has become widespread, as it can be used to quickly and inexpensively decorate a building.

An example of a façade with decorative stucco molding made of polystyrene foam

Installation of foam sandwich boards

Sandwiches with large format EPS insulation are attached to the façade with self-tapping screws or dowel screws, depending on the wall material. The fastening pitch is 30 cm.

Smaller sandwich panels are often sold under the name “composite panel”; special glue can be used to cover such panels. The sequence of work includes preparing the walls, marking guides or slabs and installing the panels themselves.

Installation of a monolithic facade

After preparing the wall, which consists of removing the old paint layer, marks, mortar residues or peeling plaster, marking the position of the slabs by level is applied to the wall.

A perforated profile is mounted - a starting strip around the perimeter of the house; its shelf should be 2 cm below the junction of the foundation or plinth and the wall. The starting strip serves as a support for the bottom row of panels and prevents rodents and insects from entering the slab.

To give corners a neat look, some manufacturers produce special corner panels. If such panels are not provided, it is necessary to secure brackets for hanging strips at the corners. Installation of finishing panels is carried out from the corner, from bottom to top. If necessary, the slabs are trimmed with a grinder. An adhesive composition is applied to the back surface of the slab along the perimeter, 2 cm away from the edge, and in the center; the panel is placed in place, pressing firmly.

For greater accuracy of finishing, it makes sense to pull the cord at the level of the width of the cladding. The correct position of the slabs is verified by a long rule. When gluing the slabs of the next row, the joint of the panels is shifted to the middle of the slab of the previous row. After the installation of the panels is completed, flashings and window sill ebbs are attached to the corners and slopes of the openings.

Installation of a ventilated facade

Finishing panels made of PPS can be used to create a curtain wall. To do this, after preparing the surface of the walls, a supporting frame is installed. The frame can be made of timber or galvanized metal profiles can be used.

A vapor-permeable film or super-diffusion membrane is attached to the surface of the walls, then a beam with a cross-section of 40x40 mm is mounted in increments of 40–60 cm, at the corners of the building and around the openings. A counter-lattice with a cross-section of 40x25 mm is attached to the beam with a step equal to the height of the panels in the horizontal direction.

The slabs are attached to the counter-lattice with self-tapping screws in the grooves, slightly recessing the heads into the body of the insulation. Otherwise, the installation of a ventilation facade made of thermal panels repeats the sequence of work when gluing the finish.

PLEASE NOTE: From the point of view of heating engineering, a ventilated facade made of thermal panels is not insulation, since when calculating the layers it is not taken into account due to the presence of a gap ventilated with cold air. However, if there is no gap, there is a high probability of fungus or algae forming on the wall.

Advantages and properties of facade decor

There are many reasons to install facade decor made from expanded polystyrene:

- Low weight of the product - imitation stucco does not put unnecessary load on the facade.

- Durability - expanded polystyrene does not deteriorate under the influence of sunlight, moisture, or temperature changes.

- Simple installation - no need to contact builders, you can do it yourself. The decor is attached with glue.

- The product can be painted - you can choose any color.

- Aesthetic qualities - the most complex architectural forms can be obtained from polystyrene foam.

- Affordable price - the purchase of material will cost much less money than if you decided to create gypsum stucco.

- Safety - since the stucco molding is very light, if it falls, it poses virtually no danger to a person walking past the building. But plaster decor can cause injury.

- Heat and sound insulation - expanded polystyrene is an insulation material that reduces heat loss and dampens sound waves.

More durable - facade decor made of foam plastic with a composite or cement-polymer coating

Features of installing facade decor with your own hands

We have already touched a little on the description of the installation of facade slabs and the application of decorative plaster.

All that remains is to learn how to attach façade elements from the most popular materials. The easiest way to install foam products and parts made of polystyrene foam. Polyurethane parts of the facade are installed in the same way. This DIY facade decoration is so simple that even a person far from construction can handle it.

First of all, you need to remember that attaching foam parts is possible only in the warm season. The outside temperature should be between +15 and +25.

- Surface preparation is one of the most important steps. If the wall is not prepared appropriately, the elements will fall off over time. First you need to clean the surface of everything unnecessary - old paint, plaster, protruding parts. To do this, use sandpaper, a spatula, and in some cases a sander. Tap the wall with a rubber or wooden hammer. Where the wall is damaged, repair the surface and allow to dry. Another important point in preparation for installation is checking the surface with a level. When gluing slabs, unevenness of 10 mm per 1 square meter is allowed. When gluing small parts, it is good if the wall is perfectly flat.

- The next stage will be disassembling and fitting the parts. Lay out all the parts on the floor, check the labels on them. Remember that both the sandals and the moldings have extra length. Cut them to size using a special knife or small hacksaw.

Trying on parts

Attach multi-spikes to the wall along the entire plane of the part. They are necessary to keep the element from moving while the glue dries. Try the pieces on the wall.

Now you need to apply glue and attach the decor to the facade. Press harder, try not to let the glue protrude from the edges. Now coat the joints with acrylic sealant. After installation, it is advisable to paint everything.

Installation of decorative foam bricks on the corner of a building

Large facade structures are mounted on anchors or other fastening systems. You can learn how to install large polystyrene foam curtain rods using video instructions.

Video: Fastening large decorative elements

Decorating the appearance of a building is a creative matter, and you need to approach it with soul. At the same time, this is serious work, since the facade decor will be the first thing your family and friends see. If you want to make a uniquely beautiful home, then apply the information from this article, a little financial investment, artistic taste and time. Anyone can do this with their own hands.

Polystyrene production

To obtain decorative products from expanded polystyrene, polystyrene granules are placed in a mold and treated with chemicals. As a result of exposure to active substances, the material foams and increases in volume, occupying the entire container. Various shapes will be cut from the resulting blank sheets.

Architectural elements of facade decor

Architectural elements for finishing facades are formed using the form cutting method. It is produced using a special tool, the attachment of which resembles a string. Computer 3D modeling is used in production. Due to this, high accuracy down to one micron is achieved. The technology used allows us to produce decorative products of a given size and shape. A designer works on the appearance of every detail. Some companies offer custom-made polystyrene decor according to an individual sketch.

Features of manufacturing foam decor

There are strict requirements for the polymer that is made for facade finishing of houses. The material for production is PSB 25f. It has all the most important characteristics and qualities in order to be used in exterior wall decoration. Thanks to modern automatic equipment, you can burn and cut contours, create products of different sizes and shapes. In order to achieve reliable protection of the created element from high humidity and sudden temperature changes, sheets of polymer material are coated with a reinforcing compound. For example, you can treat a sheet of polymer material with mineral mixtures created on the basis of acrylic paint.

Next, the sheet is sent for drying. In order for the polymer not to lose its technical and operational characteristics, it is necessary to withstand a certain temperature regime. As soon as the protective layer has dried, the workpiece is sent to the last stage of production: stripping and polishing.

Texture and color of the material

Polystyrene foam decor is most often white. But they can always be repainted. White color is universal and goes with any architectural style. Imitations of decorative stone are common. You can purchase tiles with the texture of a brick wall, wood fibers or natural stone tiles.

Foam plastic for the facade can be of any color and texture

Decorating ideas

By attaching polystyrene foam decor to the walls with your own hands, you can decorate your house in various style directions:

- Classic - in this case, complex stucco with curls is not used. Distinctive features are triangular sandstones and pediments, pilasters, rectangular window openings.

- Neo-style is a modern interpretation of one or more architectural movements. For example, you can combine pointed Gothic arches with antique columns.

- Gothic - characterized by pointed vaults and carved decorations. Bas-reliefs with sculptural compositions and false niches may be located on the walls. If your windows are standard and rectangular, you can buy a special shape that will turn them into Gothic vaulted ones. In this case, you do not have to dismantle the masonry and install a new one.

- Japanese - restrained decor, simple geometric shapes. Often elements for the facade are painted brown, and the walls are left white.

- Fairytale - usually used when decorating small country houses. The home may resemble a Disneyland palace or a hobbit hole. You can use a large amount of small decor.

- Baroque - copious amounts of stucco, panels, rosettes and floral ornaments are often used.

- Half -timbered structures use imitation of load-bearing elements - old wooden beams and crossbars.

- Romanticism - originated in Italy, absorbed elements of oriental styles, including Arabic.

Decorating with foam plastic

The production of shaped elements from foam plastic, first of all, involves its careful cutting. When carrying out such a procedure, crumbling of the material should not be allowed. That is why its cutting is ensured by a heated “string”. If the composition is made up of several parts, then the accuracy of their alignment should not exceed 1 mm.

To obtain neatly cut parts, use a heated string

In general, the production of decorative foam elements is carried out in the following order:

- Drawing up a sketch of the decor or selecting a ready-made idea with drawing all the details, methods of their articulation, places of attachment, choice of colors.

- Drawing the element on foam plastic in full size, and so that the material can be cut.

- Cutting out the intended shape from foam plastic.

- Strengthening the decorative element. For this purpose, a fiberglass mesh is fixed using an adhesive composition applied by spraying to form a layer with a thickness of about 2–2.5 mm.

How to properly make façade decor from coated polystyrene foam?

The architectural forms of a house and their individual elements at all times of human civilization were dictated by the presence of one or another type of building material. As a matter of fact, with the advent of new building materials, the decoration of buildings and their appearance also changed.

Foam insulated facade decor

Ancient style, Gothic, modernist and so on appeared. Architectural buildings were no longer monotonous in appearance. But the evolution of architectural styles did not stop, and in 1951, polystyrene foam was synthesized.

A new style has emerged for architectural structures, where facade decor made of foam plastic with a special coating played a key role in the installation of siding with insulation.

What you need for decoration

To decorate with polystyrene foam you will need a set of tools and additional materials.

In order to equip a polystyrene foam façade, you should take care in advance of the following consumables and components:

- polyurethane-based mounting foam;

- foam glue;

- dowels 12–20 cm long, umbrella type;

- reinforced fiberglass mesh;

- acrylic type putty;

- façade primer composition;

- paint for facade work;

- mineral plaster.

The following tool will help you carry out all the work efficiently:

- glue gun;

- “string” for cutting foam plastic;

- knife;

- jigsaw;

- hacksaw for metal;

- putty knife;

- paint brush;

- construction mixer;

- electric drill;

- screwdriver;

- plumb line;

- roulette;

- metal ruler;

- protractor;

- building level.

How can polystyrene foam façade decor help create a unique home decor?

A material such as facade foam can easily replace concrete, marble or plaster. It is lightweight, affordable, and durable polystyrene foam that can be used to make a variety of home decorations. Decorative elements for finishing are needed for the facade of a building of any style - classic, modern, empire, classicism, and others. Previously, exclusively heavy, expensive materials were used to decorate the house, some of them were very fragile. Now they have significant competition from cheap and easy-to-use facade foam.

Decorative elements for finishing facades do not create a noticeable load on the building. Expanded polystyrene is easy to process, so it can be used to create various textures in any color design.

Before installation of façade elements begins, they are coated with a special coating. Protected architectural elements do not undergo deformation and do not interact with water, so the service life of the material is significantly extended.

Distinctive characteristics of foam decorative elements

The decor of the facade of a polystyrene foam house has some distinctive characteristics:

- affordable price of products;

- ease and speed of installation of finished products;

- the possibility of decoration without the involvement of specialists;

- minimum weight that does not lead to additional load on the foundation of the building;

- long operational service life;

- excellent water-repellent characteristics;

- increased strength;

- environmental friendliness and resistance to decay processes

Installation work associated with the use of polymer makes it possible to carry out installation in any climatic conditions, regardless of temperature indicators.

Polystyrene products for exterior decoration of buildings

- Entablature. This piece is attached to the top of the wall, giving the home a classic look. Lightweight facade foam does not need to be supplemented with columns.

- Arch. An opening made of this material will create a feeling of warmth, especially if it is decorated with an archivolt.

- Column. If you decorate the supporting structure with a figured product, the facade will become more attractive. Numerous video clips show that decorations made of polystyrene foam look as presentable as after finishing with expensive marble.

- A balcony decorated with this material takes on a completely different look, lighter and airier.

- Cornices, consoles, window frames, portals, patterns, window sills - every decorative element can be made of polystyrene foam. You can also use facade foam to make stucco molding. This way you don’t have to buy plaster, which is much more expensive. In addition, the list of decor made from this material can be supplemented with carved bas-relief and sculptures.

Installation of decor on the facade of the house

When carrying out such work, you must follow the algorithm of actions. First you need to carry out preparatory work with the surface on which the decor will be attached. To do this, remove the remains of the old plaster from the surface, remove dust and dirt. Armed with facade plaster, it is important to eliminate all internal irregularities.

Advice! If voids are identified, you can use a cement solution to level them.

Then they mark the places where the decorative façade elements will be attached. If some elements of the product protrude by 10-15 centimeters, you will have to strengthen the structure with dowels driven into the walls of the house in advance. Before starting work related to the design of the foam plastic facade, professionals recommend checking the evenness of the surface.

The next stage of installation work will be diluting the glue and applying it to the back side of the decorative fragments

When attaching them to the wall, a little force will be required to improve the quality of adhesion of the glue to the surface being designed.

Attention! Be careful when working with decorative fragments, as the product is fragile.

The installation process is completed by sealing the fastener gaps with foam or sealant. After it is completely dry, you can remove their remains with a spatula.

Next, a high-quality primer of all decorative elements is carried out using a special solution. At the final stage, the manufactured polymer decor is painted with acrylic dyes according to the design project. To increase the service life of products, professionals recommend painting 2-3 times.

Applying additional protection to façade decor is a mandatory stage of finishing work. This will protect the finished product from sudden temperature changes and high humidity.

A little history of the use of the material

Polyamide was synthesized in 1862 from petroleum polymer products. The material immediately began to be widely used in various areas of finishing. The popularity is primarily due to heat resistance, increased strength, wear resistance and variety.

Today, the specialization of many manufacturers includes facade decor made of foam plastic, which is made using figured cutting. Extruded polystyrene is a comparative novelty that has high thermal insulation properties. Many owners of private houses were able to verify its advantages.

Advice! If you compare the cost, quality, durability, installation and weight of the product, then polystyrene foam decor will be the most attractive option.

What is expanded polystyrene

Expanded polystyrene is a material that is often used for thermal insulation. But the texture and quality parameters allow it to be used for other purposes, for example, for decorating facades.

Polystyrene production technology

In the manufacture of polystyrene foam, polystyrene balls are used, which are exposed to temperature. As a result, the volume of particles increases, and the resulting voids are filled with air, which gives the material special elasticity. Next, the balls are glued together under the influence of steam. As for the decor made of polystyrene foam, it is made using a different technology.

The production of decorative elements is carried out according to the following algorithm:

- Design. Determining the required shape and size, searching for a template or developing unique sketches.

- Making patterns for cases with non-standard decor.

- Cutting parts using equipment, it is possible to use 3D technology.

- Reinforcement of architectural elements. To do this, the surface is coated with a special acrylic-based compound.

- Coloring. This is carried out after the previous layer has completely dried. It is possible to give the decor any color, even imitate natural materials.

The technology allows you to create the most original facade elements with high quality and attractiveness.

Appearance and characteristics

The visual qualities of the material are always at their best; it can have different shapes and shades.

As for the main parameters, polystyrene foam is characterized by:

- high strength;

- resistance to external influences;

- excellent heat and sound insulation properties;

- moisture resistance;

- ease of processing;

- light weight;

- long service life.

The level of resistance to negative influences will depend on the brand of polystyrene foam, since different durations of temperature exposure result in a material with different parameters.

Rules for installing decorations

Installing a polystyrene foam facade yourself is quite simple. To do this, follow the following instructions:

- The surface of the building walls must be thoroughly cleaned of dirt and mold. For this you can use special solutions.

- The installation base must be dry and level. If there are irregularities on the surface more than 1 cm deep, then you will need to level the wall with plaster. It is also advisable to check the old coating for voids. To do this, the surface should be tapped. If the old coating is peeling, it must be thoroughly cleaned with a stiff brush.

- The facade decor is made of foam plastic using special glue. You can also use anchor devices or embedded parts. In any case, it is necessary to apply glue, as it will ensure a tighter fit of the decorations to the wall.

- The polystyrene foam façade should be completely covered with the adhesive solution, and then pressed firmly against the base. After drying, if necessary, you can secure the structure with dowels.

Advice! Dowels can only be used on a completely dry structure. Its installation is necessary if the decorative element has a thickness of more than 10 cm.

- After the main installation work, the foam facade will need to be treated with sealant in those places where the holes for the dowels and the joints of the elements are visible.

- When the sealant is completely dry, the foam facade must be painted with a special acrylic-based paint. But first, each element should be coated with a primer.

Such a façade made of coated foam plastic cannot be visually distinguished from products made from traditional materials. In addition, installation of the structure is much easier. The polystyrene foam façade can be painted in any color – stone, granite, malachite, metal, wood and other textures. Therefore, the design is a universal means for finishing buildings.

Step-by-step installation

Facade decor made of polystyrene foam

Like any finishing work, installation of facade foam must begin with the preparation of materials and tools. For work we will need:

- Primer for facade or impregnation.

- Adhesive for polystyrene.

- Set of spatulas.

- Jigsaw.

- Pencil.

- Roulette.

- Building level.

- Roller.

- Plastic container.

- hammer

If everything from the list is at hand, you can proceed to the installation of façade foam blocks.

The first step is to thoroughly clean the façade surface. Remove everything unnecessary from it: sills, ventilation grilles, gutters, lighting fixtures.

Insulation using foam plastic

If the façade surface was previously plastered, then it needs to be tapped all over with a hammer. Poor quality or old coating should fall off. All protruding irregularities and defects are also removed.

Ideally, degrease the entire facade using gasoline or solvent. This will remove possible oil and grease stains from the surface, as well as remove contaminants in the form of dirt and dust.

Important: if you install facade slabs on a non-greased surface, the glue will not obtain proper adhesion to the wall and will quickly lose its qualities.

When the facade surface is completely cleaned, it must be treated with deep penetration primer and impregnations that protect against fungus and mold. After this, the wall must dry completely, otherwise the glue will not set.

When the facade surface is completely cleaned, it must be treated with deep penetration primer and impregnations that protect against fungus and mold. After this, the wall must dry completely, otherwise the glue will not set.

Now you need to dilute the glue. To do this, pour water into a plastic container and, stirring constantly, add the mixture until it reaches a thick consistency.

Tip: you need to prepare the glue in small portions so that you have time to use it before it hardens. Drying time is approximately 30-40 minutes, based on this, you need to calculate the amount of the finished solution.

After a portion of the solution is thoroughly mixed, it should be allowed to brew for 5-10 minutes, after which it should be mixed thoroughly again. As you work, the mixture will thicken and will need to be stirred again, and perhaps add a small amount of water.

Using a notched trowel, apply glue to the surface of the foam facade block. The solution should cover the entire surface in as even a layer as possible.

Tip: when applying the solution to the block, you should leave about 5 cm on each edge, then when you press it against the wall, you won’t have to remove the excess.

Next, the facade foam block is pressed tightly against the wall, in this position it needs to be fixed for 10-15 seconds, this time is enough for the glue to set. If excess has come out from under the foam, it must be removed so that it does not interfere with subsequent joining. Now you can move on to the next slab.

Insulation of a private house using polystyrene foam

The next foam segment must fit tightly to the previous one with as little gap as possible, otherwise the joints will have to be removed with joint grout, which is extra work and additional costs.

When the façade finishing is completed, holes are drilled in all the necessary places and items removed before finishing are installed. Now all that remains is to secure the decorative elements in the form of stucco molding and cornices. They are made from exactly the same reinforced facade foam, which means their installation is no different from the installation of slabs.

Advice: decorative facade elements and the foam blocks themselves must be from the same manufacturer, then their colors and textures will not differ.

At this point, the finishing and insulation of the facade are completed, and you can forget about them for the next 30 years, and this is exactly the warranty period that manufacturers give for foam plastic facade slabs.