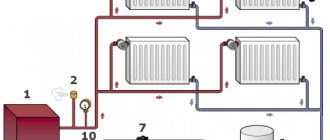

From the author: Hello, dear readers! The circulation pump plays a very important role in the heating system of almost any private home. Without this device, the coolant flows through the pipeline at a very low speed, resulting in significant wasted thermal energy losses. The result is an unevenly heated house and the danger of freezing of pipes located in non-residential premises - in the attic, basement, etc.

The circulation device easily prevents the mentioned problems. It increases the speed of the coolant flow, thereby giving the liquid the opportunity to quickly run along the route and deliver the required amount of heat to all radiators and other similar equipment. Naturally, to perform this function efficiently, the device must work flawlessly. That's why every homeowner should know how to test a heating circulation pump.

As you know, timely diagnostics can detect a malfunction even in the early stages of development, so a preventive inspection will help protect the device from possible serious damage. The nice thing is that performing the check will not take much of your time and effort, and almost any owner can handle the necessary repairs. Of course, to do this you need to have some information - and you can get it from today's article.

Need for circulation pump

Many residents of the upper floors of high-rise buildings are familiar with the situation when heating radiators heat up very little. The reason for this is low pressure. Because if there is no pumping equipment in the system, then the water moves through the pipes slowly, cooling down on certain floors. Now you understand the importance of correctly calculating the performance of the circulation pump for heating.

The same situation is familiar to those living in country houses - in remote corners of the heating system, the radiators are colder than at the start. The best solution to this problem is to install a circulation pump. The bottom line is that systems with natural circulation of liquid in small houses are quite effective. However, in such a case, it would not be superfluous to think about purchasing a pumping system, since if the operation of this equipment is properly configured, heating costs will be lower.

Teplofan recommends pumps for heated floors

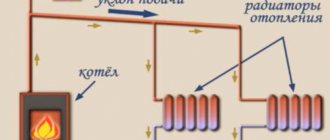

What does the pump design look like? This is a technique that consists of a motor with a rotor immersed in water. The essence of the work is this: the rotor rotates and moves liquid heated to a certain temperature through the heating system at a specific speed, as a result, pressure is required.

Pump operation is possible in various modes. If you install the pump in the heating system at maximum operation, then the home, which cools down while the owners are away, can be warmed up in the shortest possible time. Then consumers will restore the settings and receive the required amount of heat at the lowest cost.

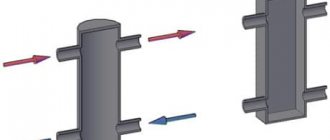

To know how to choose a circulation pump for heating, you need to know that there are devices with a dry (partial immersion in the coolant) and a wet rotor (full immersion). Devices with a wet rotor make virtually no noise - this is their difference.

Preventive examination

In order for the operation of the circulation pump to be problem-free, it is necessary to regularly check the condition of the equipment. A preventive inspection will help identify negative factors that can lead to serious breakdowns in the future. Their timely elimination will allow you to avoid force majeure situations and complex repair procedures.

A standard inspection includes a few simple steps:

- checking the tightness of connections. It is necessary to carefully inspect all fittings with which the pump is attached to the heating system. Some types of connecting elements may become loose over time and must be tightened. In addition, problems may arise with the destruction of the thread or seal - in this case, you need to unscrew the fitting, cut additional turns or wind a new layer of FUM tape, and then reassemble the element,

- adding lubricant. There are bearings inside the device that must be well lubricated. Otherwise, they will work worse, which will lead to overheating of the device,

- cleaning the filter. The mesh element gradually becomes clogged with dirt, even if you use a very high-quality coolant. Therefore, it is necessary to promptly remove rust and scale particles stuck in the filter.

Actually, this is a basic set of actions that need to be performed for prevention. In addition, you should follow some rules for operating the circulation pump:

- Avoid dry running. The pump should only be turned on if the required amount of coolant is present in the heating system. Equipment running “dry” will burn out very quickly, and may even drag down some other electrical appliances,

- Avoid prolonged idle time. In many regions, the heating system operates in seasonal mode - from September to May. It is clear that there is no point in launching it in thirty-degree heat. But if left idle for such a long time, some elements of the circulation pump may fail. Therefore, it must be turned on at least once a month for a quarter of an hour. Agree, it takes a little time, but it will help to avoid possible problems in the future,

- initially purchase a pump whose characteristics fully correspond to the needs of your heating system. It happens that owners, in an attempt to save money, buy a low-power device and try to use it in a system with a large volume of coolant. As a result, the device constantly works at the limit of its capabilities and, of course, fails very quickly. That is why it is important to make advance calculations of the parameters that you should focus on when purchasing. You can find information on how to do this on our portal,

- provide for overheating and “dry running” sensors. These regulators are not available on all models, but it is advisable to find and purchase a device with them. You may not immediately notice the problem on your own. For example, if there is a coolant leak in the system, then until you detect it, the pump will run idle and may simply burn out. And the sensor will react instantly, automatically turning off the equipment, and thereby preventing breakdown.

How to choose a circulation pump for domestic hot water?

When choosing, you need to know that the circulation pump must cope with the following tasks:

- The formation of pressure in the hot water supply system, which is able to cope with the hydraulic resistance that appears in some elements.

- Providing the required performance and facilitating the movement of heat through the system, which would be sufficient to heat the home.

Based on the goals, calculating the circulation pump for the heating system is necessary in order to establish the heat energy needs of the house and the hydraulic resistance of the entire system. If you do not know such parameters, it will be impossible to select a device.

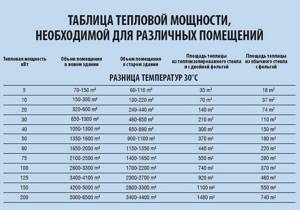

Review the table to know how to choose a circulation pump for heating.

Table of thermal power of circulation pumps

Possible causes of problems

If during your next preventive inspection you find that the circulation pump is working “somehow wrong,” then this is a reason to carry out a more in-depth check using some specialized tools. The most common problems are: lack of rotation of the rotor, overheating of the pump and poor coolant current. Each of them may have several reasons. Let's take a closer look at each possible malfunction:

- no rotor rotation when the pump is connected to the network. As a rule, this indicates some kind of failure in the delivery of power to the equipment. First of all, you need to inspect all the elements directly responsible for this function: electrical wire, device switch, etc. If you find any defect - for example, even the slightest insulation violation - you must immediately replace the damaged part with a new one. Until the defect is eliminated, the device cannot be used, as this is fraught with short circuits and other troubles. After checking the external elements, inspect the plastic fuse. With frequent voltage drops in the electrical network, it begins to melt and constantly opens the circuit. If you see that it is already openly deformed, it needs to be replaced. The next element that needs to be checked is the winding of the electric motor. To do this, you will need a multimeter, which can be used to measure the resistance level. In normal winding conditions, the indicator can vary from 10 to 15 Ohms or from 35 to 40 Ohms, depending on the specific rotor model. If the multimeter gives infinity or a value close to zero, then this indicates the need to replace the winding,

- pump overheating. This usually happens in cases where the circulation equipment for some reason is forced to work under increased load. Detecting overheating is quite simple - if the pump is hotter than the pipe, then this clearly indicates a problem. In the case when this happens with newly installed new equipment, it makes sense to check the correctness of the installation. Incorrect placement of the device may cause it to malfunction. If you find any shortcomings, you need to re-perform the installation procedures, making the appropriate adjustments. Another common cause of overheating is clogging of structural elements with dirt. Rust and scale play a big role in this. They form in some parts of the pipeline, and then fall off piece by piece and go along with the coolant, clogging all the equipment where they fall. This happens with the circulation pump. The presence of foreign particles inside the structure narrows the path along which the coolant flows. Thus, the pump has to apply more force to move the liquid. That's why overheating occurs. The solution to the problem in this case is to clean the clogged elements. The third reason for overheating has already been mentioned above - it could be an insufficient amount of lubricant on the bearings located inside the pump. The fourth reason may be too low - below 220 V - the voltage in the network. You need to check this indicator with a voltmeter and, if problems are found, correct them,

- poor coolant current. This refers to situations where the fluid circulates at insufficient speed. The reason for this may be an incorrect connection if your home uses a 380 V network. Check that the electrical wire is connected to the phase correctly - it is quite possible that it needs to be connected to another. The second reason for poor current may be the same clogging of internal structural elements mentioned above. This can be solved by cleaning the elements.

How to calculate a circulation pump for heating?

The performance of such a device is usually marked with the letter Q. This value is the heat transferred per unit of time.

For calculation use the following formula:

Q=0.86R:TF-TR

The parameters used in this formula are indicated in the table.

| Designation | Parameter | Unit |

| Q | Coolant flow | m³/hour |

| R | Thermal power required for heating the room | kW |

| TF | Liquid temperature in the supply line pipe | °C |

| TR | Temperature in the pipes leaving the system | °C |

In European countries, the R indicator depends on operating conditions and is calculated in connection with certain standards.

Namely:

- In houses with no more than two apartments, the power of the circulation pump for heating is taken at 100 W/m².

- In multi-apartment buildings - 70 W/m².

When calculating pumping equipment for rooms with poor thermal insulation, the readings of the above indicators are increased. With good insulation, R values are taken in the region of 30-50 W/m².

Resistance in the heating system

Calculating the system resistance is a rather complex, multi-stage task. The following parameters affect the system resistance:

- number and configuration of pipeline turns;

- pipe roughness coefficient;

- local resistance;

It is important to understand that, in fact, the resistance of a heating system is nothing more than the value of the pressure difference of the coolant passing from the supply part of the system to the return part. For convenience of calculations, the pressure is converted into meters and the desired value is obtained. When designing new heating systems, empirical data from similar systems or their elements are used. Rest assured, this value has already been calculated for your heating system and used in practice, for example, by a neighbor.

The given initial values are enough to understand which circulation pump

choose.

Knowing the flow rate and resistance of the heating system, it is enough to simply calculate the minimum required flow rate using the formula:

Q =W/(C(t1-t2));

where W

— required energy (1 kW per 10 m2 of room), kW;

C

— heat capacity of water (1163 W/m3*°С);

t1

and

t 2

are the temperatures in the supply and return pipelines, respectively.

The calculation result will be in liters per hour. It is worth remembering that this value is the minimum required to provide heat to a heated room under ideal conditions. Whereas pump manufacturers indicate the maximum characteristics produced by the pump. Fortunately, most modern pumps have three speeds, and accordingly, selection should be made based on the second speed of the pump.

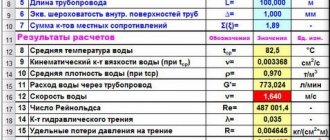

How to calculate hydraulic resistance?

To avoid counting by hand, use our calculator.

It has already been said that the selection of a circulation pump for a heating system is directly influenced by such an important parameter as hydraulic resistance, which is created by individual elements of the heating system, allows you to calculate the suction height of the pump and, as a result, makes it possible to select a model of equipment based on power and the pressure created. To calculate the pump suction (denoted by the letter H), use the following formula:

H = 1.3 x (R1L1 + R2L2 + Z1……..Zn) / 10000

The parameters used in this formula are listed in the table.

| Designation | Parameter | Unit |

| R1, R2 | Pressure loss created by the circulation pump in the supply line of the pipeline and in the return line | Pa/m |

| L1, L2 | Length of the supply and return pipelines | m |

| Z1…Zn | Hydraulic resistance created by individual elements of the heating system | Pa |

The values of R1 and R2 that are used in this table should be selected using a special information table.

The values of hydraulic resistance that are created by various devices used to equip heating systems are usually prescribed in the technical documentation for them. If such information is not available in the device passport, then you can take approximate readings of the hydraulic resistance (see table).

| Heating device | Hydraulic resistance, Pa |

| Boiler | 1000–2000 |

| Plumbing mixer | 2000–4000 |

| Thermal valve | 5000–10000 |

| Device for determining the amount of heat | 1000–1500 |

There are special information tables that allow you to find out the hydraulic resistance for almost any element of heating system equipment.

Knowing the suction height, for the calculation of which the above formula is used, you can quickly select a circulation pump based on its power and find out its required pressure.

Tips for choosing

- Previously it was said that pumps can be with “dry” and “wet” rotor types , as well as using manual or automatic speed control systems. Experts recommend using circulation devices whose rotor is immersed in liquid. This design is not only quieter, but also handles the load better.

- When choosing a circulation pump, you should pay attention to the housing material. Stainless steel, brass or bronze are best, but cast iron products are best avoided - they will not last long under such conditions.

- The efficiency of the device will depend not only on the factory parameters, but also on correctly performed calculations, so do them twice.

The heating system of a country house is a closed circuit in which water circulates, heated at one point. The circuit includes a circulation pump that maintains fluid movement. Every pipe bend, narrowing, and devices installed on the line create hydraulic resistance. The temperature difference is not enough for the coolant to move along a branched circuit in a two-story house. The use of a pump makes it possible to install a heating boiler not only in the basement.

How to choose pumping equipment by the number of speeds?

We have decided on the choice of pressure and power of the circulation pump for heating a private house, now let’s focus on the functions for adjusting the speed of operation, which are available in many models. Typically these are three-speed devices that allow you to control the amount of heat sent to heat rooms. In case of rapid cooling, the operating speed of the device is increased, and in case of warming, it is made less, while the temperature in the rooms remains comfortable for living.

To change the speed there is a lever located on the body of the pumping equipment. Pumps with an automatic system for regulating this indicator based on the temperature outside the building are popular.

Repair of the built-in Wilo circulation pump of the Ariston double-circuit automatic boiler

The Wilo circulation pump in the Ariston double-circuit boiler ensures the supply of heated liquid to the heating radiators, cooling the primary heat exchanger, after dispensing hot water to protect the heat exchanger from the formation of scale on its internal walls.

Ariston boilers in the Genus Premium, Clas System, Genus, Clas models are equipped with a Wilo MTSL 15/5 HE - 2 circulation pump, its malfunction leads to an emergency stop of the heating device.

To repair the boiler circulation pump, you need to know its components. The working device includes the following components:

- housing with inlet and outlet pipes;

- rubber gasket;

- Electrical engine;

- turbine;

- plain bearings;

- fasteners;

- air vent;

- starting capacitor;

- control terminal.

The principle of operation of the circulation pump Wilo MTSL 15/5 HE - 2

The main part of the pump is an electric motor, consisting of a stator with several inductance coils to regulate the rotation speed, and a rotor, which is integrated on a shaft with bearings.

Other pump calculation options

The above calculation method is one of the options for calculating the necessary parameters. A number of manufacturers use a different technique. You can also entrust the calculation of the circulation pump to a qualified specialist. Knowing the details of the design of a particular system and its operating conditions, he will professionally make all the calculations.

Usually the maximum load for the operation of the heating system is determined. In reality, it will be lower, so it would be wise to purchase a device whose parameters are slightly lower than the calculated data. Calculating the power of the heating circulation pump reflects the optimal result. Purchasing a more powerful device is not advisable and the system’s performance will not improve, and costs will increase.

Point A in the figure corresponds to the required parameters based on the calculation results, and point B indicates the actual characteristics of a certain device model specified by the manufacturer. The circulation pump is more suitable for the operating conditions in a particular heating system, the smaller the distance between these two points.

The above calculation method is one of the options for calculating the necessary parameters. A number of manufacturers use a different technique. You can also entrust the calculation of the circulation pump to a qualified specialist. Knowing the details of the design of a particular system and its operating conditions, he will professionally make all the calculations.

Usually the maximum load for the operation of the heating system is determined. In reality, it will be lower, so it would be wise to purchase a device whose parameters are slightly lower than the calculated data. Calculating the power of the heating circulation pump reflects the optimal result. Purchasing a more powerful device is not advisable and the system’s performance will not improve, and costs will increase.

After receiving the calculation results, it is necessary to pay attention to the pressure and flow data on pump models, taking into account its operating speeds. The characteristics can be reflected on a graph with two coordinates - pressure and productivity, and then the point of intersection of these values can be determined. Based on the graphic image, the desired heating pump model is selected for a particular home.

Point A in the figure corresponds to the required parameters based on the calculation results, and point B indicates the actual characteristics of a certain device model specified by the manufacturer. The circulation pump is more suitable for the operating conditions in a particular heating system, the smaller the distance between these two points.