The reasons for device failure can be very different, so you need to know certain design features before starting repairs. The malfunction may be due to non-compliance with specific operating rules.

Damage can be caused by:

- Changes in the power supply network;

- Problems with coolant quality.

The circulation pump may break down due to wear of parts.

Before deciding to repair the pump yourself, you need to have a good understanding of its design and find out what its operating principle is. Thanks to this, it will be possible to find out the specific cause of the problem.

The pump structure consists of:

- An electric motor in which the shaft is connected to the rotor;

- Housing made of non-ferrous alloys or stainless steel;

- A rotor on which a wheel with blades is installed, made of polymer materials or metal.

It is important to know the design of the circulation pump in order to carry out repair and maintenance work correctly and in a timely manner.

Design and operating principle

To repair a heating circulation pump with your own hands, you need to know its structure and operating principle. The design of modern devices has changed little since the invention of the first pump.

The most important components are:

metal (or partially metal) body; impeller made of composite material; rotor with rotating shaft; stator and electric motor.

The equipment also includes seals, gaskets, plug bearings, liners, etc. Modern expensive pumps are equipped with an electronic control system that allows you to set and control operating parameters.

All circulation pumps operate on the following principle: under the influence of electric current, the shaft rotates and water is sucked into the housing, where, under the influence of centrifugal forces, it is pushed towards the walls and pushed out under pressure through the outlet pipe.

With proper installation and operation, the device can operate uninterruptedly for decades, and if a malfunction occurs, you can try to repair the heating pump yourself, using a simple set of tools.

Before we begin to consider the features of repairing this type of pump, we recommend reading a review article about heating pumps.

Mechanical problems

There are many reasons why a circulation pump may require repair. The most typical are:

The heating pump hums and does not pump water

Cause: Oxidation and jamming of the rotating shaft.

Remedy: Repair of water pumps in this case involves forcibly turning the shaft and rotor. To do this, you must first turn off the power supply, drain the water and disassemble the device body.

Tip: It can be difficult to turn the shaft by hand. It is better to use a screwdriver with a blunt end for this.

The heating pump crackles, vibrates strongly, and a characteristic howl and hum is heard

Cause: Bearing wear.

Elimination: Repair work is carried out with the unit turned off and consists of disassembling and replacing the bearing. As a rule, the drive shaft bearing is subject to wear, so, first of all, you should pay attention to it.

Tip: When replacing bearings, use ready-made repair kits recommended by the pumping equipment manufacturer.

The heating pump is noisy, the shaft does not rotate

Cause: A foreign object has entered the housing.

Remedy: If the heating circulation pump is noisy, then it is necessary to disassemble it and inspect all parts. If a foreign object is detected, it is carefully removed, and the pump is assembled in the reverse order.

Tip: To prevent debris from getting inside again, it is recommended to install a fine mesh filter on the suction pipe.

Loud noise during operation, but the unit operates normally

Cause: Air in the pipeline or equipment housing.

Remedy: Repair of the heating circulation pump is not required in this case. It is enough to eliminate airiness (bleed air) from the heating system.

The pressure is unstable and constantly changes or decreases gradually.

Cause: The filter on the suction pipe is clogged.

Remedy: Repair of centrifugal pumps involves replacing/cleaning the filter. The filter is removed and cleaned. If there is damage, the filter mesh must be replaced with a new one.

Electrical faults

Why does the heating pump not start or is unstable?

Cause: Broken power cable.

Remedy: It is necessary to carefully inspect the power supply system. The power cord may be broken or the outlet may be faulty. If the power supply is working properly, it is worth inspecting the fuses of the equipment and replacing the blown ones. Often the cause of unstable operation is voltage fluctuations. In this case, it is advisable to use a control relay (for a 220 V network) or a stabilizer (for 380 V).

The heating pump gets hot and does not pump water well into the system

Reason: Working with increased load.

Remedy: If the circulation pump is hot, then this is evidence that it cannot cope with the load. Perhaps the pump was initially selected incorrectly or its power has decreased over time. To solve the problem, a major overhaul of the heating system pump or the purchase of more powerful equipment is often necessary.

Why does the heating pump start but turn off after a few minutes?

Cause: Lime deposits on the stator and/or shaft.

Remedy: In order to repair the water pump, it is necessary to disassemble it. After disassembling the device, you must carefully clean all parts of limescale. To do this, you can use low-acid products, such as table vinegar.

Tip: To prevent the appearance of lime deposits, use special water softeners in the coolant water treatment cycle.

The pump produces coolant with insufficient pressure

Reason: rotation of the motor shaft in the opposite direction.

Remedy: Incorrect shaft rotation is due to assembly defects during maintenance or repair of the home heating pump. To fix the problem, you need to disassemble the device again and reassemble it in the correct order.

The pump stops with a characteristic click after starting

Cause: The electric motor or control unit is faulty, so the motor protection is activated.

Remedy: It is very difficult to repair the power supply and engine electrics yourself. It is recommended to contact specialists or the manufacturer’s service center.

Wall polishing

In order for Grundfos to work normally again, it is necessary to polish its inner walls. At the same time, you can make the work easier if you use polishing tools, having previously secured them in the drill chuck.

If a bearing is jammed in the pump, you need to disassemble it and try to rotate the impeller.

In order to remove limescale deposits, the system is filled with a solution of acetic acid and water, which are mixed in equal parts. Threaded connections can be sealed. This will help prevent the pump from leaking in the future. You can even use a pad from a bicycle inner tube for these purposes.

Sometimes the reasons for pump stopping may be bearing jamming, failure of the water flow sensor to respond, or a decrease in pressure. To do this, you do not need to completely disassemble the pump in order to eliminate one of the above problems.

Try simply switching the equipment to manual mode by removing the switch located on the junction box from the lock and placing the handle in the middle position. This will allow the pump to operate even when the tap is closed. But if this does not help it turn on, then you need to disassemble the pump and try to rotate the impeller. If it does not rotate, the pump cannot be repaired.

If the pump operates only in manual mode, the cause of the breakdown is the flow water sensor.

The breakdown can be eliminated by replacing the sensor itself. Sometimes the pump stops working after turning off the water because air accumulates in it. In this case, you can lower it by turning the central screw.

After all these operations have been completed or when the pump is completely cleaned, it must be reassembled. This is done in reverse order.

If none of the above actions led to the resumption of pump operation, the breakdown may consist of failure of the winding of its motor or capacitor. Such a malfunction requires replacement of spare parts, which can only be provided to you by a service center. Otherwise, the only option is to replace this device. In European countries, the average service life of these pumps is about 5 years. However, water quality in Europe is better, so the lifespan can be reduced by a year or two.

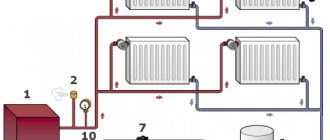

Heating circulation pump: device

Owners of private houses usually give preference to economical, low-power pumps with a “wet” type rotor.

The operating principle of this unit is simple: the impeller, rigidly fixed to the electric motor shaft, rotates and draws in the coolant coming from the inlet pipe. Then, under pressure, it pushes it into the discharge pipe, thus ensuring circulation.

If we disassemble the pump with our own hands, we must have a good understanding of its structure.

Diagram of a circulation pump with a “wet” rotor

Important! It must be taken into account that in “dry” type models, the rotor and drive motor are separated into a separate unit, and the rotation is transmitted to the impeller using a clutch.

Why does the pump get hot?

The pump temperature should be the same as the temperature of the heating system pipes. If the circulation pump heats up and its temperature is higher than the pipes, it means there are installation errors or an operation problem. Let's look at why the device heats up.

- If installed incorrectly, the pump begins to overheat immediately after switching on. Installation errors are the easiest to detect.

- Clogged closed circuit. Rust and various deposits accumulate in the system. In this case, the diameter of the passage for the coolant narrows. The load on the device increases and the engine overheats. Preventative measures to maintain the system will be required.

- Rust, debris, and limescale in clogged lines can get into the pump and jam the electric motor, causing it to overheat. The device must be disassembled and cleaned, otherwise the motor coils will quickly fail.

- The pump also gets hot due to lack of bearing lubrication. Under such conditions, they wear out much faster, thereby reducing the service life of the entire device. The electric motor jams. The pump should be taken to a workshop.

- When the network voltage is below 220 V, the pump overheats and can quickly fail. Determine the voltage in the network as soon as the engine starts to warm up in order to immediately eliminate or confirm this problem.

If the circulation pump gets hot, there is no need to immediately disassemble it. First, measure the voltage in the network. At normal voltage, the system is washed with caustic soda, leaving it in the pipes for an hour, and then drained. If the pump still gets hot, you will need professional help.

How can you eliminate typical circulation pump malfunctions?

There are a number of typical faults in circulation pumping devices that you can fix yourself. Each block will describe the symptoms of a malfunction, its causes and steps to do it yourself.

The pump is humming, there is no rotation

The cause may be oxidation of the motor shaft during prolonged inactivity of the pump. Troubleshooting instructions.

- Turn off the power to the equipment.

- We remove water from the pump and pipelines adjacent to it.

- Remove the screws securing the housing and the electric motor.

- We dismantle the electric motor complete with rotor.

- We turn the rotor by hand or with a screwdriver, resting against the working notch.

The next reason for such a malfunction may be the ingress of foreign objects.

- Turn off the power to the equipment.

- We remove water from the pump and pipelines.

- Remove the screws securing the housing and the electric motor.

- We remove the foreign object.

- We protect the pump inlet pipe with a strainer.

The lack of rotation can also be caused by a lack of power supply. To do this, we use a tester to check the presence of power at the terminals in the box and the correct connection of the electrical wires.

The pump does not hum or rotate

The main cause of such a malfunction may be a lack of power supply or insufficient voltage in the network. To eliminate it, you need to use a tester to check the voltage at the terminals and, if necessary, whether the device is connected correctly to the power supply.

Many electric pumps are equipped with a fuse. During power surges, it burns out and requires replacement.

The pump starts working, but stops after a while

The cause of this malfunction may be the deposition of limescale between the stator and the rotating rotor. The malfunction can be eliminated by dismantling the electric motor and cleaning it of limestone deposits.

The pump makes a lot of noise when turned on

The cause of this malfunction may be the presence of air in the heating system pipeline. To eliminate it, you need to bleed the air from the pipes. To automatically release air, it is recommended to install an automatic unit in the upper segment of the pipeline.

If a sharp noise is accompanied by increased vibration, it is recommended to increase the pressure at the inlet to the pumping device. Insufficient pressure can be compensated by increasing the coolant level in the system.

The pump vibrates a lot

The cause of such a malfunction is usually severe wear of the bearing that ensures the rotation of the impeller. The malfunction is eliminated by replacing the worn bearing.

What to do if the pump produces insufficient pressure?

The cause of such a defect may be the wrong direction of rotation of the wheel with blades. The cause of this phenomenon is usually an incorrectly connected phase when connecting three-phase equipment.

Also, a decrease in pressure can be caused by increased viscosity of the coolant, then the impeller encounters too much resistance. To eliminate it, it is necessary to clean the filter on the inlet pipe from deposits, check the cross-section of the incoming pipeline and set the necessary pump adjustment parameters.

What to do if the pump stops after starting?

Most likely, the cause of such a malfunction may be incorrect connection of the wires according to the phases in the terminal box. The fuse on your pump may not be tight enough. Remove it and clean the clamps.

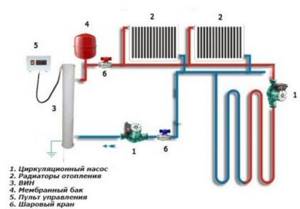

Design, internal contents and operating principle of the device

To carry out maintenance and repairs, you need to know exactly the design and internal contents of the water machine. The design features of the pump are as follows:

- stainless steel body or made of non-ferrous metal;

- a motor connected by a shaft to a rotor;

- a rotor mechanism with a fan installed on it - that is, an impeller (the blades have regular contact with water and are made of metal materials and polymer).

The operating principle, independent of the design features, has the following features:

- Electric current is supplied to the device, and the motor begins to rotate along with the rotor, which in turn sets the rotational movement of the impeller;

- liquid enters through the receiving pipe. Then the wheel with blades throws it onto the walls of the device body;

- under the influence of the same centrifugal force, pushing occurs through the supply pipe.

A heating pump with various design features is divided into different types. If we consider a device with a rotor, we can note the following:

- wet;

- dry.

Circulation pump device

For a pump with a rotor located in a humid environment, the coolant cools and acts as a lubricating element. Such equipment is used mainly in household systems. Among the main features it is worth highlighting:

- the pump makes almost no noise during operation, because the liquid dampens noise and vibration well;

- The device is very easy to install, maintain and repair.

But there are also disadvantages:

- efficiency is low;

- installation can only be done in a horizontal position;

- If there is no water, starting is prohibited.

The dry pump has a motor located in a separate chamber. The electric motor shaft transmits movement to the impeller using a clutch. Comparing such a device with a wet type device, the dry type has a coefficient (about 85%), a complex design that burdens the repair and maintenance process. Installation is carried out in such a way that the pump is soldered, screwed or welded into the pipeline and mounted on the wall. Special fasteners are used for mounting to the wall.

Useful video

A couple of removal methods:

Do-it-yourself circulation pump repair - step-by-step instructions

DIY circulation pump repair

Circulation pumping devices are very popular among owners of private houses and summer residents. The range of pumping equipment is quite wide, but the general principles of the device are the same. Such equipment can stop due to minor breakdowns, for example: the pressure switch of the pumping station does not work, what should I do? Should I take my broken pump to a service center? This costs money, and in many regions there are simply no service companies. Therefore, an economical home owner should know how to install a water pump with his own hands.

Circulation pump device

To understand how to independently disassemble, maintain, and repair a circulation pump, you need to know its structure. Such equipment is arranged as follows:

- all components and mechanisms are housed in a housing made of steel (mostly stainless), aluminum and other alloys;

- An electric motor with a rotor is located inside the housing;

- a wheel with wings is installed on the rotor - an impeller, which is usually made from technical polymers.

Circulation pump device

Operating principle of circulation pumps

After turning on the electrical circuit, the engine begins to rotate the rotor with the impeller mounted on it. Liquid is supplied to the central part of the pump. The blades rotate and throw water or other coolant towards the outside of the housing. Under the influence of centrifugal forces, the liquid moves and enters the outlet pipe of the pump.

Circulation pump in the heating system

Types of circulation pumps

There are currently two main types of circulation pump devices on the market.

- “Wet type” - in such equipment the rotor is completely immersed in the pumped liquid. A significant advantage of this configuration is the cooling of rubbing and heating parts by contact with liquid. Such equipment is quieter and costs less. When installing it, it is necessary to maintain the housing position specified by the manufacturer (usually horizontal), since the rotor must be completely immersed in the liquid. Also, “wet-type” devices are easier to maintain, but are very sensitive to the lack of liquid in the system (operating “dry” can quickly damage the pump).

- “Dry type” - in such devices, the pump motor is placed in a separate compartment or module, and torque is transmitted to the rotor through a drive device (clutch). Dry type pumps are more efficient, but also have a more complex design. A “dry” pump can operate without damage even in the absence of fluid in the system, but such operation will lead to increased wear of the drive.

Also, circulation pumps can be divided into types according to the method of execution:

- monoblock;

- console, consisting of separate blocks.

Causes of breakdowns of electric pumps

Problems usually occur due to prolonged stagnation of the system. But sometimes units fail for other reasons. It is better to entrust the restoration to specialists, but sometimes you can do everything without outside help. To do this, you will need to study the design of the device and purchase the necessary set of tools; it is advisable, of course, to have at least minimal knowledge in the repair field. It is important to know how to properly disassemble equipment.

The voltage must correspond to that indicated in the technical data sheet. Let us consider in detail the main malfunctions of the device, their causes and ways to solve problems.

Reasons include:

- the device was idle for a long period of time, after which the motor shaft oxidized, now the device makes strange sounds;

- a foreign object blocks the operation, noise is heard in the device;

- the device stopped rotating;

- little pressure;

- noise when turned on.

In any case, the heating system is very serious, so take the issue of restoration seriously and do not put it off until later. If you don’t have enough experience in the repair field, we recommend watching special video tutorials where everything is explained in detail.

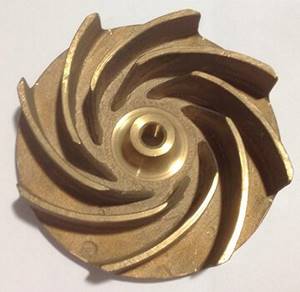

Design

Almost all circulation pumps are centrifugal type. They have an impeller mounted on the motor shaft and placed in a special “shell” chamber. The entrance to the shell is located in the center, while the exit is the outer edge of the shell with a channel extending around the circumference in the direction of movement of the impeller. The engine spins the impeller, and water, under the influence of centripetal force, rushes from the center to the edges of the sink from inlet to outlet.

Pump structural elements:

- pump part, sink and impeller mounted on the shaft;

- electric motor;

- electronic control unit.

The most susceptible to wear is the moving part of the pump - the motor shaft and impeller, as well as the bearings on which they are mounted.

What it is

The practical purpose of a rotating propeller is to force water to move in the desired direction, while increasing pressure. The device consists of several elements, depending on the type:

- Pinwheel.

- Center axis.

- Bearing.

- Retaining ring for the disc head.

- Spring to compensate for water hammer.

Important: the package may sometimes include a rubber gasket.

Maintenance of circulation pumps

Pump malfunctions and ways to eliminate them

The design of a circulation pump with a “wet” type rotor is based on a modular principle. Modules can be configured in different configurations. It all depends on the power and size of the pump.

Any repair work can only be carried out if the power is completely turned off and the area has been drained.

Malfunctions of the heating circulation pump:

- The pump turns on, sounds are heard, but the shaft does not rotate. Why is the heating pump noisy and why do other “symptoms” appear? The reason may be oxidation of the shaft after a long period of inactivity of the device. If the pump is blocked, the device must not be left on. It is necessary to drain the water and all the screws that connect the pump housing with the electric motor must be unscrewed. Next, we remove the engine itself, and its impeller is turned manually. If the pump is of low power, the shaft can be unlocked by turning it with a screwdriver. For this purpose, there is a special notch at the end of the shaft.

- A foreign object has blocked the wheel. How to disassemble a heating circulation pump? We dismantle the pump motor using the above method. To prevent blocking from happening again, a mesh type filter must be installed in front of the pump.

- There are problems with the power supply. It is necessary to check the voltage in accordance with that indicated in the technical data sheet of the device. You should also check if all phases are present and if everything is connected correctly in the terminal box.

- The circulation pump does not make sounds (the heating circulation pump does not hum) and does not turn on. There is also no supply voltage. The fuse may be damaged. In this case, the fuse will need to be replaced. If nothing has changed after replacement, then the reason may be in the motor winding. Most likely it burned out.

- The pump turns on, but after a while it turns off. The cause may be deposits that have formed between the rotor and the stator jacket. It will be necessary to dismantle the electric motor and clean the stator jacket from scale.

- When the pump is turned on, a sharp noise occurs. Why is the heating pump humming and how to de-air the heating circulation pump? It is necessary to release the air and install an automatic air vent at the top point of the pump piping unit.

- The pump vibrates. The cause may be bearing wear. Typically this problem is accompanied by a characteristic noise. To eliminate the problem, the bearing will need to be replaced.

- The water pressure and its supply are lower than those indicated in the circulation pump passport. This malfunction is typical for three-phase type pumps if they were connected incorrectly.

- After the pump has been started, the external protection of the electric motor is activated. Most likely, the problems occur in the electrical part of the engine.

- It is necessary to check if there are phases in the terminal box. You also need to check if the fuse contacts are dirty. You can also check what the phase resistance to grounding is.

Electrical repair

The electrical part of the pump includes the following components:

- inductor;

- starting capacitor;

- connecting wires;

- control terminal.

If the stator winding breaks down, the pump becomes unrepairable; all other components can be repaired or replaced. To analyze the condition of electrical parts, you will need an ohmmeter.

Photo of the circulation pump Wilo MTSL 15/5 HE – 2.

Main symptoms of malfunction

If the boiler display shows an error code corresponding to a water circulation problem, and it is not reset, the problem may be hidden in the electronic part of the device.

Circulation pump with cover removed.

To identify the problem you must:

- Turn off the heating mode in the boiler, and after stopping all components, turn off the power (soft stop).

- Open the front panel of the case.

- If the pump is covered with a large layer of dust, clean its surface.

- Using the information in the diagram, remove the control terminals and remove the terminal with the capacitor.

- Visually examine the condition of the pump contacts and terminals; they should be free of oxides, burnouts and mechanical damage.

- Using a tester in diode testing mode, determine the integrity of the connecting wires that go from the control board to the pump.

- Use an ohmmeter to determine the resistance of the inductors. On a working device, the instrument readings on the contacts will correspond to the following values:

- No. 1, 4 – 150 – 160 Ohm;

- No. 1, 6 – 290 – 300 Ohm;

- No. 2, 3 – 0 (contacts connected together);

- No. 3, 5 – 220 -230 Ohm;

- No. 4, 6 – 150 – 160 Ohm.

- The device will be considered faulty if the ohmmeter reading on any of the above pair of marks is 1 (winding wire break) or 0 (short circuit, except for contacts 2,3).

- Check the condition of the starting capacitor. To do this, switch the tester regulator to the 20 microfarad capacity test mode. Connect the probes of the device to the terminals of the capacitor and determine its capacitance. It should match the nominal ± 10%. Loss of capacity leads to a decrease in pump performance; it will emit an uncharacteristic hum.