A damp and cold garage is not the best place to keep a car. The owner is provided with problems with the technical condition of all its components. Accumulating condensation will damage not only the car body, but also the electrical wiring.

The main percentage of heat is lost through the doorway. The swing steel structure has high thermal conductivity, so insulating garage doors will be a good solution. Dealing with the walls and roof is a little easier than insulating a garage door. To do the work yourself, you will have to study methods and materials.

Comfort and convenience of the garage

Along with its direct purpose, the garage is used as a workshop. During the cold season, even a short stay in the garage will require a lot of willpower. It is convenient to do small repairs in the garage yourself, and good ventilation is essential here. Basement smell, mildew and mold on the walls are not all the troubles. Staying in such a room is life-threatening. Often, openings for supply ventilation are left in the gates. On the topic of how to insulate a garage door, there is a useful video at the end of our article.

Important! Ventilation openings must be left in the thickness of the insulation.

Answers to some general questions

Before we go directly to describing the process of insulating a garage door with our own hands, I want to answer some questions that you will definitely begin to have as the planned date of the finishing work itself approaches:

Why insulate your garage door at all?

Many car enthusiasts may object to the proposal to increase the thermal insulation properties of the “house” of their own car by saying that the main thing is the roof over their heads, and everything else is an unnecessary luxury.

But let's look at this statement and consider the problems that arise in the case of such a negligent attitude:

Your stay in the garage is not always limited to walking from the gate to the car in the morning and back in the evening. Sometimes you have to roll up your sleeves and repair your vehicle. So in winter, in the absence of insulation, doing this will be more than problematic. I don’t recommend anyone to sort through steel parts in the cold. Therefore, strengthening the thermal insulation of the room in question is primarily necessary for a person, not a machine;

It is better to overhaul the engine in a warm place, not in the cold.

Temperature changes, which are inevitable in the absence of insulation, lead to the appearance of condensation inside the garage, including in hard-to-reach parts of the car. Such an abundance of dampness accelerates corrosion processes, which can ultimately result in very expensive repairs to your vehicle.

An example of what happens to a car “living” in an uninsulated garage

As you can see, the reasons are compelling enough to begin thermal insulation of the room. But why are we talking specifically about gates? Perhaps it would be better to do global insulation of the garage from the inside with your own hands?

It all depends on what material the walls of your building are made of:

If it is made of brick, cinder block, foam block or concrete, then you can limit yourself to enhancing the thermal insulation properties of only the entrance part, which, as a rule, is made of steel. The fact is that metal has excellent anti-vandal properties and does an excellent job of preventing intruders from accessing your car, but at the same time it also has very high thermal conductivity, due to which it releases all the accumulated heat outside;

Thermogram clearly demonstrates heat loss from iron garage doors

If it is made of the same iron as the gate itself, then, of course, you should insulate the walls and even the ceiling of the garage room. Otherwise, in winter it will be incredibly cold, and regularly falling condensation will cause significant damage to the car.

An iron garage in winter is not the best place to spend time

Do all types of gates need insulation and can be insulated?

The entrance, or rather the entrance, to your garage may have various design solutions that affect the choice of approach to the process of thermal insulation work.

Here are the variations found in our area:

Swing. This is a classic, which consists of a frame and two gate leaves made of sheet steel. Such a structure undoubtedly needs to be insulated, otherwise the metal will release all the heat in winter and all the coolness in summer from the room;

Two doors opening along the vertical axis

An example of a steel swing gate with a wicket in one of the leaves

Custom lift and turn. In this case, the working part of the structure is a sandwich panel, inside of which there is foamed polyurethane, which is already an excellent heat insulator. So you can just enjoy the fashionable gate and not take any additional action;

Scheme of the structure of the door leaf of custom-made overhead gates

- Homemade rotary-lifting ones. Here everything is similar with swing structures, since again we are dealing with a steel sheet covering the entrance to the building. It can and should be insulated;

- Roller shutters. They cannot be insulated due to their design features. Moreover, I would not install them in the garage at all due to their very low protective characteristics.

Why should you insulate from the inside?

In fact, why? After all, when it comes to a residential building, all the craftsmen unanimously advise performing insulation from the outside in order to avoid transferring the “dew point” to the inside of the building. But here we should not forget that when it comes to gates, their primary functions are protective and anti-vandal. That is, by placing insulation on the street, you run a very high risk of losing it in the near future.

Insulation of garage doors should be done exclusively from the inside

Purchasing a finished product

If you decide to install a factory-made structure in your garage, then the problems of how to insulate the gate will end there. New lift-and-turn and sectional devices already have a layer of polyurethane foam. Even roller shutter types of gates are sometimes insulated, but the possibility of using them for a garage is very doubtful. Narrow aluminum slats will not provide reliable protection against burglary, and their high thermal conductivity makes them unsuitable for our climate. When ordering a gate, a swing system with a wicket would be a good option. It will significantly reduce the percentage of heat loss.

Proper insulation is the key to success

There is a wide range of insulation products for garage doors on the market. How to understand all this diversity? It is best to thoroughly understand the main types, because not everyone is suitable for your case.

- Foams are synthetic foam materials based on polymers.

Foam plastic is an easy-to-use material

Polystyrene foam, perhaps the most famous type, looks like connected white balls. Excellent for insulating gates due to its lightness, minimal hygroscopicity, strength and fire resistance. Sometimes called expanded polystyrene.

Urea-formaldehyde foam is also often used in heat and sound insulation. It has the property of not swelling when hardened. Also suitable as insulation for garage doors.

Sprayed polyurethane foam is an effective thermal insulator for gates

Polyurethane foam is divided into two types. The first is ordinary foam rubber, and the second is polyurethane foam. In thermal insulation, the latter option is used. The foam has excellent thermal conductivity properties and even serves as a waterproofing agent. Sprayed onto the surface, filling cavities. An excellent material, however, the cost of application may be a reason not to choose this material.

- Mineral wool - a material used in construction, has three subtypes: glass wool, slag wool and stone wool. The use of mineral wool is limited due to its hygroscopicity.

Glass wool consists of tiny glass particles and has low thermal conductivity: 0.03 - 0.05 W/m*K. Caution should be used when working with this material.

Slag wool is produced from metallurgical residues (slag). The thermal insulation of the material is slightly worse - 0.04-0.05 W/m*K, which does not reduce its popularity in construction, but it will not work for sheathing garage doors - the material does not “get along” well with steel.

Stone wool is made from rocks. Thermal conductivity - 0.03−0.04 W/m*K. It is also not suitable for insulating garage doors, since when heated the material releases toxic substances.

We choose the insulation wisely

The assortment is quite wide. Among the things that can be used to insulate garage doors, the most in demand are:

- Various types of foam plastics;

- Fiber insulation (glass wool, stone wool, basalt wool).

To make a choice, you need to take into account all the pros and cons of the materials.

Styrofoam

Polystyrene foam is a very economical option. The class of foamed polymers is quite diverse. They have a gas-filled structure and vary in type of polymer. Let's consider the types of foam plastics:

- Polystyrene is the most used. They are designated PSB or PSB-S. Extruded polystyrene foam (EPS) - has low hygroscopicity and good fire resistance. Insulating your garage door yourself is one of the best options.

- Polyvinyl chloride or PVC panels. Similar in characteristics to EPSS. International PVC marking. High fire resistance.

- Urea-formaldehyde foam (UFP). Used for voids and cavities. The liquid composition of CFP does not increase in volume after complete drying. Can also be used as garage insulation.

- Polyurethane foam (PPU). It is produced in the form of elastic foam rubber and polyurethane foam. Hard polyurethane foam adheres well to any surface. Good hydro and heat insulator. Fire resistant. Such insulation will be light in weight and suitable for any finish. Polyurethane foam will do an excellent job of thermal insulation of garage doors. A sprayer is used to apply the foam.

Fibrous materials

Among fibrous insulation materials, we immediately exclude stone wool and slag wool. The first is extremely harmful to humans; slag wool will oxidize the metal surface. Glass wool is dangerous to work with, but of all, it has average hygroscopicity. It is this quality that makes the use of cotton wool unsuitable for garages. The accumulation of condensate in a layer of material will reduce its thermal insulation properties. With a vapor barrier film, you can use basalt insulation.

Materials for sealing and insulating gaps and cracks

The easiest way is to cover the cracks with foam. But as the foam expands, it can deform weak masonry or plaster. In addition, the service life of such sealing is a maximum of five years, no more.

You can treat cracks that are previously insulated with other materials with polyurethane foam:

- polystyrene foam is the most affordable and accessible material. Minus - there is no guarantee that all voids will be filled with insulation;

- sprayed penoizol or polyurethane foam is a durable, hermetically sealed protective film, literally a monolith. But, an apparatus for applying insulation is required; such insulation is not cheap;

- mineral wool is the best option for any material of walls and gate leaves. Mineral wool does not burn and reliably fills all voids in cracks.

An important rule is that when insulating with mineral wool, it is imperative to reliably seal the cracks with plaster or water-repellent mastic, since mineral wool loses its properties when wet.

Another modern method of thermal insulation is paints with a warming effect, fire-resistant. This paint contains polymers and ceramics and creates a reliable thermal insulation film. You need to apply two layers of this paint, waiting until the first layer has completely dried.

The process of insulating a garage from the inside

To insulate your garage door you will need the following tools:

- Electric drill;

- Drills for wood and metal;

- Hacksaw or jigsaw for wood;

- Metal brush or drill attachment (brush);

- Screwdriver.

Also don’t forget about a tape measure, a paint brush, a hammer, a corner and a ruler, a sharp knife, a core, sandpaper and clamps. A clamp is a means for clamping parts. They will be convenient for attracting slats to the gate frame.

The order of work will depend on the insulation and type of construction.

Preparing the sashes

Cleaning

Remove old paint, rust and all dirt. This can be done conveniently and quickly using a power tool with an attachment.

Padding

The applied primer will protect the metal from corrosion. To work, take a wide paint brush. Anti-corrosion primer is applied in two layers. One across and the other along the surface.

Eliminating gaps between the frame and the canvas

Use a rubber seal. It will not interfere with the operation of the mechanism and will close unnecessary holes. Next, we will look at how to insulate garage doors from the inside.

We insulate swing gates with foam plastic.

Swing gates are durable, reliable and easy to use. The system consists of two steel sashes welded onto a frame made of a profile pipe or angle. Sometimes corrugated sheeting is used, but a steel sheet 2-3 mm thick is stronger.

It is good when the insulation of swing gates is carried out by their manufacturer. Otherwise, you can insulate your garage door yourself. After choosing the material, you should calculate how much is required. You also need to decide on the finish on top of the insulation. The final version with different types of gate cladding can be seen in the video. There are many options for covering garage doors.

Types of facing materials:

- Lining;

- Profiled sheeting;

- Fiberboard or MDF panels;

- Waterproof plywood;

- OSB or OSB boards.

Experience has shown that the latter are more suitable for cladding. OSB boards are plates made from glued and pressed sawdust and wood chips. If you look at the photo of the product, you can see its composition of several layers. The layers have different arrangements, which gives the sheets special strength and flexibility. This finish is easy to process, has low vapor permeability and is very economical.

FakeHeader

Comments 51

I chose a day where there was not much thaw and foamed the gap between the threshold and the gate, it became better) By the time I had time, the frosts now reached -30.

The bottom can be made with felt

Frozen to the gate.

Then from the heart's sleeve

Hang a curtain made of dornite, we have one of these hanging in every garage and you will be happy

You can put felt padding on the gates, but I also saw that in the neighborhood in garages people wrap a tarp around a board and just lay it down with their hands every time.

Thank you! I am also inclined towards this design, make brackets for the threshold and insert a board with felt there.

I was also intrigued by the question until I saw that people were just using the boards, not just one person, but quite a lot.

such a good corner for a sealant... my toad says that a profile for drywall would be enough, it is noticeably cheaper!

The threshold is coated with the compound and the foam is applied directly into the crack on the closed door. After hardening, the foam will remain on the door itself, creating a seal and will not stick to the threshold.

I support! I did exactly the same thing around the entire perimeter, everything worked out perfectly and it turned out hermetically sealed. Only I didn’t smear it with polish, but with a thin layer of lithol. Three years have already passed, no complaints.

The threshold is coated with the compound and the foam is applied directly into the crack on the closed door. After hardening, the foam will remain on the door itself, creating a seal and will not stick to the threshold.

You can cover it with tape; the foam won’t stick to it either.

I screwed a doubled fire hose around the perimeter. Bend outward. First, you put a galvanized metal strip with holes into the sleeve. Self-tapping screws every 200 mm.

And I have insulation around the perimeter with frost. Just so neatly.

Nope)) I don’t like this kind of insulation, I used it for a while too)

I sewed up the gate first with a wooden sheathing around the perimeter, then with polystyrene foam and then the whole OSB-3 thing on top. So I tried to adjust the OSB so that it would fit right next to the frame. But there’s still such a neat frost around the perimeter. It doesn’t grow and melts when you heat it too much. Or rather , it doesn’t melt, but falls off in pieces. I’ll have to hang a curtain.

I should have taken a photo of the gap at the bottom too, the options depend on its size

I cut rubber inner tubes from Kamaz into strips. I secured these rubber strips in two layers - on one side and the other side of the rail (it turned out to be a double shutter). I did this around the entire perimeter of the gate. Then I trimmed these strips in place (in width so as not to interfere with the closing of the gate).

Polyurethane foam. I did this to myself, everything tightly in a circle. There are a lot of videos on YouTube.

Now on sale there are a lot of rubber profiles for sealing the joints of window doors and gates. Why reinvent the wheel?

I didn't see the rapids.

You can use the same ones for thresholds. Or too small?

Create an anti-threshold! ))))) www.antiporog.ru/ustanovka-antiporoga.html

Cool stuff! I'm afraid it will freeze and the mechanism will become clogged with frost.

to seal the cracks at the gate, the first thing you need to look at is that at the exit from the garage - it’s just the ground that rises in winter or thoughtfully poured concrete... and so that it’s straight according to Feng Shui, or make second light doors so that there is a vestibule so that it plays the role of an “air cushion” or a more budget-friendly option for curtains made of felt and there will be a song

The only problem is with the threshold. I got confused with the rubber bands because I didn’t want a curtain.

A huge canvas curtain covers the entire wall, it will have a very cool effect.

I have a 50th corner welded to the prog without insulation and there are no problems.

a dozen mops with bristles down. But in general, leave it, ventilation has never harmed anyone.

ventilation and draft are very different things... and where there are cracks, in winter there will be frost and quite a bit of it, which then melts and moisture - one wonders where are the advantages of such “ventilation”...

Insulating a garage from the inside with construction foam

Another method of insulating garage doors with your own hands is polyurethane foam. Of the ways you can insulate garage doors with your own hands, this is the easiest way.

- Polyurethane foam in cylinders (consumption of 5 cylinders per 7m2).

- Spray the foam in an even layer (cut off excess material after drying with a sharp knife)

- Decorative finishing (the covering can be chipboard, lining or any other material).

The advantages of insulating garage doors with your own hands using foam are that the material penetrates even into small cracks. This will also strengthen the entire gate structure.

The safety of your premises and vehicle in proper condition depends on the quality of garage door insulation. Safety also depends on choosing a reliable garage lock.

If the garage is not insulated, then it simply turns into a rain shelter. Although a car is not a person, negative temperatures in winter are also contraindicated for it. First, you need to insulate the garage doors, through which most of the heat escapes to the street. Here it is possible to either simply get rid of drafts using seals on the doors, or more complex work with the installation of heat-insulating materials.

How is the insulation attached?

Polyurethane adhesive foam is used as fastening material. If you have never used such foam before, then working with it will bring you delight, since installation with it is reliable, quick and easy. The main advantage of this glue is the quality of the polyurethane foam.

Adhesive foam is applied to the insulation. After five minutes, the sheet with the material applied to it must be glued to the cleaned surface of the gate.

Sealant or polyurethane foam is used to fill the seams that appear between the sheets of insulation. After an hour, when the adhesive foam has completely dried, the joints and seams between the insulation sheets can be sealed with foam. Excess foam can be removed with a knife. To ensure that the insulation of metal garage doors has an attractive appearance, the installed insulation is finished with clapboard.

Selection of insulating material

Before you insulate your garage door, you should understand the following. The insulation process directly depends on whether you managed to choose the right insulation material. When choosing, consider its quality and properties

Among the choice of insulation (and there are many varieties), pay attention to the three most popular options:

- on mineral wool;

- polyurethane foam;

- extruded polystyrene foam (foam).

Each of them has a lot of advantages, but one cannot ignore the disadvantages. For example, the fire resistance of polystyrene foam leaves much to be desired. But at the same time it has high moisture resistance and low thermal conductivity. Mineral wool, on the contrary, has a high level of fire resistance, but minimal moisture resistance.

Polyurethane foam is the latest technology for insulating a garage from the inside. Spraying is quite effective and completely fulfills the task. It is different:

- seamless installation;

- low weight of insulation;

- low thermal conductivity;

- high fire resistance;

- resistance to temperature changes, chemical and biological aggressors;

- durability;

- strength;

- the ability to use any finish for the sprayed surface.

Mineral wool is a material in the form of fibers, which is made by processing a special rock. The material has low thermal insulation, but thanks to it the room is well insulated. Cotton wool is produced in rolls and slabs.

Extruded polystyrene foam is considered a more expensive finishing option. It differs from other materials in the method of installation and gluing. Installation begins with the construction of a sheathing and stretching of a film designed to protect against moisture and vapor barrier. You can see how all this is done here:

Note! When insulating garage doors, you need to understand that their surface should heat up quickly, allow heat to pass in well, and also slowly release it out. Don’t forget to measure the area you are going to insulate in advance in order to purchase the required amount of materials and other important elements (glue or fasteners)

When choosing insulation, pay attention not only to thermal conductivity, but also to the presence of thermal inertia

Why and how to insulate a garage

Inexperienced car enthusiasts do not attach much importance to the insulation of the garage space. There is a garage for a car and that's good. And soon they are surprised to discover that the car body begins to rust. It's all about humidity. Cold street air, penetrating through the gate without insulation, causes a temperature difference, which leads to condensation.

Fogging in the garage occurs in both winter and summer. This is influenced by both the cooling engine and the change in outside temperature during the day. As a result, increased humidity contributes to the development of mold, which affects the car itself and everything in the room with it. It may not be noticeable at first, but the metal parts, body and electrical wiring begin to rust, and the interior trim begins to crack.

The second point is the garage itself. Car owners use it not only as a parking place for their cars, but also often equip it with a workshop, a carpentry shop, and just a hobby club for friends. If the garage doors and walls are well insulated, then working inside will be much more comfortable. Repairing a car in the cold is still a pleasure.

Note! According to standards, the temperature in the garage must be maintained at a level not lower than +5 0 C. This is enough for the engine to start without additional heating, and for the body not to rust.

In most cases, garage walls are made thick and secure. The cold mainly enters through the gate, which must be carefully insulated. The purpose of such thermal insulation is to minimize the leakage of warm air through garage doors. A lot of heat comes from a cooling engine, you just need to prevent it from escaping into the street through the door gaps.

To minimize condensation, it is necessary to provide ventilation in any room. But in the garage it is better to get by with a simple hood with natural circulation. Moreover, it must be made in such a way that it can be blocked. There is not too much heat anyway, there is no heating, air exchange in severe frosts should be reduced to a minimum.

First stage: preparing the surface and creating the sheathing

- Even before starting work, it is worth working on the garage ventilation system. There must be supply and exhaust openings. If the air supply is already in the gate, it is important not to cover it with a layer of insulation.

Garage ventilation layout

- It is important to treat the surface of the gate by removing any corrosion with a brush or grinder. The insulation can be hampered by, for example, peeling paint. After stripping and peeling off the paint, it is necessary to treat the metal with an anticorrosive agent. It will turn out better if you apply a layer of primer from a spray bottle.

Clean Corroded Metal Garage Doors

- The next stage is the process of making the sheathing. It helps to attach the insulation, and the outer, front layer of the cladding will hold on to it. It is optimal to use 4*4 cm bars for lathing, approximately this size. The lathing is attached to the gate frame. The wood must be dry and of high quality. The bars are treated with an antiseptic to prevent rot and moisture; it is advisable to do this twice. To secure the beams in the frame, a hole is drilled for a self-tapping screw. It is important to make recesses in the sheathing for the holes in the gates. The bars can also be fastened together if there is no rigid frame.

Making lathing for insulating gates

Types of gates and features of their thermal insulation

There are several types of “doors” for entering a car garage. In some cases it is easier to buy ready-made insulated garage doors, while in others you can make them warm with your own hands after installation. However, the desire to make something yourself is not always prudent. There are gate structures that are quite problematic to insulate efficiently yourself.

The garage entrance opening can be closed with the following types of gates:

- swing;

- lift-and-swivel;

- sectional;

- rolled

The swing design is the most common and consists of one or a pair of doors that open outward. These classic doors are in demand due to their ease of installation, reliability and vandal-proof protection. They are made from metal sheets 2–3 mm thick and reinforced with a corner. Making them and then insulating them with your own hands is easier than ever.

In a lift-and-turn model, the sash rises to the ceiling. In most cases, these are products that are manufactured and insulated inside with various materials in the factory. These one-piece sandwich panels are made from two sheets of metal and polyurethane foam between them. There is no need to insulate them additionally; you just need to carry out the installation correctly according to the instructions and install the seals.

Dispelling myths and misconceptions

Today you can hear many different opinions regarding this issue. Some of them do not deserve special attention because they are not supported by facts. So, one of the myths is that there is no durable seal. This is not true! There are high-quality materials that will last for many years. Once you seal the gate once, you will forget about it for many years.

There is also an opinion that it is enough to insulate the gate itself, and not the cracks. Even if you use the most modern thermal insulation material on the gate frame, the presence of gaps will reduce the effectiveness of insulation. For this reason, the cracks must be sealed. Among other things, there is an opinion that there is only one good material. This is just a cheap marketing ploy. Each of the sealants listed in this article has its own advantages and disadvantages. And in each individual case it will be effective in its own way.

So, we have learned that sealing garage doors can be done independently. Additionally, we invite you to watch the prepared video material, which will clearly show you how to cope with the task.

Which thermal insulation material to choose

Before you start insulating your garage door with your own hands, you need to choose the right insulation. The range of insulating materials is huge, but not all of them are suitable for insulating a car “house”. For self-thermal insulation of garage doors, the following are suitable:

- Slabs of penoplex or polystyrene foam.

- Sprayed polyurethane foam or penoizol.

- Minvata.

The latter option will give a head start to the others in terms of fire resistance, but it is much inferior to them in moisture resistance. Mineral wool is cheaper, but with equal thermal conductivity, its layer will be thicker and heavier than that of expanded polystyrene and polyurethane foam.

To insulate garage doors, it is best to take one of the varieties of mineral wool. This rolled material is easier to install, but the main thing is that it is not afraid of fire. The same cannot be said about foamed and sprayed polymer-based alternatives. Despite all the impregnations and additives, they still remain a fire hazard.

Advice! Due to its non-flammability, mineral wool is the best option for thermal insulation of a garage space. The less combustible and flammable materials are used in the covering, the safer it is to leave the car in it.

You can also use heat-insulating paint. To apply it, a regular brush is enough. After the thermal paint dries, a polymer-ceramic film with high thermal insulation characteristics is formed on the door leaf. But it will have to be applied to the gate in several layers, forming a coating of the required thickness and insulating properties.

After insulating the gate, the temperature in the garage will no longer fluctuate constantly, which will reduce the risk of condensation. Most insulation systems are installed on the facade of buildings. But insulating garage doors from the outside is impractical and simply unwise. It’s not for nothing that they are made of durable iron; protection from vandals and thieves will not hurt your car.

If the insulation is attached to the outside of the garage door, it will be impossible to open it completely. The design of the hinged doors will not allow them to be opened wide in this case, and sectional models are simply not designed for such changes; they will not be able to fold even halfway. Plus, the thermal insulation material outside can simply be set on fire. The only option left is installation from the inside.

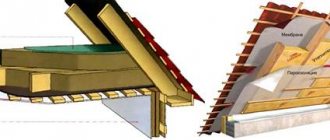

Types of roofs

To find the right approach, you first need to decide on the design features of the roof and the type of roof. Then choosing a treatment method will be relatively simple. So:

If the roof of the garage and the house is piecemeal

Here problems often arise at the junctions and transitions. Less commonly, the cause is a mechanical defect (crack, hole). Damage due to hail, wind, etc. may also occur. It is also important to evaluate the quality of liquid drainage from the surface. If in some places a lot of snow and leaves constantly accumulate, then this is one of the most vulnerable areas of the coating as a whole. The same nuances apply to designs with additional elements: cuckoo, etc.

If the roof is pitched

- Most often, in such structures, problems arise due to the lack of even a minimum angle of roof inclination. Puddles form after precipitation, water begins to seep into the room due to poor joints or loose gluing of roofing sheets.

- In some cases, a leak begins after a strong wind, when part of the coating is torn off or undermined.

- Another option is poor coating quality and frequent mechanical stress. For example, when a seasonal terrace is equipped on the roof, but this point was not thought through during construction. Consequently, the strength of the roof is not designed for additional permanent loads and problems arise.

If the roof is gable

In such a system, problems with physical defects will be more frequent. Something broke, cracked, was pierced by a branch, a stone, hail, etc. Another option: failure due to long service life, manufacturing defects, or improper installation. The joints are also considered weak: corners, turns, gutters, etc.

Next we will look at different roofing options.

How to insulate garage doors yourself

There are three methods of insulating garage doors:

- Using sealants to close gaps.

- Installation of thermal insulation materials on the leaf of the sashes.

- Hanging curtain curtains.

For thermal insulation of swing and up-and-over gates, all three methods can and should be used. And if a sectional or roll structure is installed at the entrance to the garage, then it will only be possible to insulate it using the first and last steps.

Seals – combating drafts

No matter how accurately the gate is adjusted to size, cracks will inevitably appear. To eliminate drafts, the gaps between the sashes, as well as at the points where they connect to the floor, ceiling and walls, should be sealed with a sealant. It fills the gap and prevents warm air from escaping from the room.

The sealing insert can be:

- silicone;

- rubber;

- in the form of a wax-impregnated nylon brush.

Frost-resistant garage seals are available in the form of tubes and tapes with or without a self-adhesive backing. In the second case, you will need appropriate glue to attach them. The brush version will last the longest, but it also costs more.

Advice! The seals are installed on the sashes, gate frames or on supporting structures around the perimeter of the gate. But it is much better when the sealing material is glued on both sides so that the inserts touch each other.

It is not recommended to use foam to seal cracks in garage doors. Of course, with its help you can create a reliable barrier to drafts. However, with constant closing/opening of doors, the foam layer will quickly collapse. And in the open air it begins to crumble. But as an option, it will be enough for one winter.

In addition to factory products, a garage seal can be made from improvised means: a rubber hose or a piece of a car inner tube. But the wear resistance of these options is obviously lower than the frost-resistant liners specially designed for this purpose.

Insulation in garage doors - basic thermal insulation

Seals alone are rarely enough for high-quality thermal insulation of garage doors. Often it is necessary to fully insulate the sashes. In this case, it is necessary to prepare their metal parts by cleaning them from rust and painting them, and then sheathing everything on top with decorative panels or wood.

To insulate garage door leaves you should:

- Clean off the rust on the metal of the door leaf, and then paint it with bitumen mastic for waterproofing.

- Secure a frame made of a block with a cross-section of 20–25 mm to the shutters using self-tapping screws.

- Fill the resulting honeycomb with insulation (foam polyurethane foam, cut and glue penoplex, or insert mineral wool cut to size).

- Cover the frame with OSB, clapboard or laminated MDF.

Wood boards for lining garage doors should only be used of moisture-resistant types. Regular fiberboard or plywood will swell and warp. It is better to take laminated sheets altogether. They cost more, but will last longer in a garage without heating.

On a note! The insulation attached to the garage door does not need to be covered with wood. It is enough to cover it with penofol or other dense foil material.

Sheathing with foil will additionally insulate garage doors. You just need to fasten it with a layer of aluminum inside, then the heat will be reflected back into the room. Not much, but even keeping this heat energy inside will help reduce humidity.

Homemade seal

Separately, it is worth mentioning homemade seals, which are made from improvised materials. For example, you can use an old rubber tire. The final result will depend on your skills. Some people use a heavy-duty garden hose. Moreover, the final result will be in no way inferior to the purchased material. Plus, you'll save money and be able to express your creativity.

On the other hand, the choice of source material should be approached responsibly. It must be strong enough. If you are concerned about fire safety, the material must be treated with special compounds. Also, the seal should not be too hard, otherwise gaps may remain when the gate is closed.

A selection of video lessons on the topic

Technology for insulating old garage doors:

How to seal cracks on garage doors:

Internal lining of heated garage doors:

Insulating the entrance opening and garage door yourself should not cause difficulties. This should not be considered an excess; it is safer to store the car in a warm room without condensation; rust will not affect it. To do this, it is enough to insulate the garage doors with penoplex or mineral wool, and also close the cracks with rubber or silicone sealant. And as an additional barrier to cold air, you can hang a canvas curtain.

Describe your question in as much detail as possible and our expert will answer it

I want to share how I insulated the gate around the perimeter. I attached a corner to the slopes and put a car door seal on it. Now I’m racking my brains on how to seal the gap between the gate and the threshold, there’s a breeze coming from there. Tell me, how did you solve the problem?

Types of sealing material

On the modern market you can find a variety of seals that will successfully cope with the task. Let's look at the main types of seals.

- Rubber compressor. This material is considered the most common and in demand. A rubber seal for garage doors will completely eliminate uneven cracks through which cold air flows. This material comes in different types and shapes, such as tubular, tape-shaped or flat. The choice will depend on the size of the gap.

- Silicone seal. This insulation is suitable for different types of surface. Most often it comes in the form of a tape, which is very soft and elastic. Thanks to this, it is very easy to level out the resulting gaps.

- Brush seal. Mainly used for sectional doors. The material is impregnated with a special composition, due to which their service life will be quite long. The brush seal is easy to clean from possible contamination.

- Polyurethane foam seal. Its main feature is that after installation it will take on the required shape, filling the entire space of the crack.

Gate types

There are several types of doors that can be installed in garages.

Swing. The cheapest option. Garage doors consist of two leaves.

Recoil. During the opening process, the canvas simply moves to the side. A similar door design is installed in sliding wardrobes.

Lift-and-swivel. The solid canvas rises vertically and turns horizontally towards the floor.

Sectional. The canvas is assembled from several sections. Rising upward to clear the passage, the sections fold.

Roller blinds. When the driveway is opened, the gate leaf folds into a compact box.

Mineral wool insulation

As in the case of insulation with polystyrene foam, when sheathing with mineral wool, a sheathing is installed. The surface of the gate is prepared in a similar way. Then proceed as follows:

- A layer of basalt wool is pre-wrapped in a vapor barrier material, which is covered on both sides with aluminum film. This prevents the formation of condensation and reliably protects the metal from corrosion.

- Then the finished block or roll is treated with an antifungal agent, inserted between the slats of a wooden frame, pressed against the gate sheet and secured with dowel nails.

- After covering the entire surface with cotton wool, the remaining gaps, joints and cracks are blown in with polyurethane foam.

Thermal insulation

Depending on what type of insulation you decide to use, further steps will look like this:

- Styrofoam. He is placed on polyurethane foam. There is no need to apply too much of it, as it will greatly increase in volume as it dries. Just apply a little foam to the back of the sheets and immediately press the squares to the surface of the door leaf. Place all panels end to end. Then blow out all remaining seams, cracks and gaps with foam. After drying, remove excess with a knife.

- Mineral wool. Its rolls or slabs are driven tightly between the lathing slats. If you use rolls, you must first coat them on one side with glue and only then press them against the door. Fill all joints and cracks with foam. Attach a layer of waterproofing to the top of the door leaf (oilcloth will do). But be sure to completely cover the entire surface of the cotton.

- Polyurethane foam. It is simply sprayed in even rows onto the door leaf directly from the can. Leave approximately 7-9 cm between the rows. Later the foam will expand and occupy all the voids. On average, 5 cylinders of polyurethane foam are used per 7 m2. After drying, the excess that protrudes beyond the sheathing is cut off with a knife.

Stage 4: door trim

To make the doors look aesthetically pleasing from the inside, they need to be lined. For this purpose the following materials are used:

- OSB boards. Durable, dense material. Attaches well to the sheathing. Lets air through. But quite heavy. Be prepared for garage doors to add 10-13 kg in weight.

Insulation of the entire garage with OSB slabs

- Profiled sheeting. Durable, moderately lightweight finishing material. In addition, you can choose its color at the request of the master.

- Lining. Moreover, both polymer and wood. The first option is especially good. Not afraid of water and temperature changes.

Any exterior door trim is mounted on sheathing beams. The main thing is to choose the right parameters according to the parameters of the canvas.

To learn how to insulate a garage door from the inside with your own hands, watch the video. And remember, warm doors are the key to your comfort and safety of your car.