Rating of the TOP 15 best solid fuel boilers

| Place | Name | Price |

| TOP 3 best solid fuel boilers price/quality | ||

| 1 | Protherm Beaver 50 DLO 39 kW | Find out the price |

| 2 | Stropuva Mini S8 8 kW | Find out the price |

| 3 | Teplodar Kupper Praktik 14 14 kW | Find out the price |

| TOP 3 best long-burning solid fuel boilers | ||

| 1 | Stropuva S30 30 kW | Find out the price |

| 2 | Teplodar Cooper Expert-15 | Find out the price |

| 3 | Teplodar Cooper Expert-45 | Find out the price |

| TOP 3 best solid fuel boilers with a water circuit | ||

| 1 | Kentatsu ELEGANT-03 17 kW | Find out the price |

| 2 | Lemax Forward-16 17 kW | Find out the price |

| 3 | ZOTA Topol M 14 14 kW | Find out the price |

| TOP 3 best classic solid fuel boilers | ||

| 1 | ZOTA Dymok-M AOTV-18M 18 kW | Find out the price |

| 2 | ZOTA Yenisei 18 18 kW | Find out the price |

| 3 | Teplodar Cooper Praktik 8 | Find out the price |

| TOP 3 best pyrolysis solid fuel boilers | ||

| 1 | Vesuvius Elbrus-10 10 kW | Find out the price |

| 2 | Bourgeois-K MODERN-12 12 kW | Find out the price |

| 3 | Bourgeois-K STANDARD-20 20 kW | Find out the price |

How to choose and what to pay attention to?

When choosing a solid fuel boiler, you should pay attention to the following aspects:

- Heating area is a key characteristic specified by the manufacturer for certain climatic conditions.

- Types of fuel - not all boilers are “omnivorous” and can operate on any type of fuel, like a regular stove. Many modern models are sensitive to fuel and will not provide the characteristics specified by the manufacturer, and advanced options may even fail if you try to load them with the wrong fuel.

- Energy independence - most models do not depend on electricity, but pellet models are equipped with electronic sensors and automatic fuel supply, and therefore require additional uninterrupted power supply from a single-phase or three-phase network.

No. 9. What else to consider?

Obviously, even before purchasing a boiler, it is worth deciding whether the boiler will be the main source of heat or a backup one . In the latter case, you will have to install an expansion tank or a heat accumulator - this is easier to do right away than to later upgrade an existing system.

If in the future there is an opportunity to switch to gaseous fuel , when choosing, you should pay attention to the possibility of transforming the boiler. Many traditional boilers can switch to gas by installing an inflatable burner. It’s convenient, but it’s worth considering that the efficiency of the converted boiler will be lower than that originally designed for gas.

The best solid fuel boilers price/quality

Protherm Beaver 50 DLO 39 kW

Classic solid fuel boiler, burning wood and coal . Open camera

combustion requires a stationary chimney.

The maximum thermal power is 39 kW, which is enough to heat a room with an area of up to 300 sq.m.

Built-in thermometer and pressure gauge allow you to monitor the condition of the heating system.

The control is mechanical and requires a certain skill from the operator. The device is quite bulky in size and weight and requires a separate boiler room.

The weight and dimensions are due to the high quality of materials, cast iron doors and boiler body.

Specifications:

- Type: classic;

- Circuits: single-circuit;

- Energy independence: yes;

- Combustion chamber: open;

- Efficiency: 90.2%;

- Placement: floor;

- Fuel type: wood, coal.

pros

- power;

- quality of materials;

- 8 sections;

- uniform heating.

Minuses

- the bottom heats up;

- price;

- weight and dimensions.

Stropuva Mini S8 8 kW

A long-burning unit that runs on wood and wood briquettes . Small

the power will allow heating rooms with a total area of up to 80 sq.m.

Does not depend on communications and electricity, a good option for a cottage or country house.

Maintains temperature up to 20 hours . It does not cause any trouble in assembly and installation, and is sold fully assembled.

Economical, fuel consumption is low.

Compact dimensions go together with a bright appearance - an additional aesthetic plus.

But, despite its dimensions, it is very heavy - the device weighs 145 kg, so assistance will be required during transportation and installation.

Specifications:

- Type: long burning;

- Circuits: single-circuit;

- Energy independence: yes;

- Combustion chamber: open;

- Efficiency: 85%;

- Placement: floor;

- Fuel type: firewood, wood briquettes.

pros

- economical fuel consumption;

- long-term heat retention;

- compactness;

- design.

Minuses

- the fuel window is located low;

- weight.

Teplodar Kupper Praktik 14 14 kW

The classic single-circuit model is capable of heating a room with an area of up to 140 sq.m., however, the greatest efficiency is achieved with an area of up to 80 sq.m..

It works not only on wood and coal, but also on peat briquettes, which ensures the efficiency of the model.

Suitable for systems with forced water circulation.

Small dimensions, deep firebox, steel heat exchanger and pre-installed heating element to maintain temperature are the parameters for which the model is popular.

A spacious ash pan will reduce the number of cleanings . In terms of power and price ratio, it is one of the most profitable boilers.

Specifications:

- Type: classic;

- Circuits: single-circuit;

- Energy independence: yes;

- Combustion chamber: open;

- Efficiency: 90%;

- Placement: floor;

- Fuel type: firewood, coal, peat briquettes.

pros

- budget;

- quality and reliability of design;

- deep firebox;

- spacious ash pan;

- small size and weight.

Minuses

- fuel burns out quickly;

- thin body walls.

No. 3. Heat exchanger material

There are few options here. Heat exchangers can be:

- steel;

- cast iron.

It is difficult to say unequivocally which solid fuel boiler is better to choose - it all depends on the budget, operating conditions and personal requirements. Manufacturers produce both boilers.

Cast iron heat exchangers have the following advantages:

- they are assembled from separate sections , so their transportation and installation are easier. Moreover, if one of the sections is damaged, it can be replaced , so the durability of such boilers is excellent - up to 20 years or more;

- During operation, cast iron becomes covered with a film of iron oxide. This is dry rust, which hardly progresses, protecting the rest of the material from negative effects. Cast iron is more resistant to corrosion , so you will have to clean the heat exchanger less often;

- Cast iron retains heat longer , which is a plus. The downside is that it warms up more slowly.

Among the disadvantages are heavy weight, higher fragility than steel, and poor resistance to thermal shock. With a sharp change in temperature, a cast iron heat exchanger can easily crack, so avoid getting cold water into the heat exchanger that has not yet cooled down.

The advantages of a steel heat exchanger include:

- higher strength , and since such a heat exchanger is welded in a factory and comes out in one piece, it becomes possible to manufacture combustion chambers of complex configurations , thereby increasing efficiency;

- high resistance to sudden temperature changes . Boilers with such heat exchangers, as a rule, receive more advanced automation, since the temperature can be controlled freely without fear of damaging the structure;

- not as high weight as cast iron;

- faster heating, but also faster cooling.

On the other hand, steel is more susceptible to the development of corrosion processes . Despite the resistance to temperature changes, frequent such fluctuations may cause cracks to appear at welding points. If something happens, it will be impossible to repair a steel boiler - you will have to buy a new one, therefore the durability of such structures is lower.

The best long-burning solid fuel boilers

Stropuva S30 30 kW

Powerful single-circuit boiler with a heated area of up to 300 sq.m. Suitable for private

homes, businesses and agricultural premises.

Works on both wood and wood briquettes.

The combustion zone moves smoothly from top to bottom during operation.

The maintenance process includes regular cleaning of the ash pan and chimney.

The shape of the body allows you to save space during installation, and the volume of the firebox can accommodate up to 80 kg of fuel.

Adjusting the air will extend the burning time to 31 hours. The steel body does not heat up during operation.

Specifications:

- Circuits: single-circuit;

- Energy independence: yes;

- Combustion chamber: open;

- Efficiency: 85%;

- Placement: floor;

- Fuel type: firewood, wood briquettes.

pros

- duration of operation on one fuel load;

- uniform heating;

- efficiency;

- large heating area.

Minuses

- price;

- weight.

Teplodar Cooper Expert-15

The power of this unit is sufficient to heat rooms with an area of up to 150 sq.m..

Powered by electricity at single-phase and three-phase voltage.

A design feature is the ability to connect gas or pellet burners.

The model does not have a control panel, but has a built-in thermometer and pressure gauge.

The chimney diameter is 15 cm. Additionally, it has a pre-installed heating element to maintain the temperature.

The coolant temperature ranges from 50 to 95 degrees and produces water pressure in the heating circuit of up to 3 bar.

Specifications:

- Circuits: single-circuit;

- Combustion chamber: open;

- Efficiency: 85%;

- Placement: floor;

- Mains voltage: single-phase/three-phase;

- Fuel type: wood, coal.

pros

- high-quality assembly;

- long service life;

- power;

- reliability.

Minuses

- energy dependence;

- no burner included.

Teplodar Cooper Expert-45

of heating large areas up to 450 sq.m. Steel

the heat exchanger has a long service life, the built-in pre-installed heating element produces power up to 9 kW.

The entire structure has rather large dimensions and weight, which is due to the total power.

Does not have a control panel.

It is possible to connect a gas or pellet burner.

High-quality assembly ensures a long period of use of the boiler even in harsh northern winters.

Specifications:

- Circuits: single-circuit;

- Combustion chamber: open;

- Efficiency: 85%;

- Placement: floor;

- Mains voltage: single-phase/three-phase;

- Fuel type: wood, coal.

pros

- high-quality assembly;

- long service life;

- power;

- reliability.

Minuses

- energy dependence;

- uneconomical.

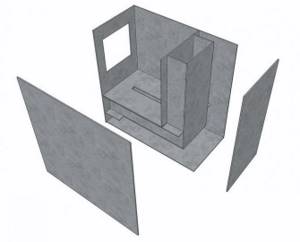

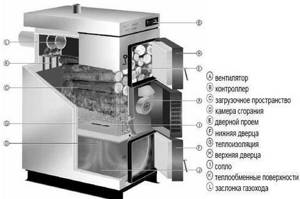

How to make your own economical pyrolysis boiler

The Internet is filled with many beautiful pictures of pyrolysis boilers, but most of these achievements of fine art have nothing to do with separate combustion of fuel. Upon careful examination, it becomes clear that an ordinary fire is burning inside such a device, and the entire fuel supply is ignited. Instead of pyrolysis, they draw a regular fuel boiler with the addition of an afterburning chamber for gaseous products in the upper part of the furnace.

This design of the internal structure of the fuel chamber increases efficiency, but does not provide long-term, controlled combustion of one load of fuel for 6–24 hours. Gases from the firebox should only exit downwards through longitudinal slots in the internal horizontal partition.

The processes inside the pyrolysis fuel chamber can be represented as follows:

- A single portion of fuel is placed into the gasification chamber through a door located in the upper part of the housing, and then ignited from below from the ash chamber.

- The smoke exhauster directs the smoke released during combustion into the flues.

- In the afterburning chamber, supply air is mixed for final combustion of the gases.

- The firebox, afterburning chamber and flues are surrounded by a “water jacket”, which is part of the heat exchanger and also protects the boiler walls from overheating.

- The coolant enters the heating chamber through the lower fitting and is discharged through the upper one.

In the boiler, the upper layers of the fuel fill only warm up, but do not ignite. Hot coals, burning completely, gradually fall into the ash chamber. The fuel, under its own weight, is pressed against the hot grate and ignites. In this way, many hours of continuous operation of the TC is maintained.

Required tools and materials

A skillful owner is able to independently produce a pyrolysis fuel boiler with a power of up to 25 kW. To assemble boilers with greater productivity, it is necessary to use the technology of welding thick sheets of heat-resistant steel. This can only be done in the factory.

For work you will need the following tools and materials:

- welding machine;

- electrodes;

- grinder type cutting tool;

- grinding and cutting discs;

- drill;

- set of metal drills;

- 10 m2 of sheet steel 5 mm thick;

- 6 m2 of galvanized steel 1.5 mm thick;

- accessories for doors - handles, latches;

- sections of steel pipes: ∅ 32 mm, wall thickness 3.2 mm - 0.5 m; ∅ 57 mm, wall thickness 3.5 mm - 8 m; ∅ 159 mm - 0.7 m;

- fireclay bricks for lining the firebox;

- cast iron grate;

- temperature sensor;

- thermal valve;

- uninterruptable power source;

- smoke exhauster

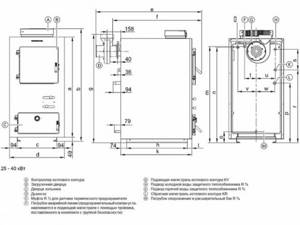

The specification must be clarified according to the working drawings. For a 25 kW TC, the letter symbols have the following actual values, expressed in millimeters: a - 1039, b - 1190, c - 430, d - 618, e - 1289, f - 1101, g - 1126, h - 765, k - 880, l - 41, m - 990, n - 980, o - 137, p - 373, r - 725, s - 255, t - 145, u - 200, v - 198, w - 202.

Making a boiler

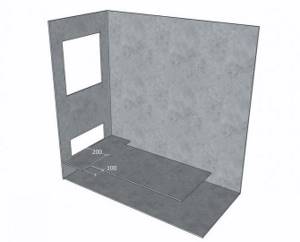

It is necessary to prepare in advance the installation site and parts for the manufacture of the TC. It is best to cut sheet metal in a factory using a guillotine. There, with a plasma cutter, you can make rectangular openings in the front wall of the boiler, and in the back - round holes for the chimney and pipes. Now you can start making the boiler.

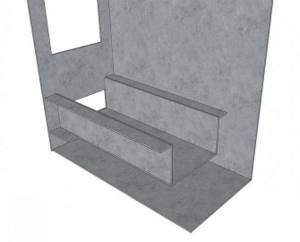

Weld together the side and front outer walls.

Sequentially install the parts of the “water jacket” of the ash chamber.

Weld the bottom and back wall of the loading hopper.

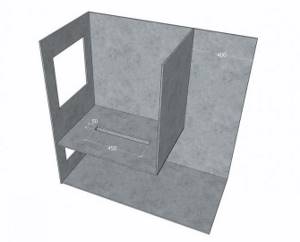

Form the gas ducts, weld all the parts of the “water jacket”, mount the heat exchanger register under the boiler cover. Only then install the outer lower, upper and rear walls.

All that remains is to complete the final work:

- Weld the mounting brackets for the smoke exhauster, hinges for the doors and the heat exchanger fitting.

- Attach legs with adjusting bolts to the bottom, with which you can install the boiler vertically.

- Remove scale, welding slag, and rust.

- Install the doors.

- Degrease all surfaces with solvent.

- Coat the body evenly with heat-resistant paint.

- Upon completion of all work, you can begin installation, connection to the heating system and adjustment of the heating system.

The best solid fuel boilers with a water circuit

Kentatsu ELEGANT-03 17 kW

Classic single-circuit unit with cast iron heat exchanger . Enlarged

The surface of the heat exchanger is provided by additional fins, which increases the efficiency of the boiler.

The maximum coolant temperature is 90 degrees at a pressure of 4 bar.

The power of the equipment is sufficient to heat a room up to 170 sq.m.

The design of the device ensures uniform heating of all rooms.

The long-life boiler grates are water-cooled. An additional advantage is the support for a mechanical thermostat and a thermometer on the front panel of the boiler.

Specifications:

- Type: classic;

- Circuits: single-circuit;

- Energy independence: yes;

- Combustion chamber: open;

- Efficiency: 90%;

- Placement: floor;

- Fuel type: wood, coal;

- Circulation pump/expansion tank: no/no.

pros

- high-quality grate bars;

- productivity;

- thermometer and thermostat.

Minuses

- price;

- weight.

Lemax Forward-16 17 kW

Economical single-circuit unit running on coal, wood and coke . Optimal for

private houses with an area of up to 170 sq.m.

Maintains system pressure up to 2 bar. Top loading allows the use of large firewood and flammable debris.

Long warranty period is an additional bonus.

It is distinguished by its reliable design and materials, high-quality assembly.

A compact heat exchanger, heat-resistant coating, coolant temperature up to 95 degrees are among the additional advantages of the model.

The disadvantages are the relatively low efficiency and the need to frequently add fuel.

Specifications:

- Type: classic;

- Circuits: single-circuit;

- Energy independence: yes;

- Combustion chamber: open;

- Efficiency: 75%;

- Placement: floor;

- Fuel type: wood, coal, coke;

- Circulation pump/expansion tank: no/no.

pros

- reliability and quality;

- top loading;

- low cost;

- power.

Minuses

- efficiency;

- It is necessary to frequently load fuel portions.

ZOTA Topol M 14 14 kW

Compact model, designed for a private house with an area of up to 80 sq.m. Distinctive

a design feature is the elevation of the entire structure, which makes cleaning the ash pan easier.

The built-in temperature sensor allows for greater control and more efficient fuel consumption.

Powered by coal and wood . The control is mechanical and requires regular monitoring by the operator.

Easy to install and operate, has small dimensions.

Due to the characteristics of the walls, it requires space for placement despite its size . In terms of price-quality ratio, it is one of the leading in many ratings.

Specifications:

- Type: classic;

- Circuits: single-circuit;

- Energy independence: yes;

- Combustion chamber: open;

- Efficiency: 75%;

- Placement: floor;

- Fuel type: wood, coal;

- Circulation pump/expansion tank: no/no.

pros

- dimensions;

- power;

- value for money;

- holds heat well.

Minuses

- efficiency;

- The walls of the housing heat up.

The best classic solid fuel boilers

ZOTA Dymok-M AOTV-18M 18 kW

A budget option equipped with a removable hob, making it ideal for a private home or country house.

Removable surfaces allow you to quickly load fuel, the deep firebox can accommodate massive logs up to 58 cm in length.

The design of the ash pan door prevents air from entering.

The combustion process is easily controlled . Thermal power at full load is enough for 7 hours with a total room area of up to 120 sq.m.

Maintains a pressure of 3 atm and a coolant temperature of up to 95 degrees . Firewood consumption is slightly less than 8 kg/hour, brown coal – 6 kg/hour.

Specifications:

- Circuits: single-circuit;

- Energy independence: yes;

- Combustion chamber: open;

- Efficiency: 70%;

- Placement: floor;

- Fuel type: wood, coal.

pros

- tight door;

- fast loading;

- hob;

- power.

Minuses

- Efficiency

ZOTA Yenisei 18 18 kW

An easy-to-install and maintain single-circuit boiler can heat rooms with a total area of up to 150 sq.m..

It consumes not only firewood and coal, but also fuel briquettes.

Seals on the doors and the air injection system allow you to regulate the combustion intensity and temperature accordingly.

The combustion chamber accommodates briquettes and logs up to 60 cm long.

The design feature is the combustion door placed at an angle.

In total, the boiler provides up to 8 hours of operation when the firebox is fully loaded.

However, it does not have the highest efficiency indicators and average efficiency indicators.

Specifications:

- Circuits: single-circuit;

- Energy independence: yes;

- Combustion chamber: open;

- Efficiency: 70%;

- Placement: floor;

- Fuel type: firewood, coal, coal and wood briquettes.

pros

- tight door;

- deep firebox;

- hob;

- low cost.

Minuses

- Efficiency

Teplodar Cooper Praktik 8

A classic single-circuit unit that runs on classic coal and wood, as well as peat briquettes.

Equipped with a thermometer that allows you to control the temperature.

The device’s power is enough for small areas of up to 80 sq.m. Optimal for small private houses and country houses.

It is distinguished by a large chimney 11.5 cm in diameter . The model is made of high-quality materials and meets modern quality standards.

The steel body allows you to retain heat for a long time.

The package does not include a thermostat; if necessary, it can be purchased separately.

Specifications:

- Circuits: single-circuit;

- Energy independence: yes;

- Combustion chamber: open;

- Efficiency: 85%;

- Placement: floor;

- Fuel type: firewood, coal, peat briquettes.

pros

- price;

- uniform heat distribution;

- compactness and weight.

Minuses

- there is not enough power for two-story buildings;

- The case heats up.

Pellet boilers

Pellet boiler FBRZH, produced in Russia

This type of boiler gets its name from the word pellets, which means special fuel pellets that are made from waste from the woodworking industry and agriculture. Pellets are an environmentally friendly material that release a large amount of heat when burned.

It is impossible not to mention the fact that the use of this type of fuel costs owners of houses and cottages much less than the use of gas, coal, electricity and liquid fuels in the form of solarium.

Pellets

Structurally, pellet boilers are made in the form of a hopper into which pellets are poured, followed by their automatic supply into the combustion chamber of the boiler, which makes it possible to not even approach the boiler for several days. The ignition process and ash removal also occur automatically. The owner’s task in servicing pellet boilers is to periodically pour pellets into the hopper and control the removal of ash.

As for the pricing policy, pellet boilers can be purchased, for example, in Moscow, at a price of 130 thousand rubles. up to 220 thousand rubles. It is quite clear that the cost depends on the power of the boiler and its functionality.

The best pyrolysis solid fuel boilers

Vesuvius Elbrus-10 10 kW

A single-circuit pyrolysis unit with a steel heat exchanger allows you to maintain a comfortable temperature in a room up to 100 sq.m..

It has small dimensions, but at the same time weighs a lot. A small firebox allows you to load logs no longer than 38 cm.

It is possible to install a heating element to maintain the temperature of the coolant, but to install it an additional thermostat is required.

The thermal insulation of the water jacket is made of basalt insulation. The device is designed to operate in cold climates.

Economical, low fuel consumption.

Specifications:

- Circuits: single-circuit;

- Energy independence: yes;

- Combustion chamber: open;

- Efficiency: 85%;

- Placement: floor;

- Fuel type: wood, coal.

pros

- efficiency;

- compact dimensions;

- possibility of installing heating elements.

Minuses

- short firebox.

Bourgeois-K MODERN-12 12 kW

A bright single-circuit boiler with a high level of efficiency, capable of heating areas up to 120 sq.m..

It has an almost “omnivorous” firebox and is capable of working on pellets and peat.

High-quality assembly ensures durable operation.

Easy to operate and maintain, has high performance – and high cost.

However, it is not economical and consumes a large amount of fuel . The built-in thermometer and pressure gauge will allow you to monitor the quality of work.

Maintains pressure up to 4.5 bar in the heating circuit with coolant temperature up to 95 degrees.

It has small dimensions and is undemanding in terms of placement.

Specifications:

- Circuits: single-circuit;

- Energy independence: yes;

- Combustion chamber: open;

- Efficiency: 92%;

- Placement: floor;

- Fuel type: firewood, coal, pellets, wood briquettes, peat.

pros

- dimensions;

- efficiency;

- appearance;

- ease of maintenance.

Minuses

- uneconomical.

Bourgeois-K STANDARD-20 20 kW

Single-circuit pyrolysis boiler with an open combustion chamber and a steel heat exchanger.

The design includes a built-in thermometer and pressure gauge, and a draft regulator. The latter allows you to regulate the rate of fuel combustion and its consumption, and change the intensity of heating of the premises.

Capable of heating a room up to 220 sq.m..

Due to the design features, it is not recommended to use birch firewood, since the chimney quickly becomes clogged with tar.

Otherwise, it is easy to maintain and does not require frequent cleaning of the ash pan..

Economical, provides a comfortable temperature with low fuel consumption.

Specifications:

- Circuits: single-circuit;

- Energy independence: yes;

- Combustion chamber: open;

- Efficiency: 85%;

- Placement: floor;

- Fuel type: wood, coal.

pros

- heated area;

- efficiency;

- ease of maintenance.

Minuses

- the firebox door does not fit tightly;

- The chimney pipe gets clogged quickly.

What determines the efficiency of a boiler?

High efficiency depends on the design features of all equipment parts and proper adjustment of thermal processes. Domestic boilers are most often manually regulated, so they periodically require attention during the kindling and combustion process. The intensity of fuel combustion depends on the amount of supply air supplied through the ash pan and grate.

The efficiency of the heating system is ensured by heat exchangers made of pipes, as well as a “water jacket” - the hollow surfaces of the gas ducts and boiler walls in which the coolant circulates. Moving from the firebox to the chimney, combustion gases give off heat to the heating system. The optimal gas temperature at the chimney outlet is approximately 170–200 degrees for boilers with natural draft. If this condition is met, you can count on maximum fuel economy.

Pyrolysis and pellet heating systems are equipped with smoke exhausters that provide adjustable forced draft, so the flue ducts are made longer to increase the heat exchange surface and more complete fuel combustion. As a result, heat is collected more efficiently, and the temperature of the flue gases is reduced to 120–140 degrees.

In a pellet fuel supply system, fuel supply from a bunker by a screw conveyor can be fully automated. To regulate the intensity of the flame, systems for monitoring the temperature of the coolant, external and internal air, and flue gases are used. In this way, the highest possible boiler efficiency is achieved.

The efficiency of the heating system is also affected by the quality of the heating system coolant. Untreated water often contains an excessive amount of hardness salts, which settle on the inner surface of the heat exchanger. This scale has a low thermal conductivity coefficient, therefore it greatly slows down the absorption of heat by the coolant.

A decrease in boiler efficiency can be avoided by using distilled water as a coolant. You can also reduce the hardness of tap water by boiling for a long time, followed by settling the sediment for 2–3 days.

High moisture content significantly reduces the efficiency of any type of heat generator. A significant amount of energy is wasted on the useless evaporation of water. Pyrolysis boilers generally do not operate on wood with a moisture content of more than 25%. In this regard, heating systems operating on pellets have an advantage. During the manufacturing process, this fuel goes through a drying stage and is then stored in moisture-proof bunkers.

Operating principle

The operating principle of a solid fuel heating unit works mainly due to the laws of physics and includes the following points:

- Fuel loading;

- Ignition;

- Combustion of fuel and transfer of generated heat to the water coolant for the heating circuit or hot water supply;

- Exhaust of flue gases into the atmosphere through a chimney by natural or forced circulation;

- Circulation of heated coolant through the heating system using forced or natural circulation.

Selection rules

The choice of a solid fuel boiler is carried out taking into account several important parameters: available fuel, operating mode, boiler power and heat supply scheme.

They also take into account the type of load, whether only heating load is required or whether hot water preparation will be additionally needed. In addition, they determine the possibility of operating the unit without electricity and take into account existing flue gas removal systems and the movement of coolant along the intra-house heating circuit.

Fuel

Even the simplest solid fuel boilers can operate on various types of solid fuel from coal to pellets. The most modern boilers provide the ability to operate the unit on liquid and gaseous fuel by installing a special burner in the combustion chamber door. This allows the owner to use available fuel in the area of residence.

Russian manufacturers use the practice of installing electric heaters in solid fuel boilers to maintain heating mode in the absence of main fuel.

It should be noted that a boiler using auxiliary fuel will operate with reduced efficiency, so you need to choose a boiler taking into account the main type of fuel and the possibility of uninterrupted supply of the required energy carrier.

Heat exchanger material

All boilers are produced with two types of heat exchangers made of cast iron and steel. The first ones are the most expensive and heavy, with a service life at least twice as long as steel ones - 20 years.

They work well in environments with high temperatures and provide good heat transfer from flue gases to the heating fluid. Cast iron heat exchangers are made of collapsible sections, so they are easy to replace during repairs.

It should be noted that cast iron heat exchangers have a number of disadvantages, including the high fragility of the product. Destruction can occur due to water hammer in the heating system during start-up or when cold water gets into hot cast iron.

Heat exchangers made of steel are almost always made in a monostructure with a boiler; they are not collapsible. Despite the fact that steel metal is more ductile and is not afraid of water hammer, it is highly susceptible to corrosion, especially in the area of welds.

Such devices are not durable, they work for no more than 10 years, and if they fail, the heating unit must be completely replaced.

Energy consumption

Boiler units operating on solid fuel are divided into 2 groups:

Volatile devices that operate only when there is voltage in the mains. Typically these are systems with forced air supply and circulation of heating fluid through the heating circuit using an electric circulation pump.

Non-volatile units do not require electricity; they work with a natural system for exhausting flue gases into the atmosphere and natural coolant circulation.

Of course, the first option is the most preferable and is used in all modern boilers with high efficiency and a level of automation of thermal processes.

Types of solid fuel boilers

Solid fuel boilers are mainly classified according to their operating principle:

- Classic - similar to a conventional oven. Heat is released and transferred to the coolant through the combustion of solid fuel; to maintain the temperature, the firebox must be loaded regularly.

- Pyrolysis - the fuel in such devices does not burn, but smolders, resulting in the release of gas saturated with heat. Such boilers have increased efficiency due to the conversion of a small amount of fuel into a large amount of heated gas, the heat from which is transferred to the heat exchanger.

- Pellet – special pellets are used as fuel. Such boilers are volatile because they require control by electronic sensors. Models with a similar principle of operation are equipped with an automatic supply of pellets and a hopper for storing them.

- Long burning - equipped with an elongated firebox surrounded by a water jacket. In such fireboxes, fuel burns from top to bottom according to the principle of a candle, due to which complete combustion is achieved and the burning life of the filling is increased. The uninterrupted operation and safety of such models is ensured by emergency extinguishing fans and a circulation pump.

Features of modern solid fuel boilers - what to choose

An interesting fact is that not a single major reputable manufacturer of heating equipment produces so-called long-burning boilers - large barrels in which wood burns from top to bottom. Such boilers are made only by small companies in the CIS and Baltic countries and are accompanied by aggressive advertising. True, in retail outlets they can call anything a long-burning boiler, just to sell it...

Pyrolysis boilers have also lost significantly in supply and demand. They have big drawbacks at their high price - this is not at all what the buyer likes.

Let's look at why long-burning and pyrolysis boilers cannot be considered as candidates when choosing a boiler for your home. Then let’s look at the modern models of solid fuel boilers that are currently on sale, and which one should be chosen.

Pyrolysis with disadvantages

The sale of pyrolysis boilers is based only on advertising - as if they have a very high efficiency (deception), as if there is no ash left (where does it go? - we’ll look at it later), they can burn for a long time (is this convenient?) ...

- As for efficiency, everything immediately becomes clear, you just have to look at the temperature of the exhaust gases. It is no less compared to conventional boilers.

- Ash is a given of any fuel, it cannot disappear by magic, it is blown away by a fan and carried away into the chimney, then settles on top of the house, on a parked car, on the ground...

- Firewood that releases resin (coniferous, birch) cannot be used - the barrel is tarred. What to heat with?

- Can you burn with raw wood? Any boiler can be fired with raw wood. You can heat it, but the energy will be 2 times less. Firewood should only be purchased dry or dried before burning, so that energy is not wasted on creating steam...

Long-term combustion is not always necessary, and the energy efficiency curve of all barrel-shaped boilers with long-term combustion does not correspond to the heat loss curve of the house - “extra” energy arises, and therefore the efficiency tends to decrease.

To eliminate the shortcoming, manufacturers directly require that a pyrolysis boiler be installed in conjunction with a buffer tank. But the boiler itself has a fivefold price, the buffer tank is not cheap - why such overpayments?

Long burning

The situation is even simpler with so-called long-burning boilers - where the discrepancy between the energy consumption of the house and the energy output of the boiler is quite significant. More precisely, the boiler is suitable for heating only in good frosts.

They cannot heat a little - which is constantly required in the off-season; only a large stack of firewood burns there. But most of the time you can heat it comfortably... only with a buffer tank.

In general, such shortcomings are difficult to sell for the price of this boiler. But aggressive advertising, plus the very concept of long burning, do their job. You can learn more about what is sometimes meant by long-burning boilers

What's popular

How is solid fuel heating developing in European countries? What is presented at heating equipment exhibitions by leading manufacturers?

Solid fuel colas are not leaving the market in favor of gas colas in Europe. They are being transformed into automated systems. How can you automate a solid fuel boiler?

Screw loading from a bunker and fine-grained fuel are used. More and more boilers are being adapted for wood chips and sawdust, as there is a lot of wood waste that can be burned.

In addition, such fuel is not expensive to prepare from any wood. Pellets and coal of the same fraction (pieces of the same size) are also used. The combustion process and fuel supply are completely controlled by electronics.

True, a finished boiler room for a private house based on such a boiler from a leading European manufacturer will cost about $25,000. Those. It is not suitable for widespread use in our country.

Before considering what is suitable for us, let’s pay attention to the main trend in the development of solid fuel heating.

What parameters should solid fuel heating have?

Nowadays in European countries state standards are being adopted, according to which it is prohibited to use solid fuel boilers (not bunker, not automated) without a buffer heat storage tank. And such a law has already been adopted in Germany. Why is it needed?

This rule is introduced to ensure that the solid fuel boiler always operates in optimal mode - with maximum efficiency and produces the least amount of CO (carbon monoxide). This requires an unlimited air supply - combustion with excess oxygen. Then the boiler works not only with better efficiency, but also at maximum power, the fuel burns quickly.

A large amount of energy is released from one firebox, which must be accumulated by a buffer tank and then gradually taken up by the house heating system, which is not at all difficult to organize.

If you carry out the combustion process with a lack of oxygen (covered by a damper), stretching out the heat transfer over time, then the efficiency of any boiler decreases, and the amount of CO increases.

Thus, new European laws are aimed at saving fuel, oblige the organization of equipment operation with maximum efficiency, and also ensure environmental protection.

By the way, in developed countries other standards for heating equipment are being introduced; in particular, the use of condensing equipment is becoming mandatory. What is a condensing boiler and what are its differences - read articles about heating.

What is better to buy, what is more reliable

Based on the experience of operating solid fuel boilers, and the development trends of this industry around the world, we can conclude that the heating system in a private home can be based on the following principles.

- Maximum oxygen supply is ensured, but fuel is supplied in small portions - as much energy as needed.

Then the house can constantly receive energy little by little. This is only possible with an expensive automated small fuel boiler with a bunker. In our country, such boilers are also called pellet boilers. But there are modifications for coal and small firewood (shavings). The pleasure is not cheap, but what to do... - The combustion is carried out in large portions with daily manual supply of fuel to the boiler. In this case, an ordinary modern boiler can be used, but with increased power (2 times the required).

The system must include a buffer tank - a heat accumulator. This will greatly simplify the process of managing the boiler for use, ensure CO emission standards, increase efficiency and save fuel.This option is most likely suitable for mass use, due to the fact that unprepared fuel (any large dry firewood and coal) is much cheaper.

You can read more about how to heat a house with wood

Selection by manufacturer

The price for a good-quality simple solid fuel boiler from a well-known European manufacturer is more than 100 thousand rubles, but rather strive for 200 thousand rubles. A boiler of similar power from a good Russian manufacturer will cost 50-60 thousand rubles. – 3 times cheaper.

Over the past few years, the quality of Russian-made boilers has improved significantly. Solid fuel boilers with long strokes for gas movement began to be produced (there are models with vertical and horizontal strokes), and this increases efficiency.

The technology of supplying additional air for afterburning gases, if they contain CO, has also been mastered. Fans are also used to regulate the air supply and electronics control the optimal combustion process.

You just need to take a closer look at well-known domestic manufacturers. A conventional solid fuel boiler paired with a buffer tank will provide the house with heat.

But our manufacturers also produce good pellet boilers. They are optimally used in large houses - 400 - 800 sq. m., then the increased cost of the boiler itself, as well as fuel, does not have such a strong impact on the background of all equipment.

Another question that arises more often than others is how to make the cheapest heating at home

Advantages and disadvantages of solid fuel boilers

Solid fuel boilers are relevant where there is no possibility of supplying gas, as well as in areas with a shortage of electricity.

Modern models of such boilers are comparable in efficiency to gas boilers, are energy efficient, environmentally friendly, and equipped with fire protection systems.

The ability to work with waste (pellets) makes them an anti-pollution method.

However, classic models do not operate environmentally friendly and emit ash and waste gas into the atmosphere, which carries heat, since its operating principle is similar to a conventional oven.

Pellet options are entirely energy-dependent, as they are demanding on electronics and automation.

Long-term combustion boilers are demanding on the volume of fuel in the combustion chamber and will not provide the required power if the amount of firewood or coal is insufficient.

Also, such models are expensive, but at the same time economical and easy to maintain.

Traditional and gas generators

Gas generator

According to the principle of operation, boilers are classical or traditional, and gas-generating or pyrolysis. The gas generators are equipped with two gas chambers, which are located one above the other and are separated only by nozzles.

Firewood is loaded into the upper chamber, where it burns and produces gas. But firewood does not burn immediately. And with the help of pyrolysis, they are first dried, while slightly heating the air. That is, in this way the most efficient heat exchange is ensured.

By the way: This also affects the load frequency of the gas generator boiler. Fuel must be loaded into it 2 times less often than in a traditional one. Consequently, the cleaning process will be required with the same frequency.

Pyrolysis boilers are also equipped with a ventilation system, which not only helps with quick kindling, but also saves the environment from harmful emissions (after all, by fanning the fire, the fan prevents the appearance of smoke in the room).

How to choose power

The accuracy of the calculation depends on whether all factors and indicators have been taken into account. First you need to determine the expected heated area.

The resulting indicator is divided by the specific value of the boiler power . The result is divided by 10 - the theoretical ratio of power for heating 10 sq.m.

The resulting value is the starting point for selecting the power of a solid fuel boiler.

In conditions with a cold climate, it is worth adding about 30% to the obtained value for heat loss and increasing technological capabilities.

Also, the boiler power can be determined by the formula V*T*K/850, where V is the volume of the heated room, T is the difference between the comfortable temperature inside the room and the minimum temperature outside, K is the heat loss coefficient.

K depends on the design of the room and is equal to 3.5 if the building is wooden or profiled sheet. 2.5 – a room with a wall thickness equal to the length of the brick; 1.5 – standard building design; 0.6 – improved design with double glazed windows, double thermal insulation and a thermally insulated roof.

No. 6. Power

One of the main indicators that you should first pay attention when choosing a solid fuel boiler is its power , which determines how much area it can provide with heat. You should proceed from the area of the heated room. You can use the generally accepted rule: for every 10 m2 , 1 kW is required . This is subject to normal thermal insulation and a ceiling height of no more than 3 m.

15 kW boiler will be enough to heat a house with an area of 150 m2 . Even at an external temperature of -360C, it will ensure that the temperature in the house is maintained at +180C . If the thermal insulation of the house is insufficient, as well as in a harsh climate, it is better to take a boiler with a small power reserve.

If the boiler will be used in a hot water supply system , then this must be taken into account when calculating the power of the heat exchanger. Experts say that to ensure comfort in the house, the power of a double-circuit boiler in any case should not be lower than 24 kW . It is better to entrust more accurate calculations to professionals who will take into account all the features of a particular house and heating system.

Which manufacturer is better?

The market is saturated with boilers from various manufacturers - both domestic and foreign.

The leading ones are:

- Stropuva - a brand from Lithuania stands out for its design, durability of models and high cost. At the same time, due to the design features, long-lasting burning of firewood and a high level of efficiency are ensured.

- Zota is a Russian nonsense that supplies classic models with small dimensions and low power. Boilers from this manufacturer are optimal for country houses and small village houses. They are distinguished by their reliable design and low price.

- Burzhuy-K is a Russian manufacturer of energy-independent pyrolysis boilers. The models are highly expensive, but at the same time they provide high efficiency indicators, retain heat for a long time and are capable of heating fairly large areas up to 450 sq.m.

No. 7. Fuel type

You can throw firewood, coal, pellets and sawdust . It is a mistake to believe that the boiler power will remain the same, no matter what fuel is used. Many boiler models can operate with different types of fuel, but maximum power will only be achieved when using the fuel that the manufacturer has indicated as the main one . When using less calorific fuel, the power will drop by 25-30% , and if it is too wet, the power drop can be up to 40%.

Average heat transfer parameters of different types of fuel:

- firewood – 2500 kcal/kg . Logs of wood are usually 25-30 cm long and can be sawn or split. It is important that the firewood is dry;

- anthracite coal - 7400 kcal/kg;

- hard coal – 7000 kcal/kg;

- brown coal – 3500 kcal/kg;

- pellets – 4500 kcal/kg.